Oil well deep composite blocking profile control agent and application thereof

A technology of profile control agent and plugging agent, which is applied in the direction of wellbore/well components, sealing/isolation, drilling composition, etc. Pores and other problems can be improved to increase the swept area and oil washing efficiency, reduce the interfacial tension of oil and water, and supplement the formation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

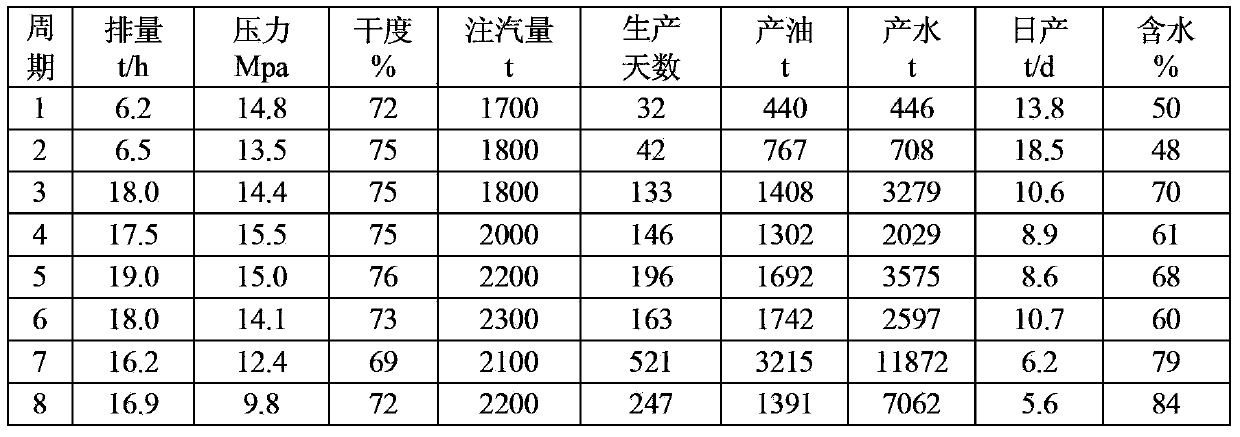

[0043] When Well Du 84-29-91 was subjected to 8 cycles of steam injection huff and puff, steam channeled adjacent to two oil wells, Du 84-27-93 and Du 84-29-93, and the cycle production and cycle daily production of this well showed a significant downward trend. The autogenous gas source (CO(NH 2 ) 2 ) 2 tons, surface active substance (model: EOR-CL / LY-Ⅰ; manufacturer: Liaoning Liaohe Oilfield Taihua Construction Group Co., Ltd.) 1 ton, gel plugging agent (model: PR-HTTB / LY-Ⅵ; manufacturer: Liaoning Panjin Friendship Welfare Science Industry and Trade Center) 60 tons and granular plugging agent (model: PR-HTPC / LY-Ⅰ; manufacturer: Panjin Liaohe Oilfield Jinhui Industrial Co., Ltd.) 6 tons. On-site construction pressure 10MPa.

[0044] Table 1. Periodic production of Well Du 84-27-91 before measures taken

[0045]

[0046]After the measures, no steam channeling occurred during the steam injection process, 2 directions of steam channeling were reduced, and the output affect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com