Medical waste treatment device

A technology for processing equipment and medical waste, applied in the field of medical waste processing equipment, can solve the problems of inability to process and recycle waste, interruption, etc., and achieve the effect of simple structure, improved effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

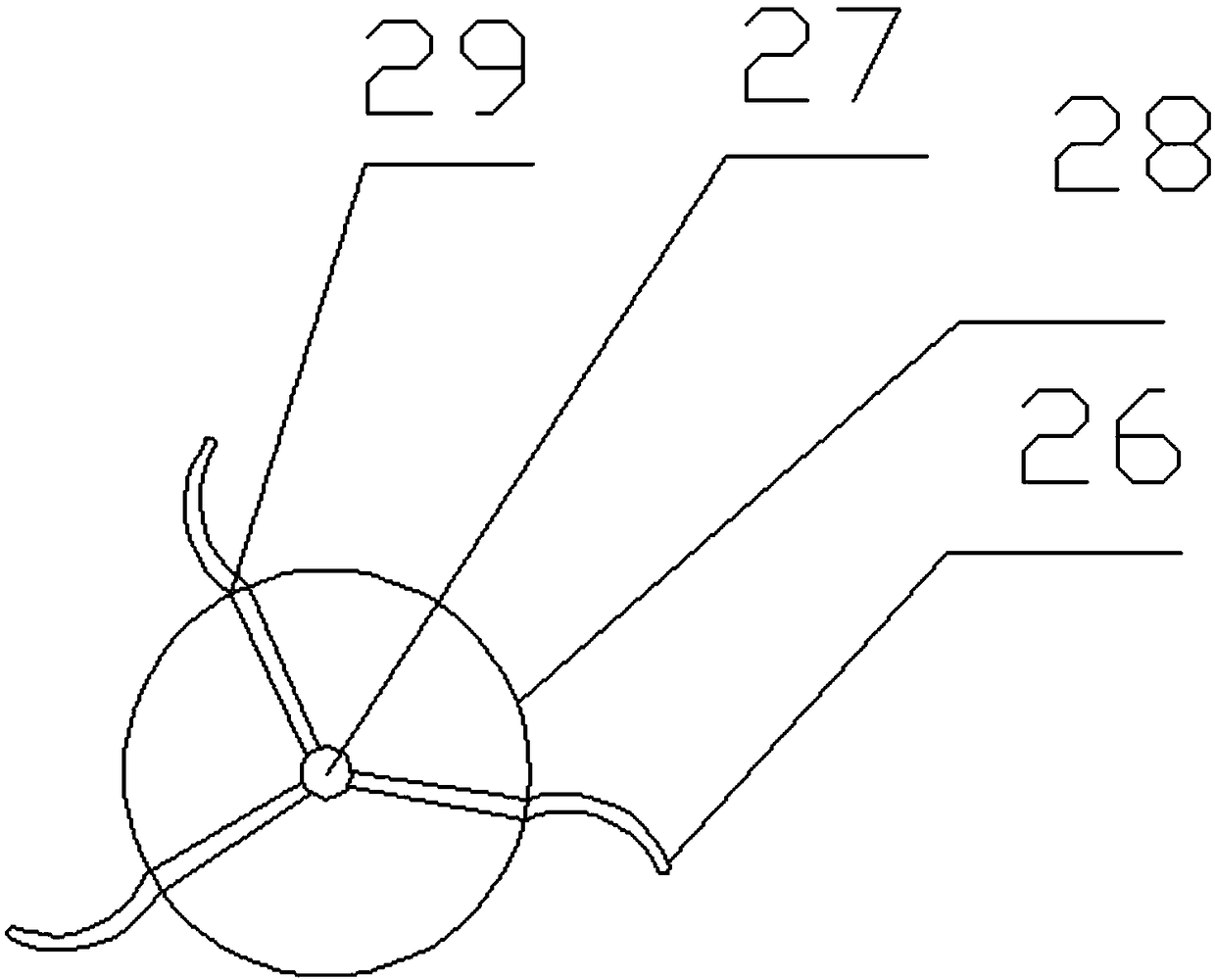

[0027] see Figure 1-3 , a medical waste treatment equipment, including a housing 1, a crushing device 12, a cleaning tank 10 and a heat melting furnace 21. A water tank 4 is fixedly installed at the bottom of the housing 1 , and a water inlet 3 is provided on the top of the side of the water tank 4 . Water tank 4 side bottoms are provided with water outlet 2, and water outlet 2 is provided with valve, and opening valve can discharge accumulated water in water tank 4 by water outlet 2. A water pipe 22 is arranged at the bottom of the water tank 4 , and the water pipe 22 communicates with the water pump 19 . Driven by the water pump 19 , the water in the water tank 4 is pumped into the water pipe 22 . The top of the housing 1 is provided with a feeding port 11, which extends to the inside of the housing 1. The setting of the feeding port 11 facilitates the entry of medical waste.

[0028] A horizontal first fixed plate 8 is fixed inside the housing 1, and a crushing device 12...

Embodiment 2

[0034] see Figure 4 , On the basis of Embodiment 1, the side of the water tank 4 is provided with a water viewing window 32, the water viewing window 32 is made of a transparent material, and the water in the water tank 4 can be observed through the water viewing window 32. Scale line 31 is engraved on the water viewing window 32, and the setting of scale line 31 can quantitatively measure the water yield in the water tank 4. The right end of the filter screen 15 is provided with a vibrator 33, the vibrator 33 is fixedly installed on the inner wall of the housing 1, the left end of the filter screen 15 is provided with a spring 34, and the spring 34 is fixed on the lower surface of the second fixed plate 14, Driven by the vibrator 33, the filter screen 15 vibrates with the internal materials at high frequency, which is conducive to the rapid dripping of water on the granular materials and the rolling of the granular materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com