Treatment method of high saline wastewater

A treatment method and high-salt technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Water quality treatment standards and other issues, to achieve significant economic and social benefits, efficient economic treatment and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

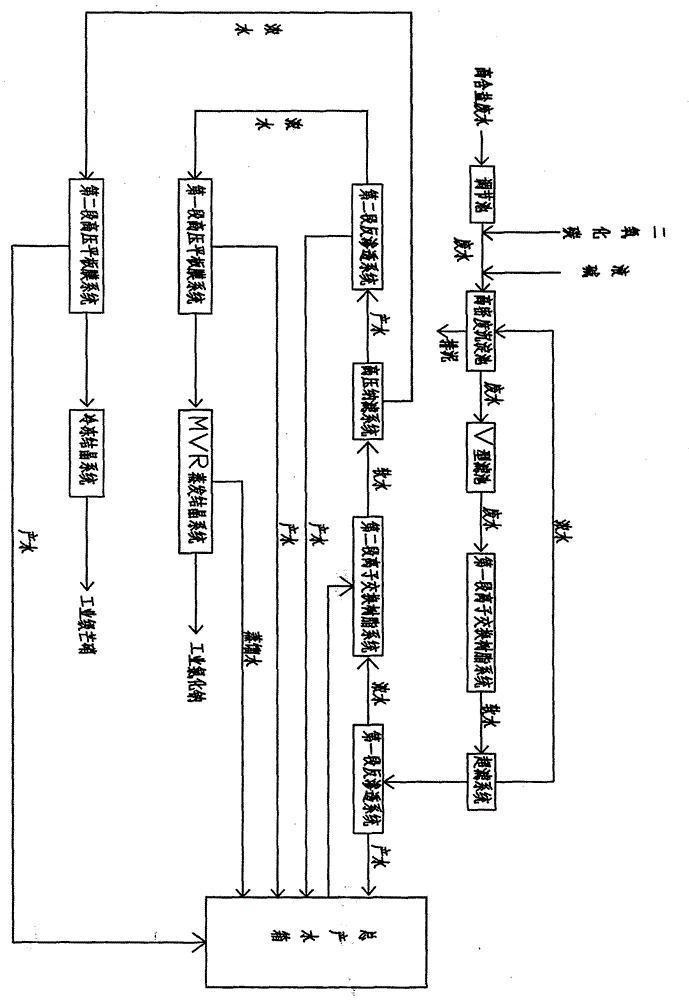

Method used

Image

Examples

Embodiment 1

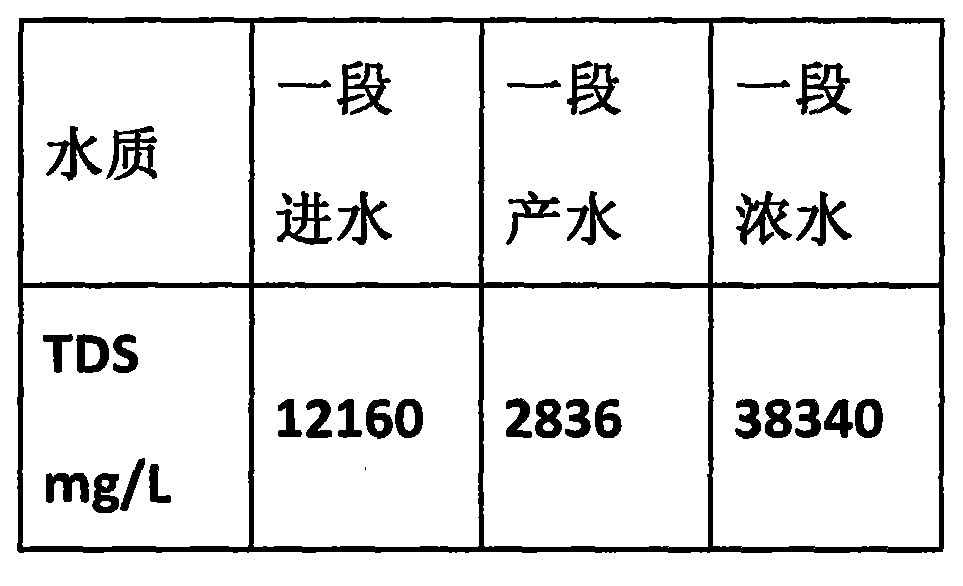

[0068] Highly salty wastewater discharged from a chemical industry park, the wastewater COD≤200mg / L, TDS≤3000mg / L, NaCl≤3000mg / L, NaCl≤3000mg / L, Na 2 SO 4 ≤6000mg / L, total hardness ≤800mg / L,.

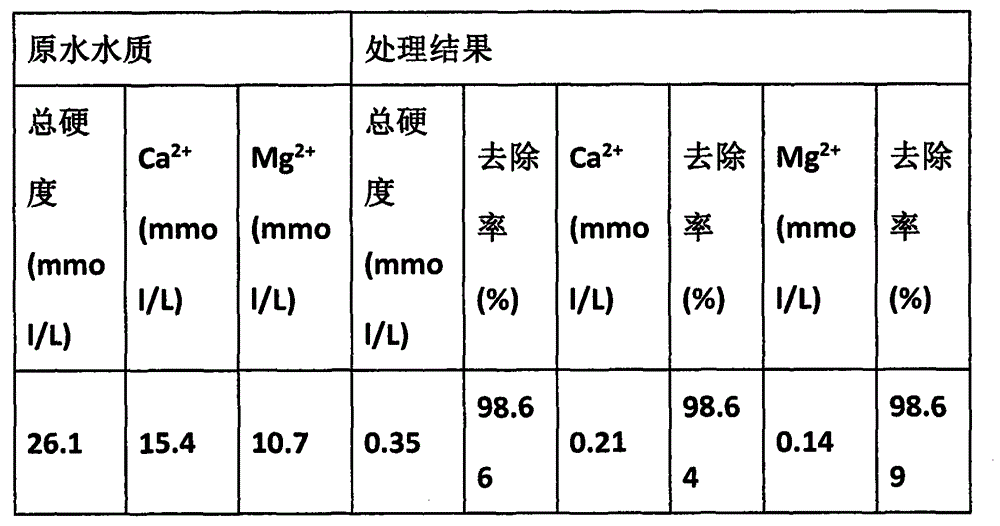

[0069] (1) chemical softening

[0070] Chemical softening uses the addition of NaOH and carbon dioxide to remove calcium and magnesium ions in wastewater. After the high-salt wastewater is precipitated by 25% NaOH and a certain amount of carbon dioxide, 8% to 12% polyferric sulfate (coagulant) and 0.8% PAM (coagulant) are added to the sedimentation tank for mixing. Most of the hardness and calcium and magnesium ions in coagulation precipitation, solid-liquid separation, and high-salt wastewater are removed. The added carbon dioxide comes from the exhaust gas of a certain factory in the industrial park. This method not only reduces the operating cost, but also enables the resource utilization of the exhaust gas of the factory. The treatment conditions and treatment results of chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com