Trivalent chromium electroplating solution formula for automobile logo production and trivalent chromium electroplating process

An electroplating process and electroplating solution technology, which is applied in jewelry and other fields, can solve the problems of poor corrosion resistance of automobile logos and low coating hardness, and achieve the effects of color resistance to harsh weather, beautiful color, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

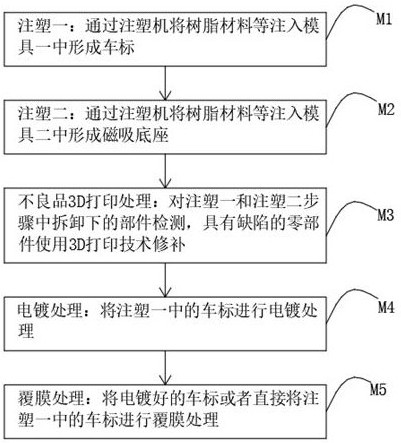

Method used

Image

Examples

Embodiment 1

[0031] The embodiment of the present invention provides the trivalent chromium electroplating solution formula for the production of automobile signs, also known as the trivalent chromium electroplating solution formula, including the raw materials of the following components: potassium chromium sulfate 8g / L, chromium sulfate 6g / L, basic chromium sulfate 2g / L, sodium sulfate 3g / L, aluminum sulfate 2g / L, acrylic acid-itaconic acid copolymer 1g / L, sodium fluoride 4g / L, sulfide 0.2g / L, sodium vinylsulfonate 0.5g / L, Polyethylene glycol 0.2g / L, the balance is water.

[0032] The molecular weight of acrylic acid-itaconic acid copolymer is 10000, and the molecular weight of polyethylene glycol is 400.

[0033] The pH value of the trivalent chromium plating solution is 1.8, adjusted with ammonia water or hydrochloric acid.

[0034] The electroplating process of the trivalent chromium electroplating solution for automobile logo production comprises the following steps:

[0035] A st...

Embodiment 2

[0045] The embodiment of the present invention provides the formula of trivalent chromium electroplating solution for automobile logo production, including the raw materials of the following components: potassium chromium sulfate 10g / L, chromium sulfate 7g / L, basic chromium sulfate 4g / L, sodium sulfate 4.5g / L , aluminum sulfate 3g / L, acrylic acid-itaconic acid copolymer 1.5g / L, sodium fluoride 6g / L, sulfide 1.1g / L, sodium vinyl sulfonate 1g / L, polyethylene glycol 0.4g / L , The balance is water.

[0046] The molecular weight of acrylic acid-itaconic acid copolymer is 25000, and the molecular weight of polyethylene glycol is 650.

[0047] The pH value of the trivalent chromium plating solution is 2, adjusted with ammonia water or hydrochloric acid.

[0048] The electroplating process of the trivalent chromium electroplating solution for automobile logo production comprises the following steps:

[0049] A standard iron sheet test product with a thickness of 0.1cm and a length an...

Embodiment 3

[0059] The embodiment of the present invention provides the formula of trivalent chromium electroplating solution for the production of automobile signs, comprising the raw materials of the following components: potassium chromium sulfate 12g / L, chromium sulfate 8g / L, basic chromium sulfate 6g / L, sodium sulfate 6g / L, Aluminum sulfate 4g / L, acrylic acid-itaconic acid copolymer 2g / L, sodium fluoride 8g / L, sulfide 2g / L, sodium vinyl sulfonate 1.5g / L, polyethylene glycol 0.6g / L, The amount is water.

[0060] The molecular weight of acrylic acid-itaconic acid copolymer is 40000, and the molecular weight of polyethylene glycol is 900.

[0061] The pH value of the trivalent chromium plating solution is 2.2, adjusted with ammonia water or hydrochloric acid.

[0062] The electroplating process of the trivalent chromium electroplating solution for automobile logo production comprises the following steps:

[0063] A standard iron sheet test product with a thickness of 0.1cm and a lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com