Preparation method and application of modified ZSM-22 molecular sieve

A technology of ZSM-22 and molecular sieves, applied in the field of molecular sieves, to achieve strong adsorption, enhanced structural strength, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

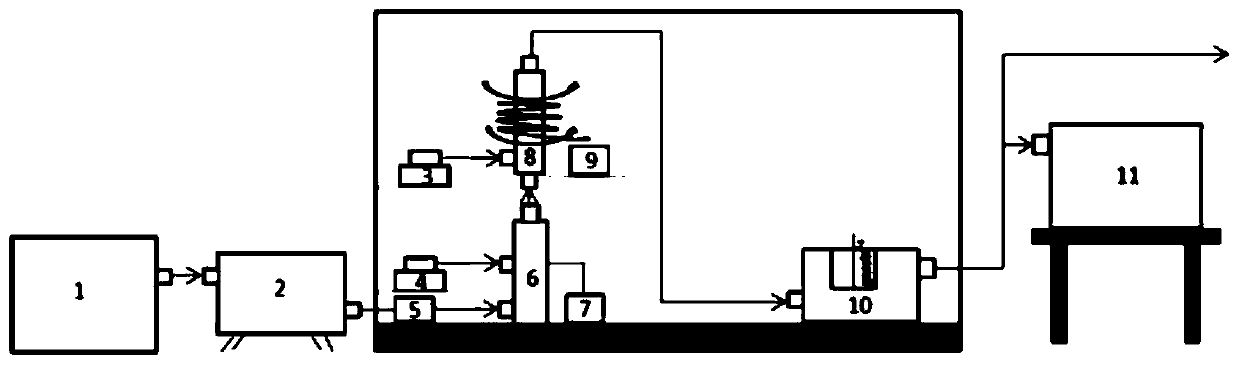

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of modified ZSM-22 molecular sieve, comprising the steps of:

[0022] (1) According to the molar ratio of SiO 2 :Al 2 o 3 : Template agent: OH – : distilled water=1:0.01:0.2:0.2:10, 32.48g hexamethyldisiloxane, 0.375g aluminum nitrate, 7.69g cetylpyridinium bromide, 1.13g potassium hydroxide and 18mL distilled water were mixed and stirred, After the gel-like mixture was formed, the mixture was transferred to a stainless steel reactor with a polytetrafluoroethylene lining, and placed in an oven at 160°C for crystallization reaction for 72 hours to obtain a precursor, which was separated and cleaned to medium properties, dried at 90°C, and then baked in a muffle furnace at 3°C min -1 The heating rate was raised from room temperature to 500°C, and roasted at constant temperature for 8 hours to obtain ZSM-22 molecular sieve;

[0023] (2) Disperse 1g of ZSM-22 molecular sieve in 5mL of butyl titanate, dry it at 80°C and roast it in a muffle furnac...

Embodiment 2

[0025] A preparation method of modified ZSM-22 molecular sieve, comprising the steps of:

[0026] (1) According to the molar ratio of SiO 2 :Al 2 o 3 : Template agent: OH – : Distilled water=1:0.02:0.4:0.3:20, 16.24g hexamethyldisiloxane, 0.75g aluminum nitrate, 7.68g cetylpyridinium bromide, 0.842g potassium hydroxide and 18mL distilled water were mixed and stirred, After the gel-like mixture was formed, the mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and placed in an oven at 165°C for crystallization reaction for 48 hours to obtain a precursor, which was separated and cleaned to medium properties, dried at 90°C, and then baked in a muffle furnace at 3°C min -1 The heating rate was increased from 20°C to 550°C, and the constant temperature was roasted for 8 hours to obtain ZSM-22 molecular sieve;

[0027] (2) Disperse 1g of ZSM-22 molecular sieve in 10mL of butyl titanate, dry it at 80°C and roast it in a muffle fu...

Embodiment 3

[0029] A preparation method of modified ZSM-22 molecular sieve, comprising the steps of:

[0030] (1) According to the molar ratio of SiO 2 :Al 2 o 3 : Template agent: OH – : distilled water=1:0.03:0.6:0.4:30, 32.48 hexamethyldisiloxane, 2.25g aluminum nitrate, 23.07g cetylpyridinium bromide, 1.48g calcium hydroxide and 54mL distilled water are mixed and stirred, and After the gel-like mixture is formed, the mixture is transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, and placed in an oven at 170 ° C for crystallization reaction for 72 hours to obtain a precursor, which is separated and cleaned to neutral , dried at 90°C, and then baked in a muffle furnace at 3°C min -1 The heating rate was increased from 30°C to 600°C, and the constant temperature was roasted for 9 hours to obtain ZSM-22 molecular sieve;

[0031] (2) Disperse 1g of ZSM-22 molecular sieve in 15mL of butyl titanate, dry it at 80°C and roast it in a muffle furnace, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com