Liquid ammonia gasifying system and gasifying process thereof

A technology for liquid ammonia and ammonia gas, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the increase in the cost of ammonia purification process, the limitations of the promotion and application of ammonia methods, and the limitations of the promotion and application of ammonia methods and other issues, to achieve the effect of novel system design, remarkable energy saving effect, energy saving and environmental protection of technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

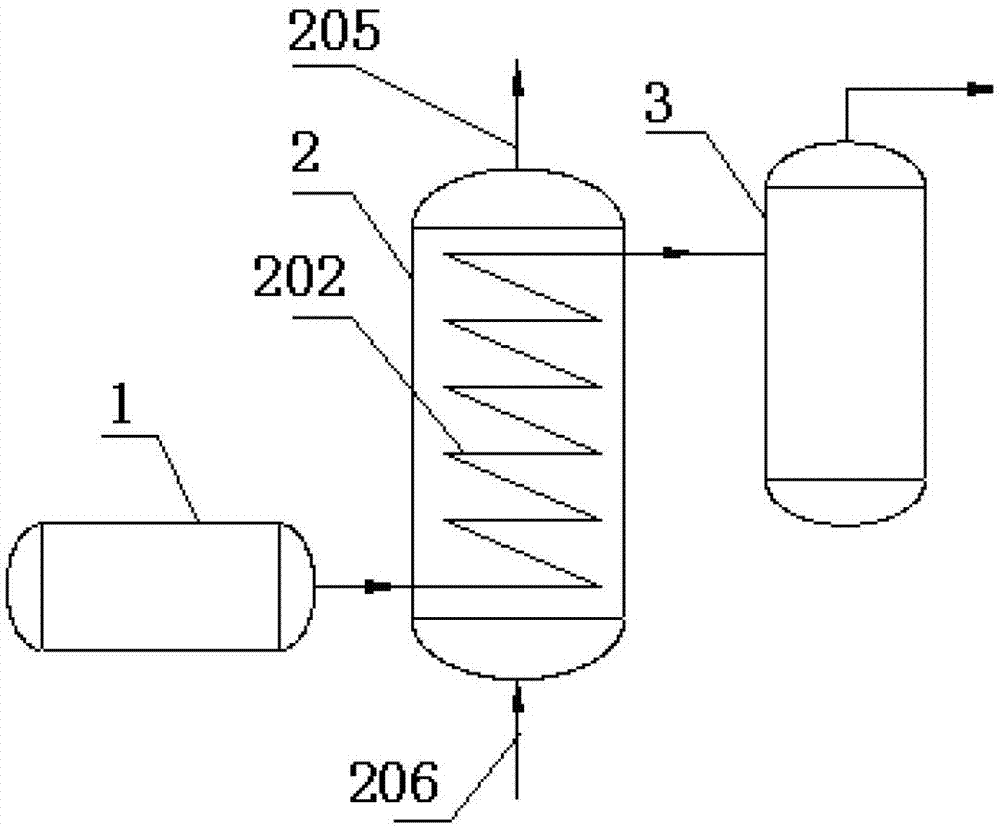

[0034] like figure 1 As shown, a liquid ammonia gasification system of the present invention includes a liquid ammonia delivery device 1 , a heat exchange device and a gas ammonia storage device 3 connected to each other, wherein the heat exchange device is a circulating water heat exchange device 2 .

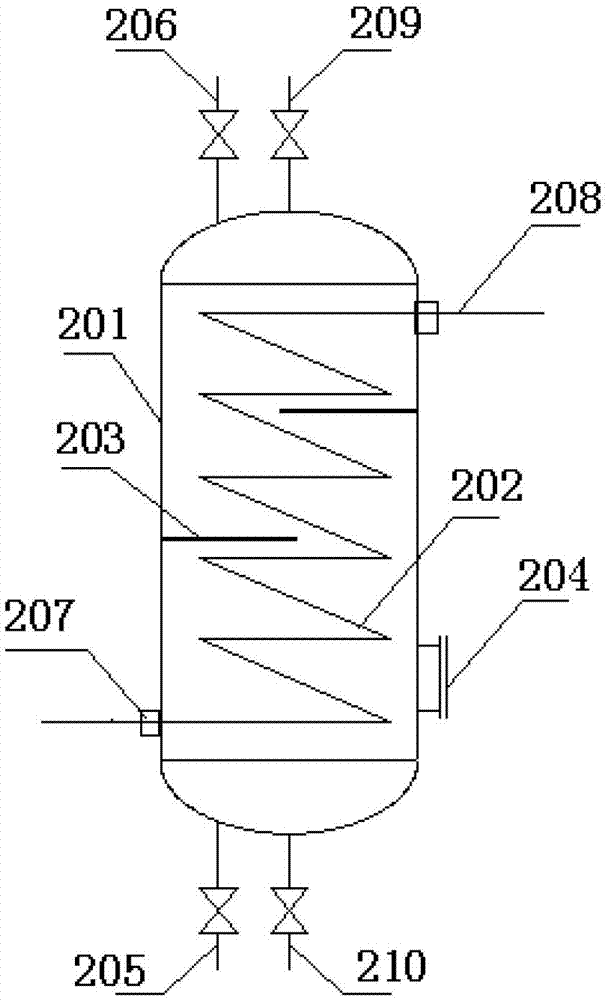

[0035] like figure 2 As shown, the circulating water heat exchange device 2 includes a casing 201, a heat exchange tube 202 arranged in the casing 201, three baffles 203 arranged at intervals in the casing 201, and an inspection port arranged at the lower part of the casing 201. 204. The circulating water input port 205 and the circulating water output port 206, the liquid ammonia input port 207 and the gas ammonia output port 208, the exhaust port 209 and the net discharge port 210 arranged on the housing 201; wherein the circulating water input port 205 is set At the bottom of the housing 201, the circulating water output port 206 is arranged on the top of the housing 201; ...

Embodiment 2

[0050] like figure 1 and figure 2 As shown, the setting and distribution of a liquid ammonia gasification system are the same as those in Example 1, wherein the difference is that: the heat exchange tubes are arranged side by side in parallel, that is, a tube-and-tube heat exchanger is used; the heat exchange tubes It is made of 16Mn alloy steel pipe; the number of said baffles is 4.

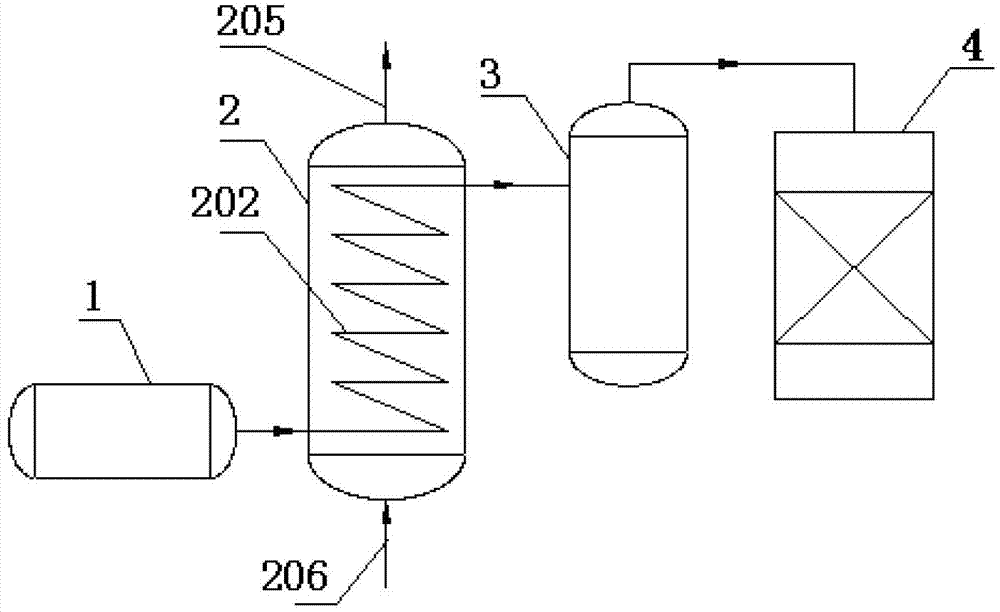

[0051] like image 3 As shown, taking the amount of gas ammonia of 380kg / h provided to the SCR denitrification process system of a coal-fired power plant as an example, the liquid ammonia gasification system of the present invention is used to gasify liquid ammonia, the same as in Example 1, except for the following steps:

[0052] In step (1), when the circulating water enters the heat exchange device 2 from the circulating water input port 205, the temperature at the inlet is 30°C;

[0053] In step (3), the flow rate of the circulating water used is 52.3m 3 / h.

[0054] Applying the pres...

Embodiment 3

[0056] like figure 1 and figure 2 As shown, the setting and distribution of a liquefied ammonia gasification system are the same as in Example 1, wherein the difference is that: the heat exchange tubes are arranged in parallel; the heat exchange tubes are made of 16Mn alloy steel pipes; The number of flow plates is 6.

[0057] like image 3 As shown, taking the amount of gas ammonia of 360kg / h provided to the SCR denitrification process system of a coal-fired power plant as an example, the liquid ammonia gasification system of the present invention is used to gasify liquid ammonia, the same as in Example 1, except for the following steps:

[0058] In step (1), when the circulating water enters the heat exchange device 2 from the circulating water input port 205, the temperature at the inlet is 32°C;

[0059] In step (3), the flow rate of the circulating water used is 45m 3 / h.

[0060] Applying the present invention to gasification of liquid ammonia, the cooling capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com