Treatment device and method for recycling chlorine-containing waste acid

A processing device and a technology for recycling, which is applied in the field of waste acid treatment and recycling to achieve the effect of avoiding dangerous gypsum slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

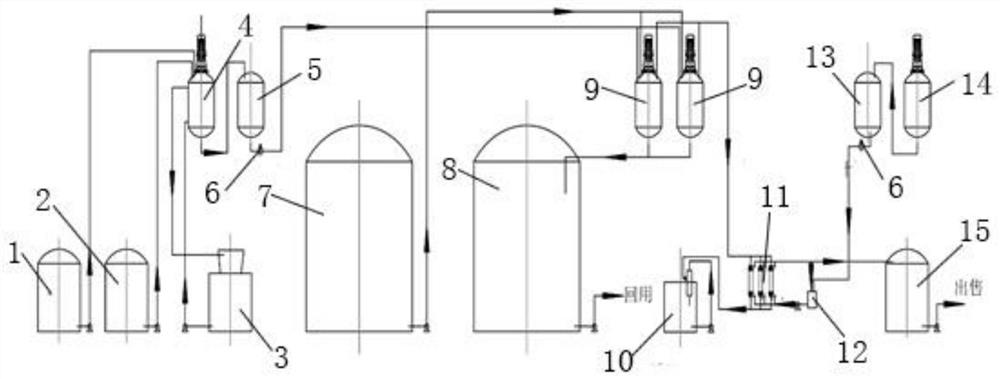

Method used

Image

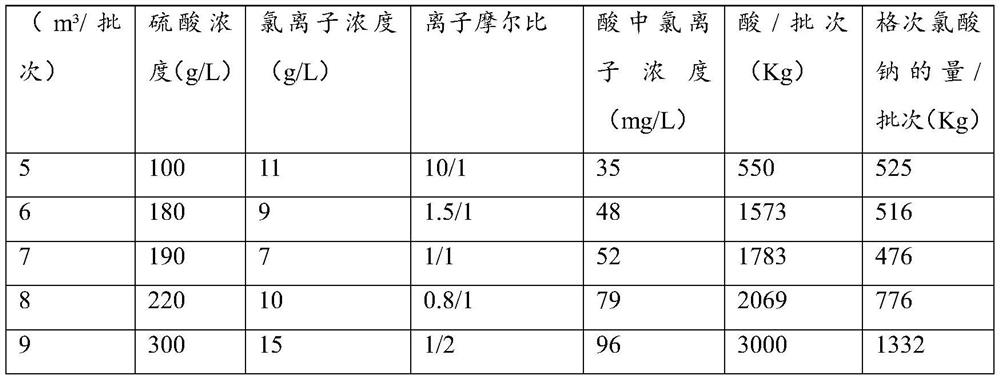

Examples

Embodiment 1

[0062] The parameters involved in this embodiment are the parameters obtained by using the device and method of the invention to carry out field tests in a smelting enterprise in Hunan Province.

[0063] Use a metering pump to pump 0.5m 3 Sulfuric acid (98%) and 0.3m 3 Put the hydrogen peroxide (50%) into the corresponding sulfuric acid and hydrogen peroxide metering tank, and press 0.1m from the metering tank 3 The above-mentioned sulfuric acid and hydrogen peroxide are transported to the dechlorination agent reactor (2m) at a flow rate of / min 3 ), turn on the cooling circulating water, turn on the agitator at 150r / min, and react the sulfuric acid and hydrogen peroxide at 25°C for 1 hour to generate the dechlorination agent. The produced dechlorination agent is transported to the dechlorination agent stainless steel storage tank (5m 3 ),spare.

[0064] 25m generated in different time periods 3 The waste acid is transported to the carbon steel waste acid storage tank (30...

Embodiment 2

[0070] The parameters involved in this embodiment are the parameters obtained by using the device and method of the invention in a test in a smelting enterprise in Guangxi Province.

[0071] Use a metering pump to pump 0.5m from the sulfuric acid carbon steel storage tank and the hydrogen peroxide carbon steel 3 Sulfuric acid (70%) 0.4m 3 Hydrogen peroxide (50%) is injected into the sulfuric acid and hydrogen peroxide metering tank, and then press 0.2m from the metering tank 3 The above-mentioned sulfuric acid and hydrogen peroxide are transported to the dechlorinating agent reactor (5m) at the flow rate of / min 3 ), turn on the cooling circulating water, turn on the agitator at 120r / min, and make the sulfuric acid and hydrogen peroxide react at 35°C for 1 hour to generate the dechlorination agent. The produced dechlorination agent is transported to the dechlorination agent stainless steel storage tank (8m 3 ),spare.

[0072] 40m generated in different time periods 3 The ...

Embodiment 3

[0078] The parameters involved in this embodiment are the parameters obtained by using the device and method of the invention to carry out tests in a smelting enterprise in Henan Province.

[0079] Use a metering pump to pump 0.5m 3 Sulfuric acid (98%) and 0.3m 3 Hydrogen peroxide (70%) is injected into sulfuric acid and hydrogen peroxide metering tank, and then press 0.15m from the metering tank 3 The above-mentioned sulfuric acid and hydrogen peroxide are transported to the dechlorination agent reactor (2m) at a flow rate of / min 3 ), turn on the cooling circulating water, turn on the agitator at 150r / min, and react sulfuric acid and hydrogen peroxide at 55°C for 0.5h to generate a dechlorination agent. The produced dechlorination agent is transported to the dechlorination agent stainless steel storage tank (6m 3 ),spare.

[0080] 20m generated in different time periods 3 The waste acid is transported to the carbon steel waste acid storage tank (30m 3 ), start stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com