Treating and recycling method for waste water of lead-acid battery industry

A technology for lead-acid batteries and industrial wastewater, applied in the field of water treatment, can solve the problems of low recovery rate of produced water, unfavorable industrialization, cumbersome steps, etc., and achieve the effects of low input cost, filtering harmful substances, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

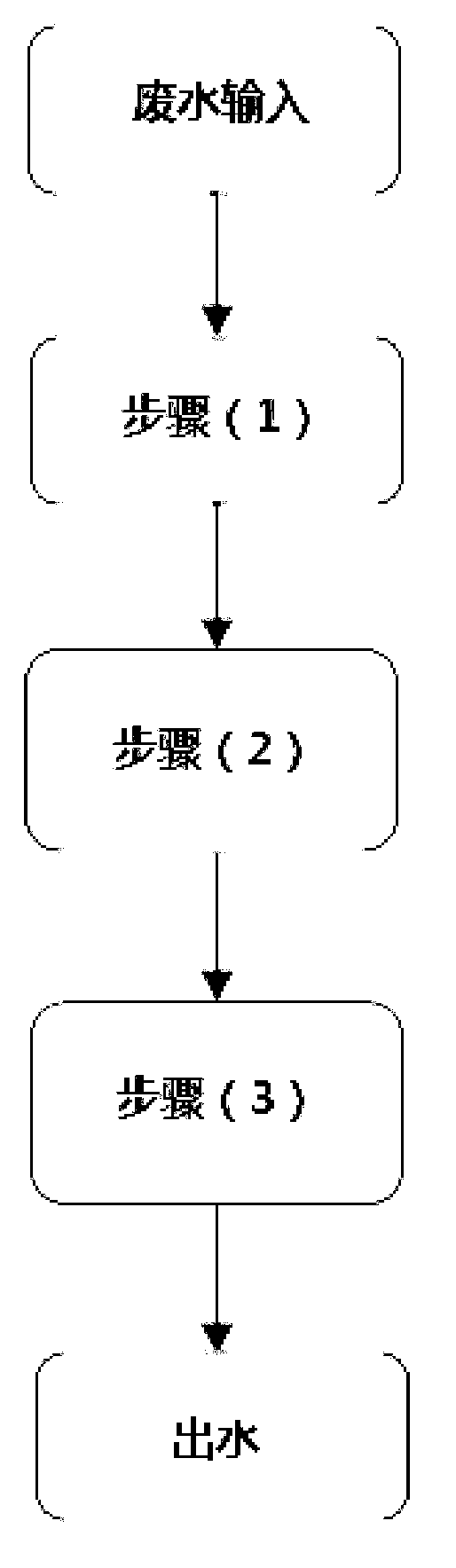

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one, the processing lead concentration is 10mg / L, pH value is 2, COD Cr The process steps of lead-acid wastewater with a total hardness (calculated as calcium carbonate) of 30mg / L, a total hardness (calculated as calcium carbonate) of 200mg / L, and a conductivity of 3500mg / L are as follows:

[0037] (1) Pretreatment: Add a certain amount of lye to the pretreatment tank containing lead-acid wastewater, so that the pH value of lead-acid wastewater reaches 8.0, and then add 220mg / L polyferric sulfate to the pretreatment tank in turn, 4.0mg / L anionic polyacrylamide, the molecular weight of the anionic polyacrylamide is 13 million;

[0038] (2) Ultrafiltration membrane treatment: transport the precipitated supernatant from the pretreated lead-acid wastewater in step (1) to the ultrafiltration membrane treatment system for treatment. The ultrafiltration membrane is made of polyethersulfone, and the operating pressure of the ultrafiltration membrane is set to 0.5MPa...

Embodiment 2

[0041] Embodiment two, processing lead concentration is 150mg / L, pH value is 1.0, COD Cr The process steps of lead-acid wastewater with a total hardness (calculated as calcium carbonate) of 80mg / L, a total hardness (calculated as calcium carbonate) of 620mg / L, and a conductivity of 6500mg / L are as follows:

[0042] (1) Pretreatment: Add a certain amount of lye to the pretreatment tank containing lead-acid wastewater, so that the pH value of the lead-acid wastewater reaches 8.5, and then add 130mg / L polyaluminum chloride to the pretreatment tank in turn , 8.0 mg / L anionic polyacrylamide, the molecular weight of the anionic polyacrylamide is 6 million;

[0043] (2) Ultrafiltration membrane treatment: The pretreated lead-acid wastewater in step (1) is transported to the ultrafiltration membrane treatment system for treatment. The ultrafiltration membrane adopts the US GE ultrafiltration membrane The filter membrane is made of polyvinylidene fluoride, and the operating pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com