Automatic production line optimization method based on cache region capacity calculation

An automated production line and optimization method technology, applied in design optimization/simulation, calculation, manufacturing calculation system, etc., can solve the problems of complex calculation of buffer area capacity formula, production efficiency and low precision of production line logistics congestion, and achieve the elimination of production logistics congestion , reduce computational complexity, and optimize the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

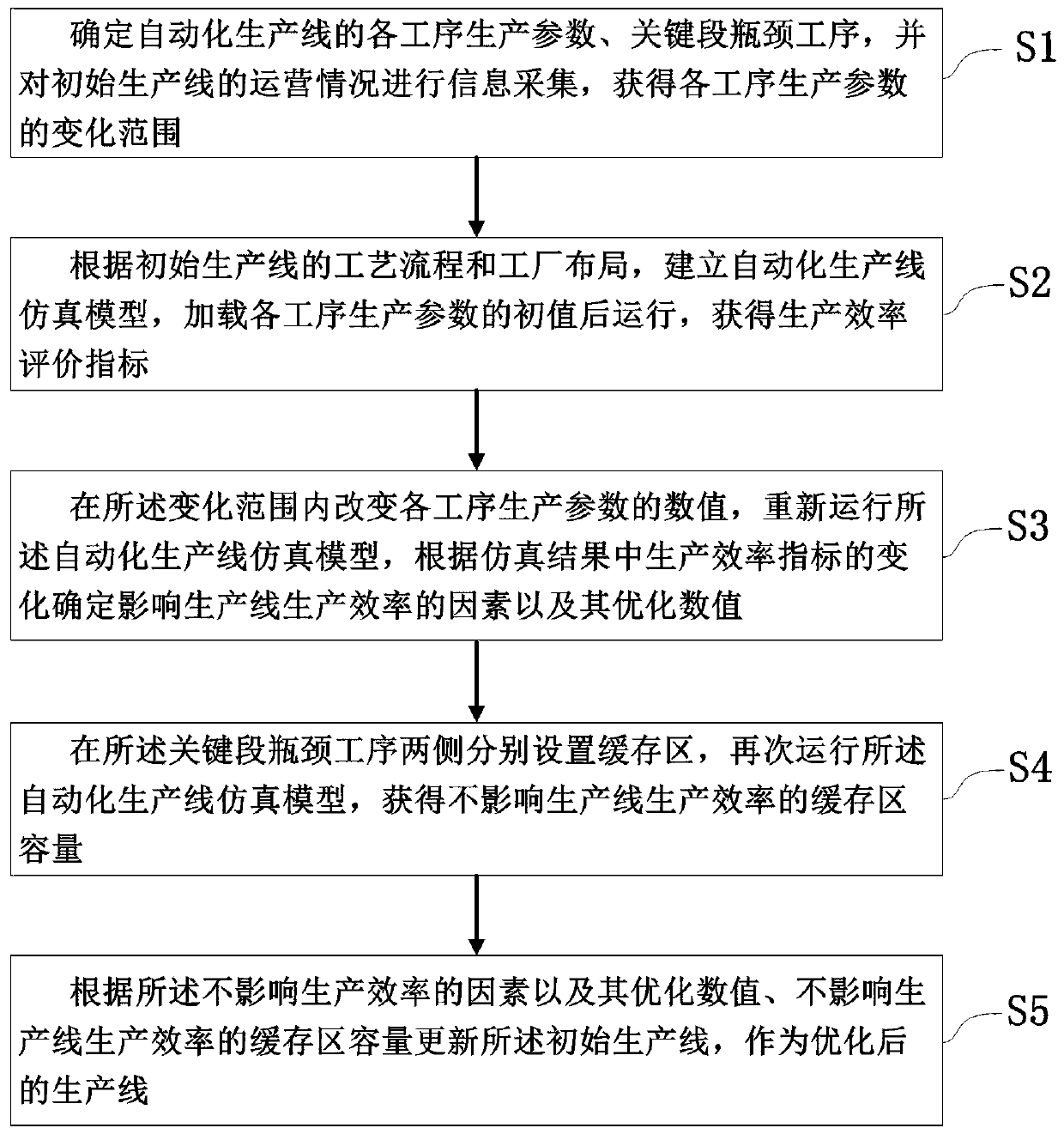

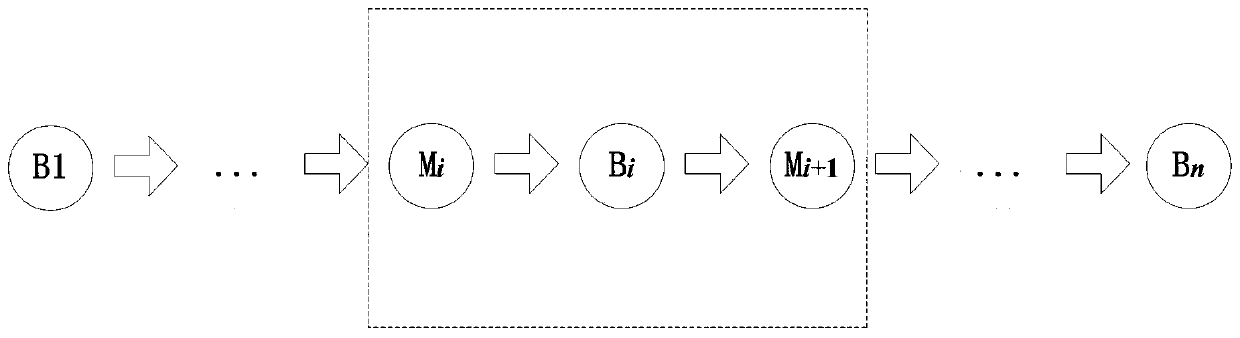

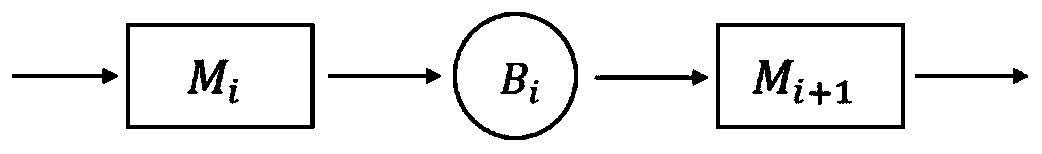

[0066] A specific embodiment of the present invention discloses an automatic production line optimization method based on buffer capacity calculation, such as figure 1 shown, including the following steps:

[0067] S1. Determine the production parameters of each process of the automated production line, the bottleneck process of the key section, and collect information on the operation of the initial production line to obtain the range of production parameters of each process; the key section refers to the operation mechanism and process characteristics that are complex and at the same time non-existent Linear, time-delayed, time-varying processes.

[0068] S2. According to the process flow and factory layout of the initial production line, establish the simulation model of the automated production line, load the initial values of the production parameters of each process and run it, and obtain the production efficiency evaluation index.

[0069] S3. Change the values of ...

Embodiment 2

[0074] Optimizing on the basis of Example 1, the method also includes the steps:

[0075] S5. Based on the optimized value of the cache area capacity and the factors affecting the production efficiency of the production line, run the simulation model of the automated production line again to obtain the availability B of the key section;

[0076] S6. Judging whether the linear ratio of the key segment availability B to the buffer capacity is less than the rated value, if less, determine that the buffer capacity at this time is the optimal value of the buffer capacity; if not less than, adjust the buffer capacity and the key Segment process beat until the linear ratio of key segment availability B to buffer capacity is less than the rated value. Then, update the initial production line according to the factors that do not affect the production efficiency, their optimized values, and the optimal value of the buffer capacity, and further serve as the optimal production line.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com