Method of producing eriochrome black with sodium bisulfate, byproduct of chromic trioxide

A technology of sodium bisulfate and by-products, applied in the field of chromium salts, can solve the problems of high cost and low economic benefit, and achieve the effects of low cost, simple process flow and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

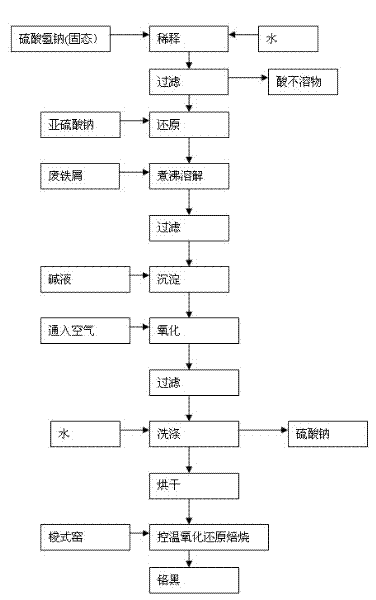

Method used

Image

Examples

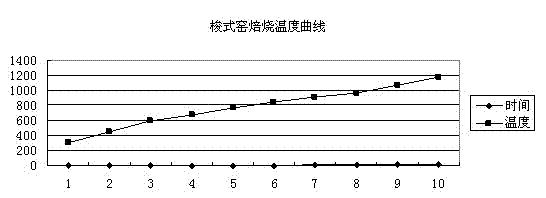

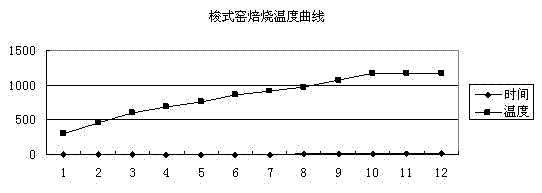

Embodiment 1

[0039] Get 1.314 kg of chromic anhydride by-product sodium bisulfate (solid state), stir and dilute (55 Baume) with 1 liter of water and filter to obtain sodium bisulfate solution (H 2 SO 4 : 280g / L, Cr 6+ (in Na 2 Cr 2 o 7 .2H 2 O meter): 46g / L), add 60 grams of 98w% sodium sulfite and stir to dissolve, after fully reacting, add 12 grams of iron scraps containing 95.8w% iron, boil to dissolve, filter to remove impurities. Add sodium hydroxide solution to the obtained filtrate and stir until the pH value is 5. Pour the reacted slurry into a cylinder container with a diameter of φ35mm and a height of 1500mm. Connect a 20KPa Roots fan through the vent hole at the bottom of the container, and blow in air to stir for 1 Hour. Filter the air-stirred slurry, wash the precipitate with hot water at 70°C until pH = 7, and dry the precipitate in an oven at 105°C for 2 hours. Grind the dried materials until all of them pass through a 200-mesh sieve, put the obtained raw material in...

Embodiment 2

[0043] Get 1.314 kilograms of chromic anhydride by-product sodium bisulfate, filter after stirring and diluting (55 Baume) with 1 liter of water, the gained sodium bisulfate solution (H 2 SO 4 : 280g / L, Na 2 Cr 2 o 7 .2H 2O: 46g / L), add 69.5 grams of 98w% sodium sulfite and stir to dissolve. After fully reacting, add 8.5 grams of iron scraps containing 95.8w% iron, boil to dissolve, and filter to remove impurities. Add potassium hydroxide solution to the obtained filtrate and stir until the pH value is 6. Pour the reacted slurry into a cylindrical container with a diameter of φ35mm and a height of 1500mm. Connect a 20KPa Roots-type fan through the vent hole at the bottom of the container, and blow in air to stir. 1 hour. Filter the air-stirred slurry, wash the precipitate with hot water at 70°C until pH = 7, and dry the precipitate in an oven at 250°C for 1.5 hours. Grind the dried materials until all of them pass through a 200-mesh sieve. Put the obtained raw material...

Embodiment 3

[0047] Get 1.971 kilograms of chromic anhydride by-product sodium bisulfate, filter after stirring and diluting (53 Baume) with 1.5 liters of water, gained sodium bisulfate solution (H 2 SO 4 : 280g / L, Na 2 Cr 2 o 7 .2H 2 O: 46g / L), add 92.6 grams of 98w% sodium sulfite and stir to dissolve. After fully reacting, add 16.9 grams of iron scraps containing 95w% iron, boil to dissolve, and filter to remove impurities. The obtained filtrate is adjusted to a pH value of 7 with 25w% ammonia water, and the reacted slurry is poured into a cylinder container with a diameter of φ35mm and a height of 1600mm, and a 20KPa Roots blower is connected through the vent hole at the bottom of the container, and air is blown in and stirred for 2 hours. Filter the air-stirred slurry, wash the obtained precipitate with hot water at 80°C, and dry the precipitate in a high-temperature furnace at 450°C for 1 hour. Grind the dried materials until all of them pass through a 200-mesh sieve, put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com