Zero-discharge treatment process and device for printed circuit board developing wastewater

A printed circuit board and treatment device technology, which is applied in the field of zero-discharge treatment process and device of printed circuit board development wastewater, can solve the problems of increasing the difficulty of mixed wastewater treatment and exceeding the COD standard, and achieves good environmental protection benefits, prolongs service life, and improves reliability. biochemical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

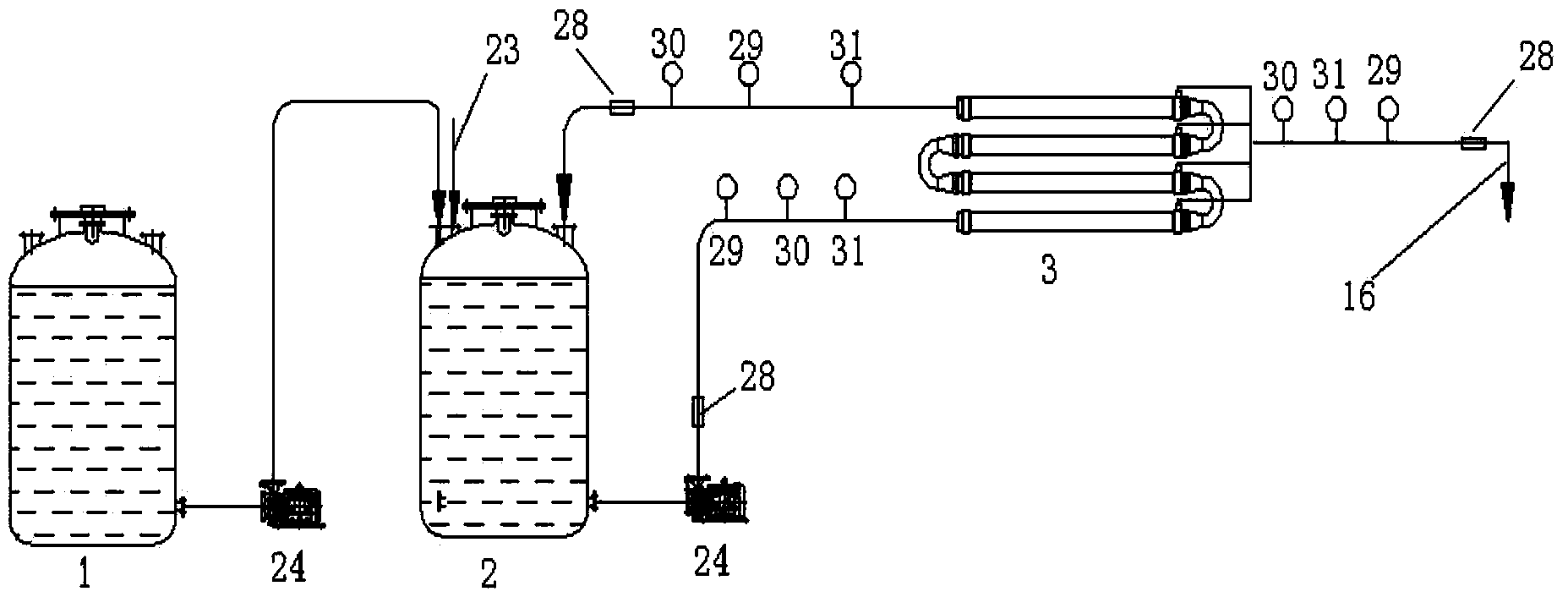

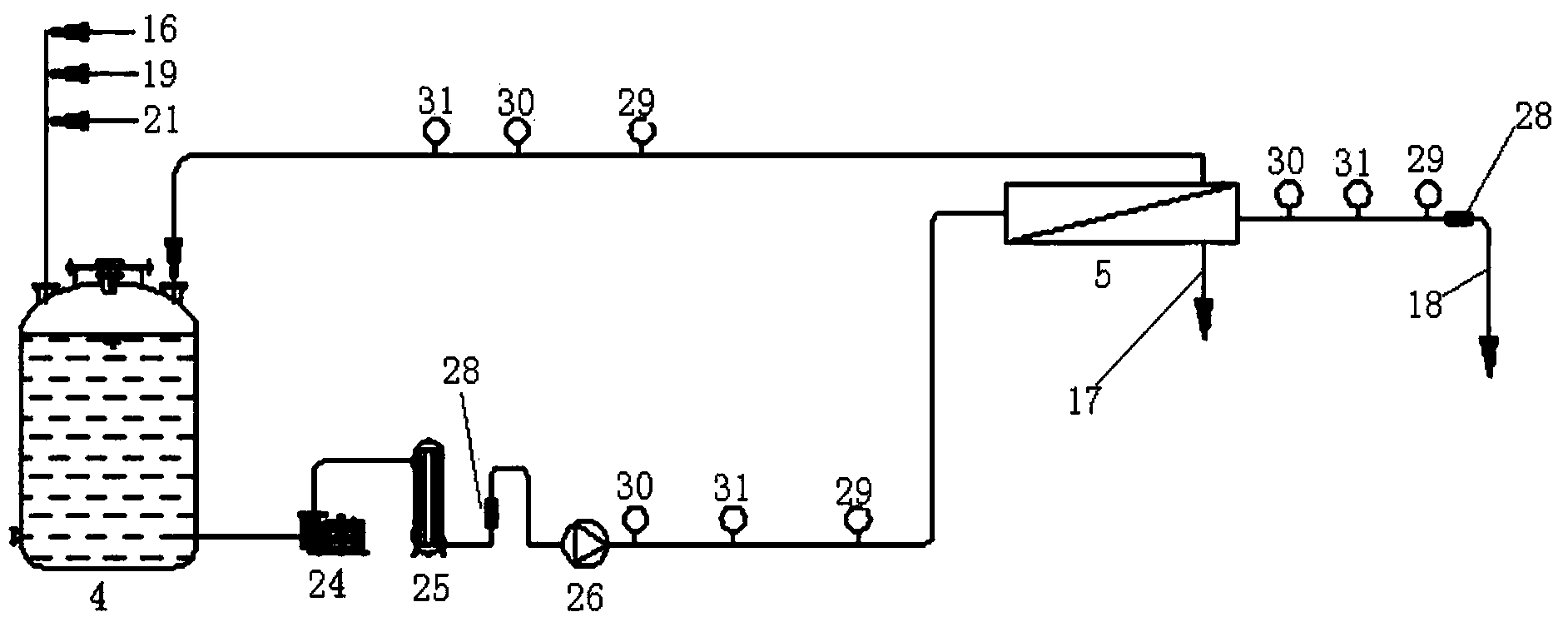

[0039] A zero-discharge treatment device for printed circuit board developing wastewater in this embodiment, such as Figure 2-6 As shown, it consists of a microfiltration device, a primary reverse osmosis device, a secondary reverse osmosis device, a seawater desalination device, and an acidification-iron-carbon micro-electrolysis device. The circulation tank 2 and the microfiltration filter 3; the first-level reverse osmosis device comprises a first-level reverse osmosis circulation tank 4 and a first-level reverse osmosis filter 5 connected by pipelines; the second-level reverse osmosis device comprises a pH adjustment tank 6, The secondary reverse osmosis circulation tank 7, the secondary reverse osmosis filter 8 and the water reuse tank 9; the seawater desalination device includes a seawater desalination circulation tank 10 and a seawater desalination filter 11 connected by pipelines; the acidification-iron-carbon micro-electrolysis device includes sequentially setting Ac...

Embodiment 2

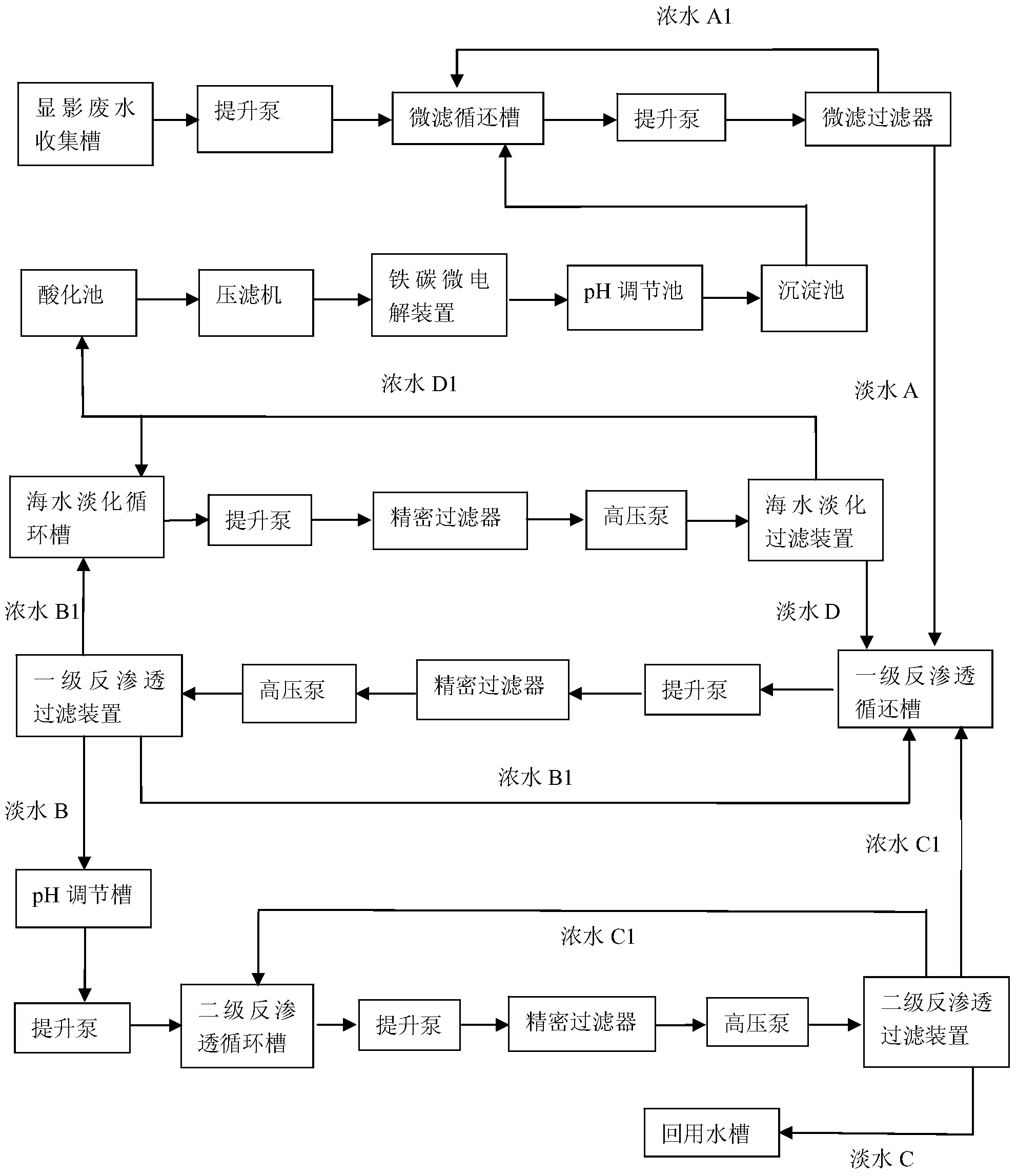

[0046] Utilize the device of embodiment 1 to carry out the process of zero discharge treatment to 10 batches of printed circuit board developing waste water, as figure 1 shown, including the following steps:

[0047] (1) Collect the printed circuit board developing wastewater into the developing wastewater collection tank, start the microfiltration device, make the printed circuit board developing wastewater enter the microfiltration circulation tank, and then pass through the microfiltration filter for cross-flow filtration to obtain fresh water A and concentrated water A1, Concentrated water A1 is returned to the ultrafiltration circulation tank through the circulation loop for circulation and concentration, the final concentrated water A is sent to the filter press, and after being compressed by the filter press, the water is discharged to the ultrafiltration circulation tank, and the sludge after filtration is outsourced. , the fresh water A enters the primary reverse osmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com