Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reasonable optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

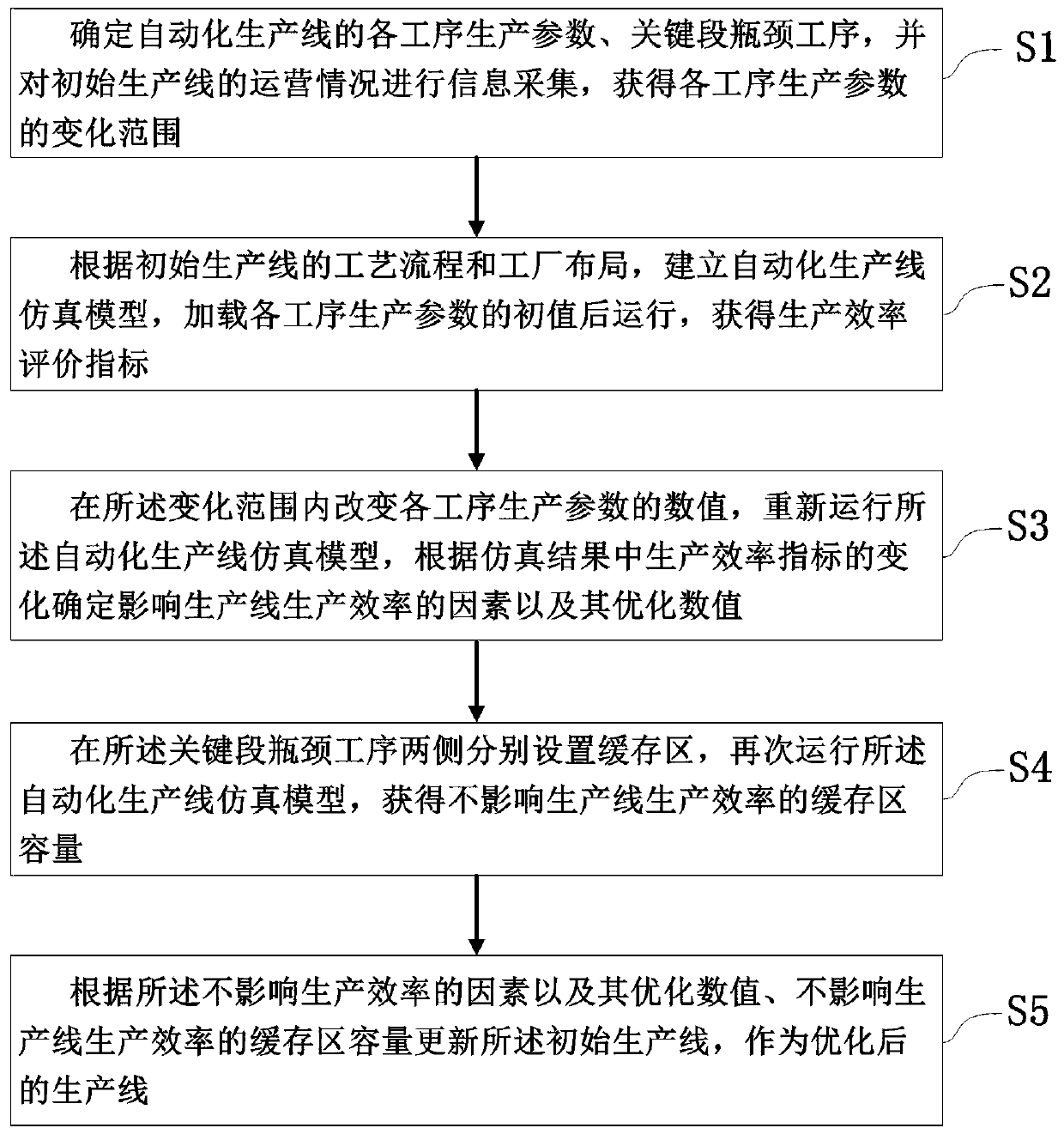

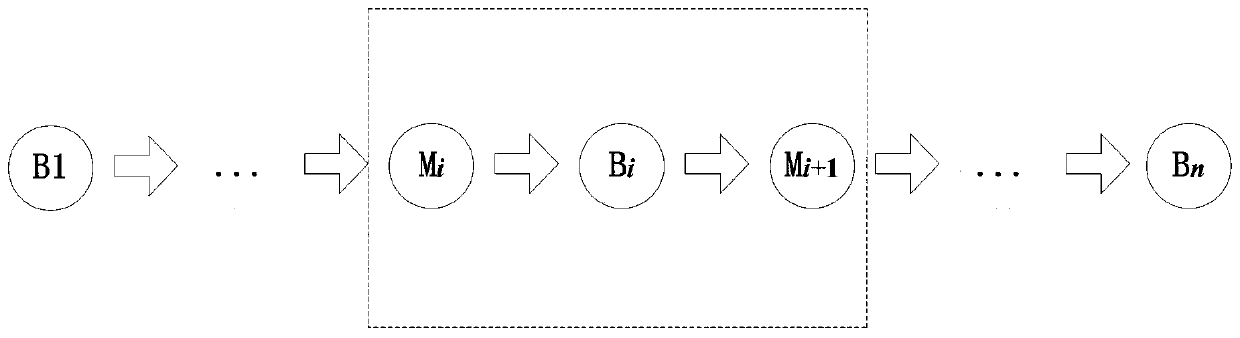

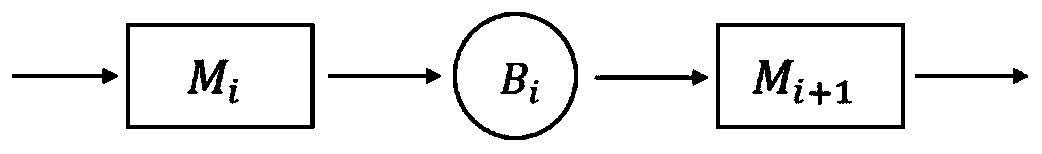

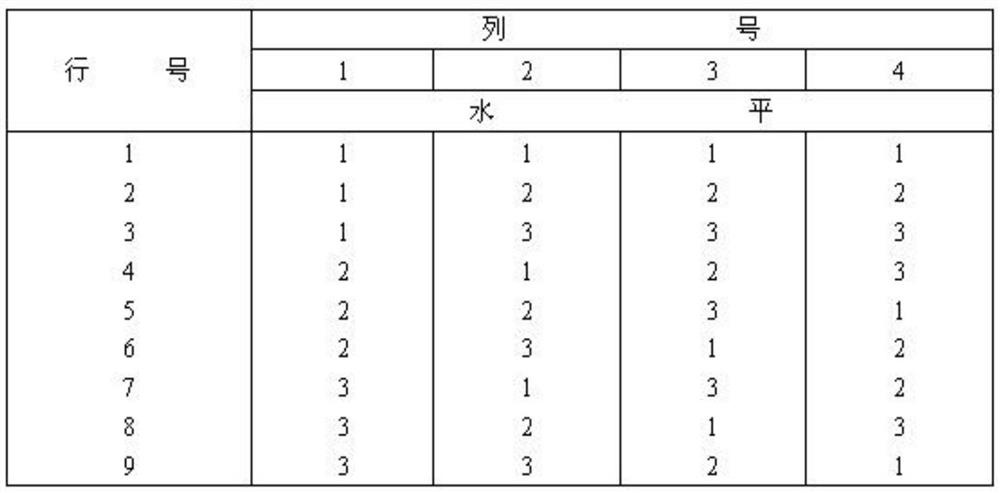

Automatic production line optimization method based on cache region capacity calculation

ActiveCN110276126AProductivity Impact EliminationReasonably optimize the valueDesign optimisation/simulationResourcesProduction lineLogistics management

The invention relates to an automatic production line optimization method based on cache region capacity calculation, belongs to the technical field of automatic production line optimization design, and solves the problems of production line logistics blockage, low production efficiency, complex cache region capacity formula and low precision caused by incapability of eliminating equipment failure rate in the prior art. The method comprises the following steps: determining production parameters and key section bottleneck procedures of an automatic production line; establishing an automatic production line simulation model according to the process flow of the initial production line and the factory layout, loading production parameters of each procedure, and then running to obtain a production efficiency evaluation index; changing the numerical values of the production parameters of each procedure, re-operating the model, and determining factors influencing the production efficiency of the production line and optimization numerical values according to a simulation result; arranging cache regions on the two sides of the bottleneck procedure of the key section respectively, operating the model again, and obtaining the cache region capacity which does not affect the production efficiency of the production line; and updating the initial production line as an optimized production line.

Owner:BEIJING MECHANICAL EQUIP INST

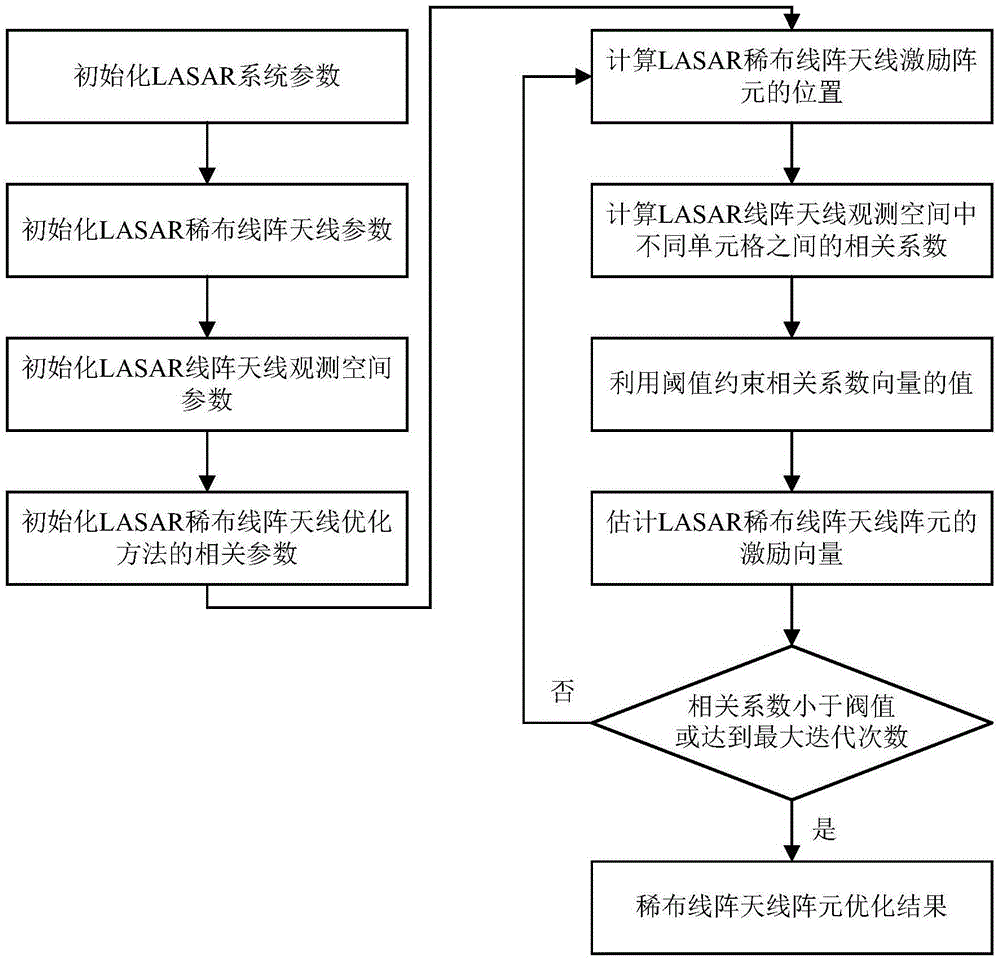

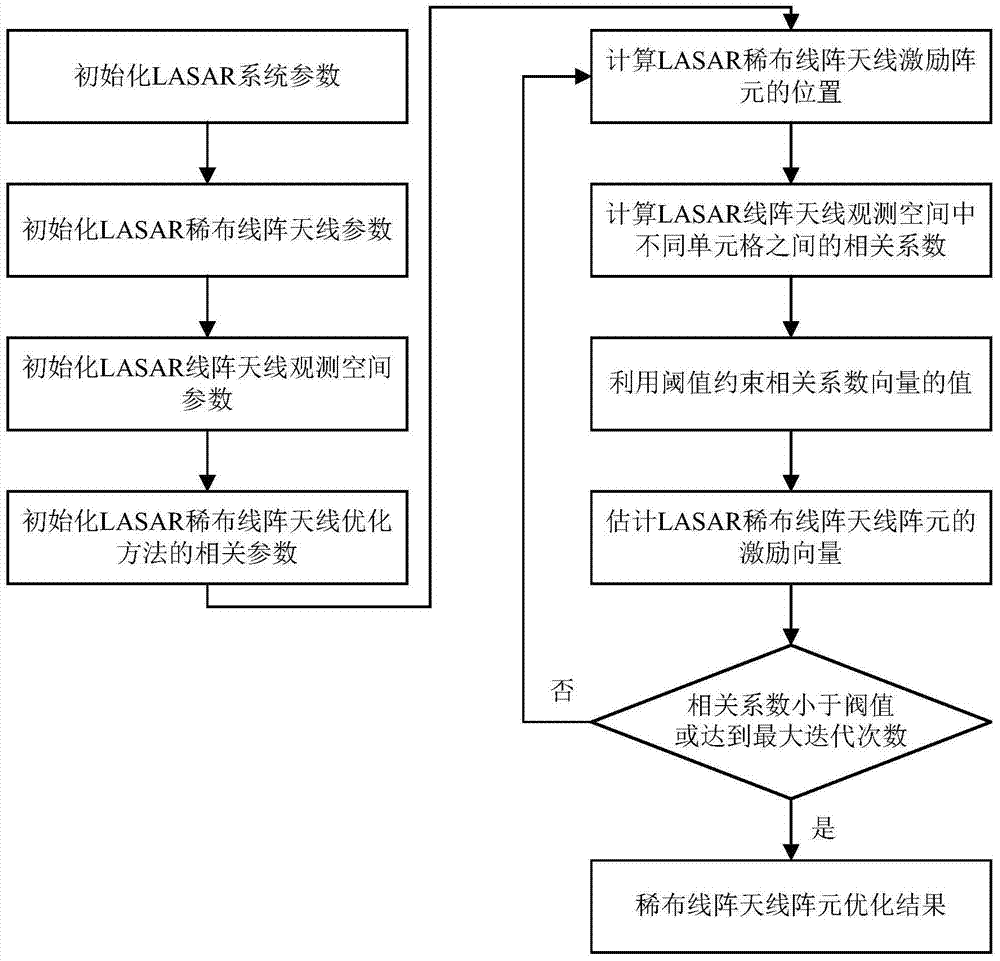

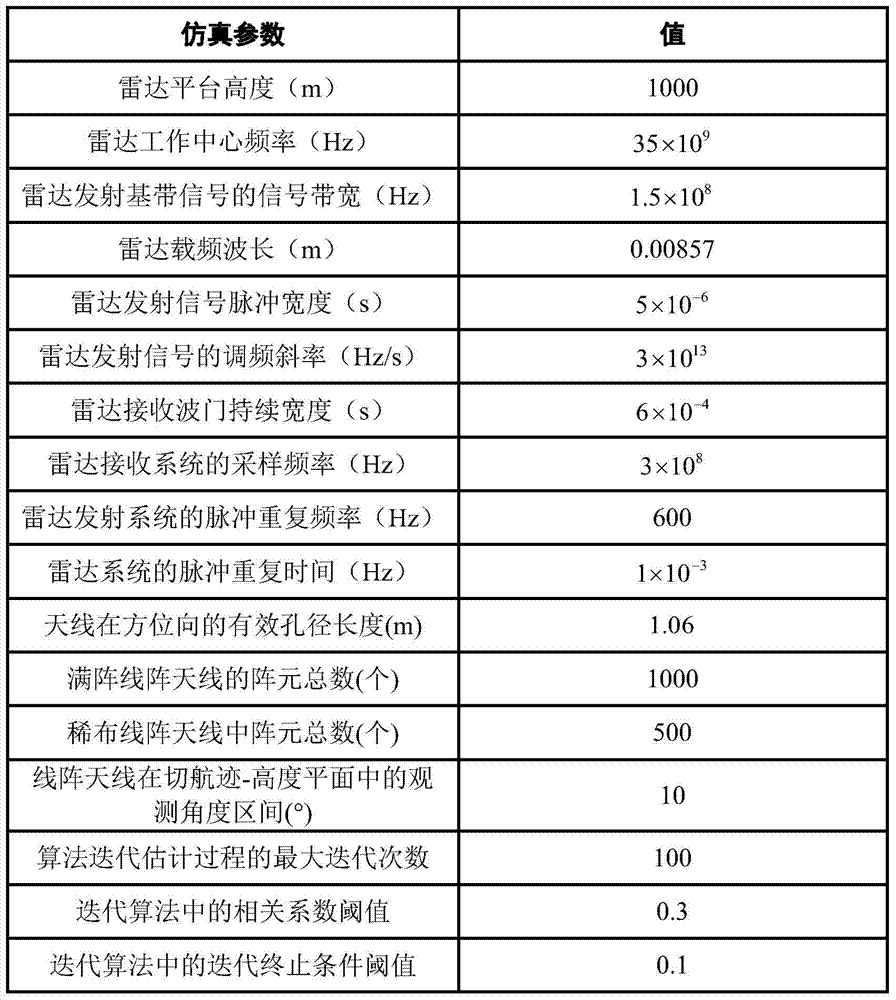

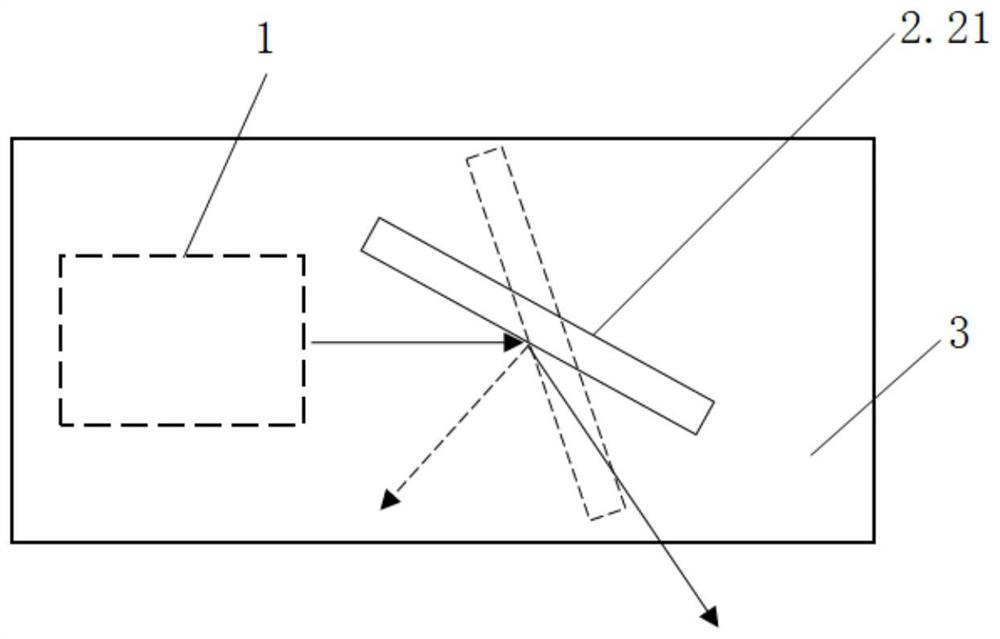

Compressed sensing LASAR sparse linear array optimization method based on low coherence

InactiveCN105487052AReasonable optimizationHigh imaging performanceRadio wave reradiation/reflectionIterative searchCompressed sensing

The invention discloses a compressed sensing LASAR sparse linear array optimization method based on low coherence. The method is characterized in that coherence characteristic of a measurement matrix in the compressed sensing theory is utilized as a reference basis for compressed sensing LASAR sparse linear array optimization; and on the basis of minimum of coherence of the compressed sensing measurement matrix in a LASAR system, and by means of a Fourier transform iterative search method, compressed sensing LASAR sparse linear array antenna array element distribution optimization design is realized, more reasonable sparse linear array optimization is realized, and imaging performance of the compressed sensing LASAR system is improved favorably. The method provided in the invention is also suitable for other sparse linear array antenna optimization technical fields based on compressed sensing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

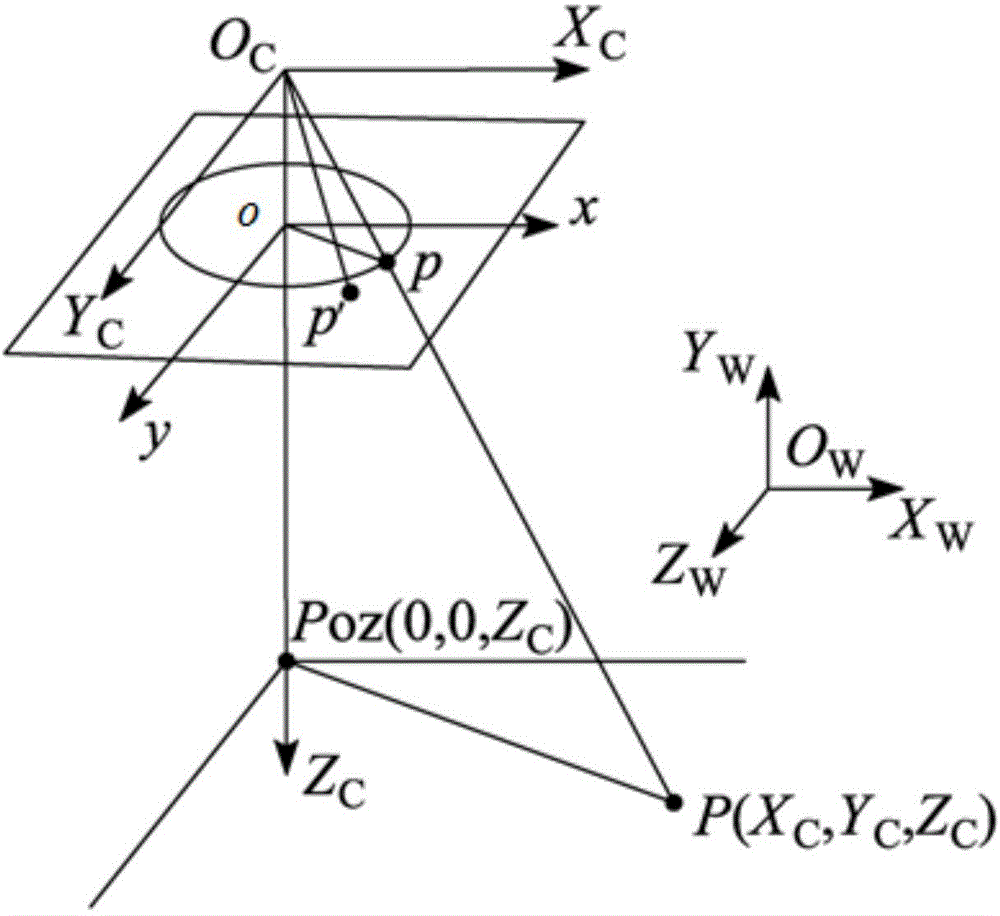

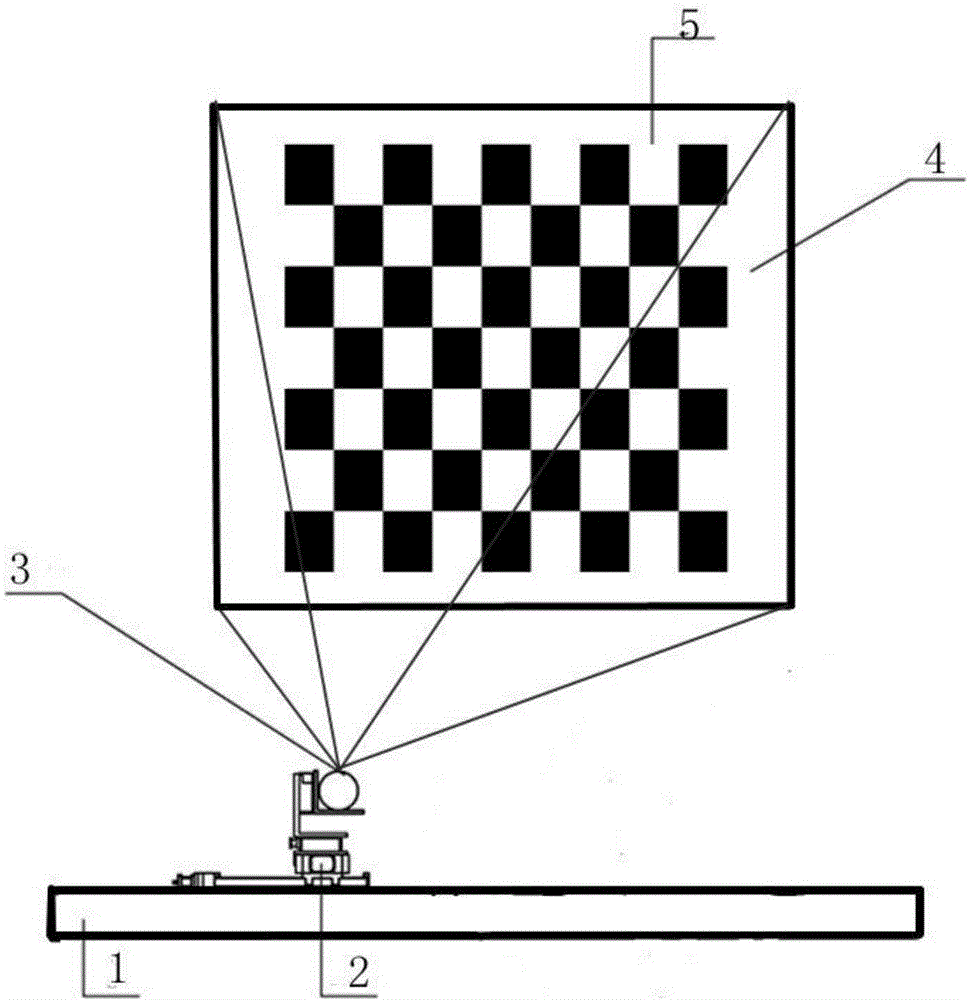

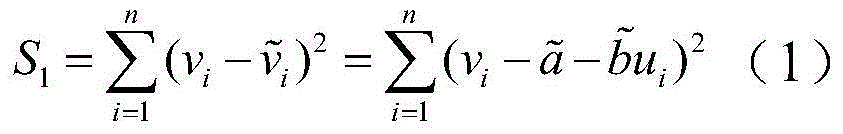

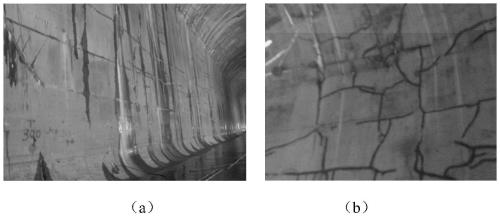

Camera distortion calibration method on basis of multiple constraints

InactiveCN104156974AReasonable optimizationAvoid redundancyImage analysisDistortion correctionEssential matrix

The invention discloses a camera distortion calibration method on the basis of multiple constraints, belongs to the field of image processing and computer visual inspection and particularly relates to distortion correction in the field calibration process of parameters in a camera in a large-scale forged piece size measurement system. The calibration method utilizes projective invariance of a straight line, i.e. projected line segments corresponding to linearity and parallel lines are guaranteed to be crossed at a hidden point, and inherent characteristics in pure translation two-view geometry, i.e. the antisymmetry characteristic of the epipolar constraint and a basic matrix, to enable optimization of the parameters of the camera to be more reasonable; a target is controlled to be positioned at different positions in a view field when the camera is in different postures in the active visual calibration process and finally, the target equivalently covers the integral view field; and comprehensive solution of a distortion coefficient is carried out according to one large-scale target so as to avoid miscellaneousness of the measurement system. According to the invention, influence of distortion on estimation of the basic matrix and parameter calibration of the camera can be eliminated; and the camera distortion calibration method can be well applied to the field calibration of the camera in the large-scale forged piece size measurement system.

Owner:DALIAN UNIV OF TECH

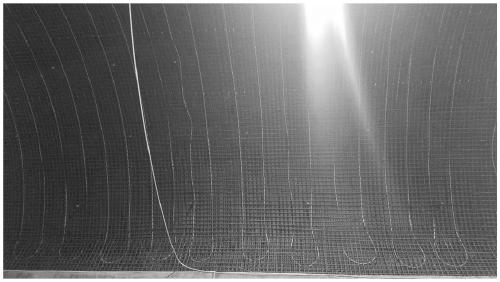

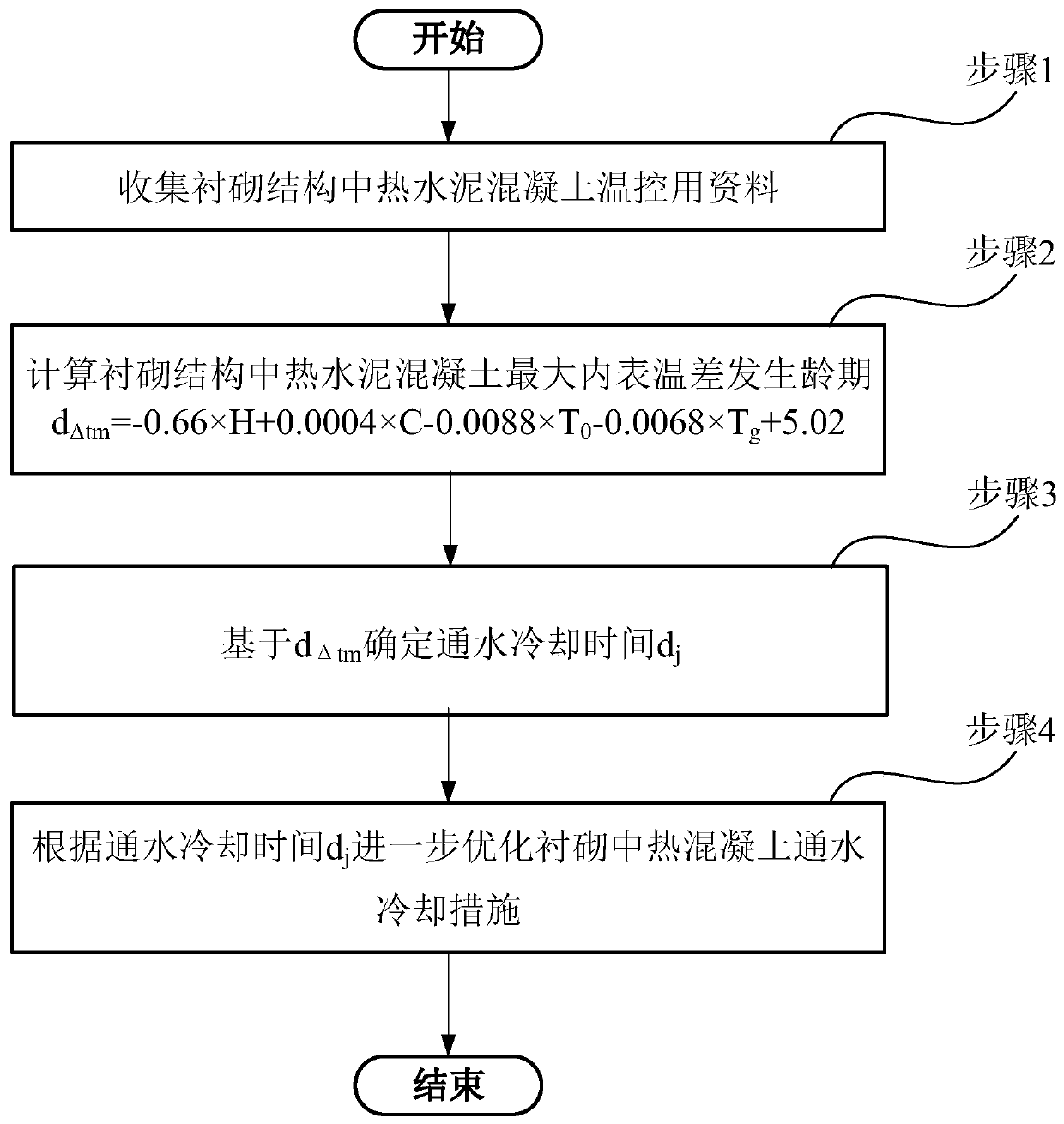

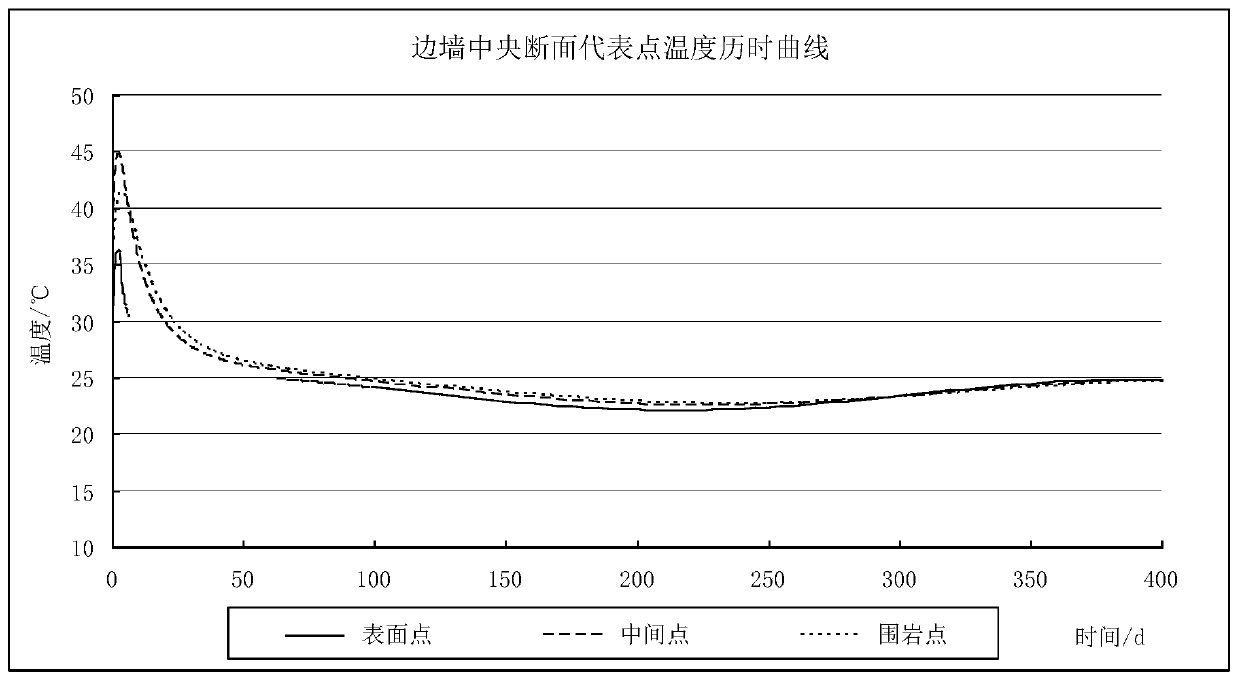

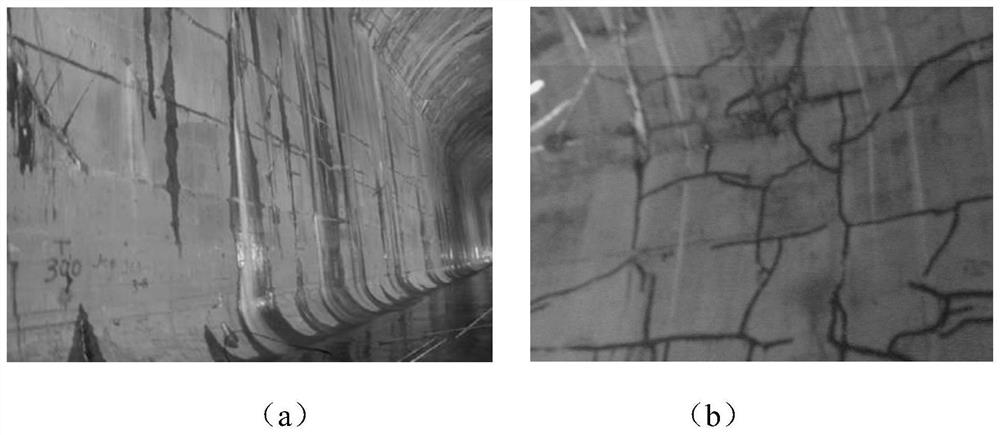

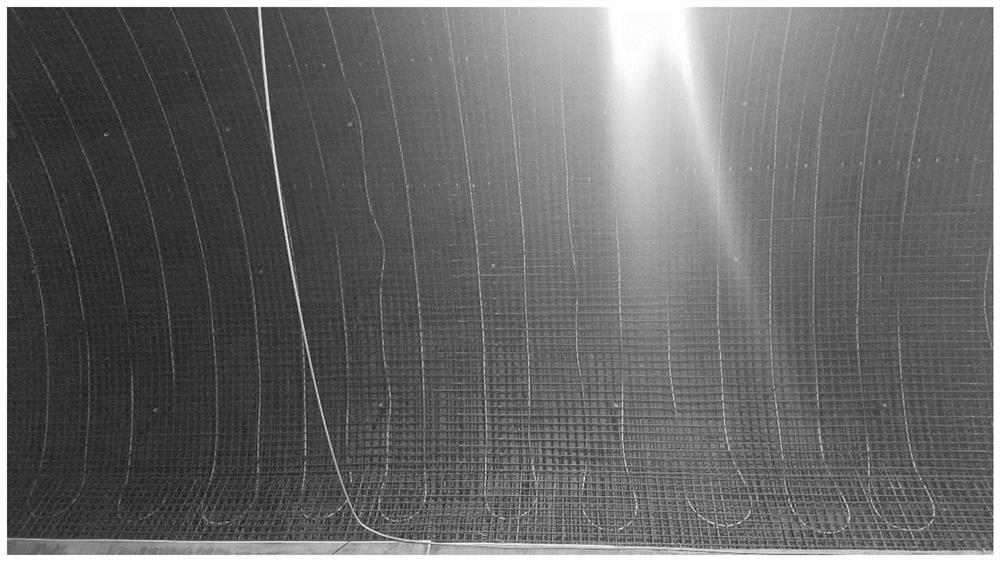

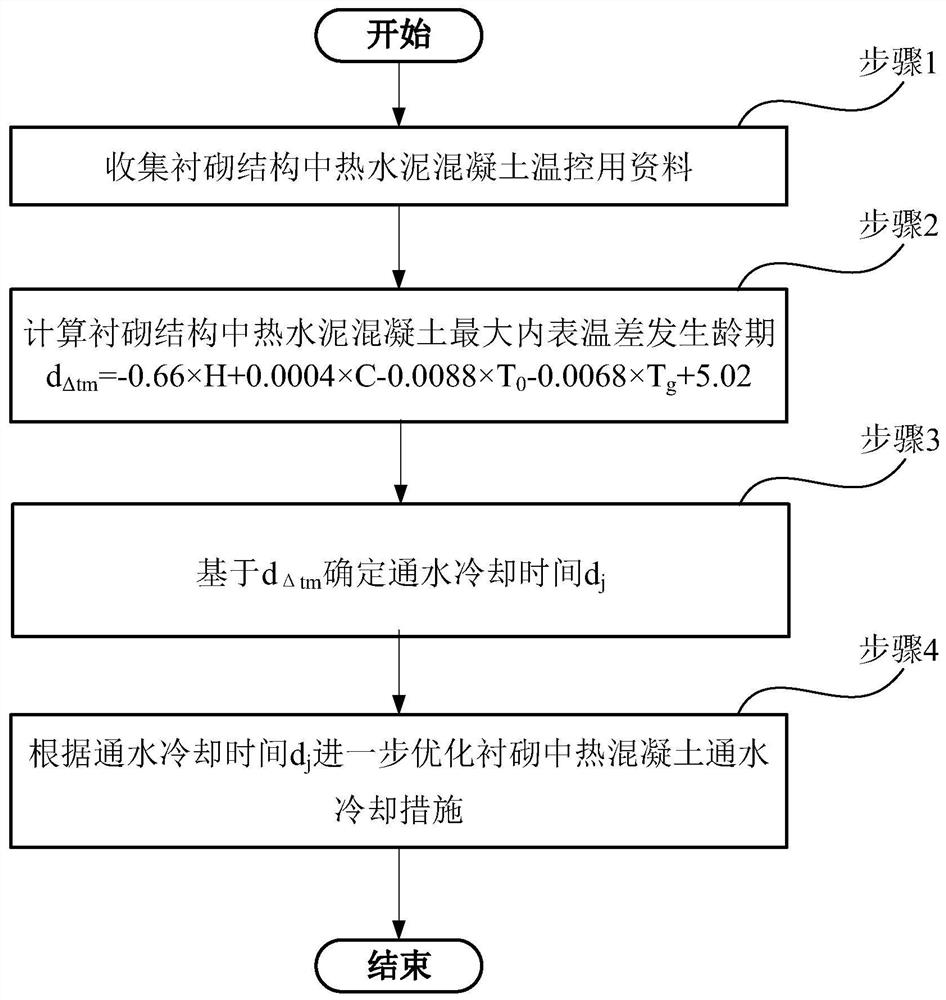

Medium-heat lining concrete water cooling method based on maximum inner surface temperature difference age

ActiveCN111411628AScientificIncrease temperatureBarrages/weirsWater-power plantsEngineeringEnvironmental geology

The invention provides a medium-heat lining concrete water cooling method based on a maximum inner surface temperature difference age. The medium-heat lining concrete water cooling method is characterized by comprising the following steps of step 1, collecting temperature control data of medium-heat cement concrete in a lining structure; step 2, calculating the maximum inner surface temperature difference generation age d [delta] tm =-0.66*H+0.0004*C-0.0088*T0-0.0068*Tg+5.02 of the hot cement concrete in the lining structure, wherein H is the thickness of the hot cement concrete in the liningstructure; C is the strength grade of the hot cement concrete in the lining structure; wherein T0 is the pouring temperature of the hot cement concrete in the lining structure; wherein Tg is the watercooling equivalent water temperature value, Tg=35-Tw, and Tw is the water cooling water temperature; step3, determining the water cooling time dj based on d [delta] tm, and step 4, further optimizingwater cooling measures of the hot concrete in the lining according to the water cooling time dj, and scientifically and reasonably realizing temperature cracking.

Owner:GUANGDONG YUANTIAN ENG +1

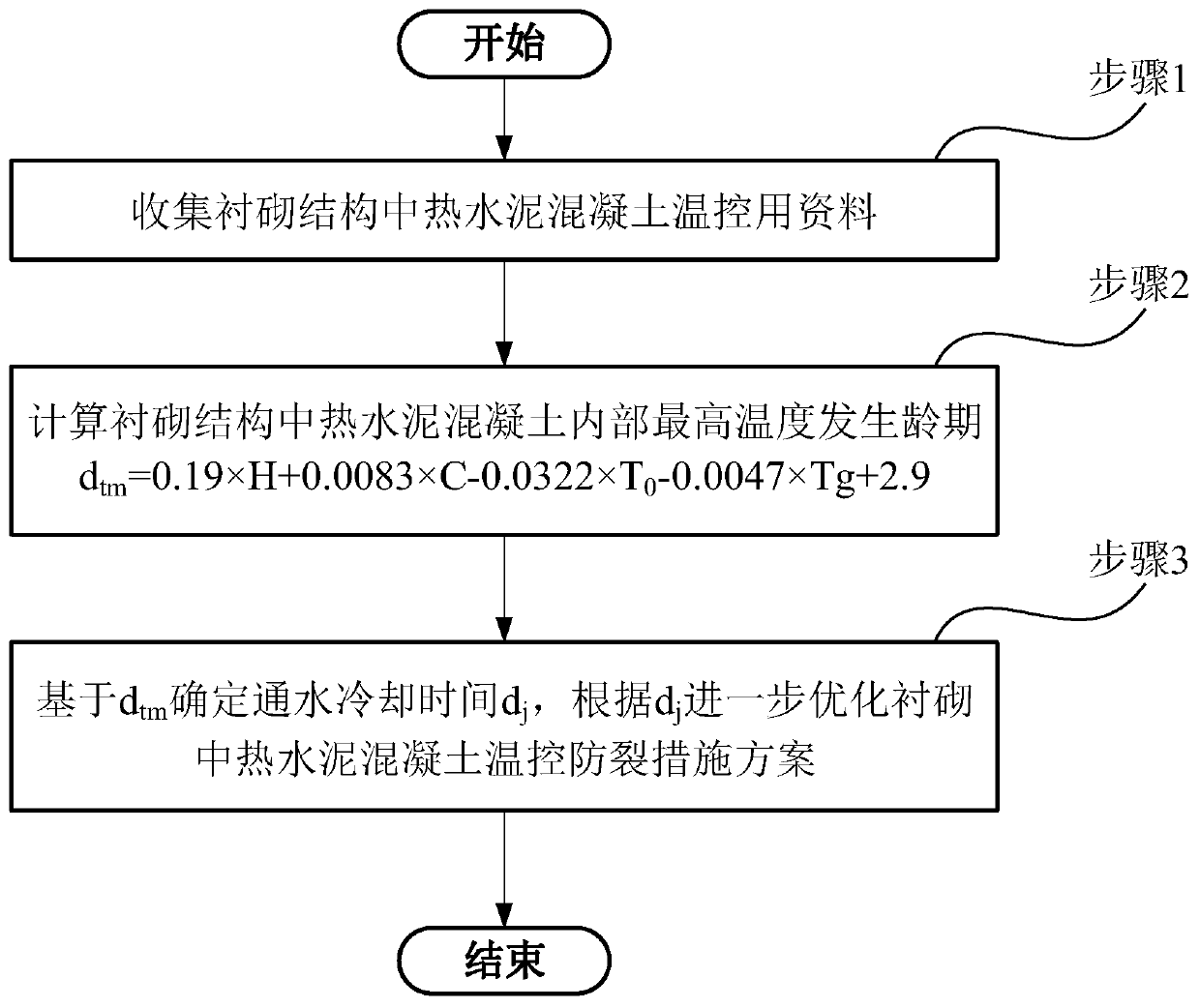

Temperature control anti-cracking method for hot cement concrete in lining structure

ActiveCN110457738AIncrease temperatureScientificSpecial data processing applicationsTemperature controlUltimate tensile strength

The invention provides a temperature control anti-cracking method for hot cement concrete in a lining structure. The temperature control anti-cracking method is characterized by comprising the following steps: step 1, collecting temperature control data of the hot cement concrete in the lining structure; 2, calculating the highest temperature generation age dtm in the hot cement concrete in the lining structure, wherein dtm = 0.19 * H + 0.0083 * C-0. 0322 * T0-0. 0047 * Tg + 2.9, and H is the thickness of the concrete, C is the concrete strength grade, t0 is the concrete pouring temperature, Tg is a water cooling equivalent water temperature value, Tg = 35-Tw, and Tw is a water cooling water temperature; and step 3, determining water cooling time dj based on dtm, and then further optimizing a lining moderate heat cement concrete temperature control anti-cracking measure scheme according to the water cooling time dj. Temperature control anti-cracking is conducted on the hot cement concrete in the lining structure through the method, the durability of the lining structure can be effectively improved, and the service life of the lining structure can be effectively prolonged.

Owner:WUCHANG UNIV OF TECH +1

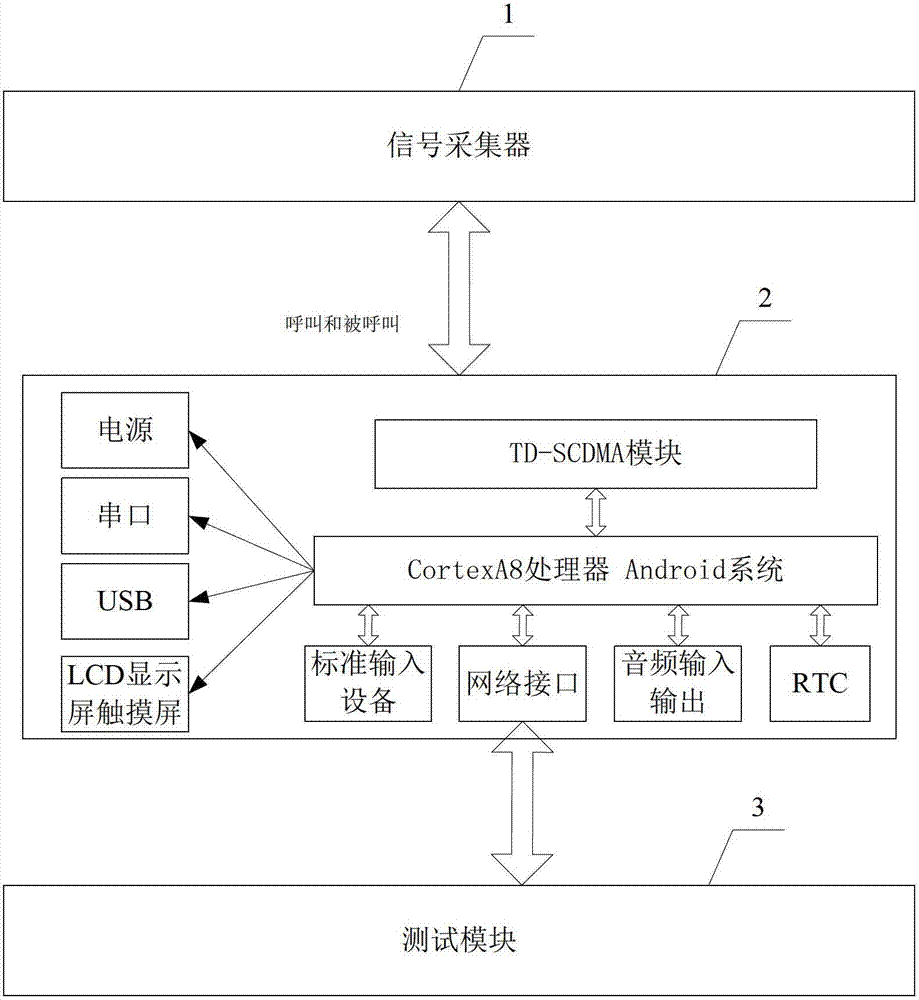

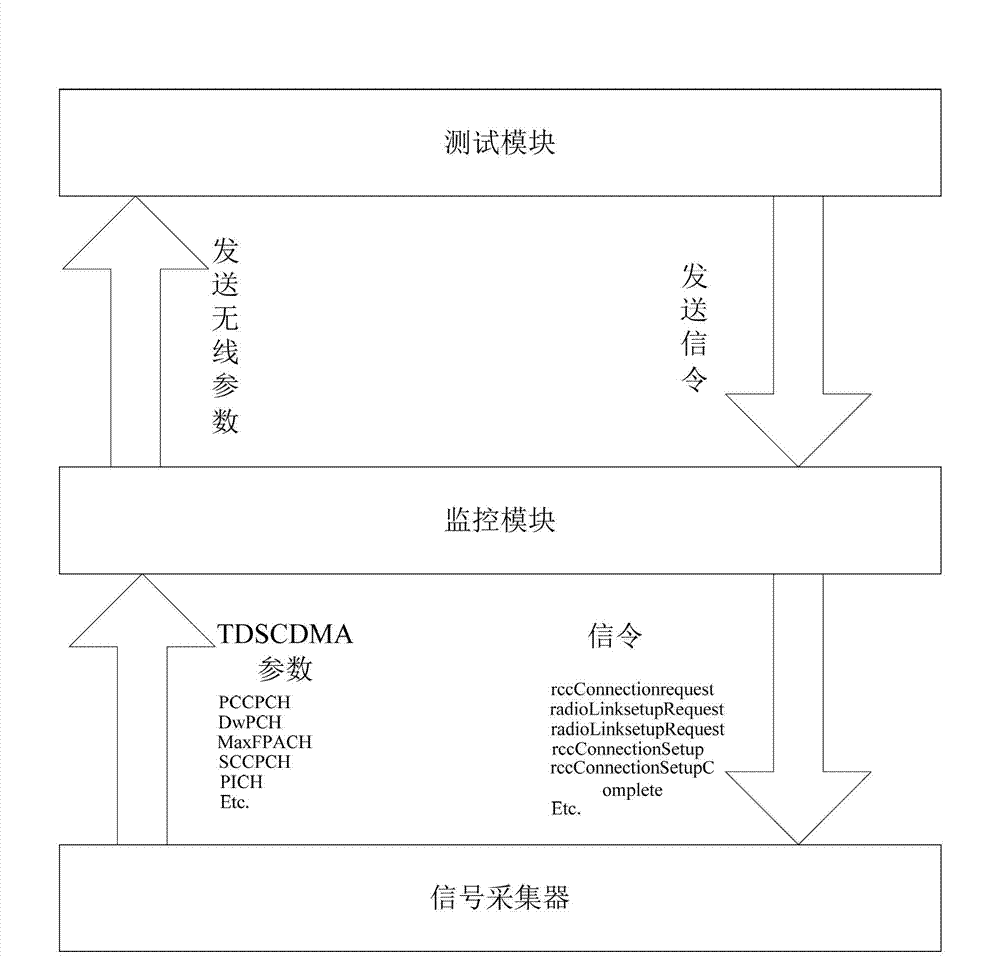

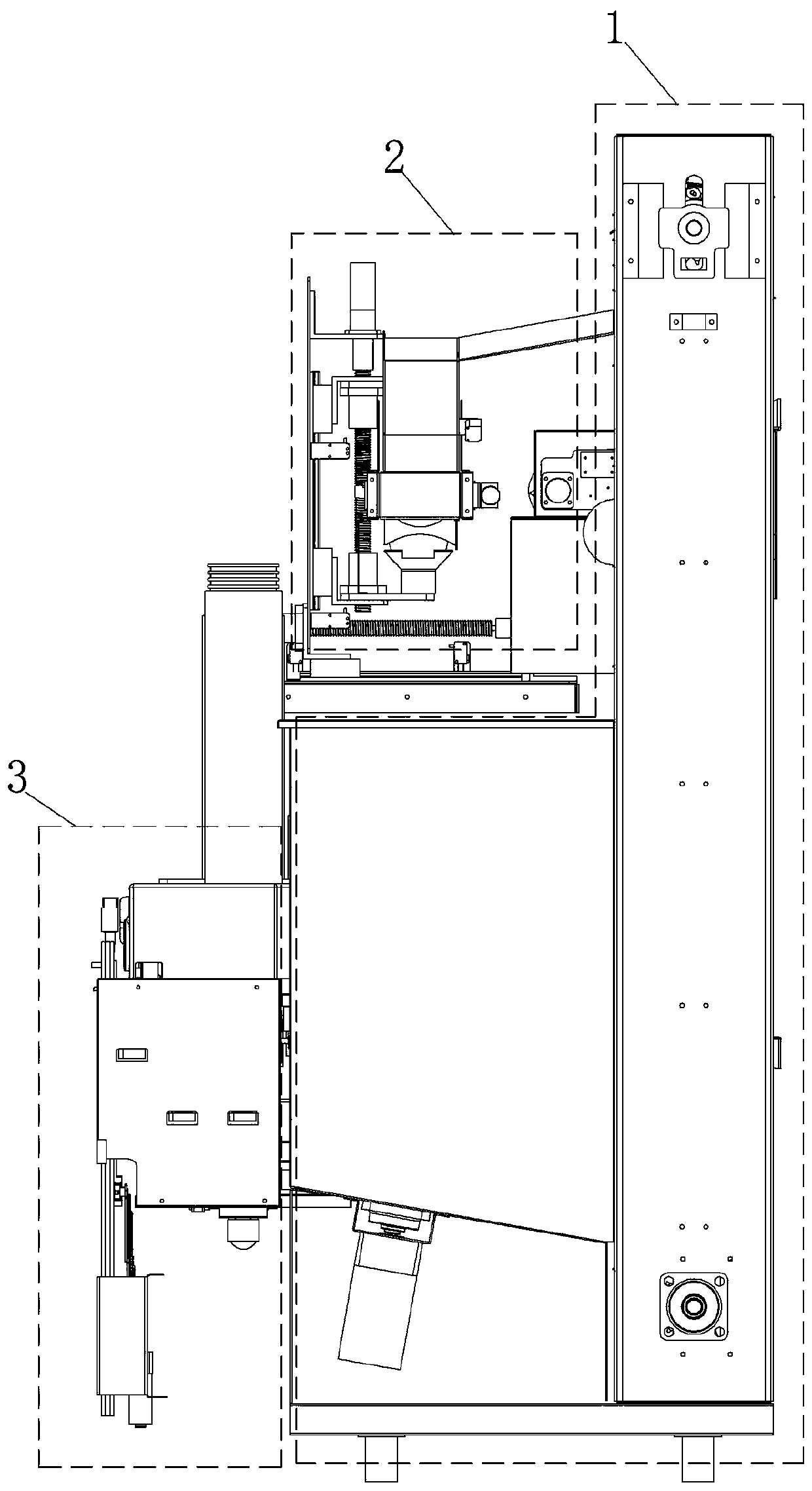

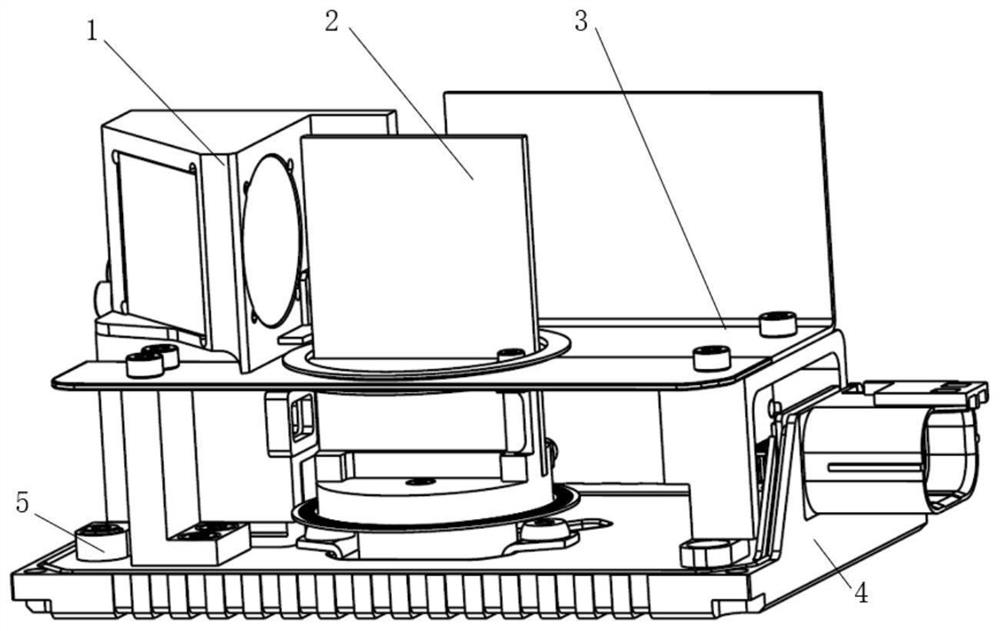

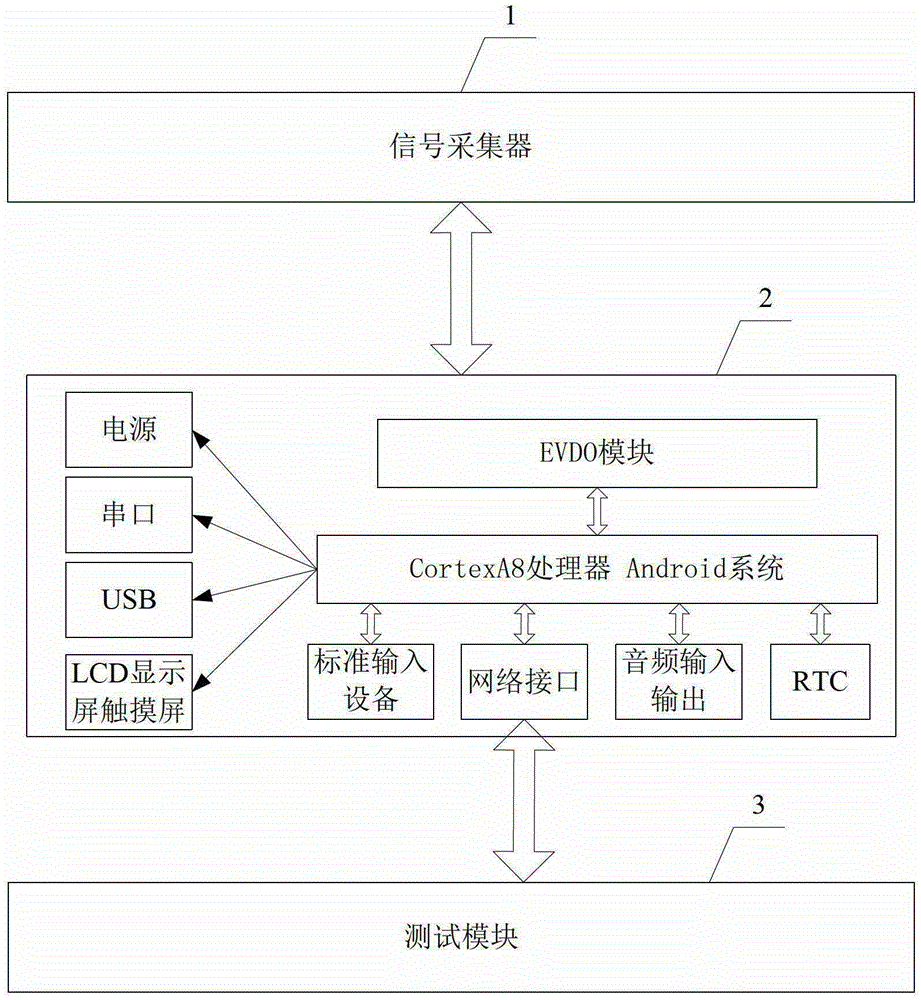

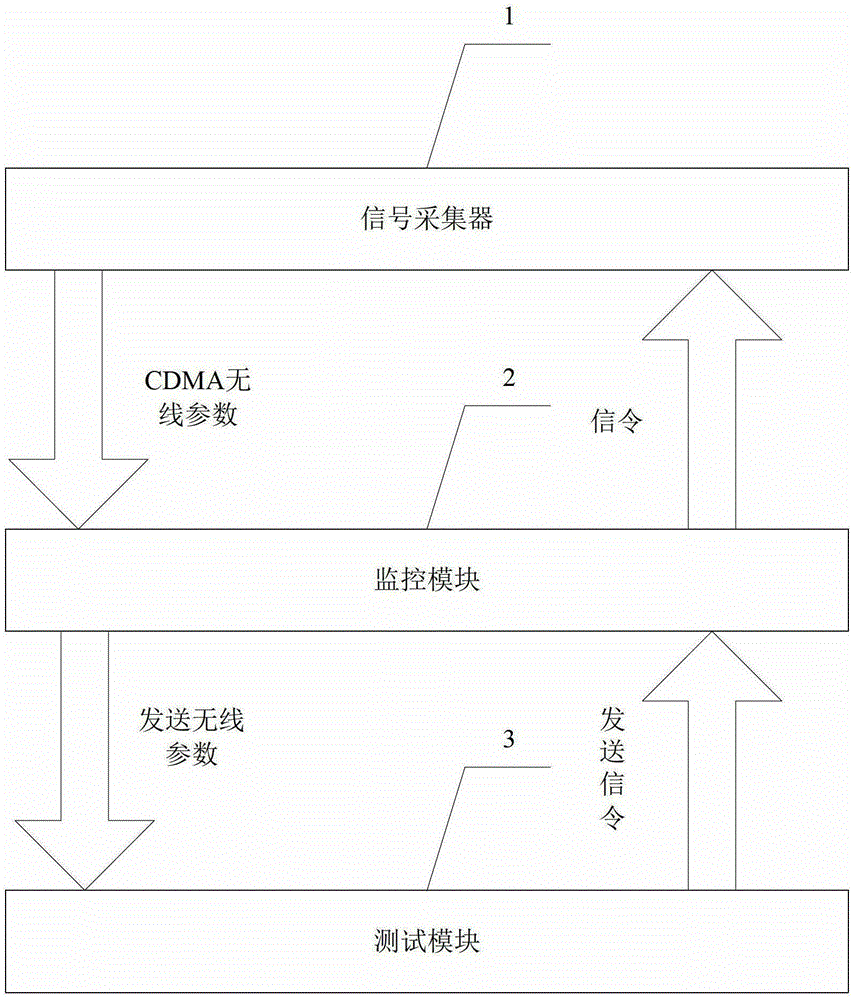

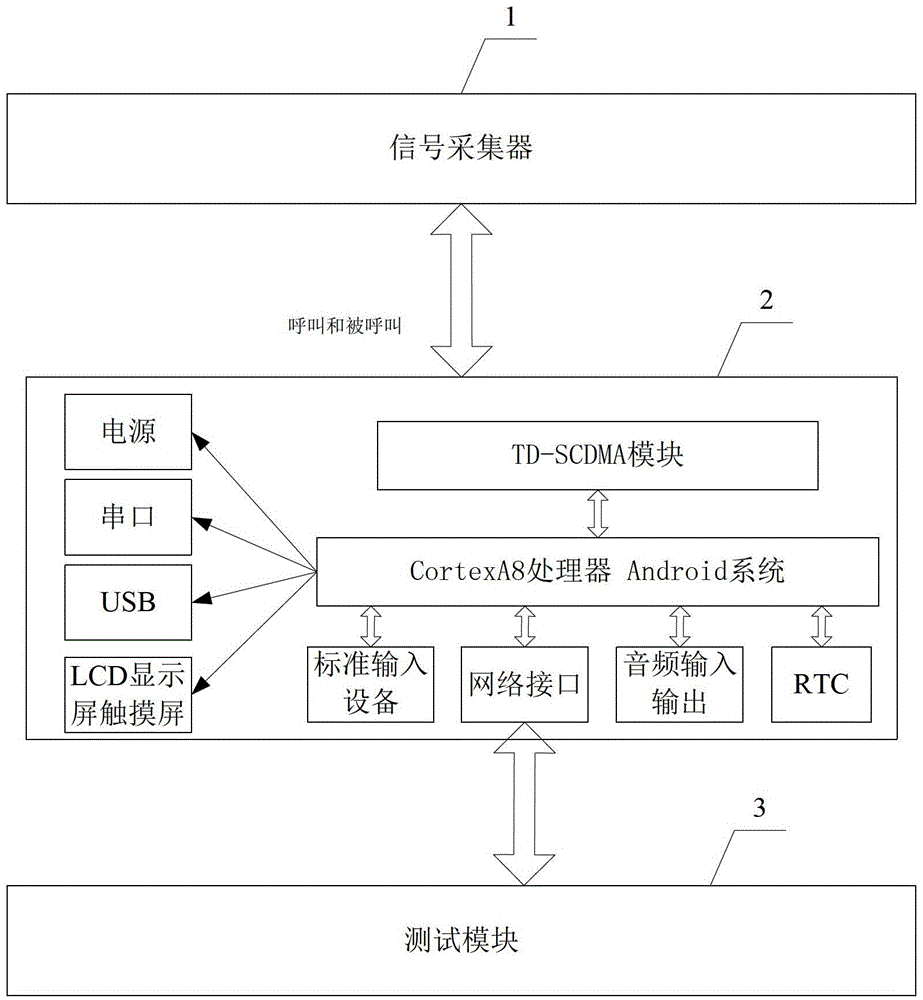

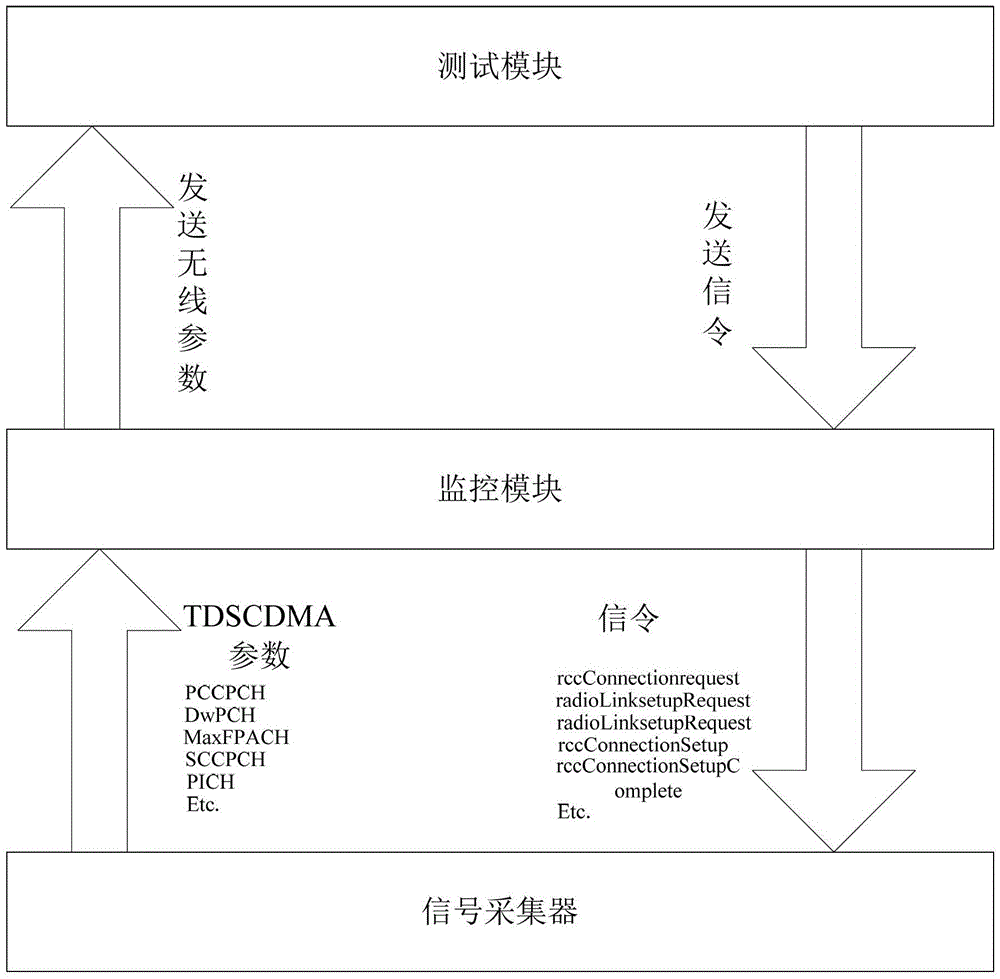

Time division-synchronous code division multiple access (TDSCDMA) signal test practical training platform device

InactiveCN102883353AReasonable optimizationUnderstand comprehensivelyWireless communicationTD-SCDMAVIT signals

The invention provides a time division-synchronous code division multiple access (TDSCDMA) signal test practical training platform device, which comprises a signal acquirer, a monitoring module and a test module, wherein the signal acquirer is used for acquiring a TD-SCDMA wireless signal parameter and outputting the TD-SCDMA wireless signal parameter to the monitoring module; the monitoring module is used for sending the received TD-SCDMA wireless signal parameter to the test module, executing corresponding signaling operation according to received signaling and sending a signaling operation result to the test module; and the test module is used for displaying the received TD-SCDMA wireless signal parameter, selecting the corresponding signaling according to an input command, sending the signaling to the monitoring module and displaying the signaling operation result. By the platform device, a beginner who is not familiar with running and optimization of a TD-SCDMA network can gradually know well a network optimization process and comprehensively learn about parameters in the TD-SCDMA network running and optimization process; furthermore, after the acquired TD-SCDMA wireless signal parameter is analyzed, the TD-SCDMA network can be rationally optimized; and a corresponding solution can be supplied to construction of TD-SCDMA.

Owner:NANTONG ZHIXIANG INFORMATION TECH

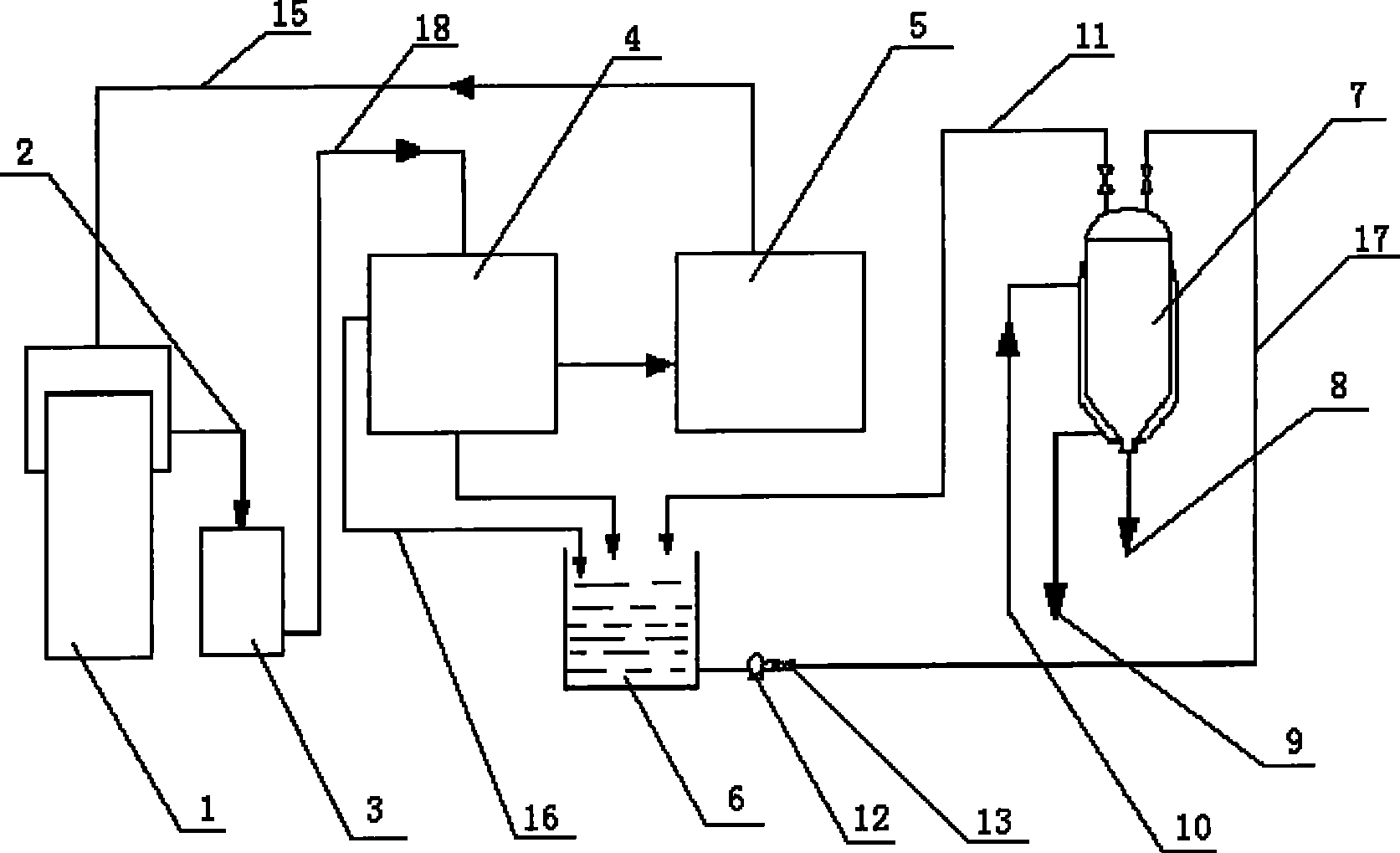

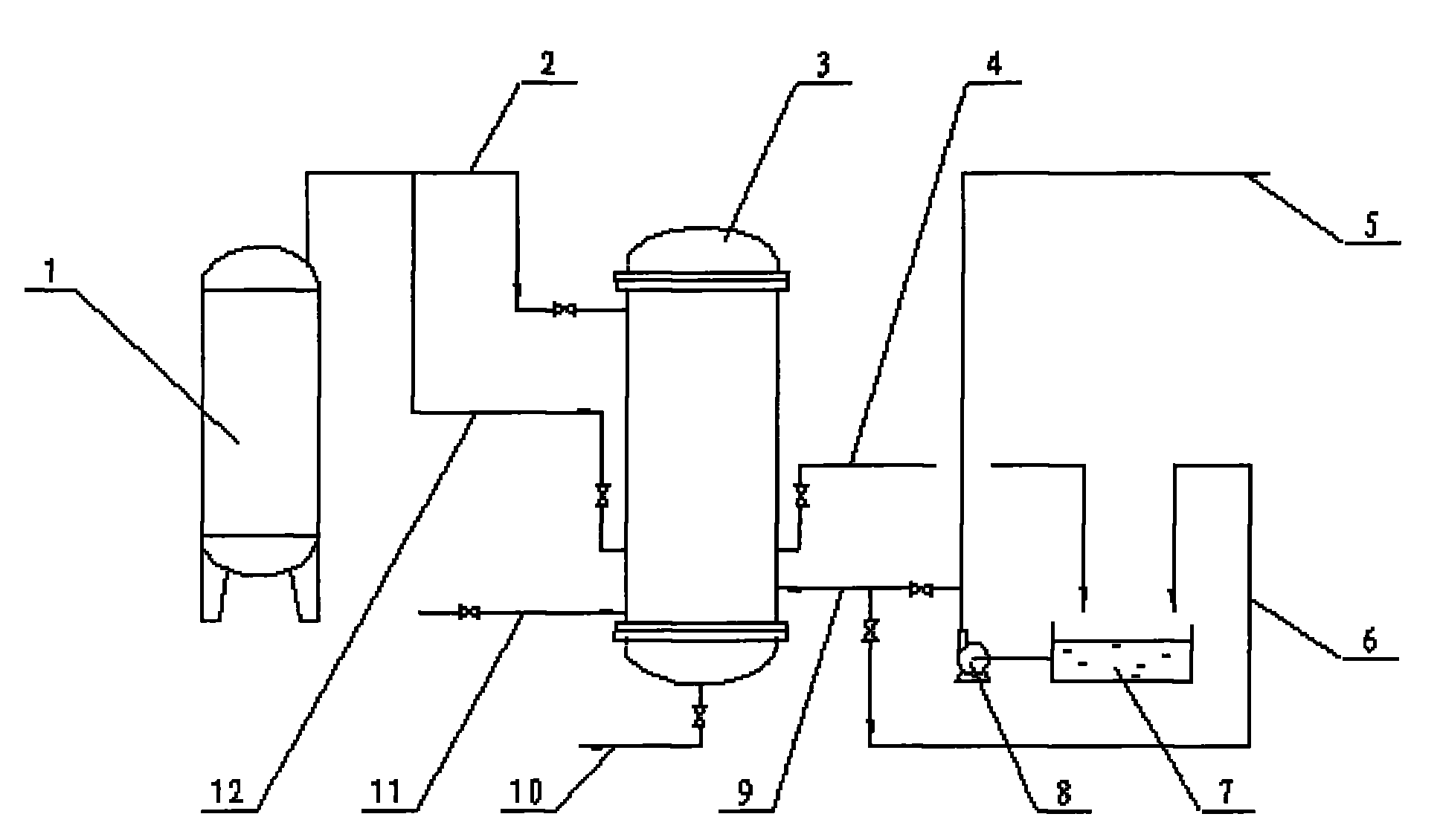

System for synthesizing N-methyl-2-pyrrolidone

The invention relates to a system for synthesizing N-methyl-2-pyrrolidone. The system is characterized by comprising a 1,4-butanediol dehydrogenation device, a mixed amine synthesis device and a N-methyl-2-pyrrolidone preparation device. The system provided by the invention has the advantages as follows: the system is simple in process, and low in energy consumption and input; in addition, multiple circulating exchange among devices is adopted, so that gamma-butyrolactone is completely converted into N-methyl-2-pyrrolidone, separation in a later period is easier, high-purity N-methyl-2-pyrrolidone can be synthesized and the purity can reach 99.9 wt % or above.

Owner:江苏恒祥化学股份有限公司

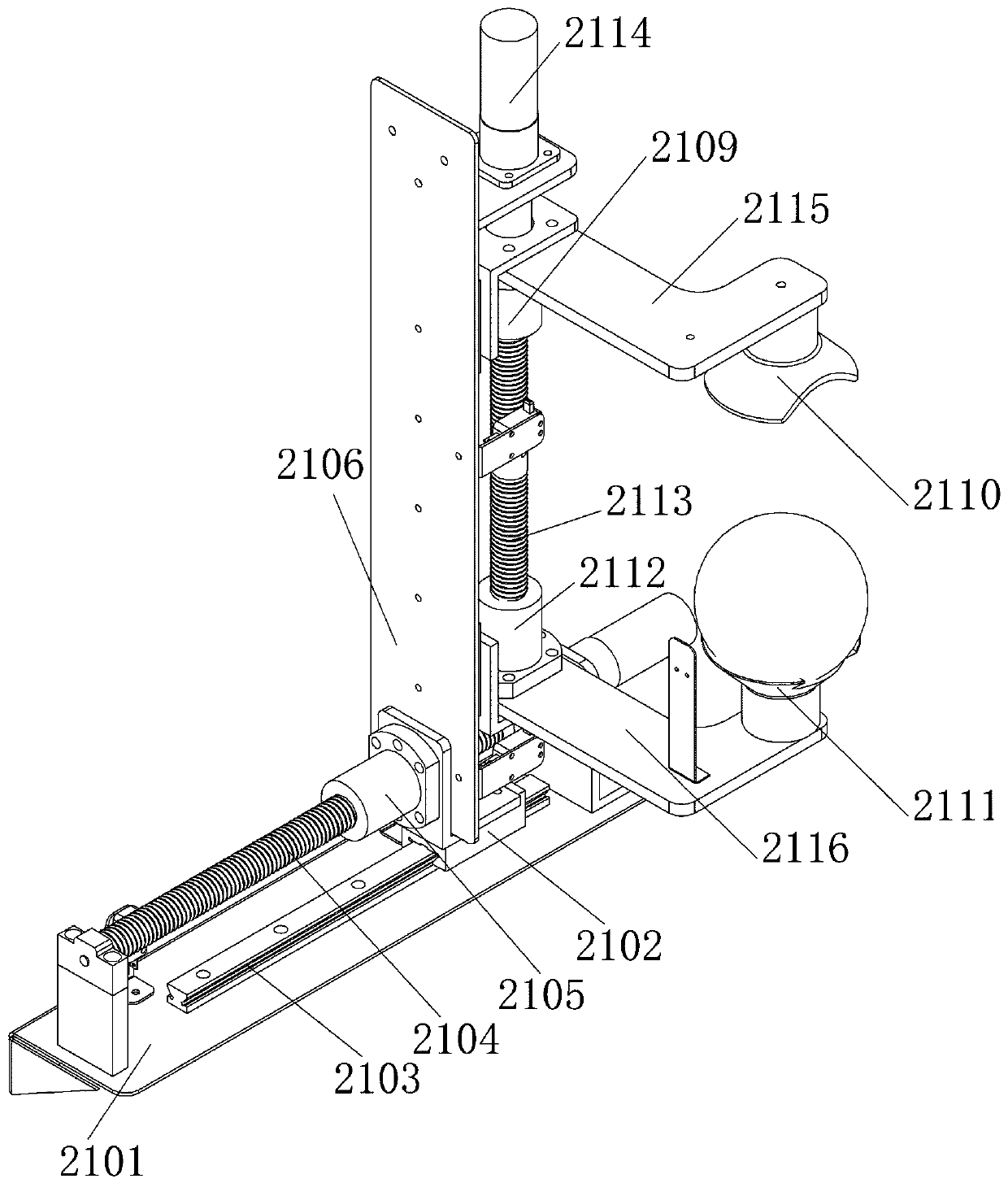

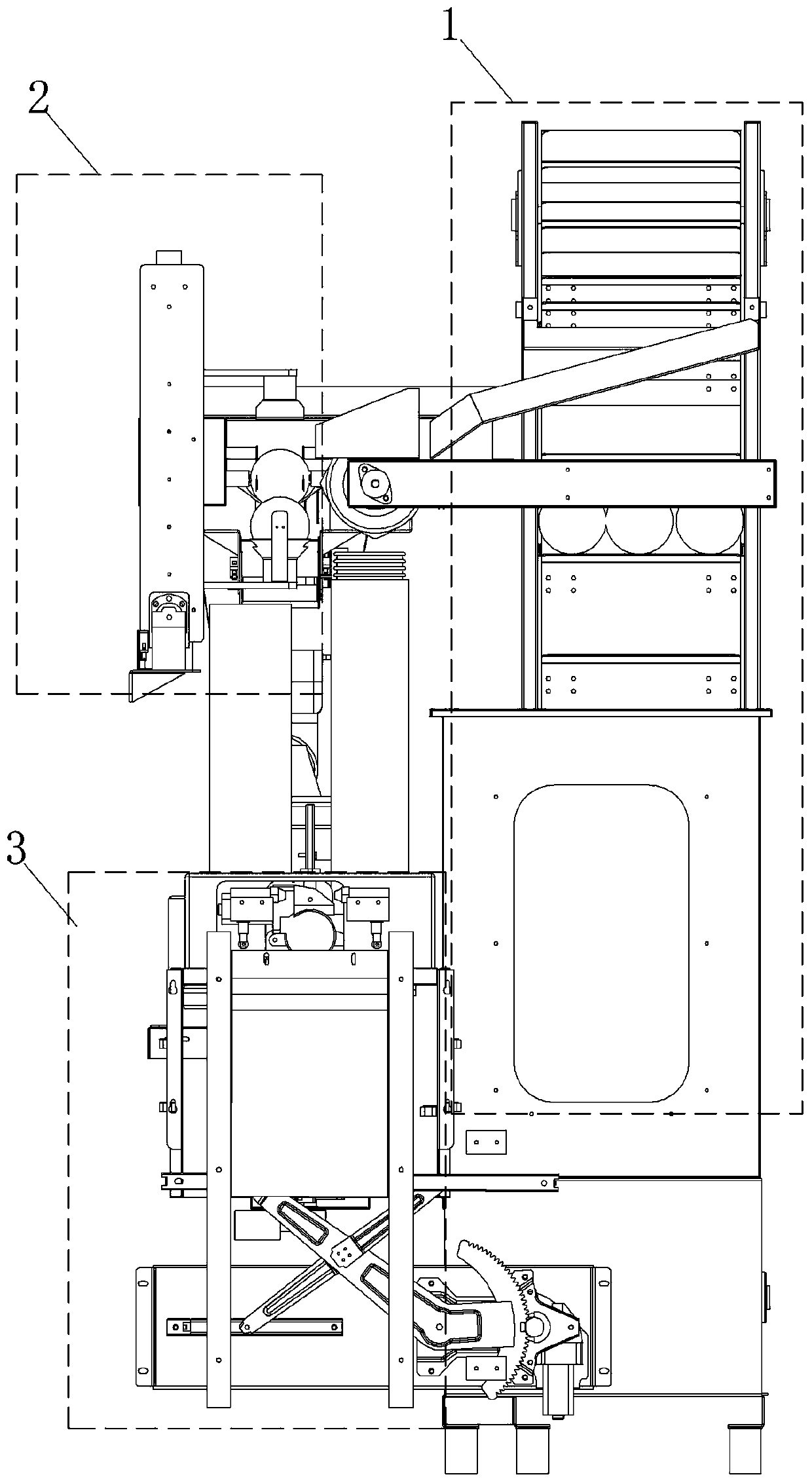

Self-service peeling juicer

PendingCN108038977AReasonable optimizationReduce difficultyJuice extractionCoin-freed apparatus detailsEngineeringSelf adaptive

A self-service peeling juicer comprises a fruit storage and lifting device and a self-adaptive fruit peeling device. The fruit storage and lifting device is provided with a lower storage box and capable of lowering fruit supplying difficulty. The self-adaptive fruit peeling device is capable of peeling to-be-juiced fruits to increase juice yield. A discharging device is provided with a temporary storage chamber and a waste juice collection cup, reasonable optimization treatment of residual juice in juicing can be realized, and accordingly saving is realized to the greatest extent.

Owner:HENAN HENGCHUN AGRI S&T

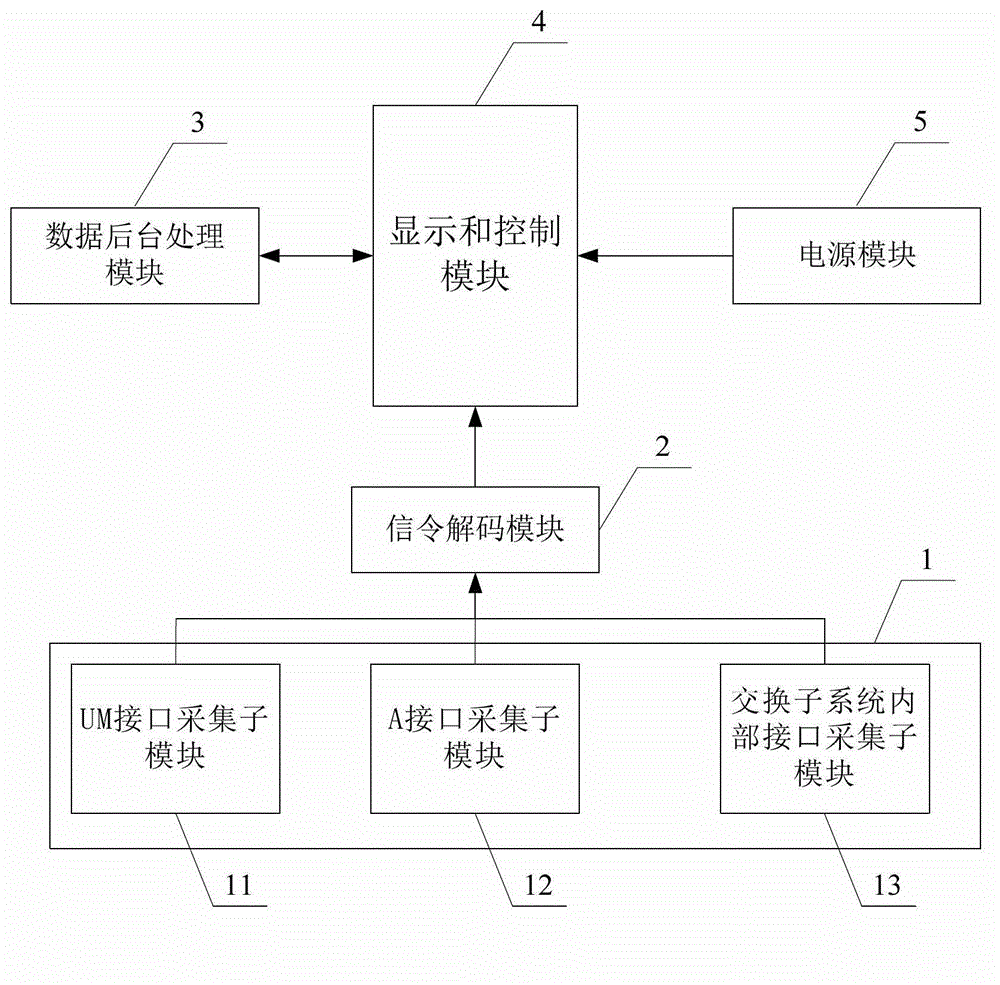

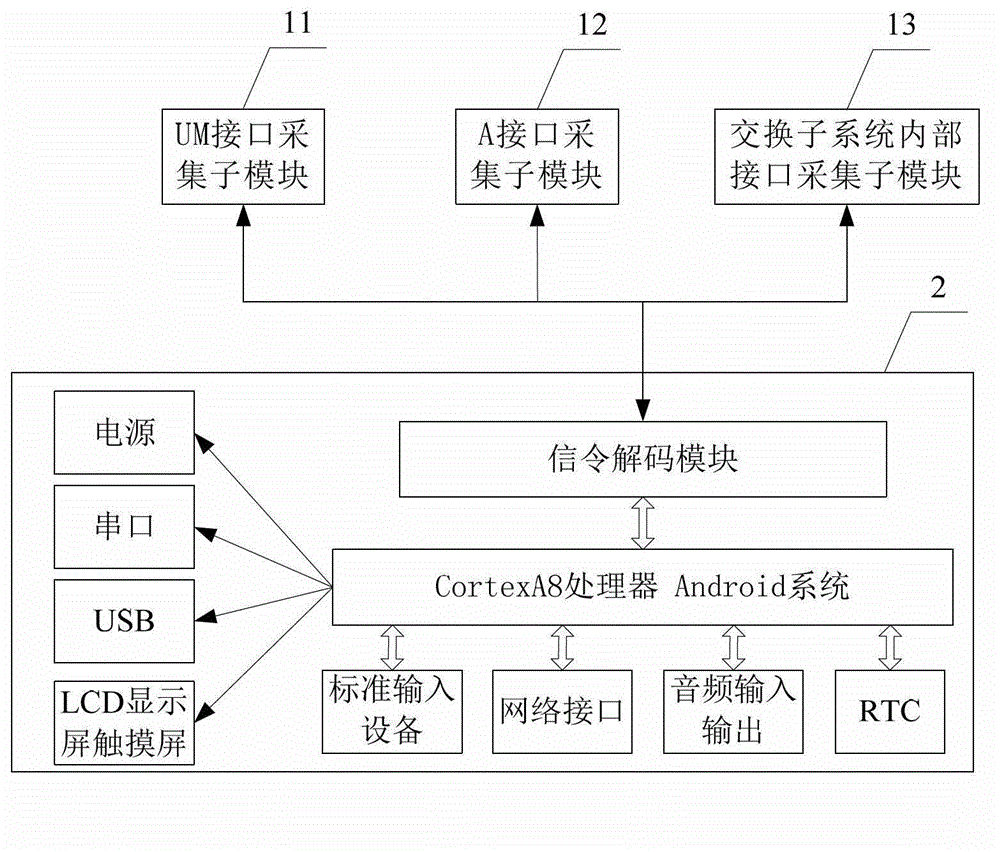

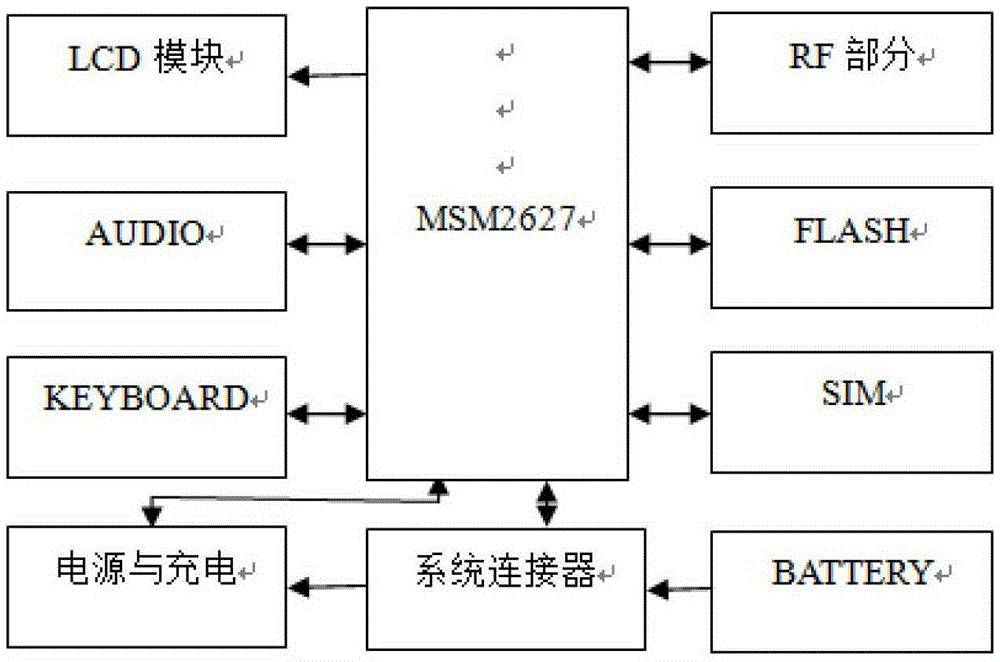

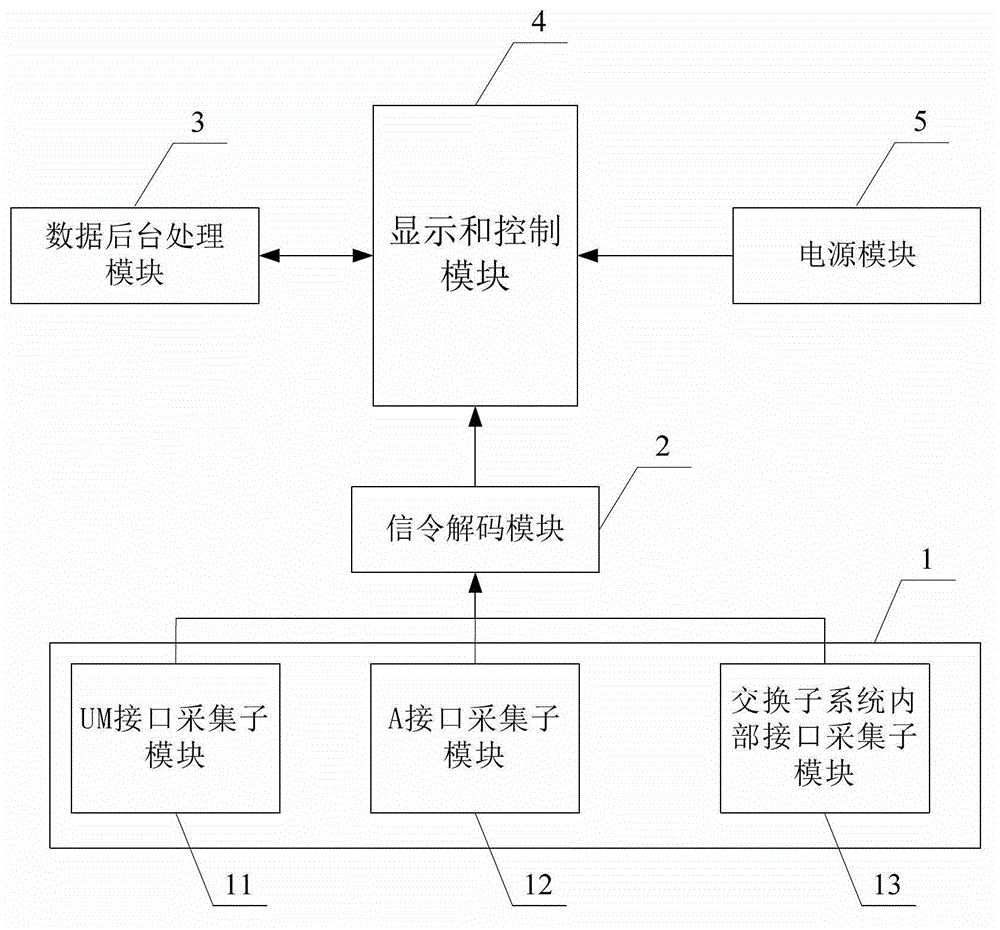

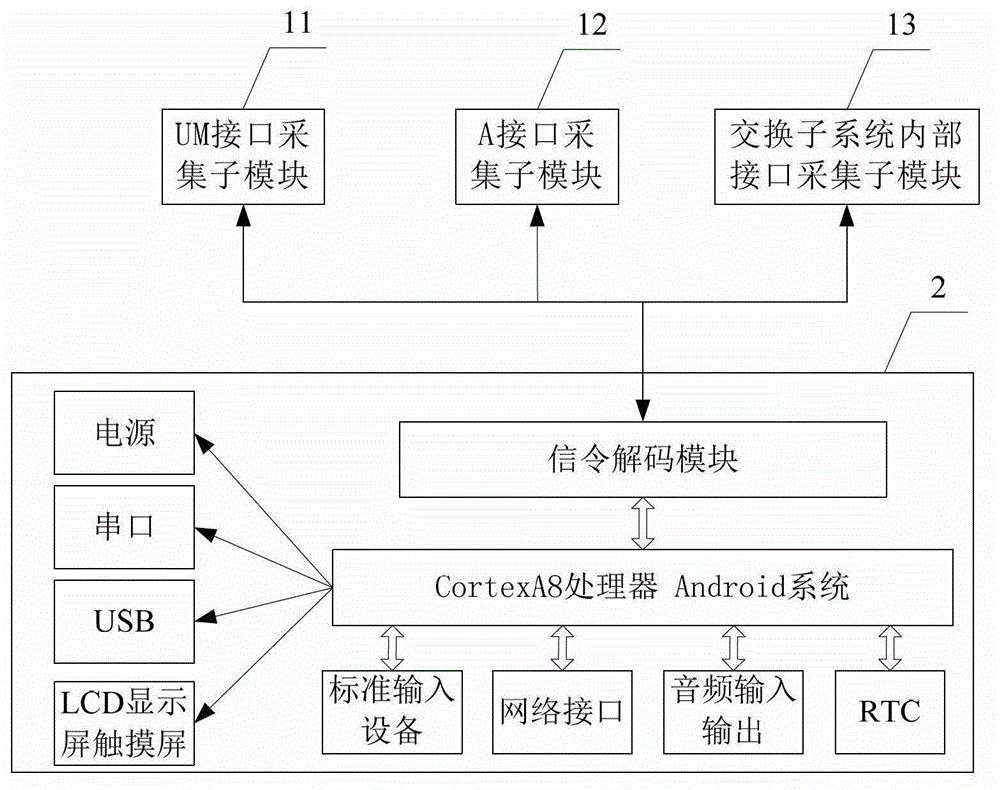

CDMA (Code Division Multiple Access) signaling analysis teach simulated training equipment

ActiveCN102867445AUnderstand comprehensivelyReasonable optimizationEducational modelsComputer moduleComputer science

The invention provides CDMA (Code Division Multiple Access) signaling analysis teach simulated training equipment, which comprises a signaling acquisition module, a signaling decoding module, a data background processing module and a display and control module; the display and control module is used for providing common application of signaling analysis in drive test, analyzing a preset communication case according to the received operation command, and displaying an analysis result. Beginners who do not contact CDMA network optimization can be gradually familiar with the network optimization process, can reasonably optimize the CDMA network and provide corresponding solution scheme to the CDMA establishment after more comprehensively knowing all parameters in the CDMA network optimization process and analyzing the acquired data.

Owner:鼎利元(上海)科技发展有限公司

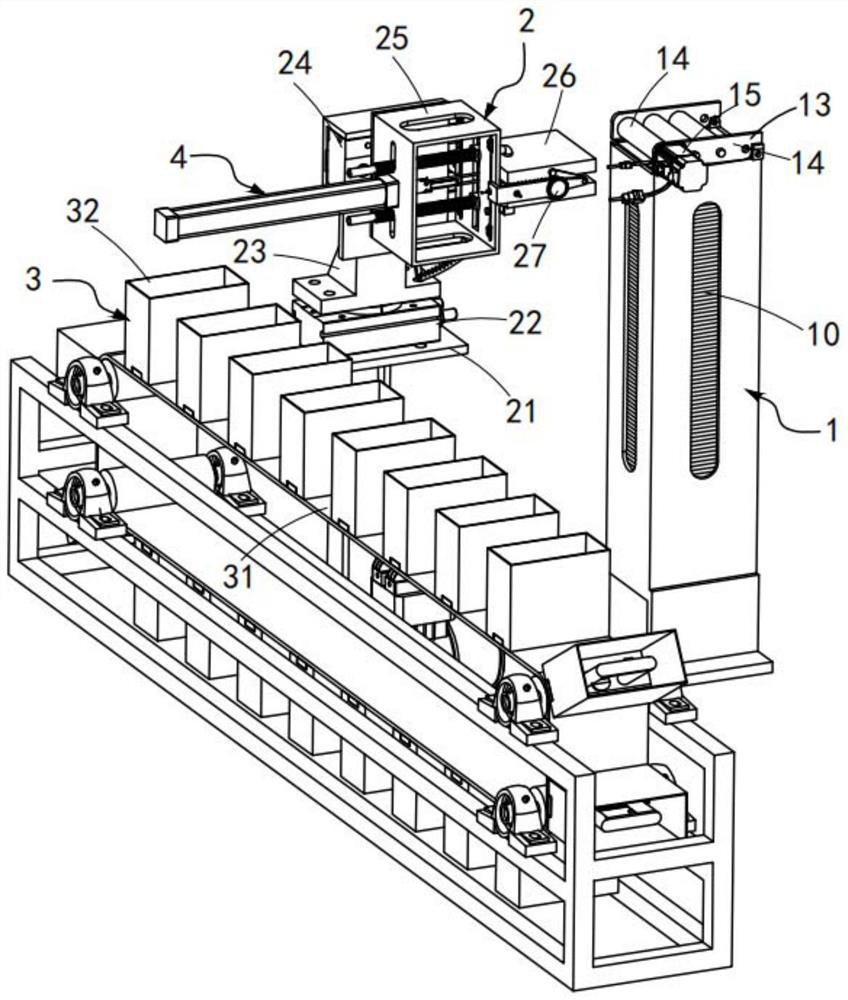

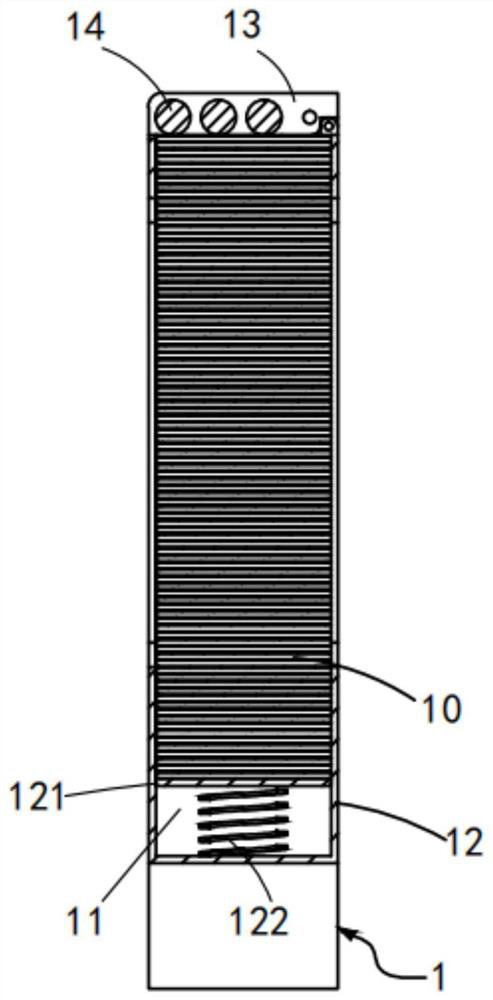

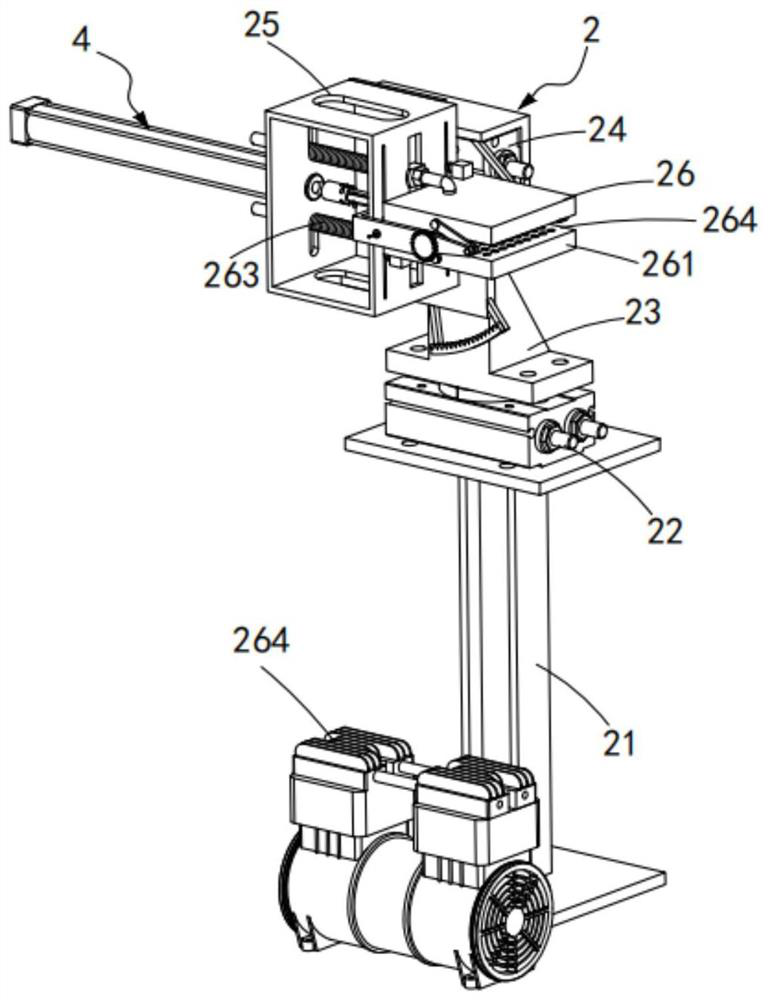

Continuous automatic bag opening device for supermarkets

ActiveCN111907806AEasy accessSolve the technical problems of manual bag openingPackagingMechanical engineeringIndustrial engineering

The invention relates to the technical field of packaging bag opening mechanical structures, and particularly discloses a continuous automatic bag opening device for supermarkets. The continuous automatic bag opening device comprises a bag feeding mechanism, a bag opening mechanism, a continuous conveying mechanism and a pushing mechanism, wherein the bag opening mechanism comprises a bottom mounting frame, a first rotary driving part, a top mounting frame, a second rotary driving part, a rotary mounting frame, an adsorption assembly and a bag opening assembly, the continuous conveying mechanism comprises a conveying belt and a packaging bag box, the two sides of packaging bags are adsorbed through adsorption plates, and then the packaging bags are opened through movement of the adsorptionplates, then the packaging bags are separated from the adsorption plates through the pushing mechanism, the opened packaging bags are output to the continuous conveying mechanism for rotary conveying, the multiple opened packaging bags are kept on the continuous conveying mechanism all the time, customers can take the packaging bags conveniently, the technical problem of manual bag opening of thecustomers in the supermarkets is solved, the bags can be automatically opened without waiting for a long time and can be used immediately after being taken, and convenience and quickness are achieved.

Owner:阜阳汇中芯自动化技术有限公司

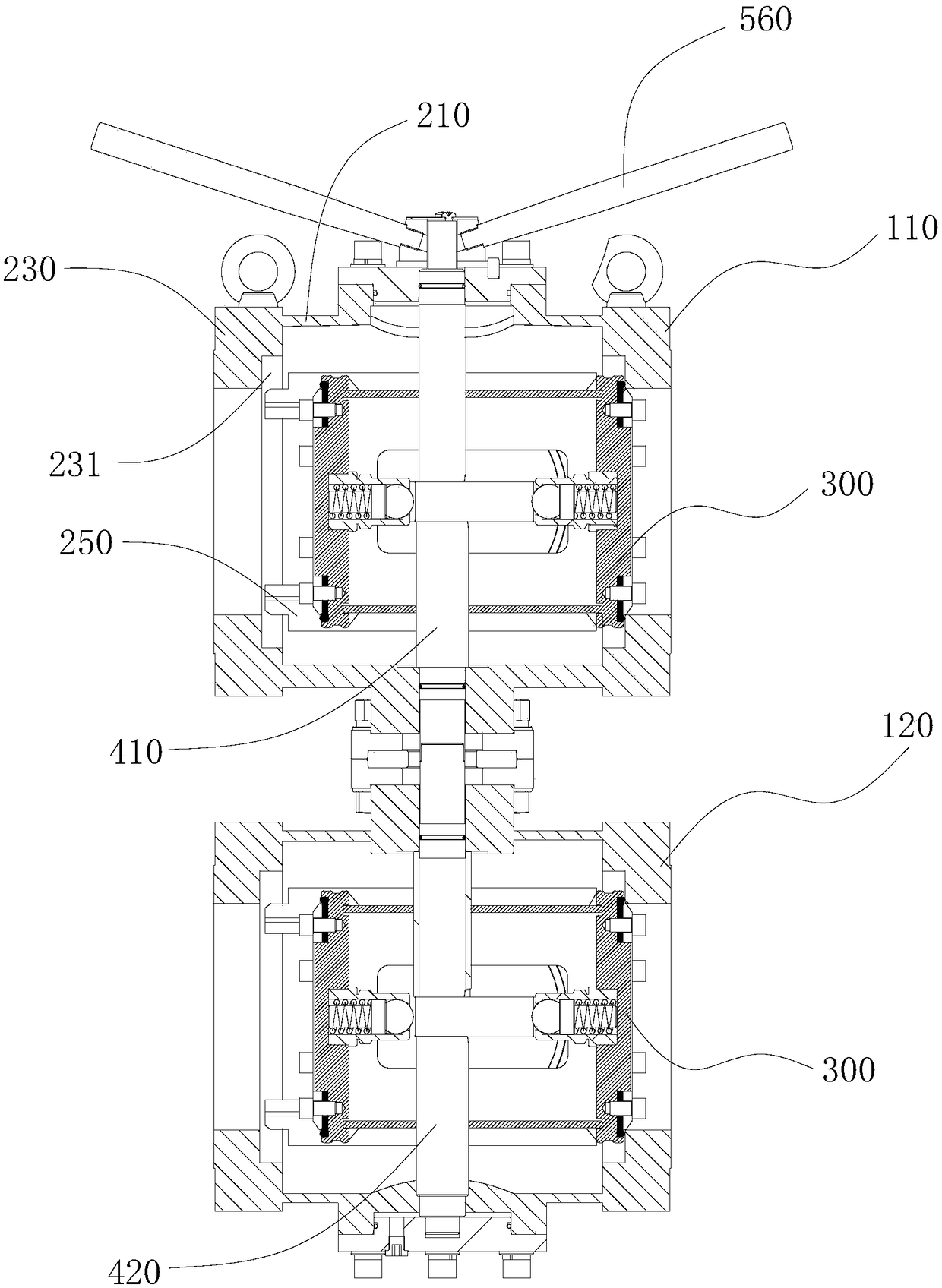

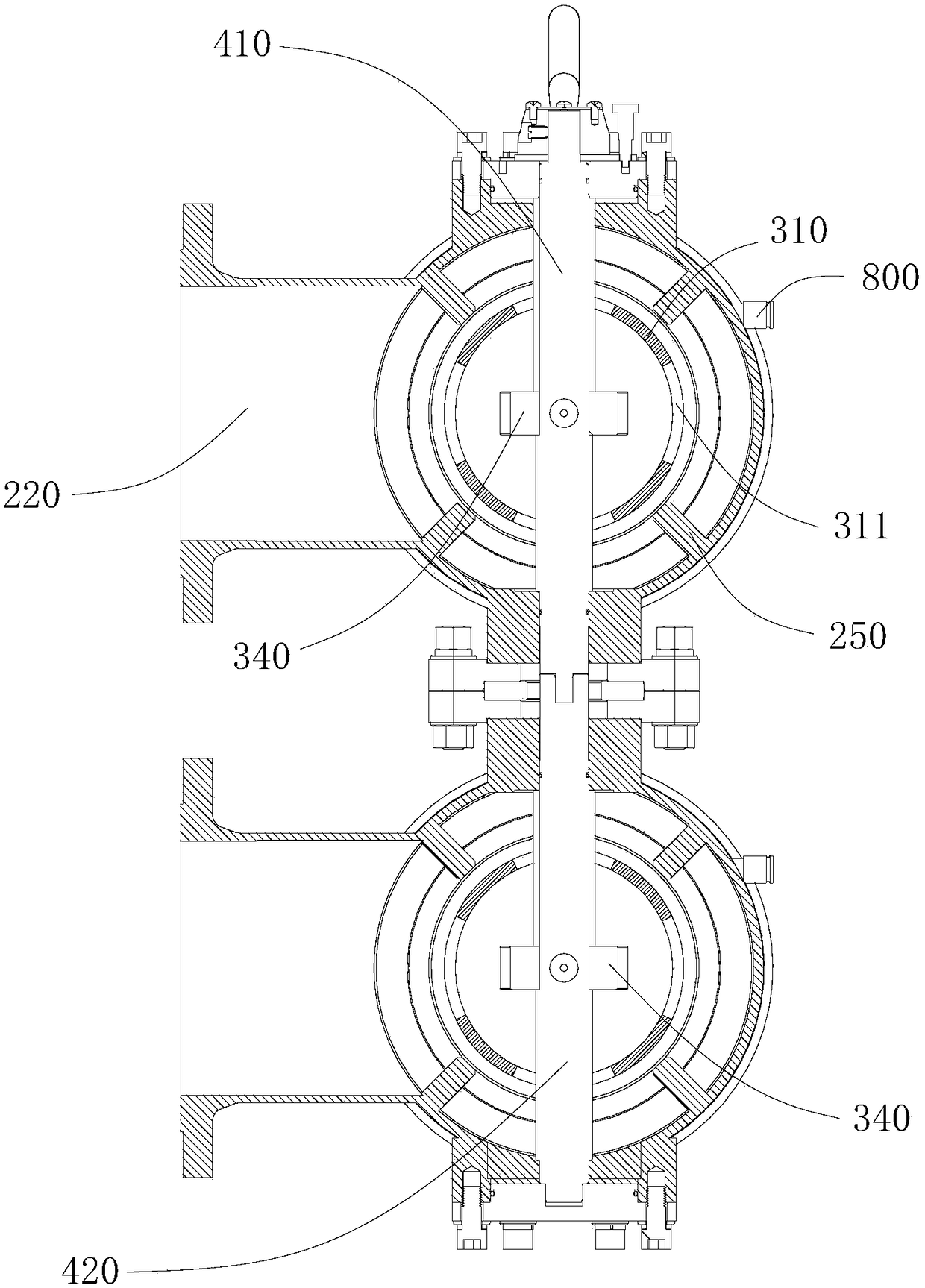

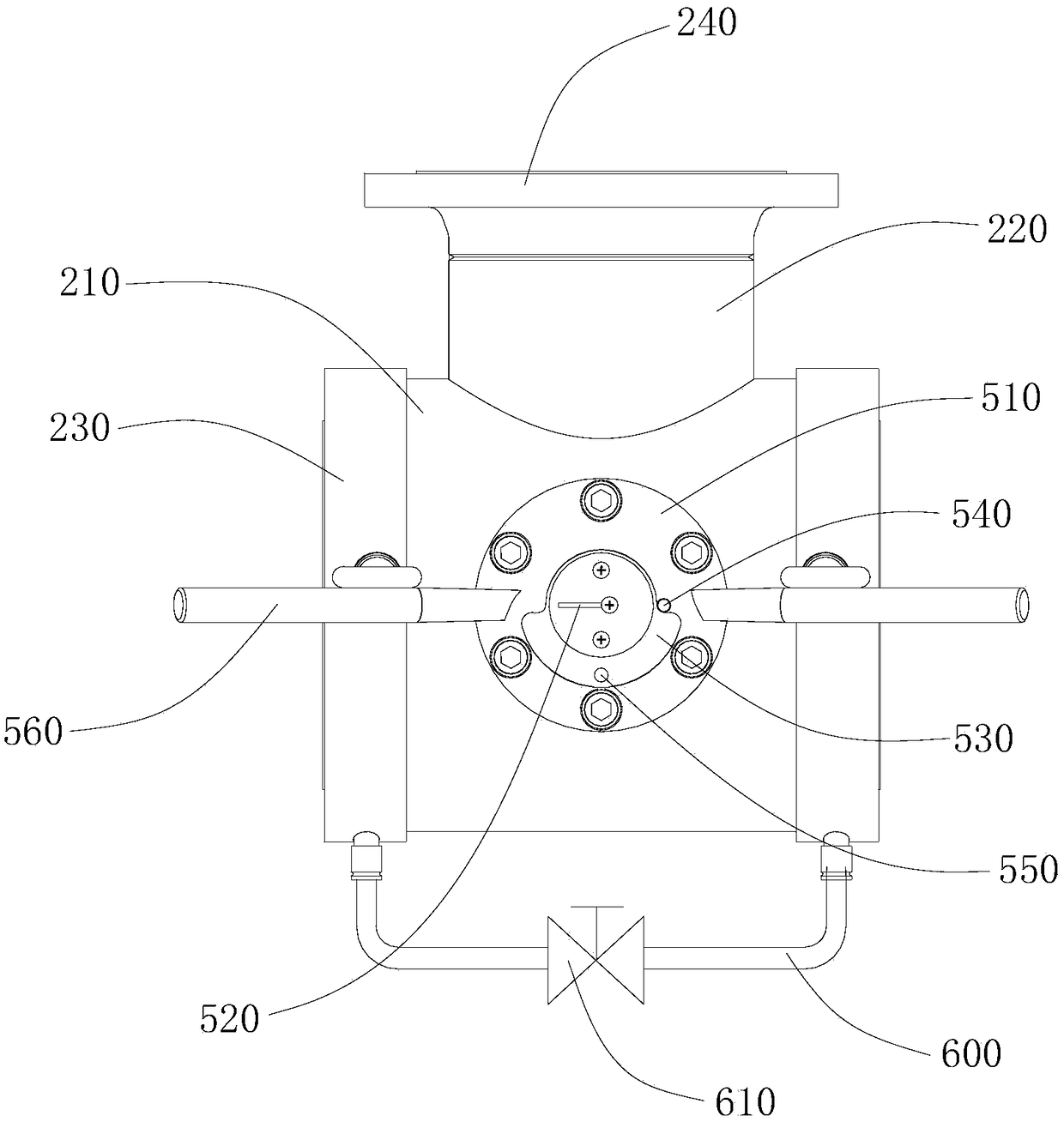

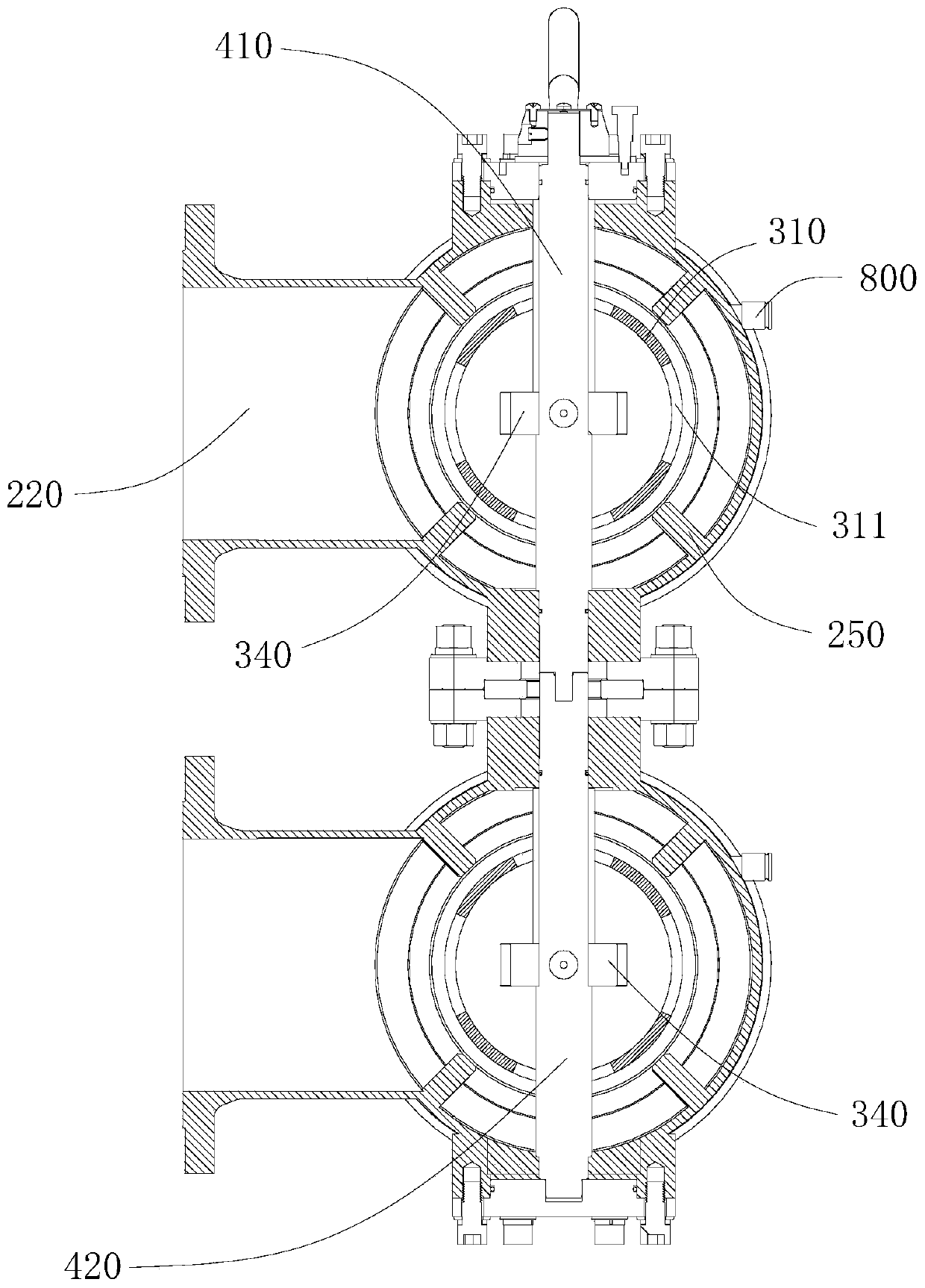

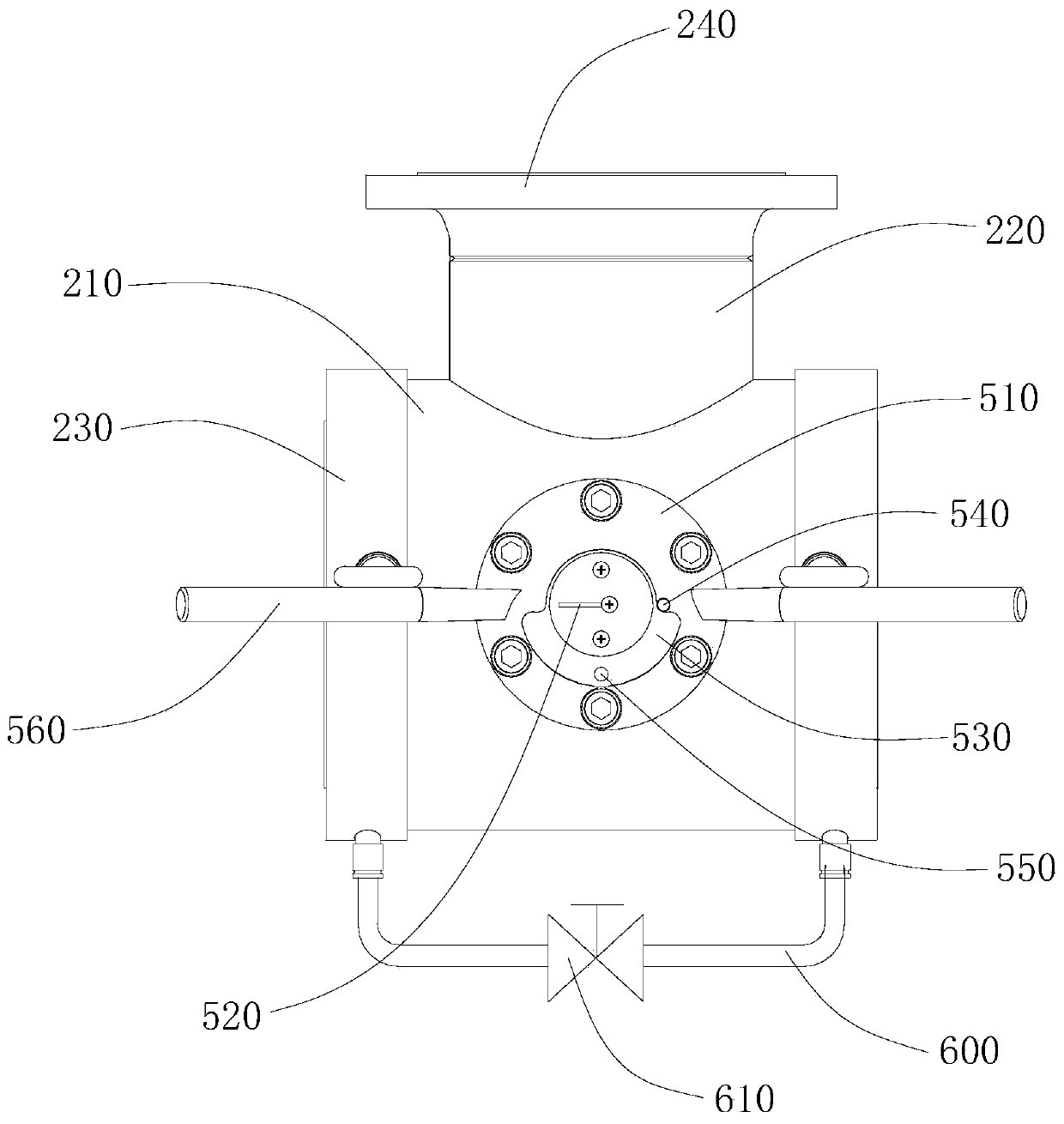

Differential pressure limiting type six-way switch valve for conveying fluid

ActiveCN109185497ANovel structureReasonable optimizationOperating means/releasing devices for valvesPressure relieving devices on sealing facesDifferential pressureEngineering

The invention provides a differential pressure limiting type six-way switch valve for conveying fluid. The differential pressure limiting type six-way switch valve comprises a first valve body and a second valve body which are mutually connected. The first valve body and the second valve body each comprise a pipe body and a header pipe, wherein the two ends of the pipe body are provided with transition flanges, the flow passage junction of the header pipe and the pipe body is provided with a linkage valve element, the two end faces of the linkage valve element are provided with sealing rings,multiple guide sliding rails are fixedly arranged on the inner wall of the pipe body, the side walls, close to the axial line of the pipe body, of the guide sliding rails are in sliding abutting connection with the side wall of a valve plate, a cam is arranged in the linkage valve element, the two ends inside the linkage element are fixedly provided with elastic supporting parts, the two elastic supporting parts located in the same linkage valve element make abutting contact with the cam so as to build rolling connection, a first rotating shaft penetrating through the linkage valve element isarranged in the first valve body, a second rotating shaft penetrates through the linkage valve element is arranged in the second valve body, and the second rotating shaft is connected with the first rotating shaft. The differential pressure limiting type six-way switch valve is novel, optimal and reasonable in structure, and has the advantages that moving is smooth, sealing is reliable, and maintenance is convenient.

Owner:九江七所精密机电科技有限公司

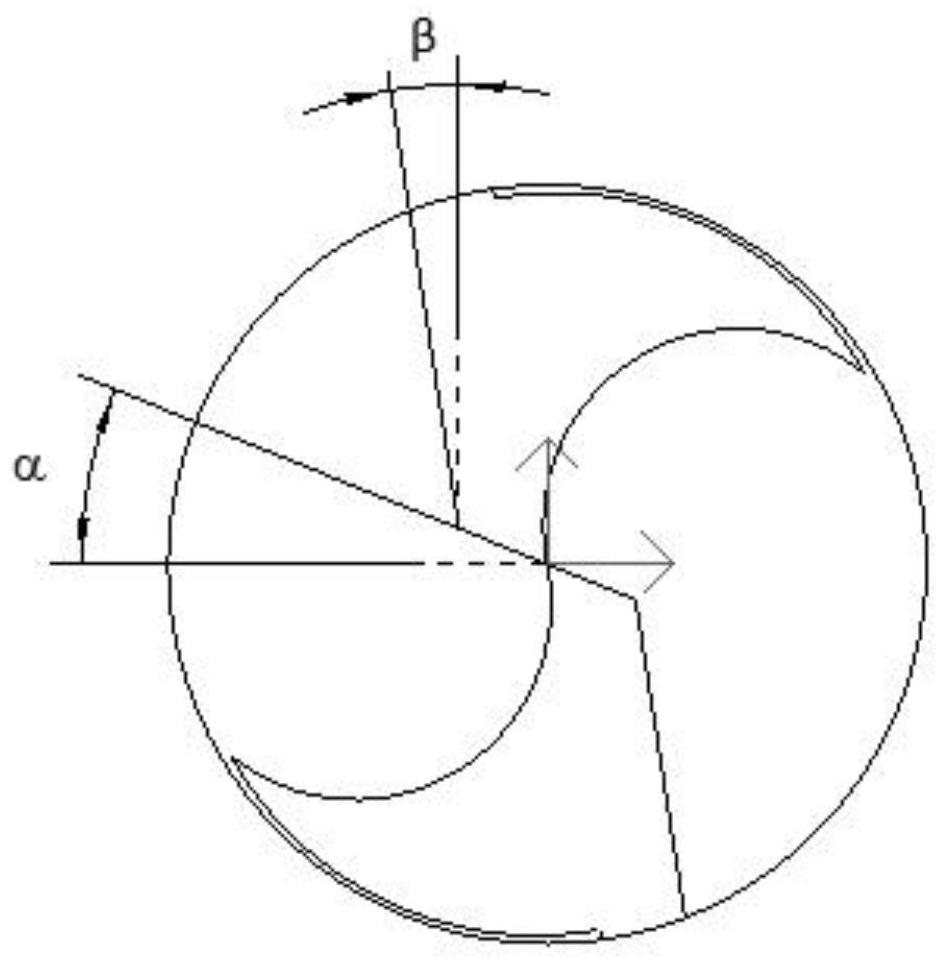

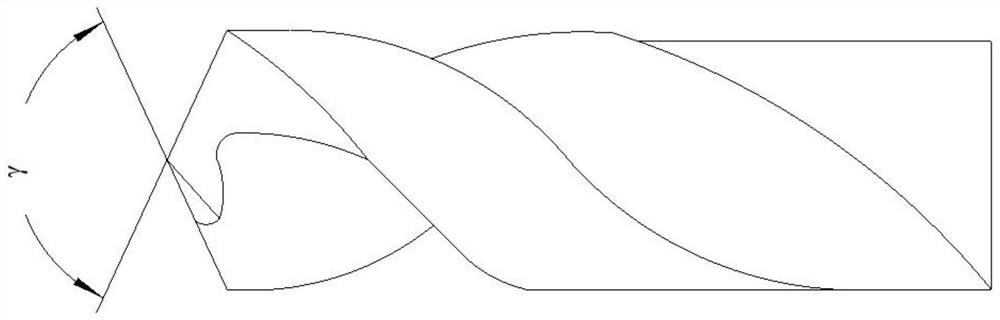

Carbide drill machining and manufacturing method

PendingCN112643414ASolve bottlenecksImprove cutting performanceDrilling toolsAviationCeramic composite

The invention discloses a carbide drill machining and manufacturing method, and belongs to the field of aviation and aerospace difficult-to-machine materials. The original drill tip form is changed, a composite form drill tip is innovatively researched and developed, and the cutting angle of a cutter is optimized through statistical analysis of cutting test data, so that a special novel drill cutter is formed to be mainly used for drilling machining of products made of high-temperature alloy, low-expansion alloy steel and ceramic composite base materials; and a design and manufacturing method for innovating the shape of the drill tip in a targeted mode and optimizing the angle of the cutter is used for meeting the requirement for drilling machining of products made of difficult-to-machine materials in scientific research and production. The cutting angles of the drill are reasonably compared through experiments, and the optimal machining angle is selected, so that wear resistance is achieved; on the other hand, a stepped cutting edge is added, so that the situation that the drill is damaged and scrapped due to the fact that the temperature of the drill is too high since the drill always uses a first cutting edge for machining is prevented; and optimization is reasonable, practicability and reliability are achieved, difficult-to-machine materials can be effectively drilled, and the blank in the field of the method in China is filled.

Owner:航天科工哈尔滨风华有限公司

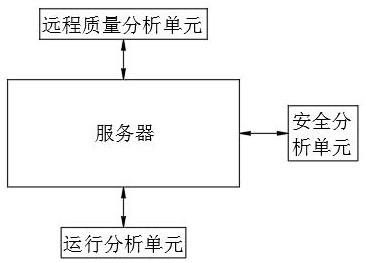

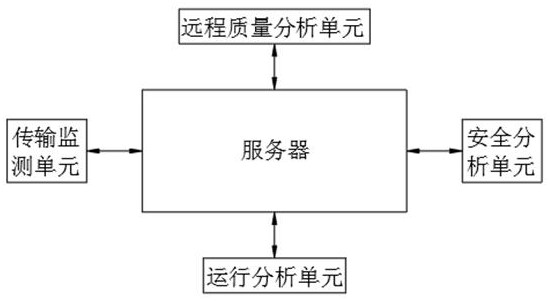

On-campus and off-campus management system based on remote education

ActiveCN114444984AImprove management efficiencyImprove managementResourcesSecuring communicationTele educationManagement system

The invention discloses an in-school and out-school management system based on remote education, belongs to the field of in-school and out-school platforms, relates to a remote education management technology, and is used for solving the problems that the in-school and out-school platforms are low in management efficiency and cannot comprehensively perform platform management. The server is in communication connection with a remote quality analysis unit, an operation analysis unit and a safety analysis unit; real-time quality analysis is carried out on remote education of the campus platform, the real-time quality of current remote education is judged, so that the working efficiency of the remote quality is analyzed, the management efficiency of the campus platform is improved, the operation state of the campus platform is analyzed, and whether the education operation of the current campus platform is qualified or not is judged; therefore, the management strength of the on-off campus platform is effectively improved, the operation of the on-off campus platform can be reasonably monitored and optimized, and the working efficiency of the on-off campus platform is indirectly improved; and analyzing the safety of the corresponding on-off campus platform so as to analyze whether the on-off campus platform has a safety risk or not.

Owner:深圳市度易科技有限公司

Process for preparing basic chromium sulfate by using waste chromium material

ActiveCN102432067BReasonable optimizationAvoid pollutionSolid waste disposalChromium compoundsLiquid wasteFiltration

The invention relates to a process for treatment of heavy metal and recovery of an inorganic salt and especially to a process for preparing basic chromium sulfate by using a waste chromium material. In the process, a waste chromium liquid storage tank, an acidifying device, a reduction device, a reaction vessel, a condensation kettle, a press filtration device, a spray drying device and a gas purifying device are utilized; the process comprises the following steps: collecting electroplating and other chromium-containing waste liquid and waste residue, adding the collected waste liquid and waste residue into an acidifying reaction vessel, optimizing a formula for reagents, removing other impurity components except chromium components through addition and reaction of the reagents and press filtration, carrying out further dehydration by adjusting the condensation kettle for further reaction and preparing the product of basic chromium sulfate by using a centrifugal spray drier. The process provided in the invention is optimized, reasonable, simple and easy, makes the most of natural resources and natural conditions, has the advantages of low production cost, small investment and high yield and enables the problem of waste chromium pollution to be effectively overcome and the waste chromium material to be processed into inorganic chemical products, thereby producing remarkable environmental and economic benefits.

Owner:无锡金品环境技术有限公司

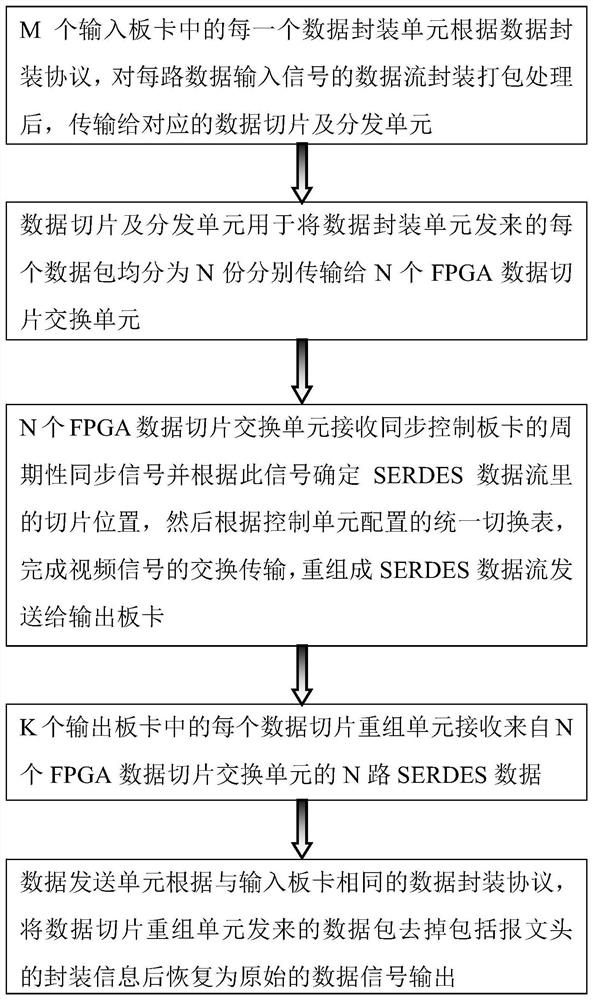

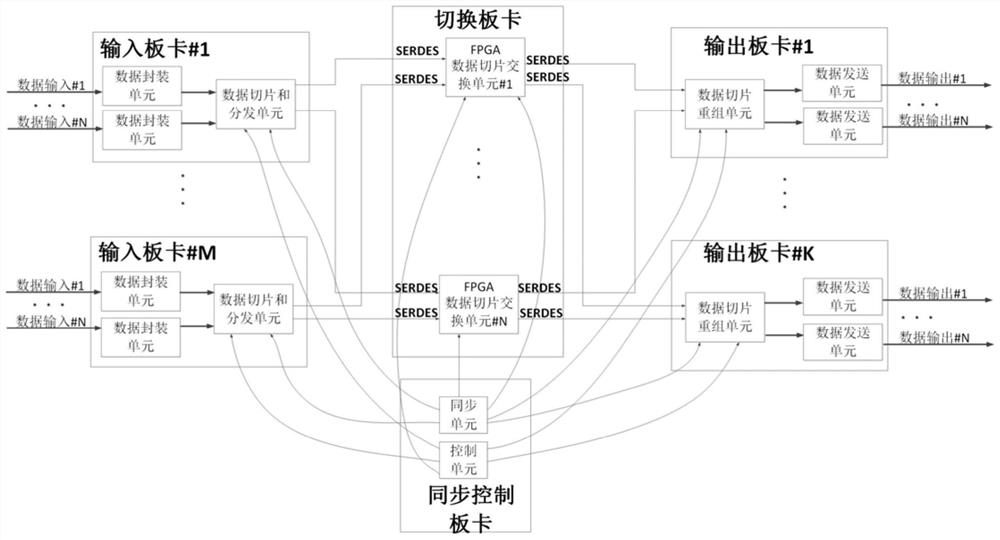

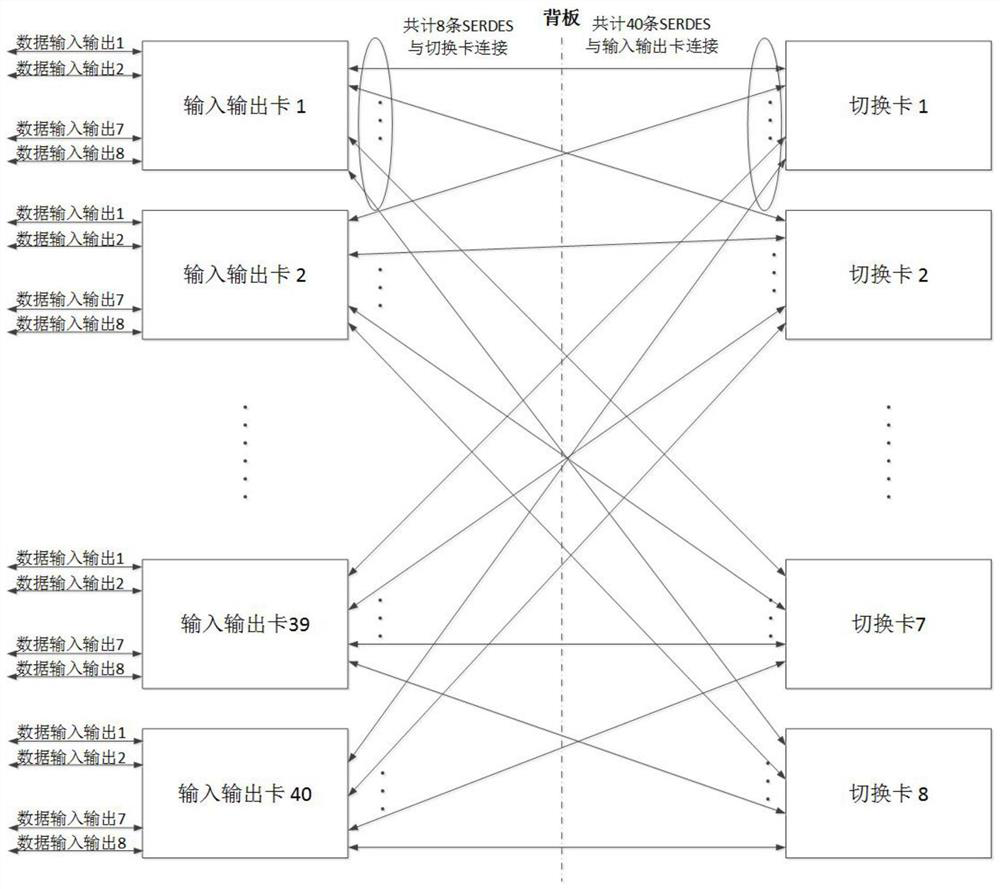

A multi-channel high-bandwidth data exchange method based on fpga stacking

ActiveCN110351509BImprove transmission efficiencyImplementing Parallel Slice TransfersTelevision system detailsColor television detailsData packData stream

Owner:BEIJING DIGIBIRD TECH CO LTD

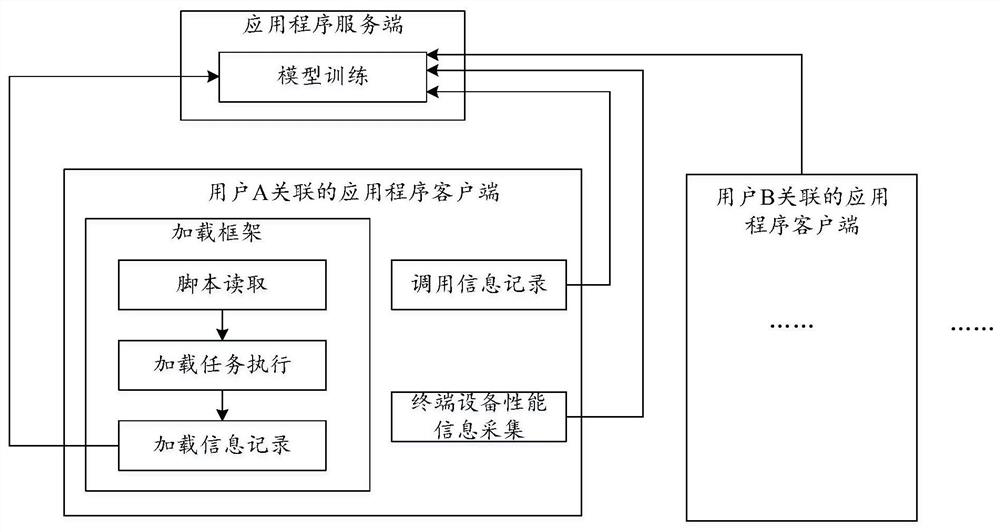

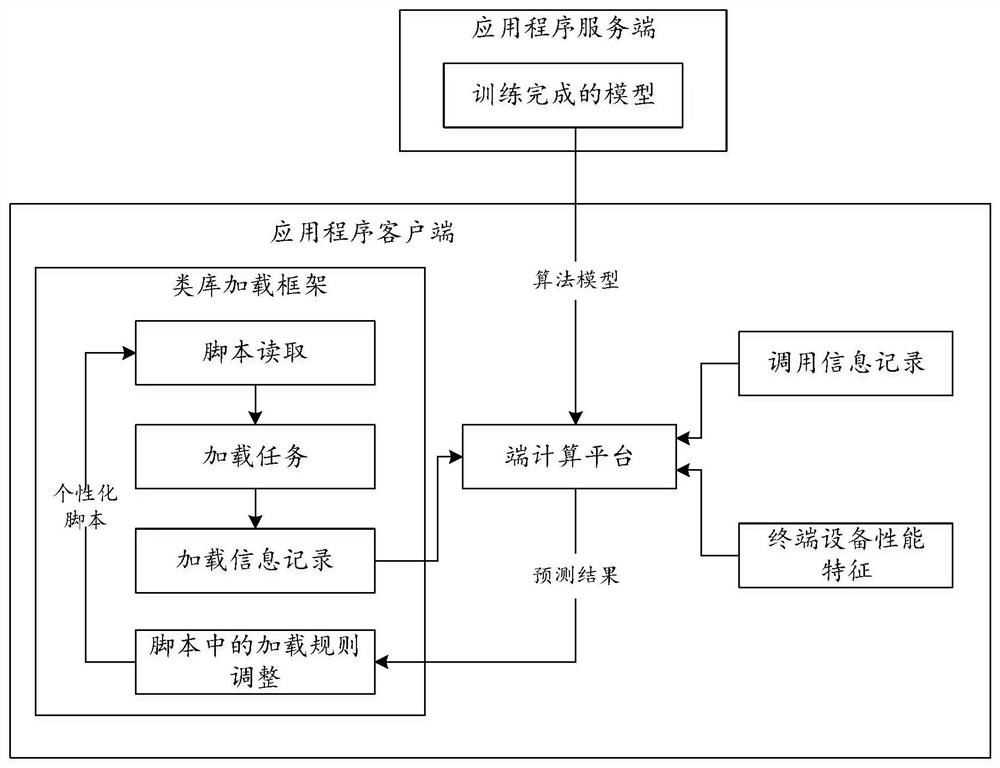

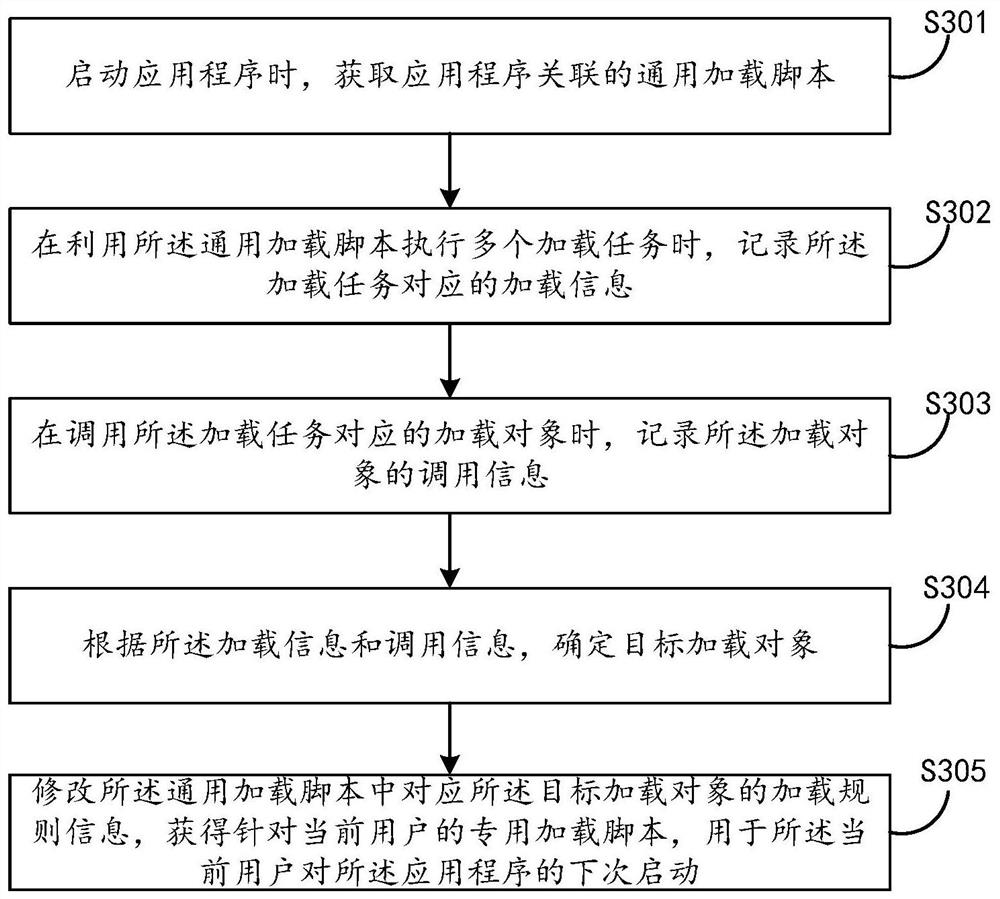

Information processing method and device and electronic equipment

PendingCN112905255AReasonable optimizationProgram loading/initiatingInformation processingApplication procedure

The embodiment of the invention discloses an information processing method and device and electronic equipment, and the method comprises: obtaining a universal loading script associated with an application program when the application program is started; when a plurality of loading tasks are loaded and executed by utilizing the universal loading script, recording loading information corresponding to the loading tasks; when a loading object corresponding to the loading task is called, recording calling information of the task loading object; determining a target task loading object according to the loading information and the calling information; modifying loading rule information, corresponding to the target task loading object, in the universal loading script, and obtaining a special loading script for the current user, wherein the special loading script is used for next starting of the application program by the current user. Through the embodiment of the invention, the loading logic of the loading object can be more conveniently and reasonably optimized.

Owner:ALIBABA GRP HLDG LTD

Optimization method of compressed sensing lasar sparse wiring array based on low coherence

InactiveCN105487052BAchieving Distribution Optimal DesignReasonable optimizationRadio wave reradiation/reflectionIterative searchComputer science

The invention discloses a low-coherence based compression sensing LASAR sparse line array optimization method, which uses the coherence characteristics of the measurement matrix in the compressed sensing theory as a reference basis for the compression sensing LASAR sparse line array optimization, and is based on the compression sensing method in the LASAR system. The minimization of the coherence of the perceptual measurement matrix, with the help of the Fourier transform iterative search method, realizes the optimal design of the array element distribution of the compressed sensing LASAR sparse wiring array antenna, which is more reasonable for the sparse linear array optimization and is conducive to improving the compressed sensing LASAR System imaging performance. The method proposed by the invention is also applicable to other technical fields of sparse wiring array antenna optimization based on compressed sensing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

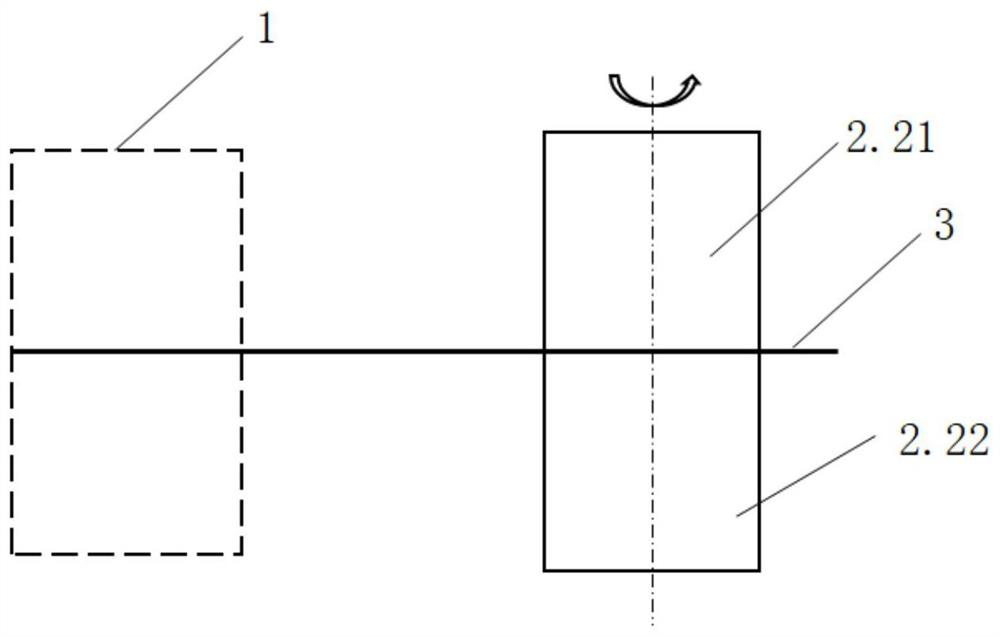

Laser radar

InactiveCN113985385AReasonable optimizationReduce loadWave based measurement systemsEngineeringDiffuse reflection

The invention relates to a laser radar, which comprises a laser emitting mechanism, a laser receiving mechanism and a light scanning mechanism. The laser emitting mechanism and the laser receiving mechanism are longitudinally isolated. The light scanning mechanism comprises a reflecting mirror mechanism and a motor, the reflecting mirror mechanism is installed on the motor, the motor drives the reflecting mirror mechanism to rotate, and the reflecting mirror mechanism is longitudinally divided into a transmitting end reflecting mirror and a receiving mirror. The laser emitting mechanism emits linear laser with a preset angle. The linear laser is reflected to a detected object through the transmitting end reflecting mirror, the detected object performs diffuse reflection on the light, and the light subjected to diffuse reflection is reflected back to the laser receiving mechanism by the receiving mirror to complete measurement. The system is stable and miniaturized through the arrangement and assembly mode of the system, and the requirement for a large view field can be met.

Owner:TANWAY TECH (BEIJING) CO LTD

A cdma signal test and training platform device

The invention provides a CDMA (code division multiple access) signal testing and practical-training device comprising a signal acquirer, a monitoring module and a testing module. The signal acquirer is used for acquiring CDMA wireless signal parameters of a base station and outputting the monitoring module, the monitoring module is used for transmitting the received CDMA wireless signal parameters to the testing module, executing corresponding signaling operations according to received signaling and transmitting results of the signaling operations to the testing module, and the testing module is used for displaying received CDMA wireless signal parameters, selecting corresponding signaling to transmit to the monitoring module according to input commands and displaying results of the signaling operations. By the aid of the CDMA signal testing and practical-training device, beginners who do not contact with running and optimization of the CDMA network can be gradually acquainted with the network optimization process, after various parameters during running and optimization of the CDMA network can be completely known and acquired CDMA wireless signal parameters are analyzed, the CDMA network can be reasonably optimized, and corresponding resolution schemes are provided for the CDMA construction.

Owner:NANTONG ZHIXIANG INFORMATION TECH

Water cooling method for medium-heat lining concrete based on the age of maximum internal and external temperature difference

ActiveCN111411628BScientificIncrease temperatureBarrages/weirsWater-power plantsTemperature controlEngineering

The invention provides a water cooling method for medium-heat lining concrete based on the age of the maximum internal and external temperature difference, which is characterized in that it includes: step 1. collecting data for temperature control of cement concrete in the lining structure; The age of maximum internal and external temperature difference of cement concrete d Δtm =‑0.66×H+0.0004×C‑0.0088×T 0 ‑0.0068×T g +5.02, H is the thickness of hot cement concrete in the lining structure; C is the strength grade of hot cement concrete in the lining structure; T 0 is the pouring temperature of hot cement concrete in the lining structure; T g is the equivalent water temperature value of water cooling, T g =35‑T w ,T w Cooling water temperature for passing water, step 3. Based on d Δtm Determine the water cooling time d j ; Step 4. According to the water cooling time d j Further optimize the water cooling measures of the hot concrete in the lining, and realize the temperature cracks scientifically and reasonably.

Owner:GUANGDONG YUANTIAN ENG +1

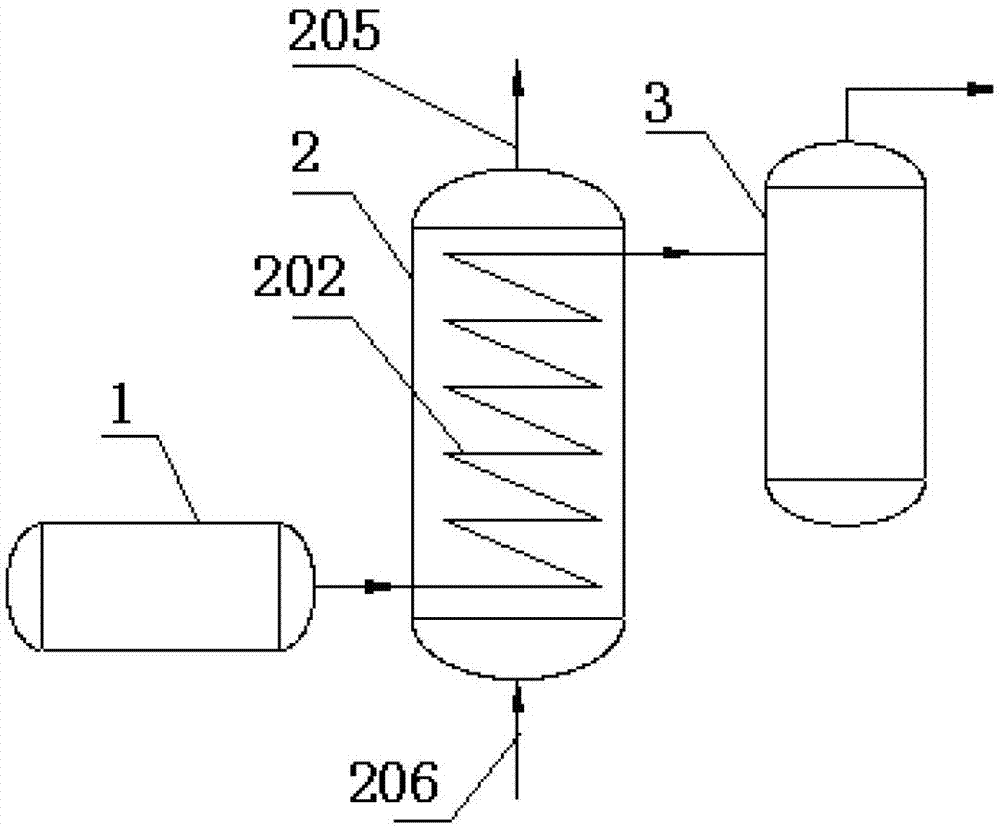

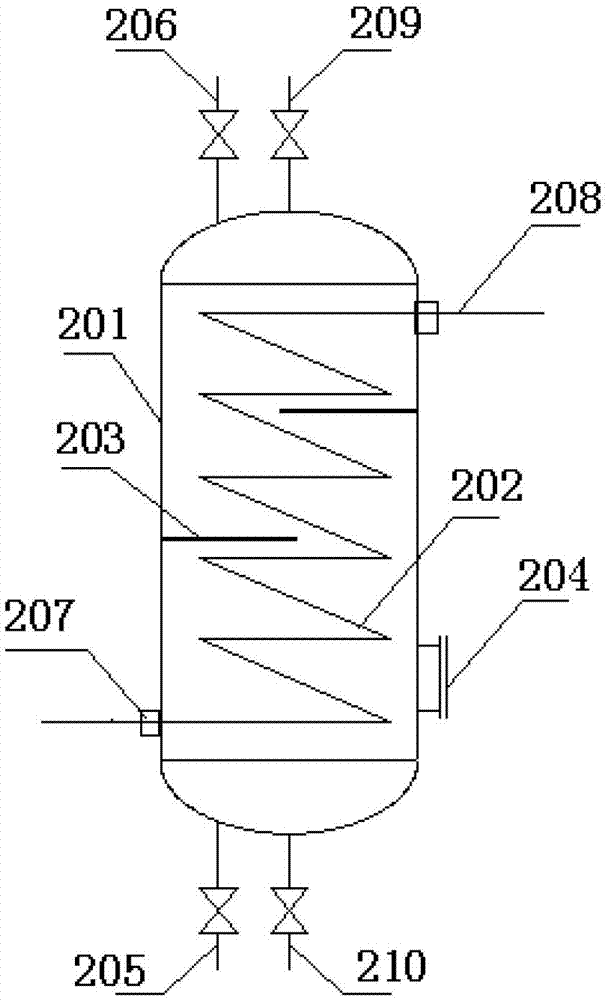

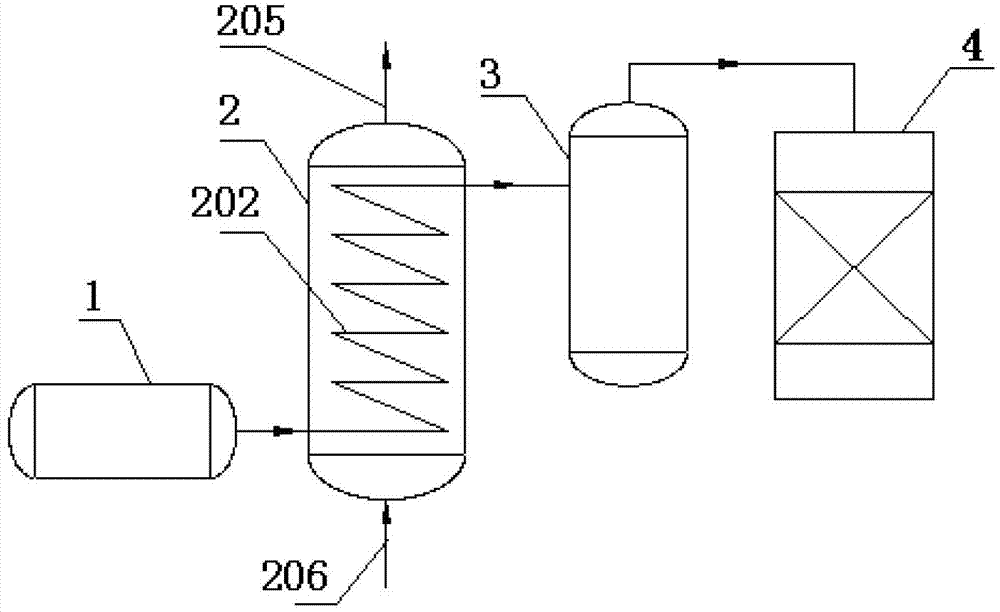

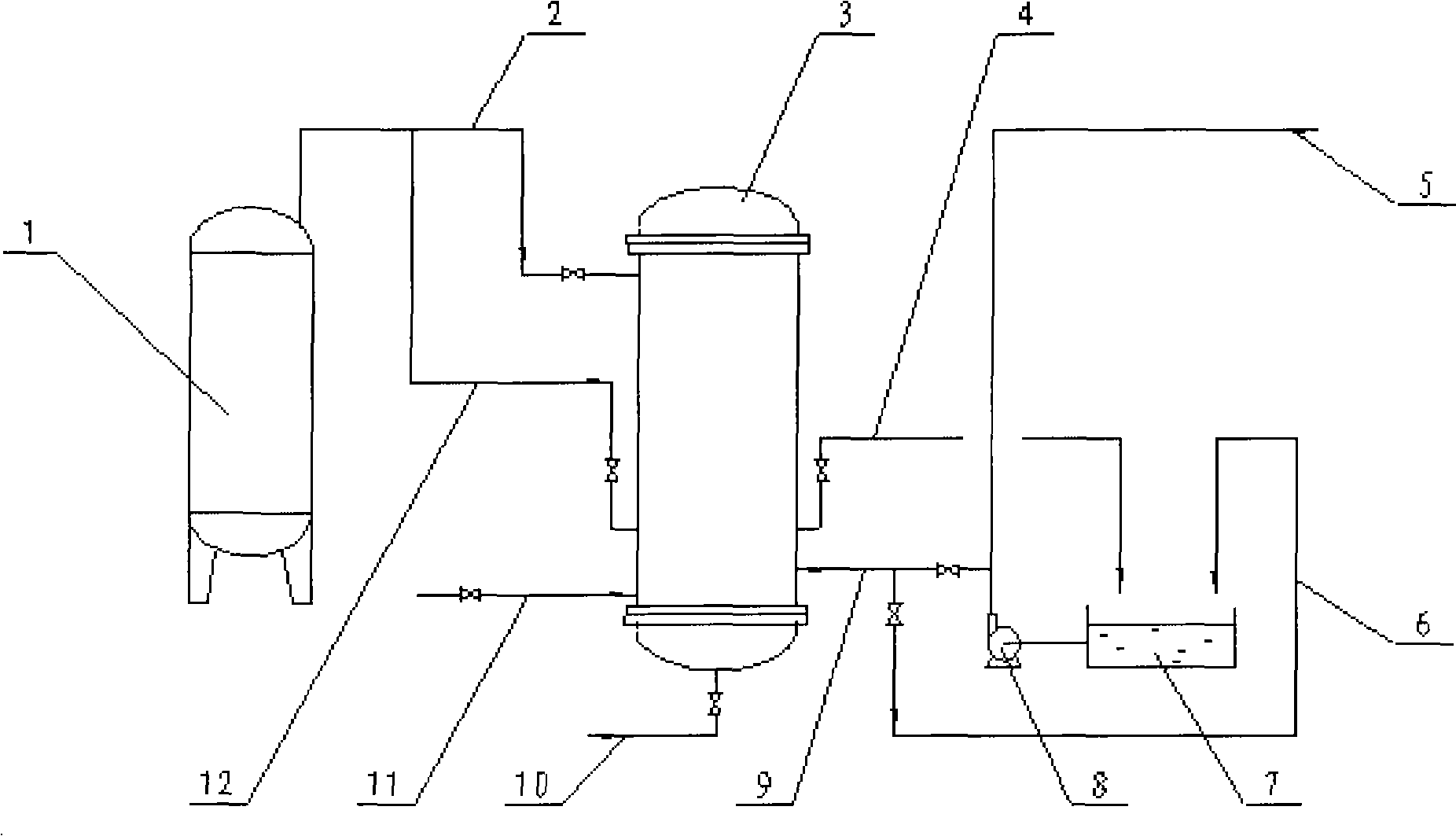

Liquid ammonia gasifying system and gasifying process thereof

ActiveCN102720947BSimple structure setupAvoid wastingPressure vesselsStationary tubular conduit assembliesSystems designAmmonia storage

The invention relates to a liquid ammonia gasifying system and a gasifying process thereof, in particular to the liquid ammonia gasifying system applied to a selective catalytic reduction (SCR) denitration or ammonia desulphurization process and the gasifying process thereof. The liquid ammonia gasifying system comprises a liquid ammonia conveying device, a heat exchange device and a gas ammonia storage device which are connected with each other. The heat exchange device is a circulating water heat exchange device and comprises a casing, a heat exchange pipe arranged in the casing, a circulating water input port, a circulating water output port, a liquid ammonia input port and a gas ammonia output port, wherein the circulating water input port and the circulating water output port are arranged on the casing. In the process, circulating water is applied to gasify liquid ammonia. Compared with the prior art, the liquid ammonia gasifying system is optimized in design, simple in process flow, energy-saving and environment-friendly, the refrigeration performance of the liquid ammonia is fully utilized simultaneously when the required gas ammonia is obtained at low energy consumption and low investment, comprehensive utilization of energy is achieved, energy-saving effect is remarkable, utilized land is saved, economic cost is greatly reduced, and the liquid ammonia gasifying system is suitable for popularization and application in the fields of SCR denitration and the like where the gas ammonia needs applying.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

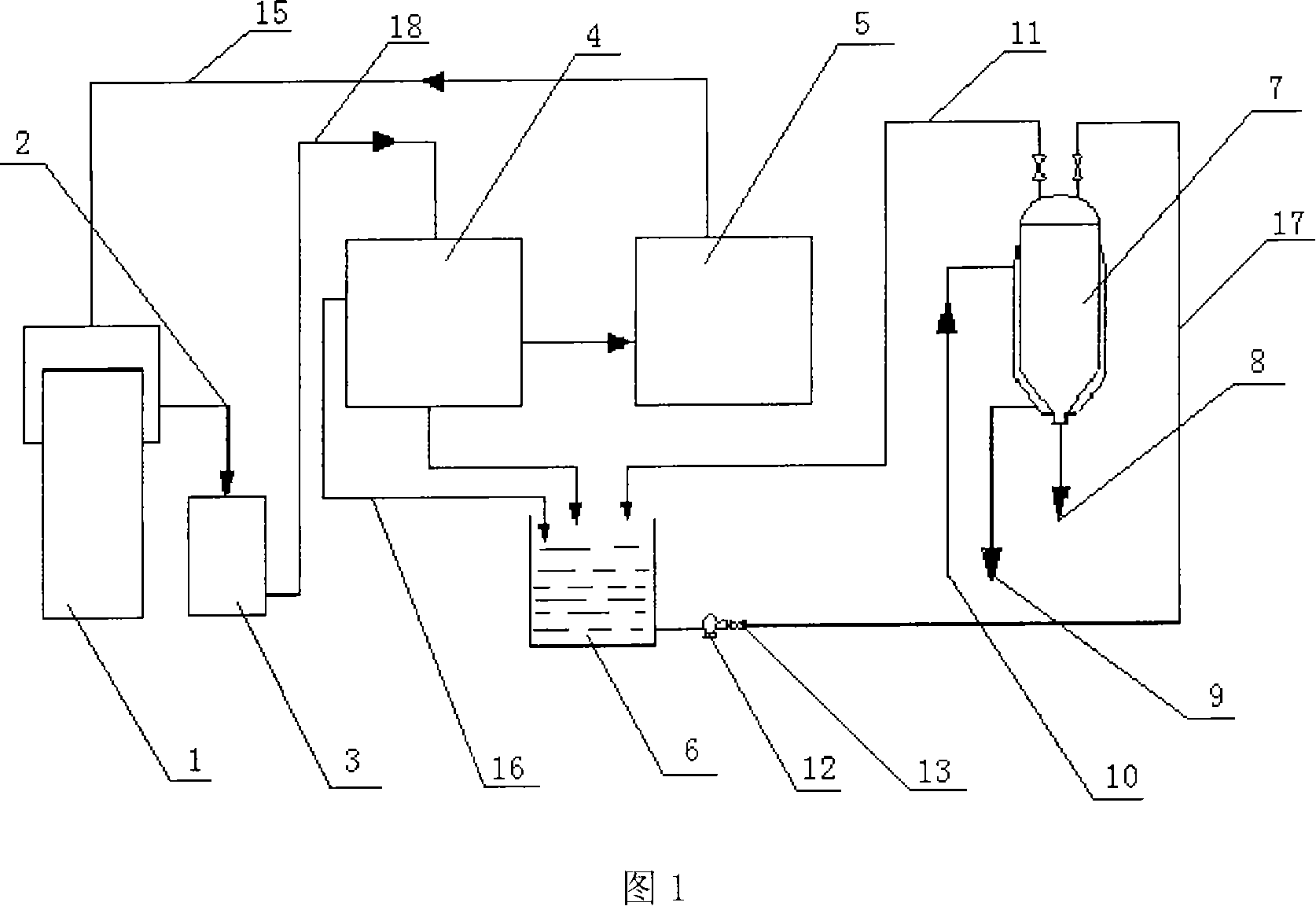

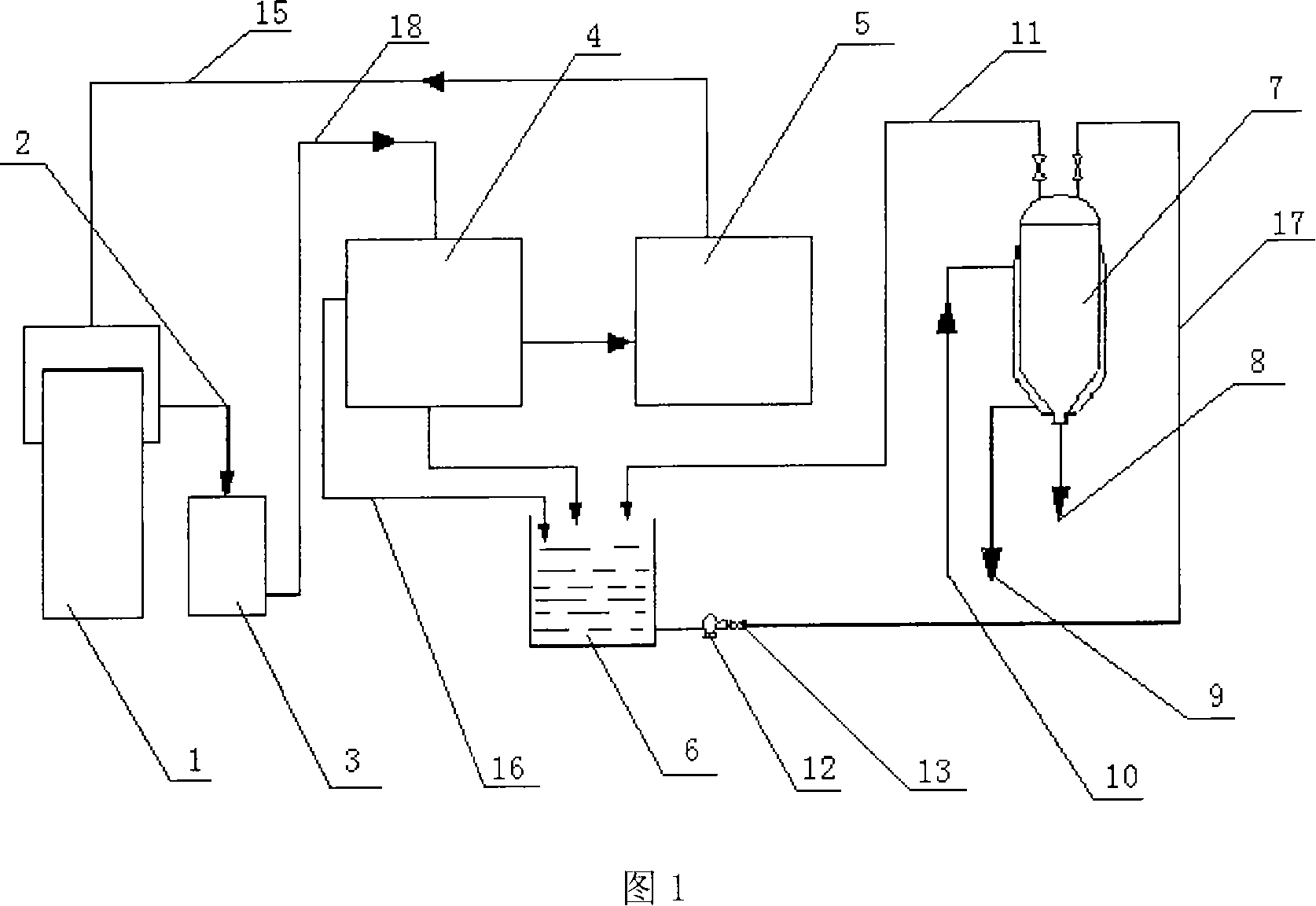

Device for automatically and continuously recycling doctor solution and recycling technique thereof

InactiveCN101172887BSimple processReasonable optimizationAmmonium nitrate fertilisersAmmonium salt fertilisersSulfurFilter system

The invention relates to an automatic serial reclaiming desulfurizing liquid device and the reclaiming technique. The device consists of a desulfurizing serially filtering system, a desulfurizing liquid automatically reclaiming system and a serially sulfur fusing system, and all systems are connected by pipelines. The concrete technique of the automatically reclaiming comprises the steps as below: firstly, the sulfur foam enters into a sulfur foam feed groove through a sulfur foam pipe and an oxygenation regeneration groove; secondly, the sulfur foam in the sulfur foam feed groove enters an vacuum filtering machine, the filtered solid containing sulfur enters a sulfur foam diluting groove, the desulfurzing liquid enters a desulfurzing liquid groove to be reclaimed to the oxygenation regeneration groove by the oxygenation regeneration groove which is provided with a subpressure absorber; thirdly, the sulfur foam diluting liquid in the sulfur foam diluting groove is sent to a sulfur melting kettle; fourthly, after the sulfur foam diluting liquid in the sulfur melting kettle being heated by the saturated steam, the remnant liquid enters the sulfur foam diluting groove again, the condensing water is discharged out of the sulfur melting kettle and the sulfur is reclaimed. The invention having the advantages of simple technique, reasonable optimization, small device, stable and reliable work, no pollution, low maintaining charge, high efficiency as well as big production ability, thereby realizing the energy saving and discharging reduction.

Owner:兖矿峄山化工有限公司(破产清算)

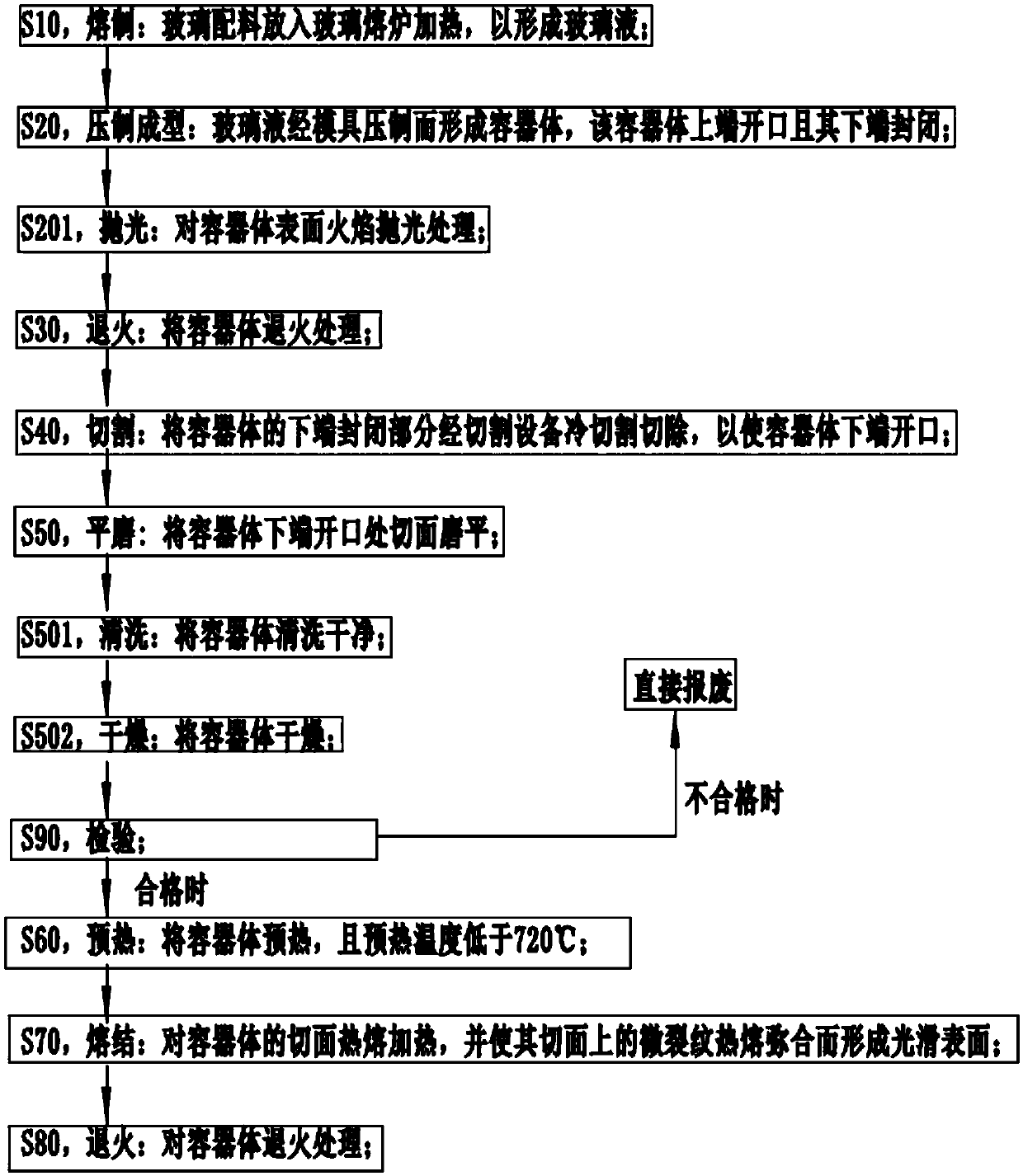

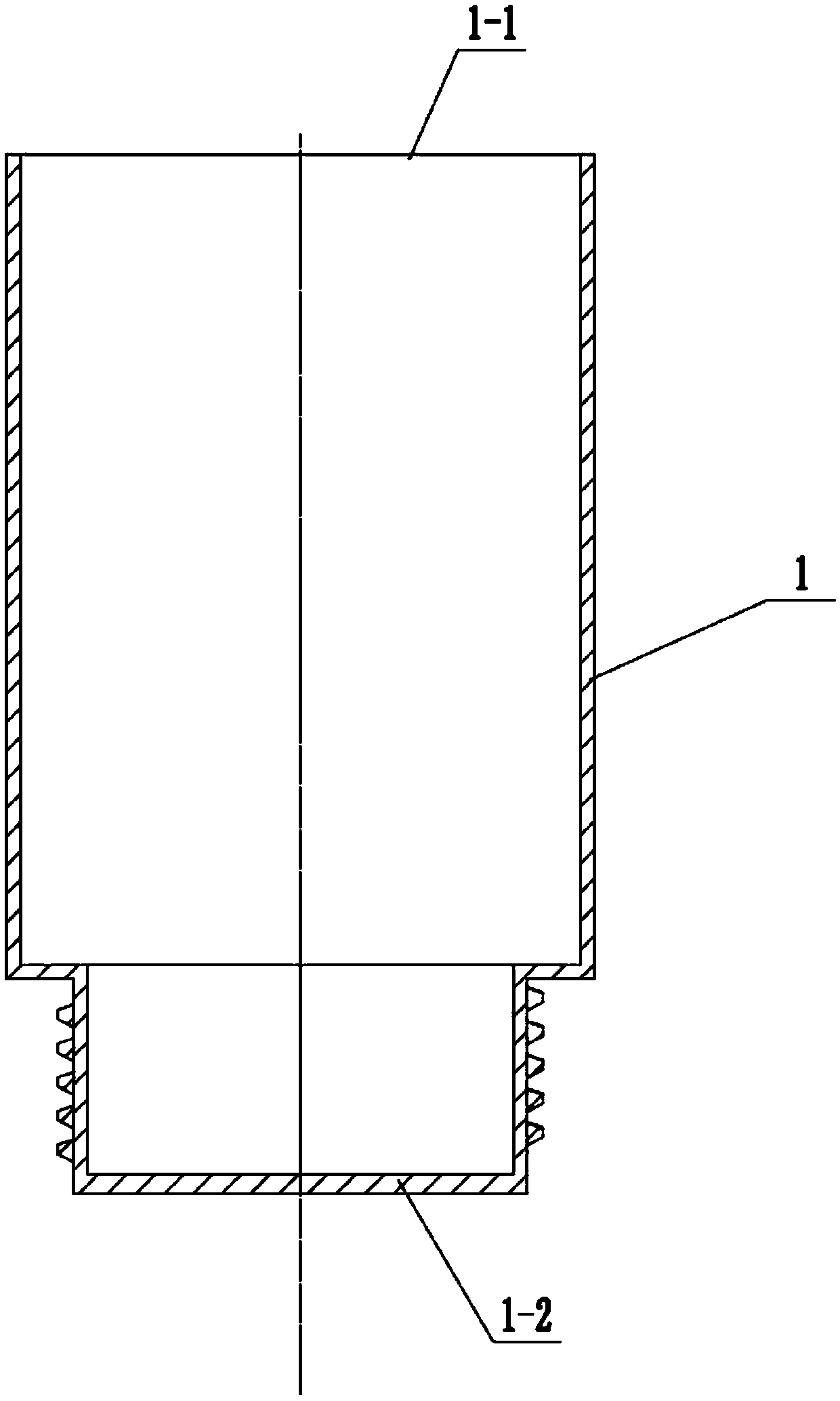

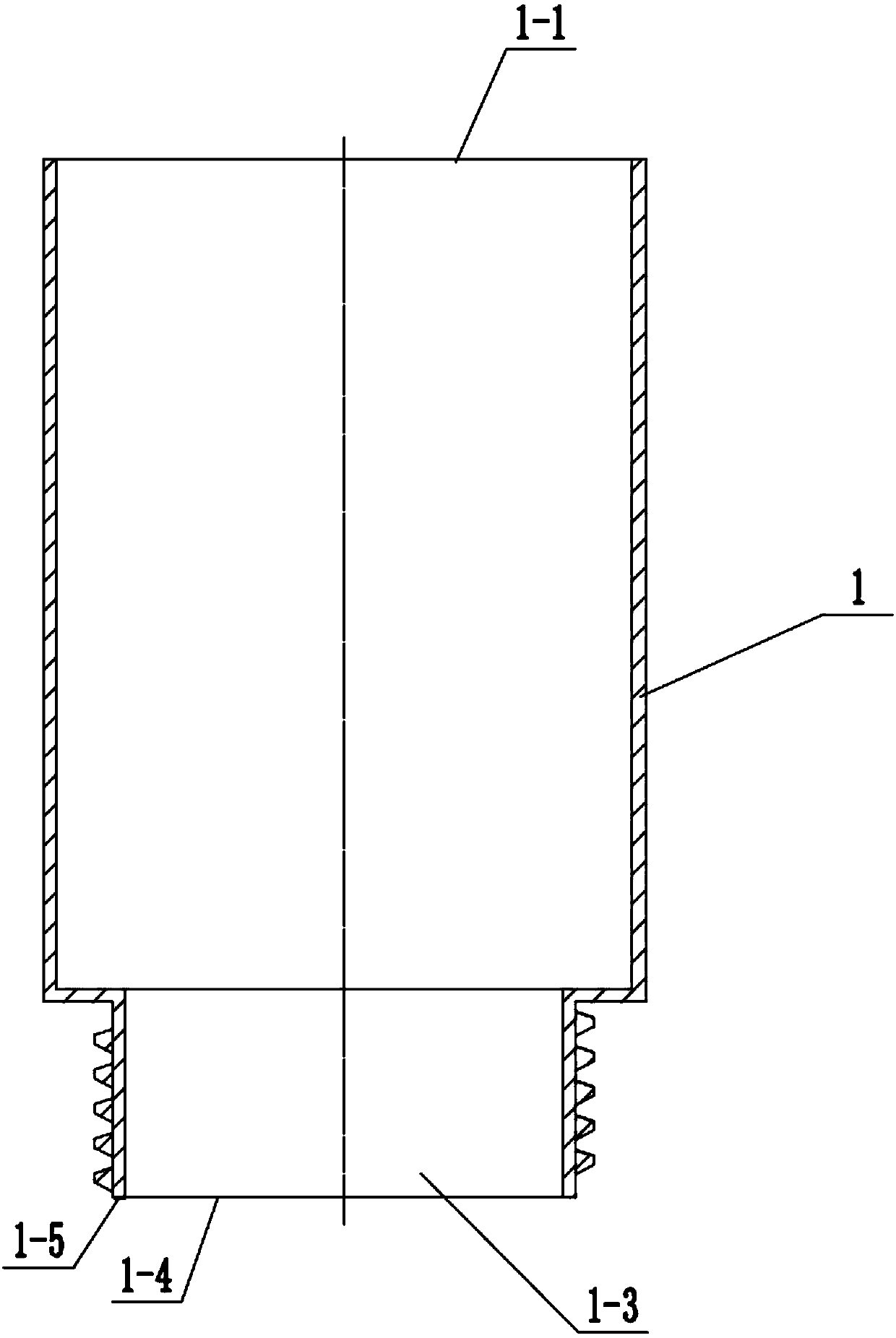

Process for preparing pressed high borosilicate glass product

InactiveCN110803858ASolve the problem of microcracksImprove thermal shock resistanceEdge grinding machinesGlass pressing apparatusCrazingGlass melting

The invention discloses a process for preparing a pressed high borosilicate glass product. The process is characterized by comprising the following steps: S10, performing melting, namely putting glassingredients into a glass melting furnace, and performing heating so as to obtain molten glass; S20, performing pressing molding, namely pressing the molten glass by using a mold so as to obtain a container, wherein the upper end of the container is opened, and the lower end of the container is closed; S30, performing annealing, namely performing annealing treatment on the container; S40, performing cutting, namely performing cold cuttingtocut off the closed part of the container so as to open the lower end of the container; S50, performing flat grinding, namely grinding the cut surface at theopening in the lower end of the container to be flat; S60, performing preheating, namely preheating the container at a preheating temperature lower than 720 DEG C; S70, performing clinkering, namelyperforming hot melting heating on the cut surface of the container, so that micro cracks in the cut surface of the container are made up due to hot meltingso as to form a smooth surface; and S80, performing annealing, namely performing annealing treatment on the container. By adopting the process, the surface of the opening in the lower end of the container has no grinding crack, the micro crackscaused by cutting and polishing can be completely made up, and thus glass cup breakage caused by micro crack expansion can be avoided.

Owner:重庆市润发玻璃器皿有限公司

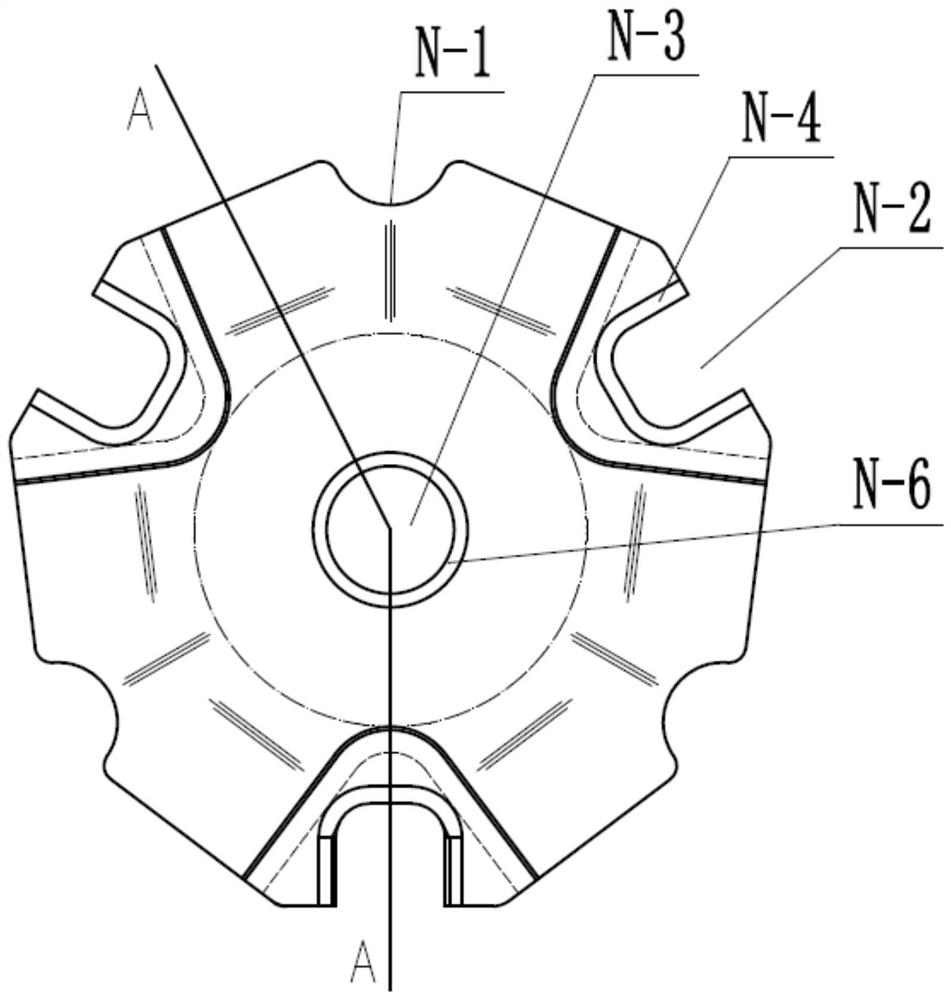

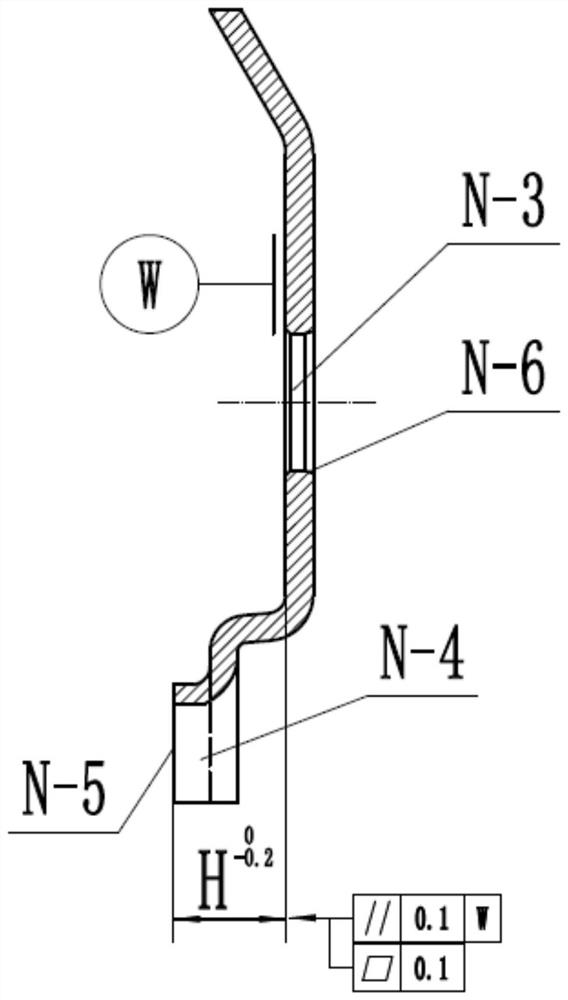

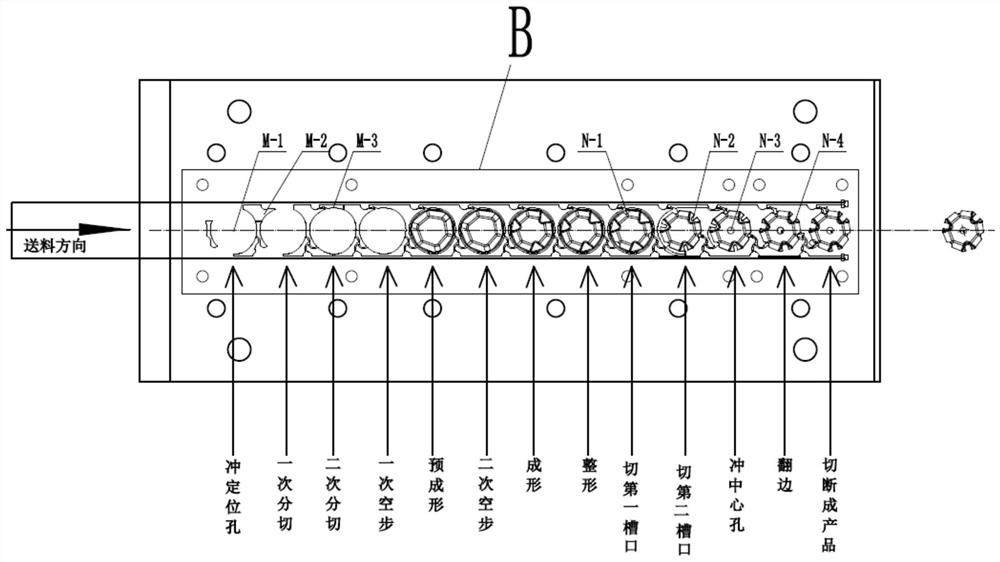

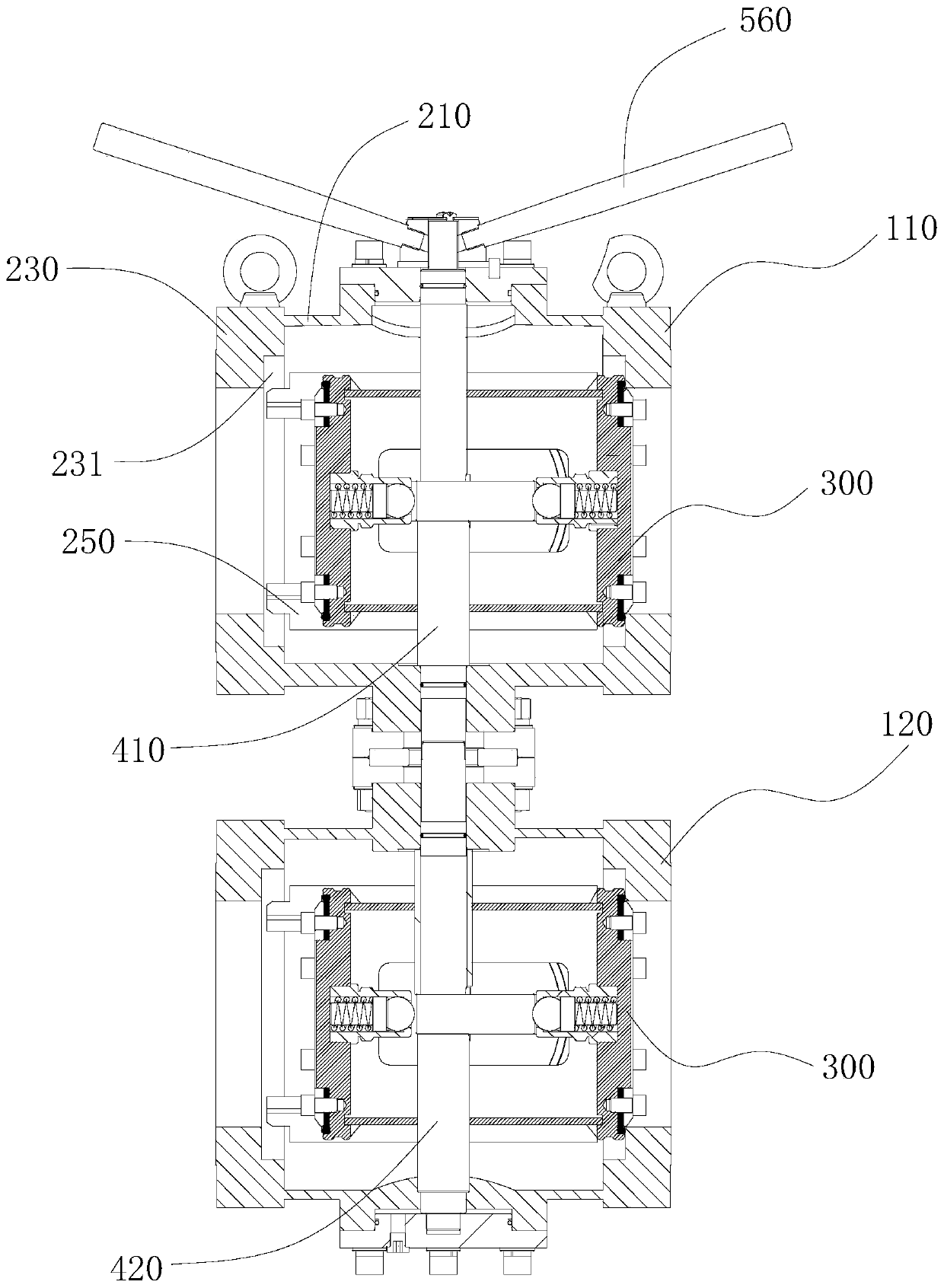

A kind of processing method of inclined plate

ActiveCN110340621BRealize manufacturing and processingOptimize the process routeSolid state diffusion coatingFurnace typesPolishingMachining process

The invention discloses a processing method for a slanted plate. The slanted plate is processed with SPCC material and has a thickness t=3mm. It is characterized in that it comprises the following steps: (a) stamping and forming with a continuous mold; (b) turning the end face; (c) chamfering of the central hole; (d) rolling grinding; (e) heat treatment; (f) shot blasting; (g) inspection; (h) cleaning and antirust; (i) packaging and storage. The invention can realize the manufacturing and processing of the slant plate, and at the same time, the process route is more optimized to meet the design requirements. At the same time, the invention adopts continuous die stamping and the optimization of the continuous processing process is reasonable, which can improve the pass rate and stability of the product and reduce the cost of subsequent processing of the product. Accumulate errors to effectively control product geometry.

Owner:重庆申耀机械工业有限责任公司

A pressure-difference-limiting six-way switching valve for conveying fluid

ActiveCN109185497BNovel structureReasonable optimizationOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringCam

The invention provides a differential pressure limiting type six-way switch valve for conveying fluid. The differential pressure limiting type six-way switch valve comprises a first valve body and a second valve body which are mutually connected. The first valve body and the second valve body each comprise a pipe body and a header pipe, wherein the two ends of the pipe body are provided with transition flanges, the flow passage junction of the header pipe and the pipe body is provided with a linkage valve element, the two end faces of the linkage valve element are provided with sealing rings,multiple guide sliding rails are fixedly arranged on the inner wall of the pipe body, the side walls, close to the axial line of the pipe body, of the guide sliding rails are in sliding abutting connection with the side wall of a valve plate, a cam is arranged in the linkage valve element, the two ends inside the linkage element are fixedly provided with elastic supporting parts, the two elastic supporting parts located in the same linkage valve element make abutting contact with the cam so as to build rolling connection, a first rotating shaft penetrating through the linkage valve element isarranged in the first valve body, a second rotating shaft penetrates through the linkage valve element is arranged in the second valve body, and the second rotating shaft is connected with the first rotating shaft. The differential pressure limiting type six-way switch valve is novel, optimal and reasonable in structure, and has the advantages that moving is smooth, sealing is reliable, and maintenance is convenient.

Owner:九江七所精密机电科技有限公司

cdma signaling analysis teaching simulation training equipment

ActiveCN102867445BUnderstand comprehensivelyReasonable optimizationEducational modelsComputer scienceTeaching simulation

The invention provides CDMA (Code Division Multiple Access) signaling analysis teach simulated training equipment, which comprises a signaling acquisition module, a signaling decoding module, a data background processing module and a display and control module; the display and control module is used for providing common application of signaling analysis in drive test, analyzing a preset communication case according to the received operation command, and displaying an analysis result. Beginners who do not contact CDMA network optimization can be gradually familiar with the network optimization process, can reasonably optimize the CDMA network and provide corresponding solution scheme to the CDMA establishment after more comprehensively knowing all parameters in the CDMA network optimization process and analyzing the acquired data.

Owner:鼎利元(上海)科技发展有限公司

Device for automatically and continuously recycling doctor solution and recycling technique thereof

InactiveCN101172887ASimple processReasonable optimizationAmmonium nitrate fertilisersAmmonium salt fertilisersProcess optimizationFiltration

An automatic and continuous desulfurization liquid recovery device and recovery process. The device is composed of a desulfurization liquid continuous filtration system, a desulfurization liquid automatic recovery system and a continuous sulfur melting system. The systems are connected by pipelines. The specific process of automatic recovery is as follows: 1) sulfur foam enters the sulfur foam feed tank from the oxidation regeneration tank through the sulfur foam pipe; 2) the sulfur foam in the sulfur foam feed tank enters the vacuum filter, and the filtered sulfur-containing solid enters the sulfur foam for dilution The desulfurization liquid enters the desulfurization liquid tank, and is absorbed back to the oxidation regeneration tank by the oxidation regeneration tank with a negative pressure absorber; 3) The sulfur foam dilution liquid in the sulfur foam dilution tank is sent to the sulfur melting tank; 4) The sulfur melting tank After the sulfur foam dilution liquid in the furnace is heated by saturated steam, the residual liquid enters the sulfur foam dilution tank, the condensed water is discharged from the sulfur melting tank, and the sulfur is recovered. The invention has simple process, reasonable optimization, less equipment, stable and reliable work, no pollution, low maintenance cost, high efficiency, large production capacity, and can realize energy saving and emission reduction.

Owner:兖矿峄山化工有限公司(破产清算)

A tdscdma signal test and training platform device

InactiveCN102883353BReasonable optimizationUnderstand comprehensivelyWireless communicationTD-SCDMATest platform

The invention provides a time division-synchronous code division multiple access (TDSCDMA) signal test practical training platform device, which comprises a signal acquirer, a monitoring module and a test module, wherein the signal acquirer is used for acquiring a TD-SCDMA wireless signal parameter and outputting the TD-SCDMA wireless signal parameter to the monitoring module; the monitoring module is used for sending the received TD-SCDMA wireless signal parameter to the test module, executing corresponding signaling operation according to received signaling and sending a signaling operation result to the test module; and the test module is used for displaying the received TD-SCDMA wireless signal parameter, selecting the corresponding signaling according to an input command, sending the signaling to the monitoring module and displaying the signaling operation result. By the platform device, a beginner who is not familiar with running and optimization of a TD-SCDMA network can gradually know well a network optimization process and comprehensively learn about parameters in the TD-SCDMA network running and optimization process; furthermore, after the acquired TD-SCDMA wireless signal parameter is analyzed, the TD-SCDMA network can be rationally optimized; and a corresponding solution can be supplied to construction of TD-SCDMA.

Owner:NANTONG ZHIXIANG INFORMATION TECH

Method and device for secondarily filtering desulfuration liquid by side stream

InactiveCN101530693BImprove desulfurization efficiencyReduce tower pluggingFiltration circuitsFilter regenerationSulfurFilter system

The invention relates to a method and a device for secondarily filtering a doctor solution by side stream, and belongs to the technical field of purification of the doctor solution of synthesis ammonia. The method adopts a doctor solution side-stream filter process, and desulfurizes the doctor solution by a doctor solution side-stream filter system and a filter regeneration system which regenerates the filter system; and the device consists of the doctor solution side-stream filter system and the filter regeneration system. The invention is suitable for tannin extract normal pressure desulfurization systems; and after the doctor solution shunted on a doctor solution main pipeline is desulfurized by the device, suspending sulfur and secondary salt contents in deficient liquid after the desulfurization can be effectively reduced, and phenomenon of tower blockage of a desulfurizing tower is reduced. The method and the device not only improve the desulfurization efficiency of the tannin extract desulfurization systems and prolong the stable operation cycle of the systems, but also reduce the discharge of the doctor solution due to tower cleaning; and the suspending sulfur particles after the desulfurization are not discharged and have no pollution, the phenomenon of the tower blockage of the desulfurizing tower is reduced, and the system is stably operated in a long cycle; and themethod and the device realize online operation and online back washing, and optimally configure a back washing solution to prevent the back washing solution polluting the environment.

Owner:YANKUANG GRP CO LTD +1

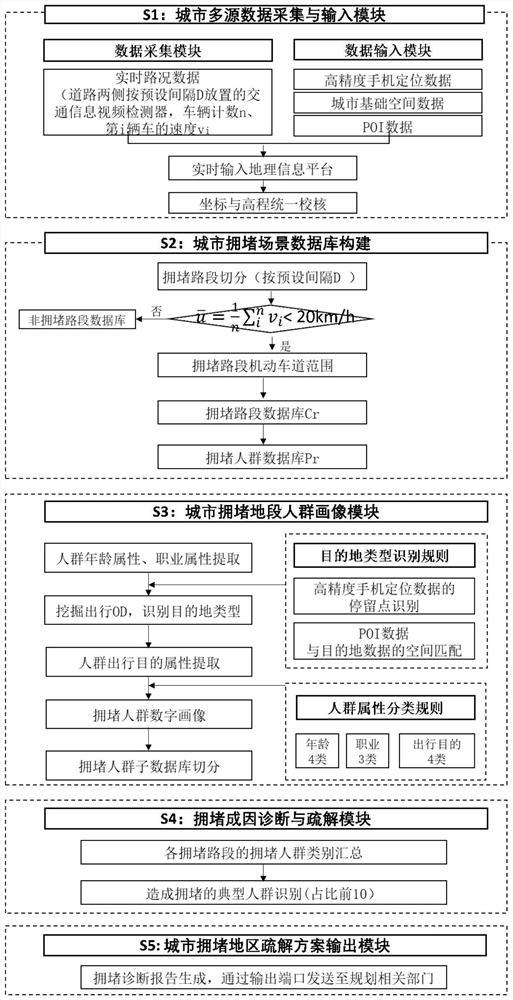

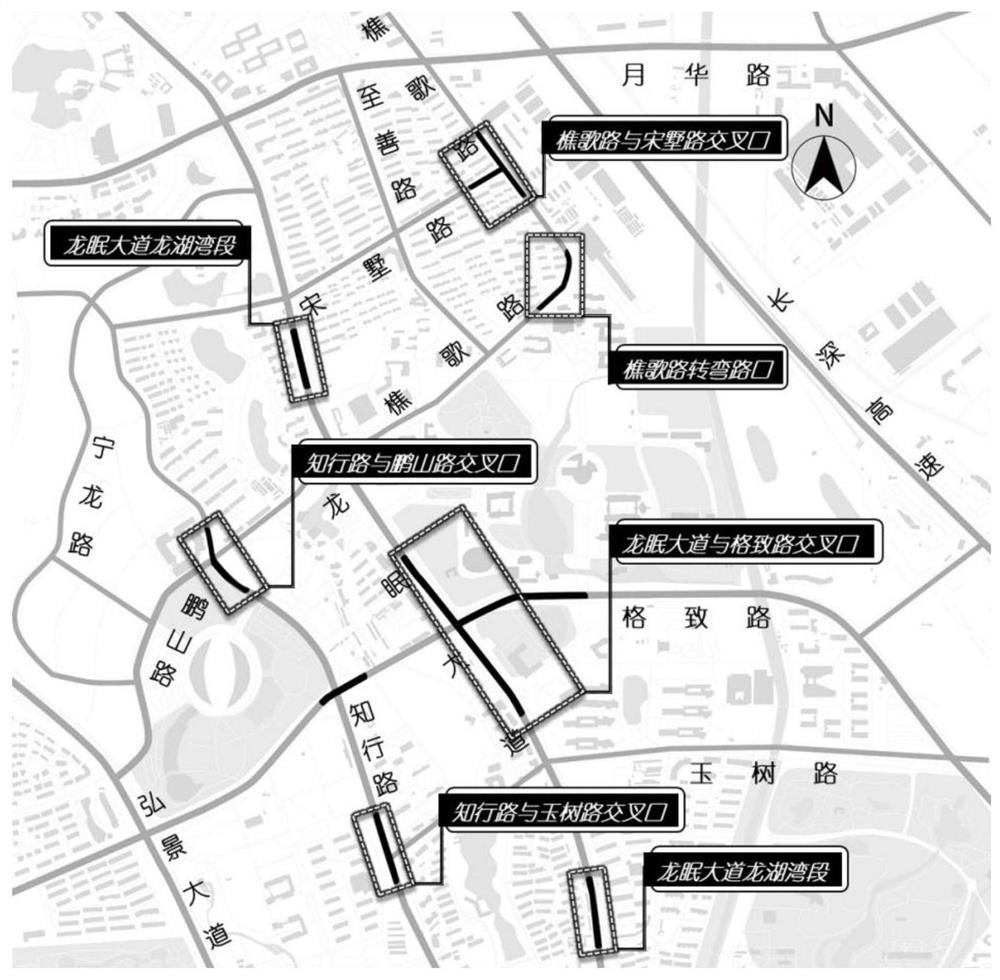

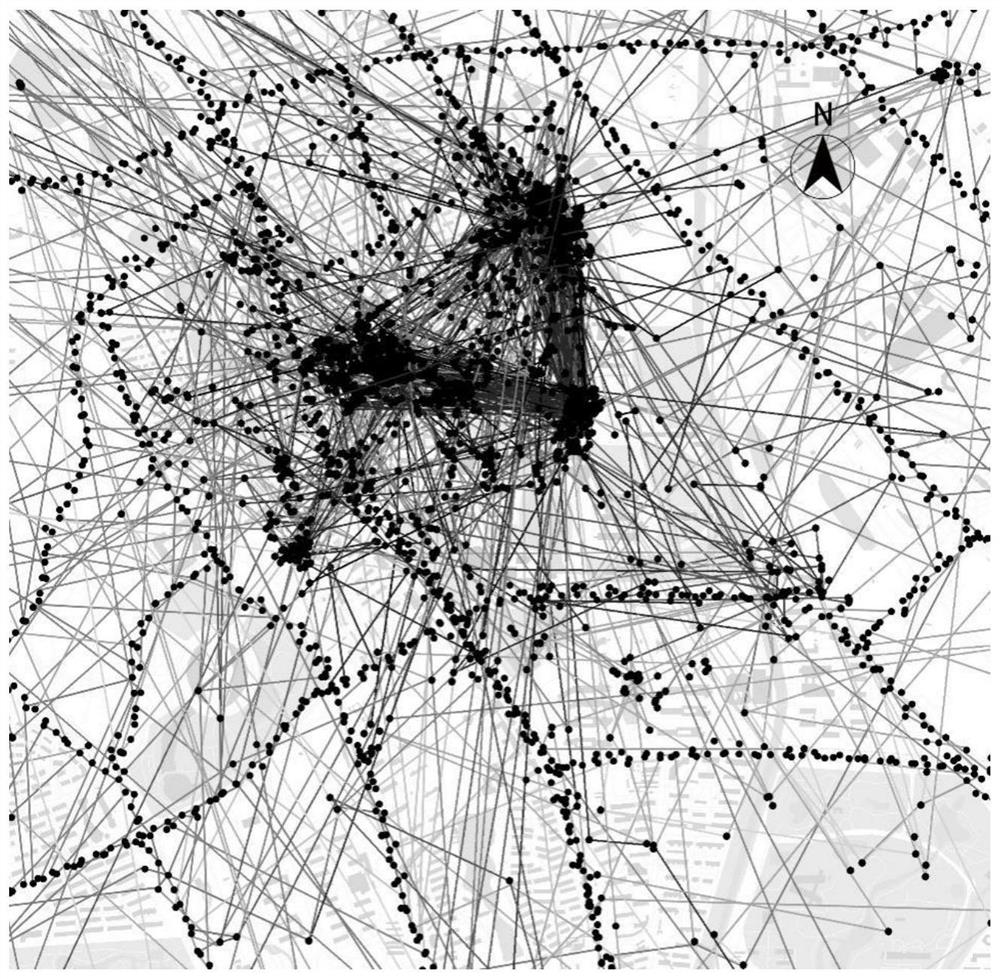

Urban congestion area diagnosis method and system and storage medium

InactiveCN113256978AQuick identificationEasy to identifyDetection of traffic movementCrowdsOperations research

The invention relates to the field of urban planning and traffic, in particular to an urban congestion area diagnosis method, the following scheme is put forward, the method comprises the steps: inputting road condition data, mobile phone positioning data and basic space data of a city into a geographic information platform in real time, and unifying coordinates and elevations of all the data in real time; constructing a congested road section database and a crowd database of the congested road section, and hooking the congested road section database and the crowd database; extracting personal positioning data of all people in the crowd database from the mobile phone positioning data, and sequentially connecting the personal positioning data of different time periods according to a time sequence to form personal behavior track data; and classifying crowds in a crowd database according to the behavior track data of the individuals, and sorting classification results to distinguish crowds causing congestion. According to the invention, accurate and intelligent diagnosis of the congestion section is realized, and the purposes of reducing traffic congestion and optimizing transportation are achieved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com