Method and device for secondarily filtering desulfuration liquid by side stream

A desulfurization liquid and sideline technology, which is applied in the field of synthetic ammonia desulfurization liquid purification, can solve problems such as affecting the normal production of enterprises, affecting the desulfurization efficiency, and deteriorating the quality of the lean liquid, so as to reduce the content of suspended sulfur and secondary salts, improve the desulfurization efficiency, and avoid environmental protection. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

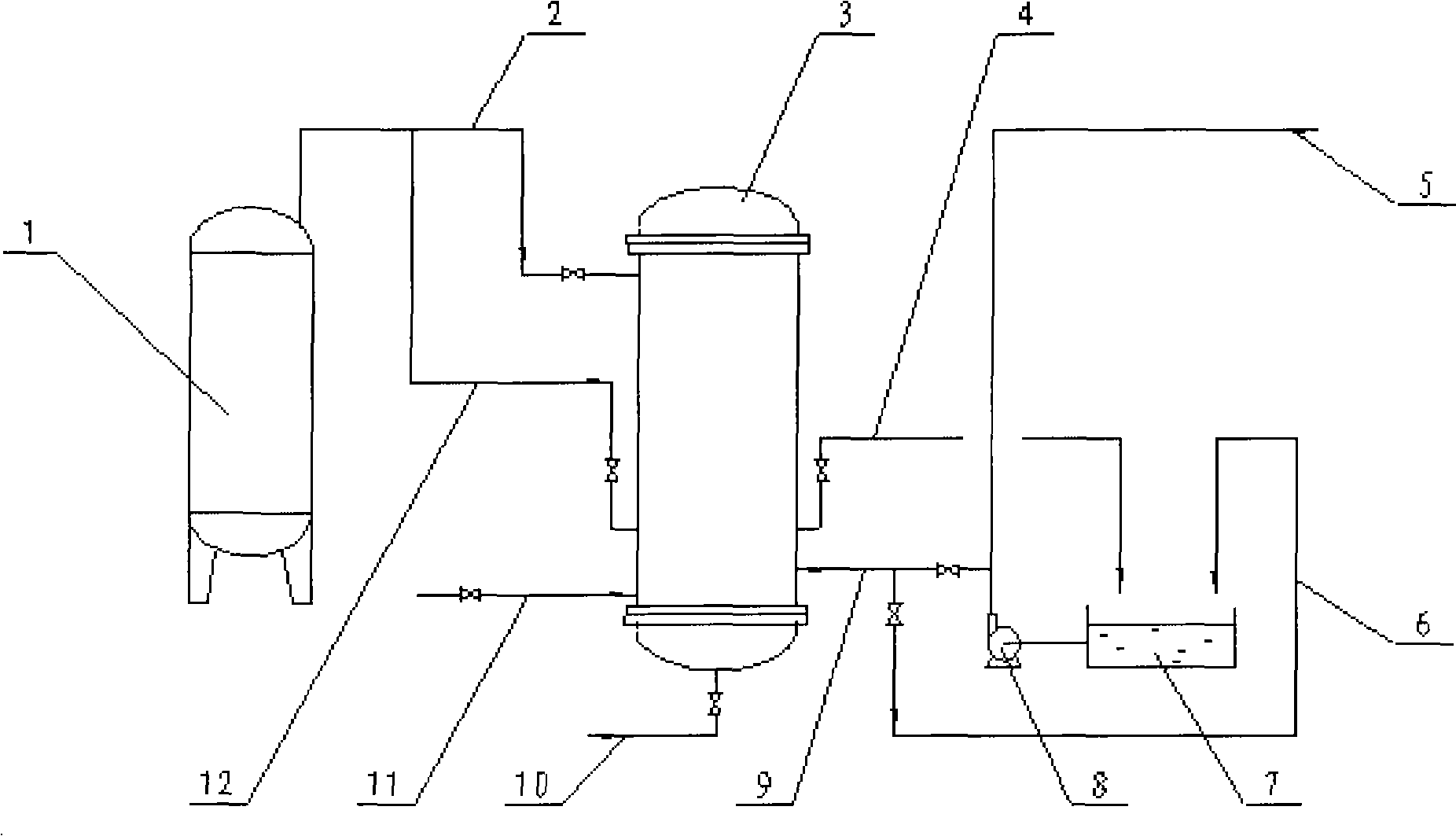

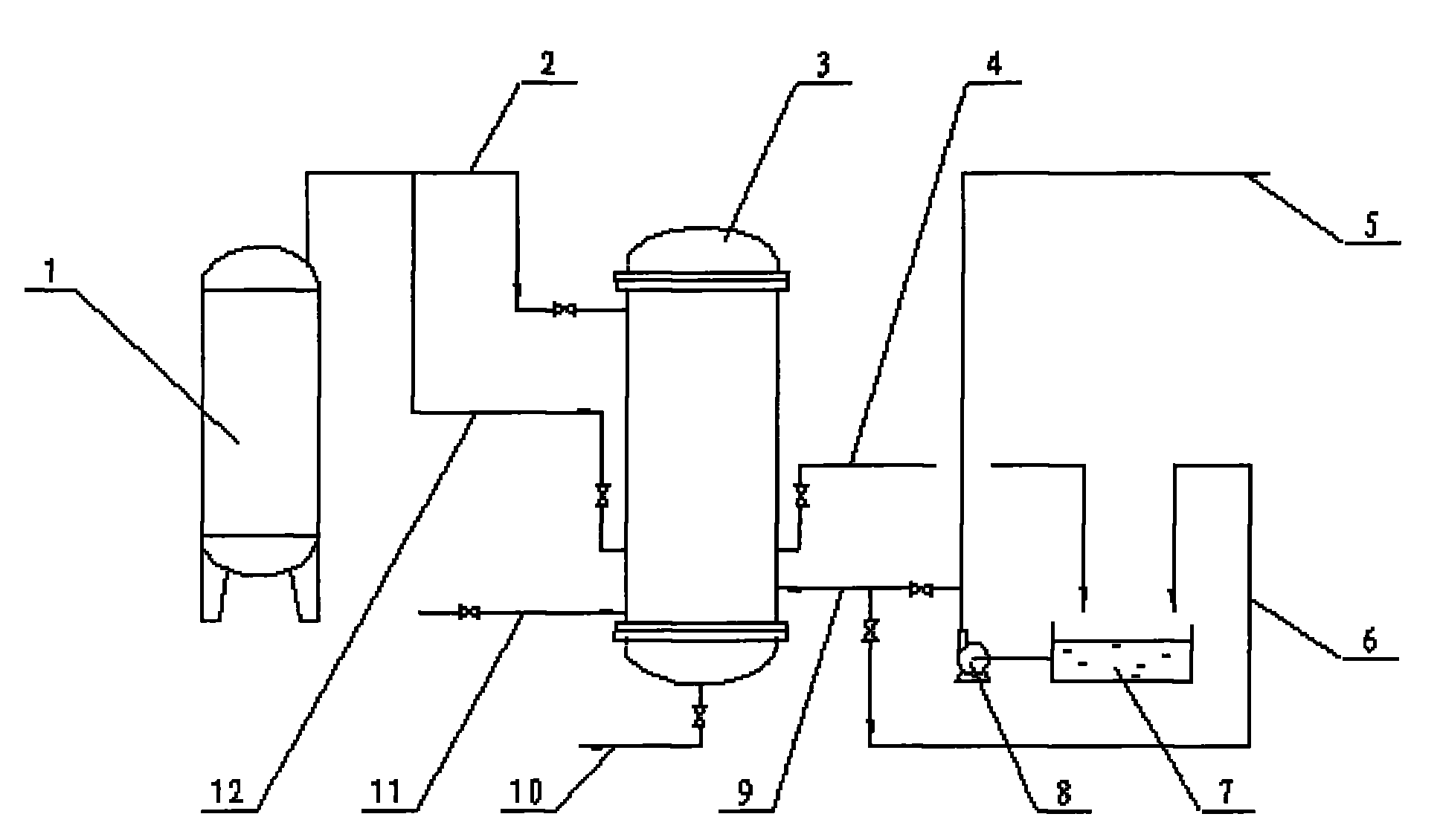

[0021] Embodiment 1: (method embodiment)

[0022] A method for finely filtering desulfurization liquid with a side line, the steps are as follows:

[0023] 1) Use a desulfurization pump to pump the desulfurization liquid from the lean liquid tank into the main pipeline of the desulfurization liquid;

[0024] 2) Open the valve connected to the desulfurization liquid side line pipeline diversion on the desulfurization liquid main pipeline, the desulfurization liquid side line pipeline diverts about 8% of the flow rate of desulfurization liquid, and is sent to the filter for filtering;

[0025] 3) The filtered desulfurization liquid filtrate is sent back to the lean liquid tank through the filtrate pipe;

[0026] 4) When the filtered desulfurization liquid filtrate sent back to the lean liquid tank is significantly reduced, the filter equipment needs to be regenerated. The valve is opened, and the air from the air tank enters the filter for forward blowing through the forward b...

Embodiment 2

[0030] Embodiment 2: (method embodiment)

[0031] Same as embodiment 1, except that in step 2, about 12% of the flow of the desulfurized liquid diverted from the side line pipeline of the desulfurized liquid is sent to the filter for filtration.

Embodiment 3

[0032] Embodiment 3: (method embodiment)

[0033] Same as Example 1, except that in step 2, the desulfurized liquid with about 18% flow diverted from the side line pipeline of the desulfurized liquid is sent to the filter for filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com