Method for using carbon monoxide to detoxicate chromium residue

A carbon monoxide and chromium slag technology, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of large coal consumption, high detoxification cost, rising hexavalent chromium ions, etc., and achieve the effect of reducing the amount of coal and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

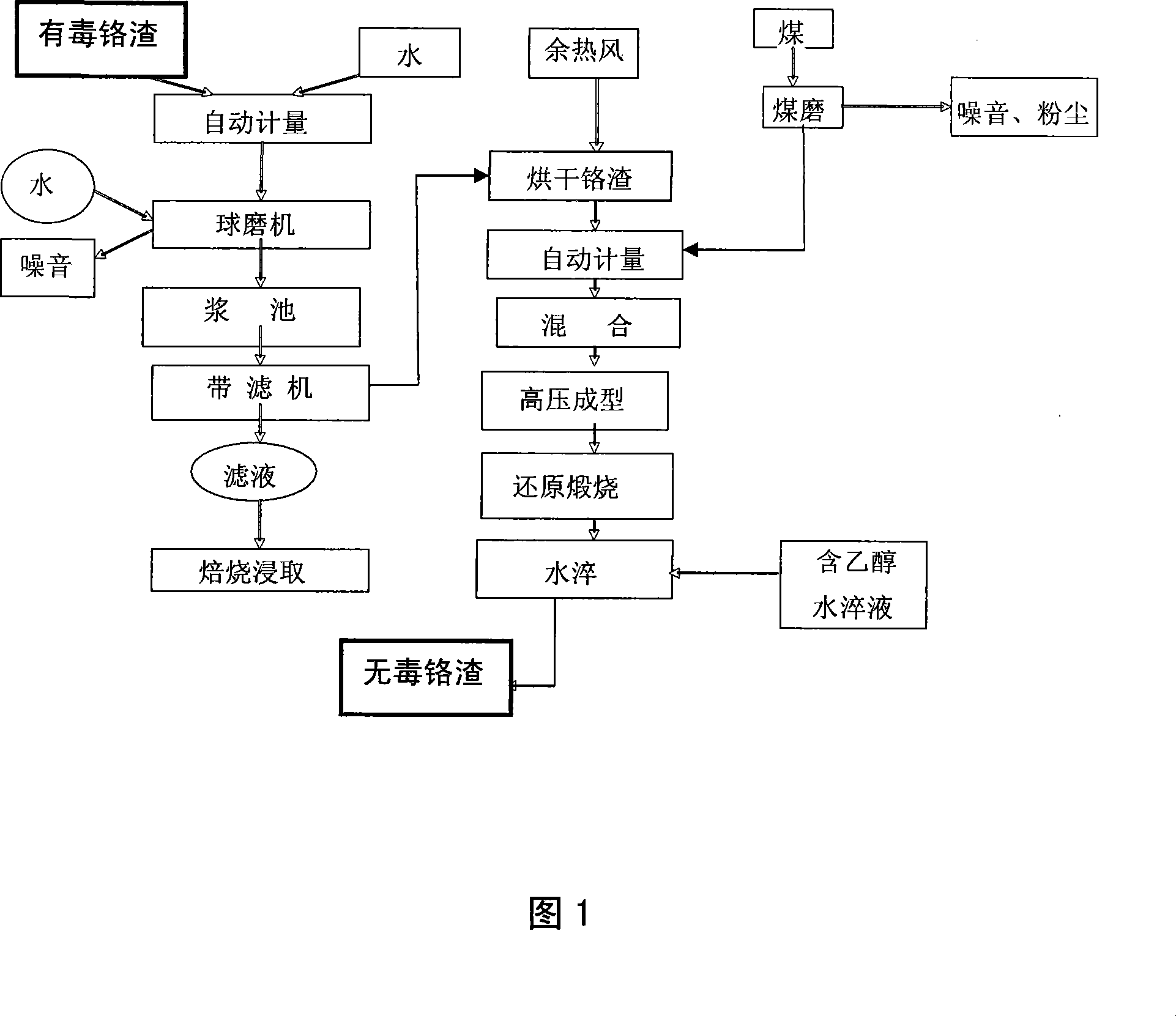

Image

Examples

Embodiment 1

[0018] The method for detoxifying chromium slag with CO: comprises the following steps:

[0019] (1) Abrasives: chromium slag [solid, containing hexavalent chromium ions (Cr 6+ ) is about 1.0% or more] After adding water, wet grind into slurry; dry coal into coal powder; measure and mix according to the ratio of chromium slag: water = 1:5 by weight, and then use ball mill for wet ball milling, the fineness of slurry It is controlled at about 150 mesh, and the slurry is directly suction-filtered by a vacuum belt filter, and part of the hexavalent chromium ions (Cr 6+ ), recovered hexavalent chromium ions (Cr 6+ ) of the filtrate is returned to the red alum sodium production process for recycling; the filtered chromium slag also contains a large amount of hexavalent chromium ions (Cr 6+ ), the following steps are to filter hexavalent chromium ions (Cr 6+ ) detoxification treatment;

[0020] (2) Drying: filter the chromium slag and water to separate the chromium slag from the...

Embodiment 2

[0027] The method for detoxifying chromium slag with carbon monoxide: comprise the following steps:

[0028] (1) Abrasives: chromium slag [solid, containing hexavalent chromium ions (Cr 6+ ) is about 1.0% or more] After adding water, wet grind into slurry; dry coal into coal powder; measure and mix according to the ratio of chromium slag: water = 1:3 by weight, and then use a ball mill for wet ball milling, the fineness of the slurry It is controlled at about 100 mesh, and the slurry is directly filtered by a vacuum belt filter to recover part of the hexavalent chromium ion (Cr 6+ ), recovered hexavalent chromium ions (Cr 6+ ) of the filtrate is returned to the red alum sodium production process for recycling; the filtered chromium slag also contains a large amount of hexavalent chromium ions (Cr 6+ ), the following steps are to filter hexavalent chromium ions (Cr 6+ ) detoxification treatment;

[0029] (2) Drying: filter the chromium slag and water to separate the chromiu...

Embodiment 3

[0036] The method for detoxifying chromium slag with carbon monoxide: comprise the following steps:

[0037] (1) Abrasives: chromium slag [solid, containing hexavalent chromium ions (Cr 6+ ) is about 1.0% or more] After adding water, wet grind into slurry; dry coal into coal powder; measure and mix according to the ratio of chromium slag: water = 1:1 by weight, and then use a ball mill for wet ball milling, the fineness of the slurry It is controlled at about 120 mesh, and the slurry is directly filtered by a vacuum belt filter, and part of the hexavalent chromium ions (Cr 6+ ), recovered hexavalent chromium ions (Cr 6+ ) of the filtrate is returned to the red alum sodium production process for recycling; the filtered chromium slag also contains a large amount of hexavalent chromium ions (Cr 6+ ), the following steps are to filter hexavalent chromium ions (Cr 6+ ) detoxification treatment;

[0038] (2) Drying: filter the chromium slag and water to separate the chromium sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com