Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Potassium Glutamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monopotassium glutamate (MPG) is a compound with formula KC5H8NO4. It is a potassium acid salt of glutamic acid. It has the E number E622 and is used in foods as a flavor enhancer. It is a non-sodium MSG alternative.

Silk-reeling technology by utilization of tussah fresh cocoon live pupae

The invention relates to a silk-reeling technology by the utilization of tussah fresh cocoon live pupae. The technology includes the steps that vacuum low-temperature permeation is performed on tussah fresh silkworm cocoons of the live pupae after refrigeration and freshness retaining in a vacuum environment at water temperature of 26 DEG C-40 DEG C, wherein the pH value is 6.5-8; according to vacuum low-temperature chemical cocoon reeling, water, sodium carbonate, sodium silicate, sodium borate, hydrogen peroxide and N-coconut oil-potassium glutamate form a reeling solution, and at temperature of 30 DEG C-46 DEG C, vacuumizing is performed for reeling in the pH value of 4-14; according to constant-temperature cocoon blanching, the cocoons are soaked in the reeling solution at temperature of 30 DEG C-40 DEG C for blanching; low-temperature silk reeling is performed, and raw silks are reeled again to be arranged to obtain a finished product. Pupa linings are manually removed from the silkworm pupae after silk reeling, so that the silk-reeling live pupae are obtained. The cocoons are not dried and cooked, silk reeling is directly performed, cost and energy consumption are reduced, and the survival rate of the by-products silk-reeling silkworm pupae is over 95%. Protein, amino acid and other kinds of nutrient active substances of pupa bodies are not affected, the utilization rate of the silk-reeling silkworm pupae is increased, breeding cocoons are provided for a sericulture department to perform orientated breeding, fine-breed breeding is accelerated, and the technology has great significance.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

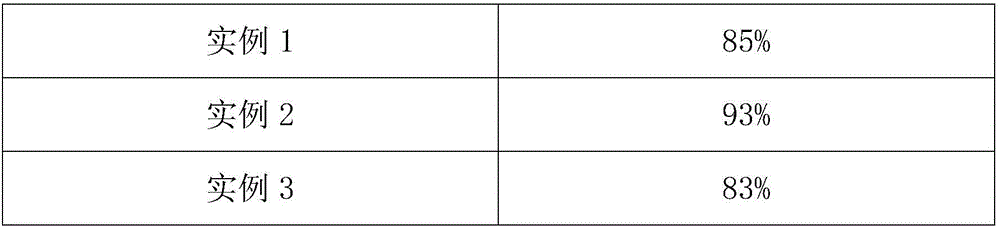

Seasoning capable of reducing blood lipid

ActiveCN103598557AChange the tasteImprove freshnessMulti-step food processesFood ingredient functionsSecondary hyperlipidemiaSodium Glutamate

The invention belongs to the field of food, and specifically relates to a seasoning capable of reducing blood lipid. The seasoning comprises following ingredients, by weight, chicken meal, sodium chloride, potassium glutamate, chilli powder, sodium glutamate, shiitake, red date, pepper, cucumber, haw, carrot, ginger powder, green Chinese onion powder, and celery. Ingredients capable of reducing blood lipid, such as semen cassia, radix polygoni multiflori, rhizoma alismatis, shiitake, red date, carrot and cucumber are added into the seasoning, so that taste of the seasoning is changed, freshness of the seasoning is improved, and treatment and prevention on hyperlipidemia are realized with dinning.

Owner:ANHUI QIANGWANG FLAVORING FOOD

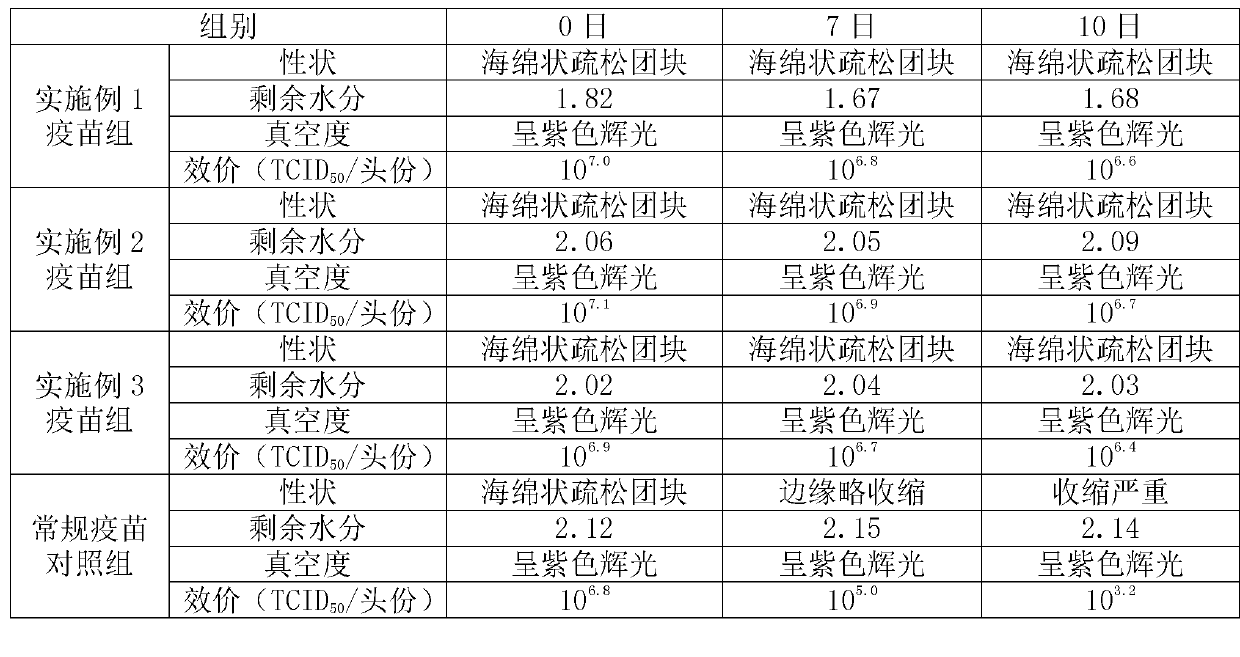

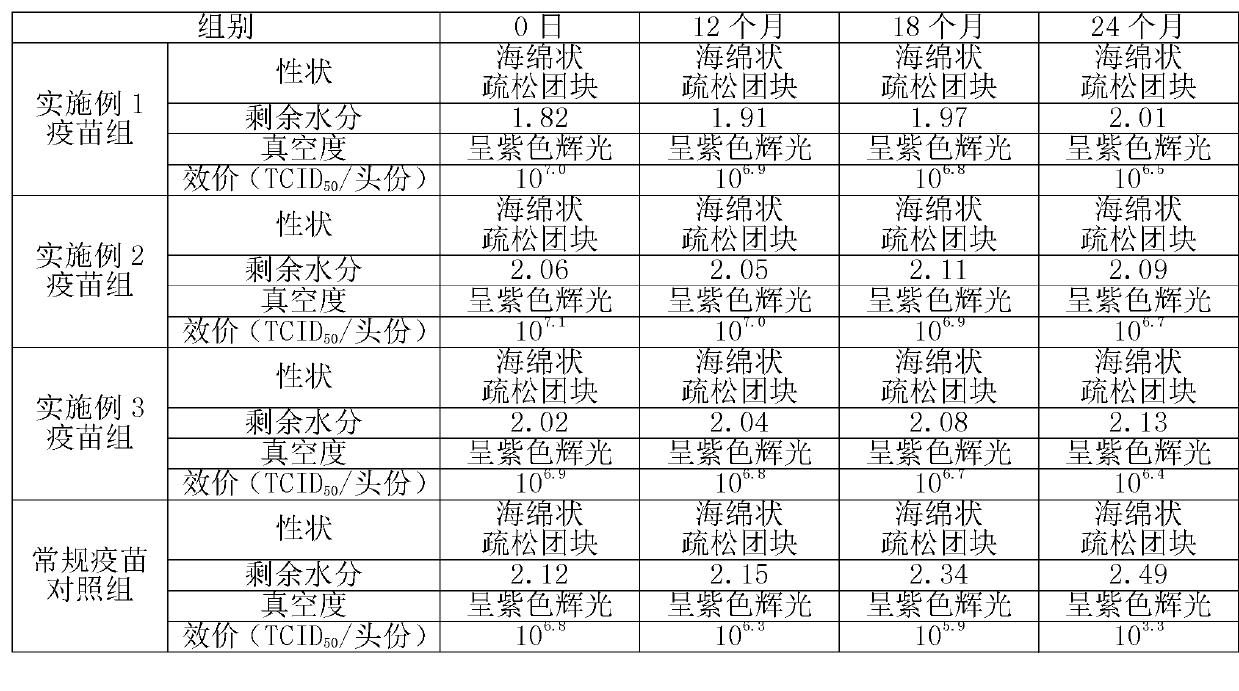

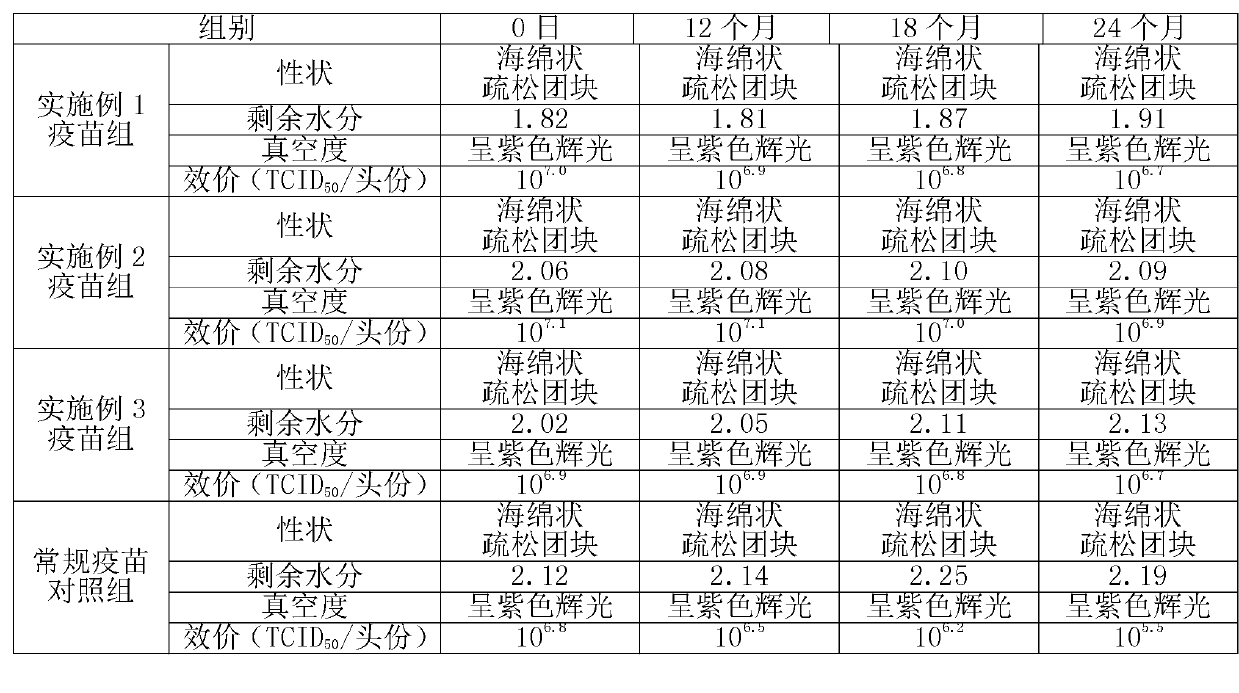

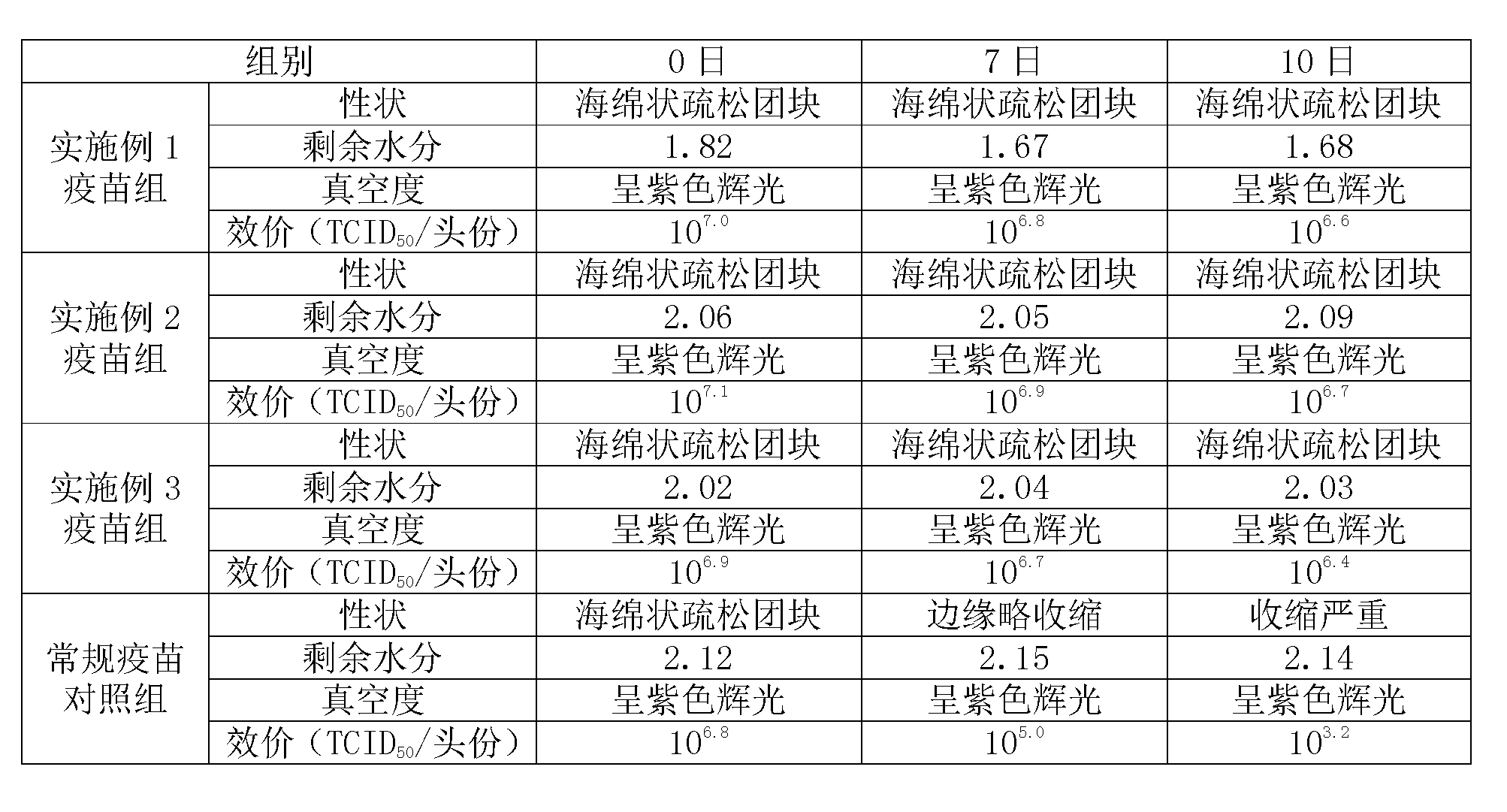

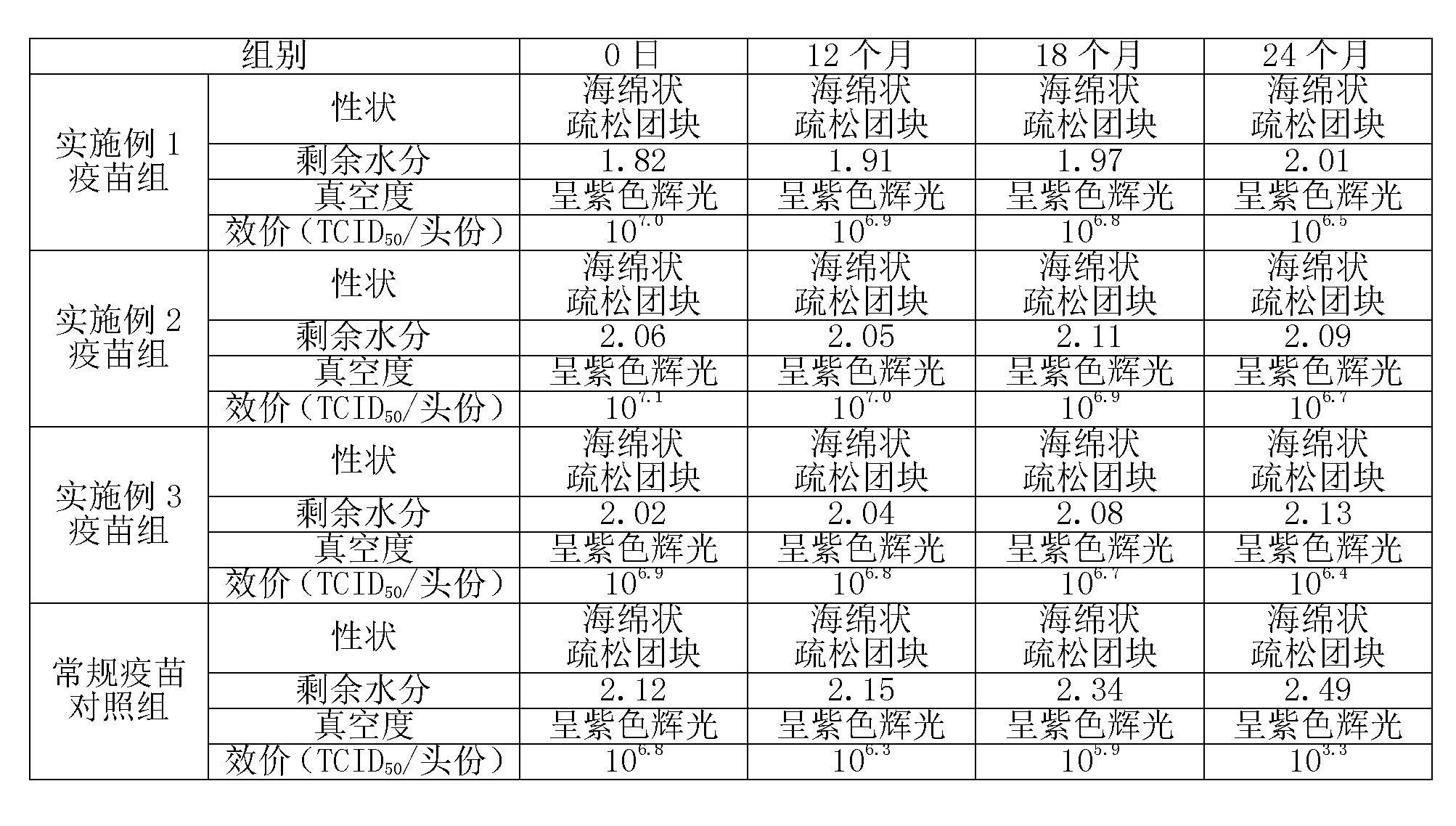

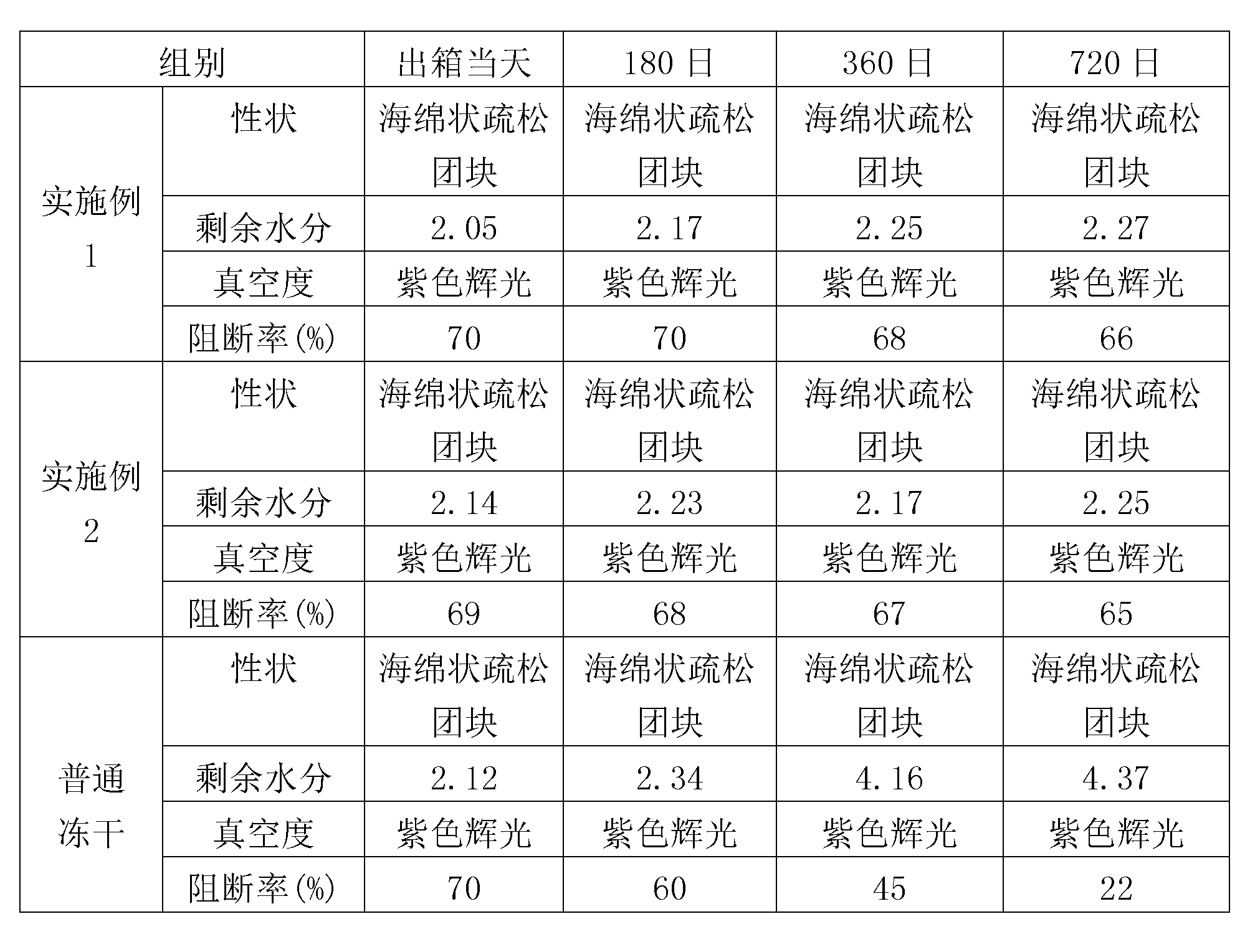

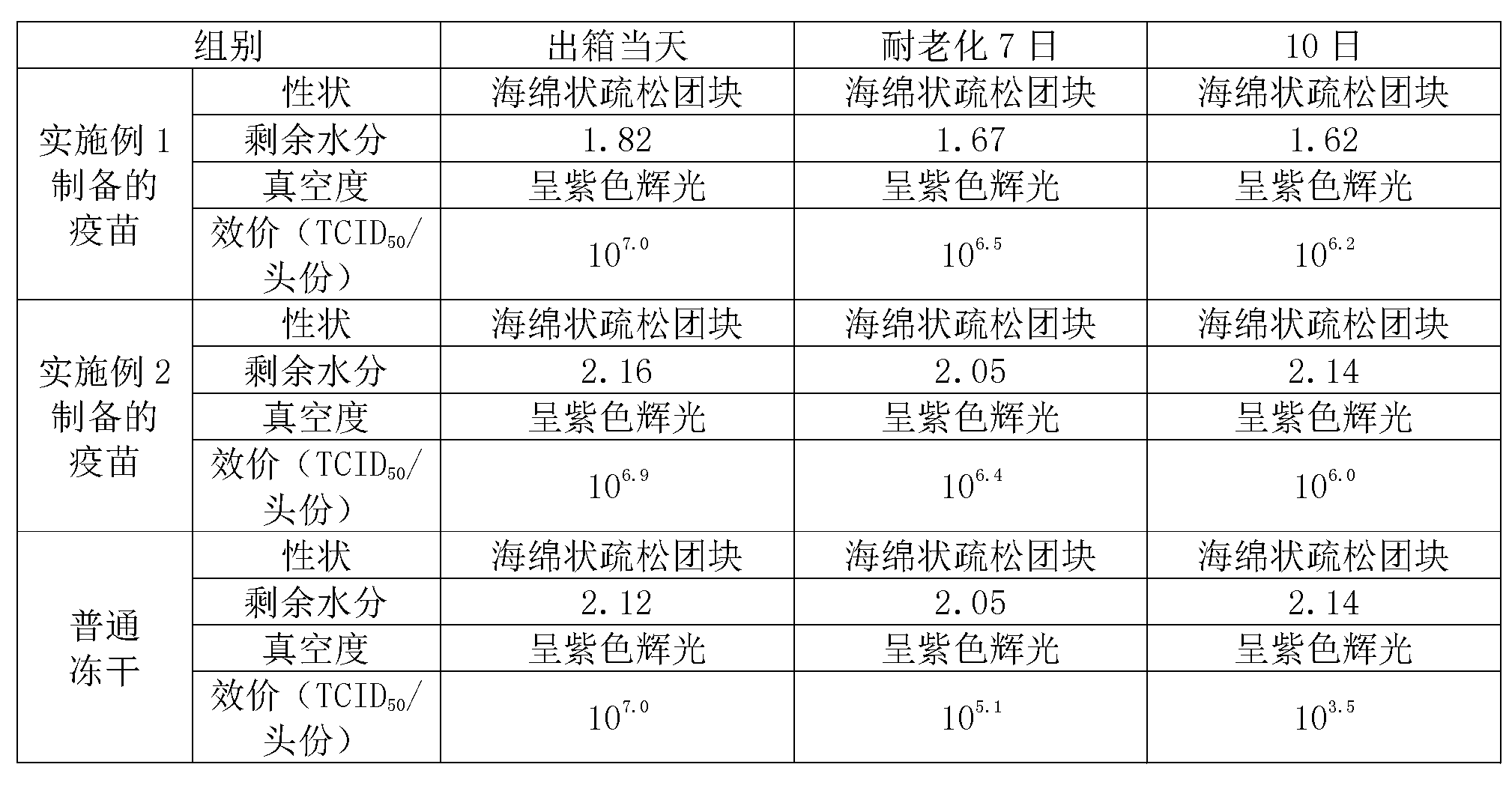

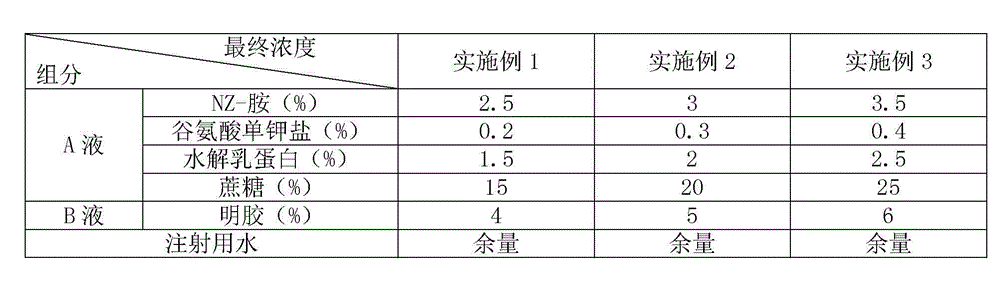

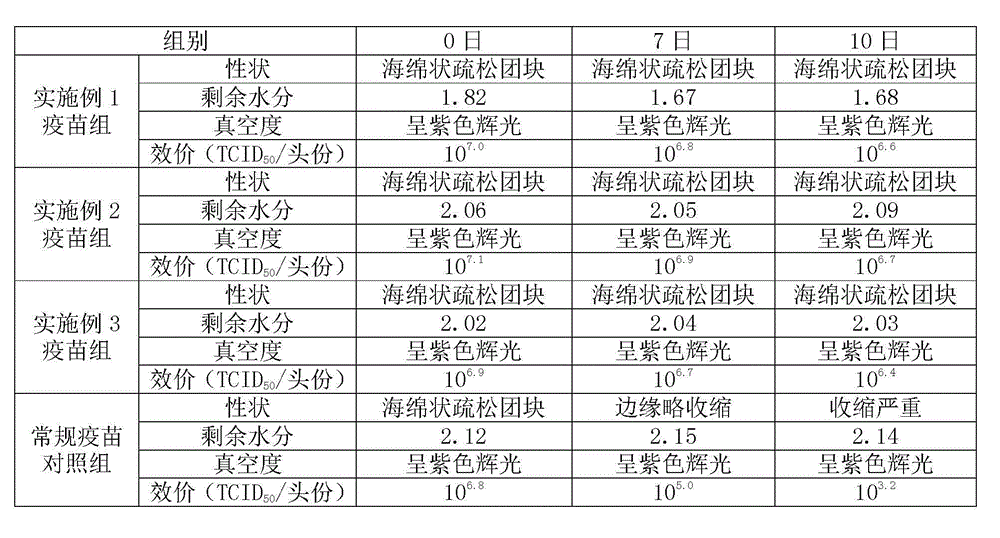

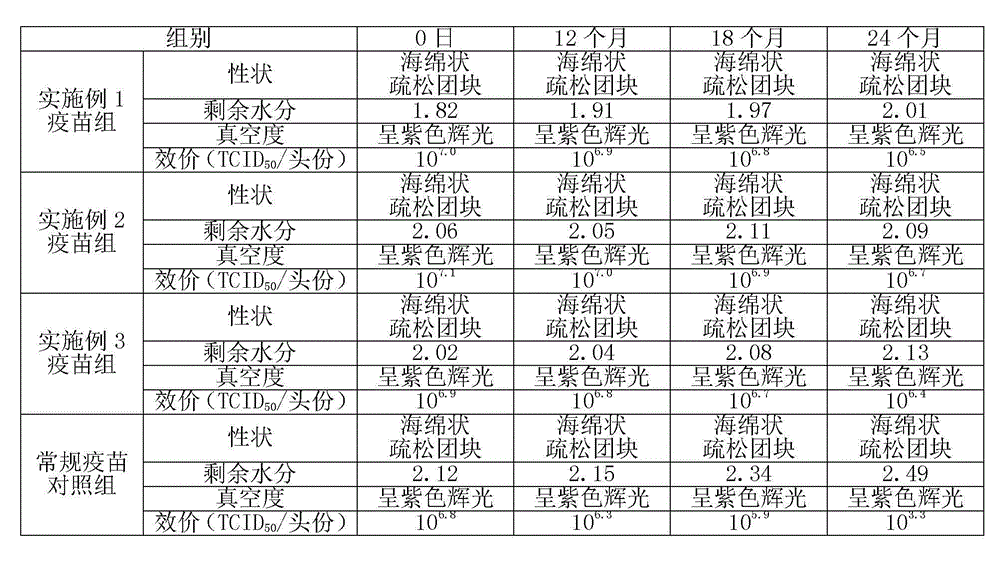

Freeze-drying protective agent for vaccines

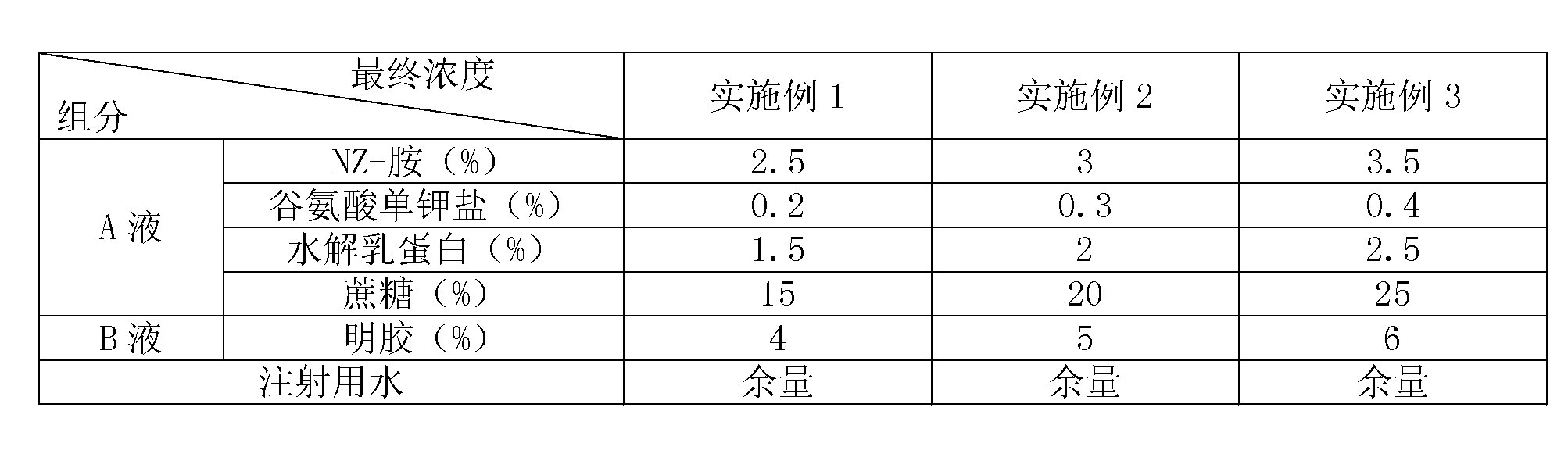

The invention relates to a freeze-drying protective agent which is composed of the following components in percentage by mass or volume: 2.4-4% of NZ-amine, 0.3-0.5% of monopotassium salt of glutamic acid, 20-25% of sucrose, 1.5-2.5% of hydrolyzed lactoprotein, 4-6% of hydrolyzed gelatin and the balance of water. The freeze-drying protective agent provided by the invention is low in raw material cost and simple to operate, and can implement large-scale production. After the vaccines are stored at 2-8 DEG C for 24 months, the titers of the vaccines are respectively greater than or equal to 105.7TCID50 / dose (Chinese Standard), thereby effectively prolonging the storage life of the vaccines.

Owner:YEBIO BIOENG OF QINGDAO

Shampoo containing folium artemisiae argyi and having anti-itch effect

InactiveCN105434232AImprove anti-dandruff and anti-itch effectRestoring the balance of the ecological environmentCosmetic preparationsHair cosmeticsGlycerolSalicylic acid

The invention discloses a shampoo containing folium artemisiae argyi and having an ant-itch effect. The shampoo comprises, by mass percentage, 10%-20% of traditional Chinese medicine extract liquor, 2%-5% of fatty alcohol polyoxyethylene ether sodium sulfate, 6%-8% of alkyl glycoside, 6%-8% of sodium cocoyl glutamate, 3%-5% of potassium myristoyl glutamate, 3%-5% of polydimethylsiloxane, 2%-5% of salicylic acid, 0.5%-1% of vitamin B5, 0.6%-1.2% of sodium citrate, 1%-3% of glycerinum, 0.5%-1.5% of essential oil and 37%-65% of deionized water. The traditional Chinese medicine extract liquor is extracted from the folium artemisiae argyi, bark of Chinese catalpa, oriental variegated coralbean bark, rhizoma curcumae longae, lemon grass and wild chrysanthemum. The shampoo belongs to the field of daily chemical products. The shampoo is suitable for the cleaning of human hair, good in anti-itch effect, free of irritation after skin irritation test and suitable for the use of all ages.

Owner:GUANGDONG GEECHING BIOMEDICAL TECH CO LTD

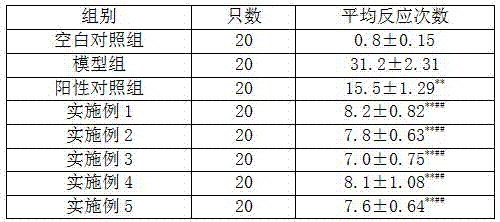

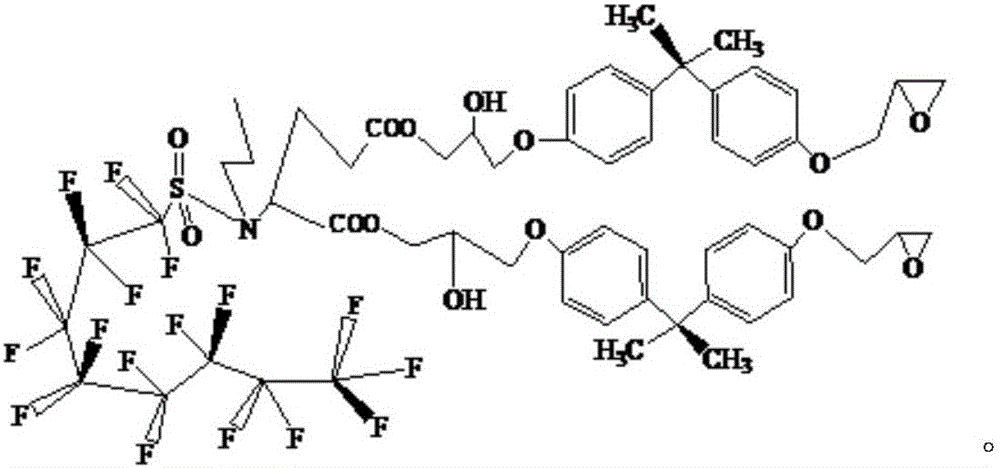

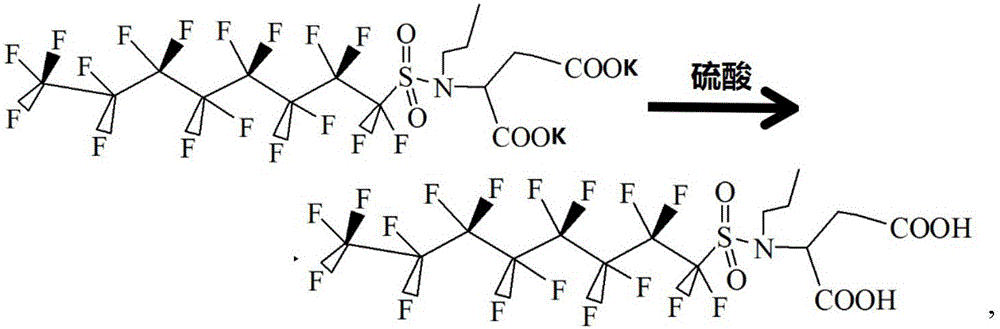

Fluorination bisphenol-type glycidyl ether and preparing method and application thereof

ActiveCN105801524AStrong adhesionImprove adhesionOrganic chemistryAnti-corrosive paintsWater bathsSodium bicarbonate

The invention discloses fluorination bisphenol-type glycidyl ether and a preparing method and application thereof. The preparing method of the fluorination bisphenol-type glycidyl ether includes the steps that N-propyl perfluor octyl sulfonyl ammonia potassium glutamate and bisphenol-A diglycidyl ether are taken to be added into ethyl alcohol, an ethanol sulfate solution of 10% and a catalyst are added, the mixture is subjected to water-bath heating to be at 55 DEG C-80 DEG C, sodium bicarbonate is added after the reaction is completed, pressure reducing and distillation are carried out to remove ethyl alcohol, and washing and drying are carried out. The fluorination bisphenol-type glycidyl ether is applied to a graphene coating which comprises 75-85 parts of first ingredients and 15-25 parts of curing agent, the first ingredients comprise 30.0-45.0 parts of bisphenol-A epoxy resin, 0.5-5.0 parts of graphene, 0.5-2.0 parts of epoxy siloxane coupling agent, 2.0-6.0 parts of reactive diluent, 5.0-10.0 parts of fluorination bisphenol-type glycidyl ether, 3.7-7.3 parts of assistant and 31.0-55.0 parts of pigment and filler. The coating is low in production cost and good in heat dispersion performance, brightness, abrasive resistance and chemical resistance.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

Efficient super-heavy oil demulsifier and preparation method thereof

InactiveCN106190229APromote demulsificationFast dehydrationDewatering/demulsification with chemical meansEpoxyPhosphate

The invention discloses an efficient super-heavy oil demulsifier and a preparation method thereof. The efficient super-heavy oil demulsifier comprises, by weight, 14-19 parts of C10-16-alkyl alcohol ethoxylate propoxylate, 12-17 parts of tetraethylenepentamine polypropylene oxide polyoxyethylene ether, 7-13 parts of nonoxynol-10 phosphate, 5-10 parts of emulsifier OP-4, 6-12 parts of ethylene oxide-epoxy propane segmented copolymer, 4-8 parts of sorbeth hexalaurate, 3-6 parts of ammonium polyacryloyldimethyl taurate, 5-9 parts of sodium lauryl diphenyl ether disulfonate and 4-7 parts of N-propyl-perfluorooctane sulfonamide potassium glutamate. The raw materials such as C10-16-alkyl alcohol ethoxylate propoxylate, tetraethylenepentamine polypropylene oxide polyoxyethylene ether and ethylene oxide-epoxy propane segmented copolymer are added in the demulsifier, so that the demulsifier has the advantages of good demulsifying performance, high dehydration rate, low dehydration temperature and the like, and is wide in application range and promising market prospect.

Owner:安徽炎胜新材料科技有限公司

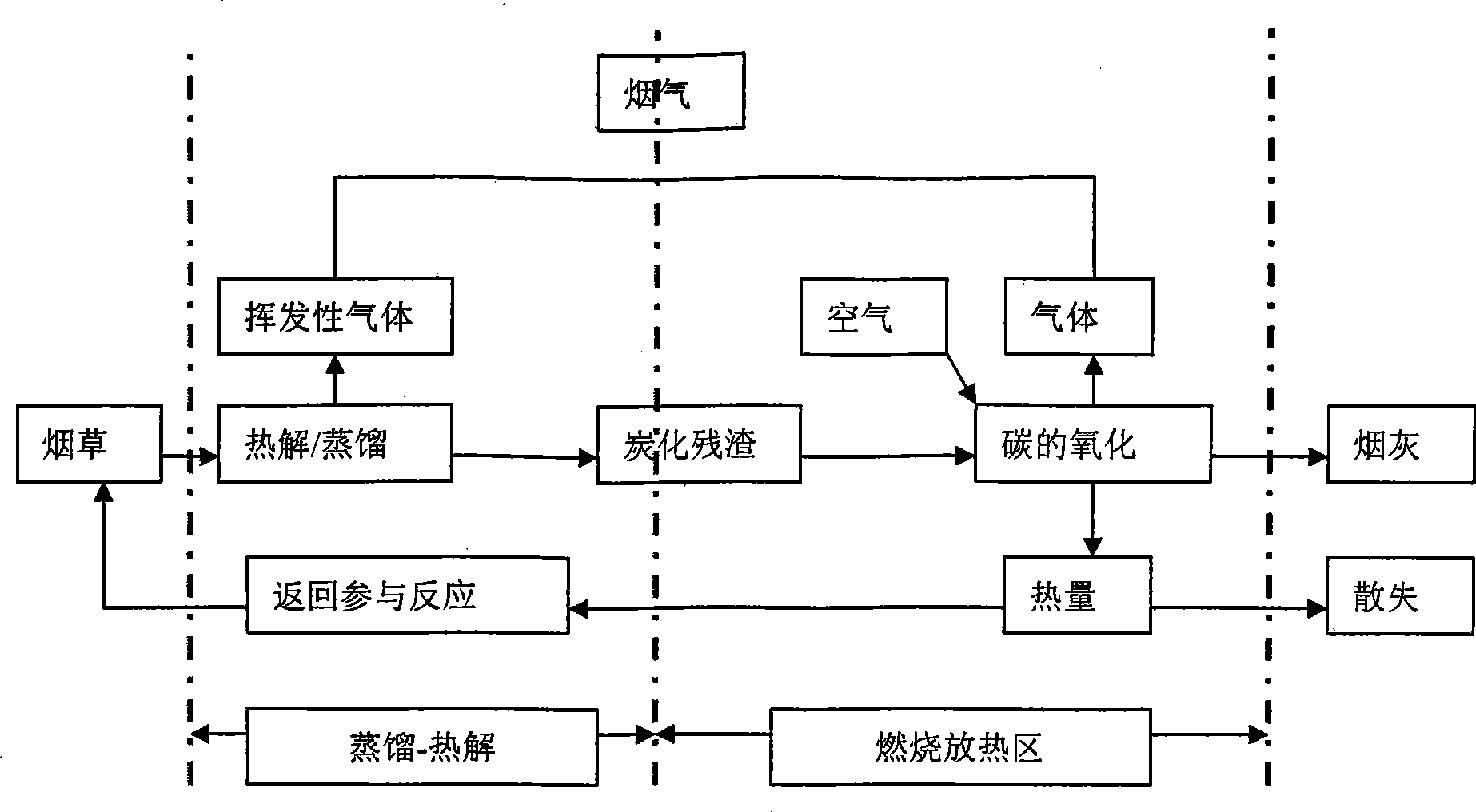

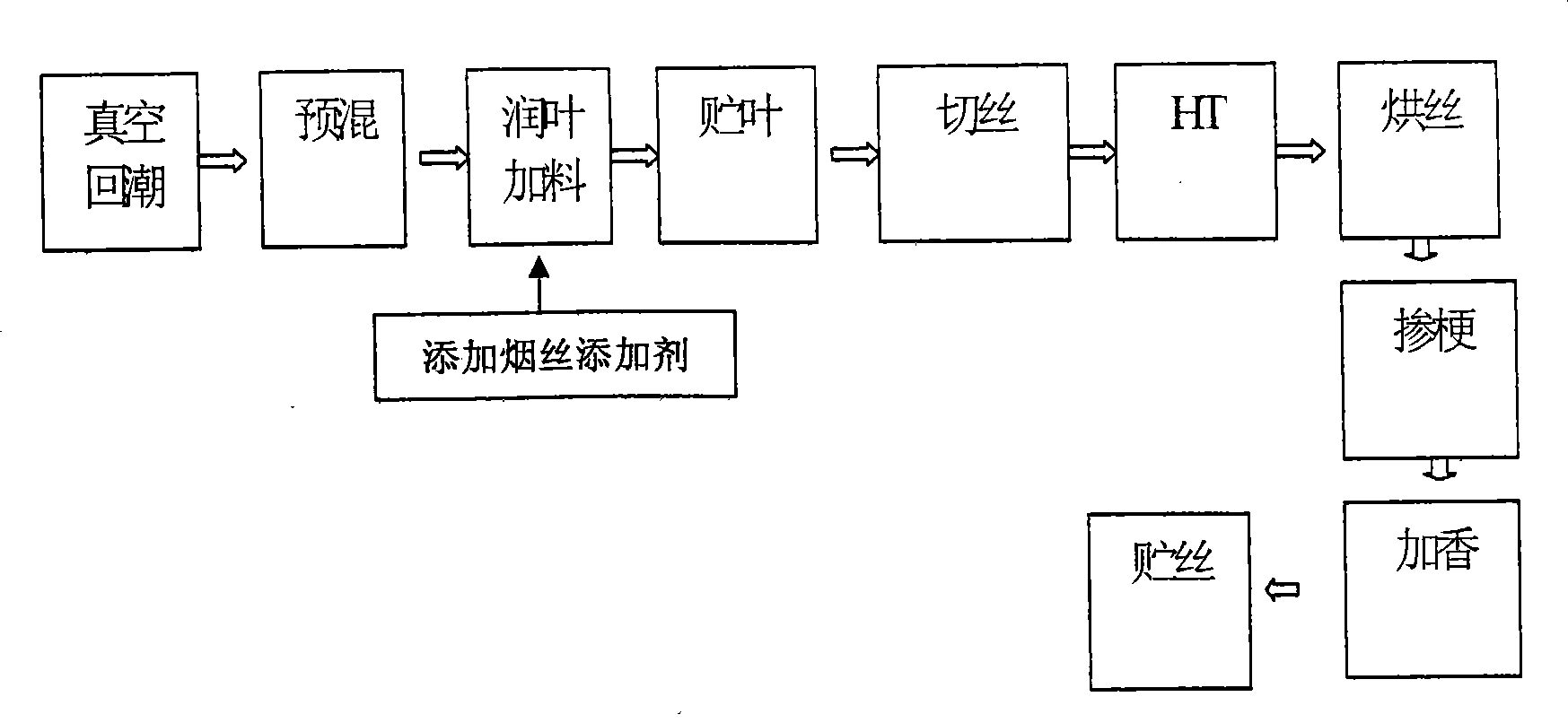

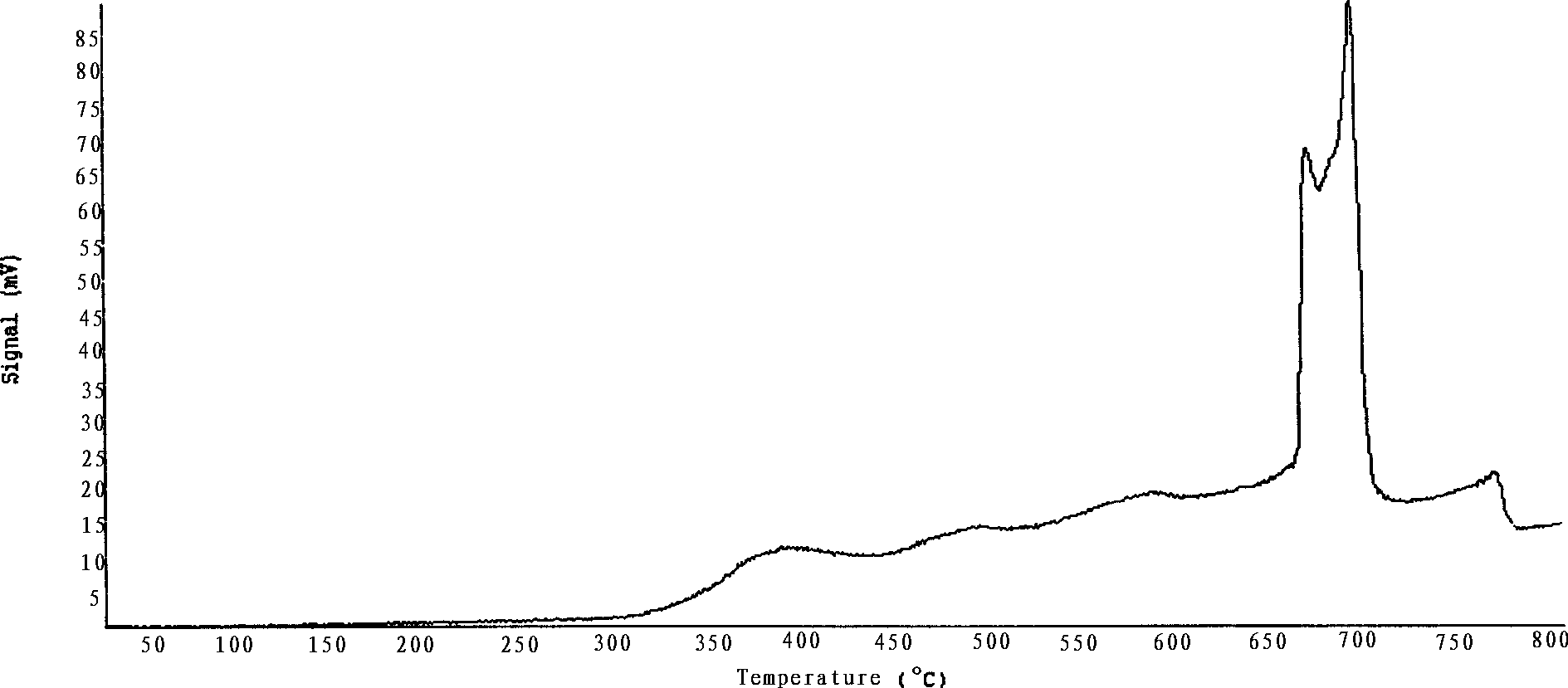

Tobacco shred additive capable of reducing carbon monoxide in cigarette fume

InactiveCN101416779ARaise the combustion temperatureReduce delivery volumeTobacco preparationTobacco treatmentHYDROSOLSodium sulfate

The invention discloses a cut tobacco additive which can reduce the CO in the smoke gas. The additive is colloid water solution and comprises the components with the weight percentage as follows: 90 to 100 percent of organic sodium stannate kalium; 0 to 8.5 percent of cerous hydroxide as well as 0 to 1.5 percent of crystalline hydrate; wherein, the organic sodium stannate kalium is selected from one or two mixtures of sodium glutamate, potassium glutamate, sodium citrate and potassium citrate; the crystalline hydrate is selected from one of aluminum potassium sulfate dodecahydrate or hydrate sodium sulfate. The preparation method is as follows: 5 portions of CeO2 nano-hydrosol is prepared at first; then 60 portions of organic acid salt water solution with a content of 50 percent are added into one portion of the crystalline hydrate with a weight percentage of 30 percent and uniformly mixed and stirred for 30 minutes, thus obtaining the needed product. The product can effectively reduce the feed amount of the CO in a sample cigarette; for different test brands, the range by which CO is reduced is between 8.15 to 11.49 percent.

Owner:YUNNAN RES INST OF TOBACCO SCI

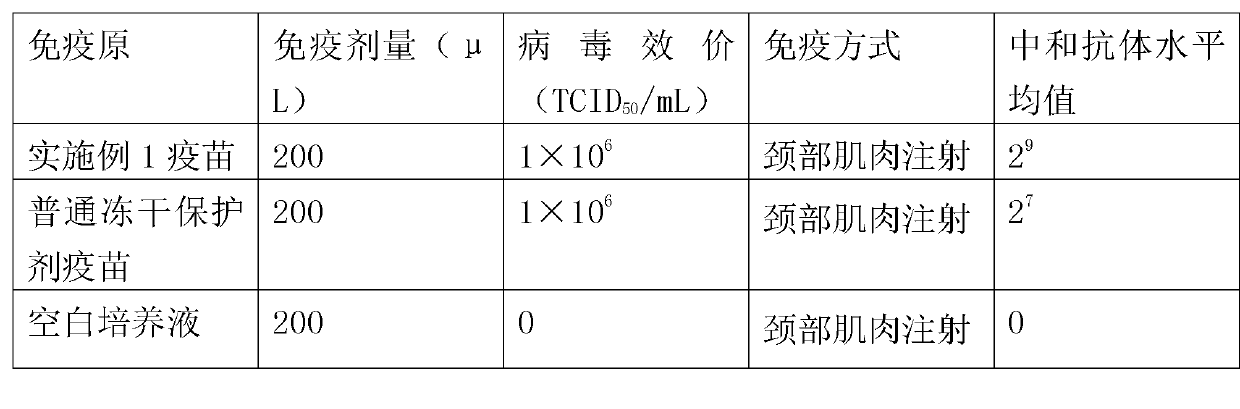

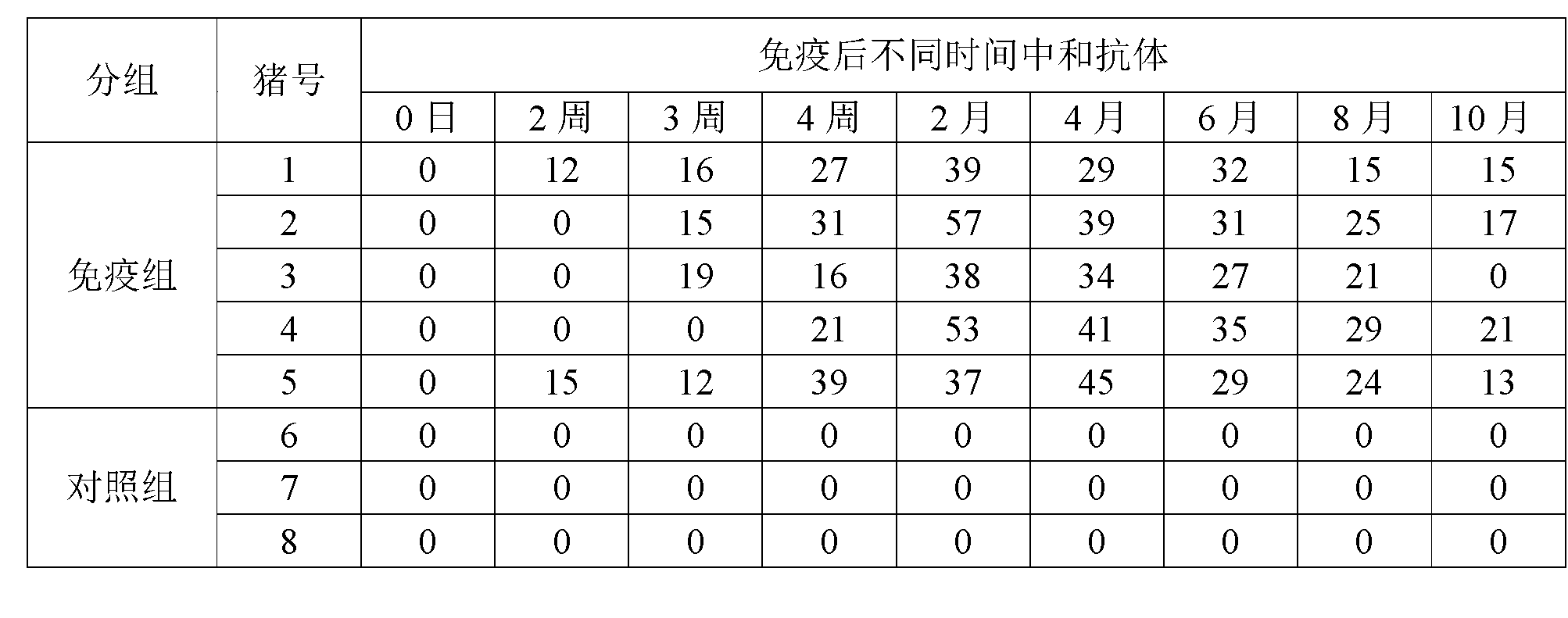

Lyophilized vaccine for swine encephalitis B and preparation method thereof

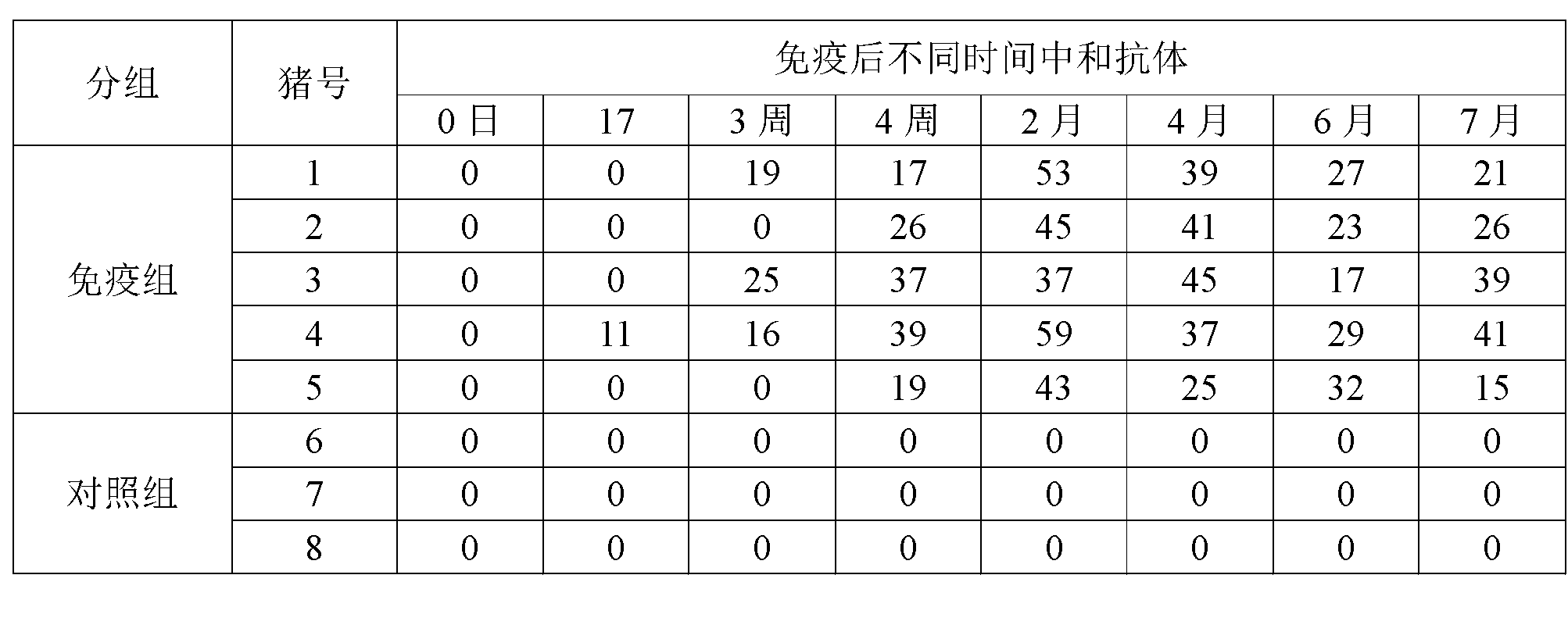

ActiveCN103301452AAvoid damageReduce titer lossViral antigen ingredientsAntiviralsProtective antigenAntigen

The invention relates to a lyophilized vaccine for swine encephalitis B. The lyophilized vaccine consists of Japanese encephalitis virus serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the potency of the vaccine is not smaller than 10<5.7>TCID50 / head (Chinese Standard), so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

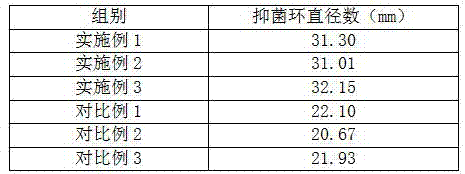

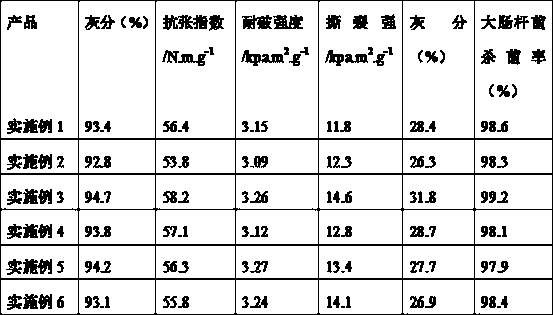

Surface treatment method for antibacterial calcium carbonate special for papermaking

ActiveCN108516572AGood dispersionGood hydrophilic and lipophilicCalcium/strontium/barium carbonatesInorganic compound additionDispersityPapermaking

The invention discloses a surface treatment method for antibacterial calcium carbonate special for papermaking. The surface treatment method includes the steps that limestone is added into a smashingmachine, smashing is carried out, and calcium-carbonate coarse powder is obtained; the calcium-carbonate coarse powder is added into a grinding machine, first modifying agent is added, grinding is carried out, and calcium-carbonate fine powder is obtained; the calcium-carbonate fine powder is delivered to a high-speed stirring machine, second modifying agent is added, the mixture is stirred at high speed and mixed to be even, drying is carried out, and modified calcium carbonate for papermaking is obtained, wherein the first modifying agent is prepared from nonylphenol polyoxyethylene ether phosphomonoester sodium salt and octakis(trimethylsiloxy)silsesquioxane; the second modifying agent is prepared from sapindus-saponin, chitosan and N-propyl-perfluor octyl sulfamide potassium glutamate.The calcium carbonate obtained through surface modification has good dispersity, hydrophilic oleophylic performance, thixotropy, processing fluidity and bonding adhesive force, and also has good antibacterial bacteriostasis effect, ageing resistance and yellowing resistance, and the antibacterial calcium carbonate can serves as an excellent papermaking filler.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Freeze-dried vaccine of porcine transmissible gastroenteritis

The invention relates to a freeze-dried vaccine of porcine transmissible gastroenteritis. The vaccine comprises a porcine transmissible gastroenteritis virus serving as an antigen and a protective agent, wherein the protective agent comprises the following substances in percent concentration by mass: 2.4-4% of NZ-amine, 0.3-0.5% of monopotassium glutamate, 16-20% of sucrose, 6-20% of lactalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. A freeze-drying protective agent used in the vaccine disclosed by the invention is low in raw material cost and simple to operate and can be produced on a large scale. The titer of the vaccine prepared by adopting the protective agent is greater than or equal to 105.7TCID50 (Tissue Culture Infectious Dose 50) / dose (national standard) after the vaccine is preserved for 24 months at 2-8 DEG C, so that the storage life of the vaccine is effectively prolonged.

Owner:YEBIO BIOENG OF QINGDAO

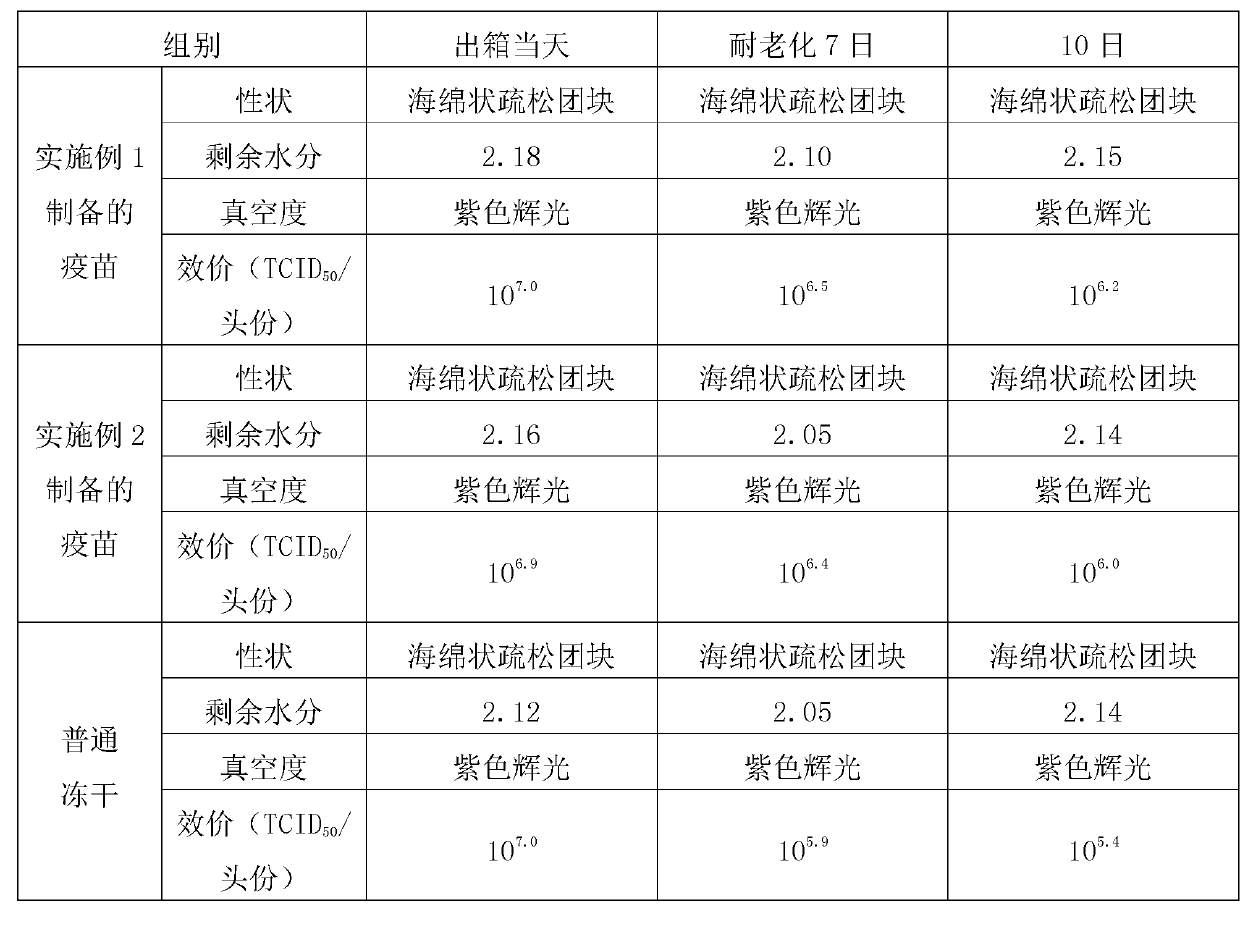

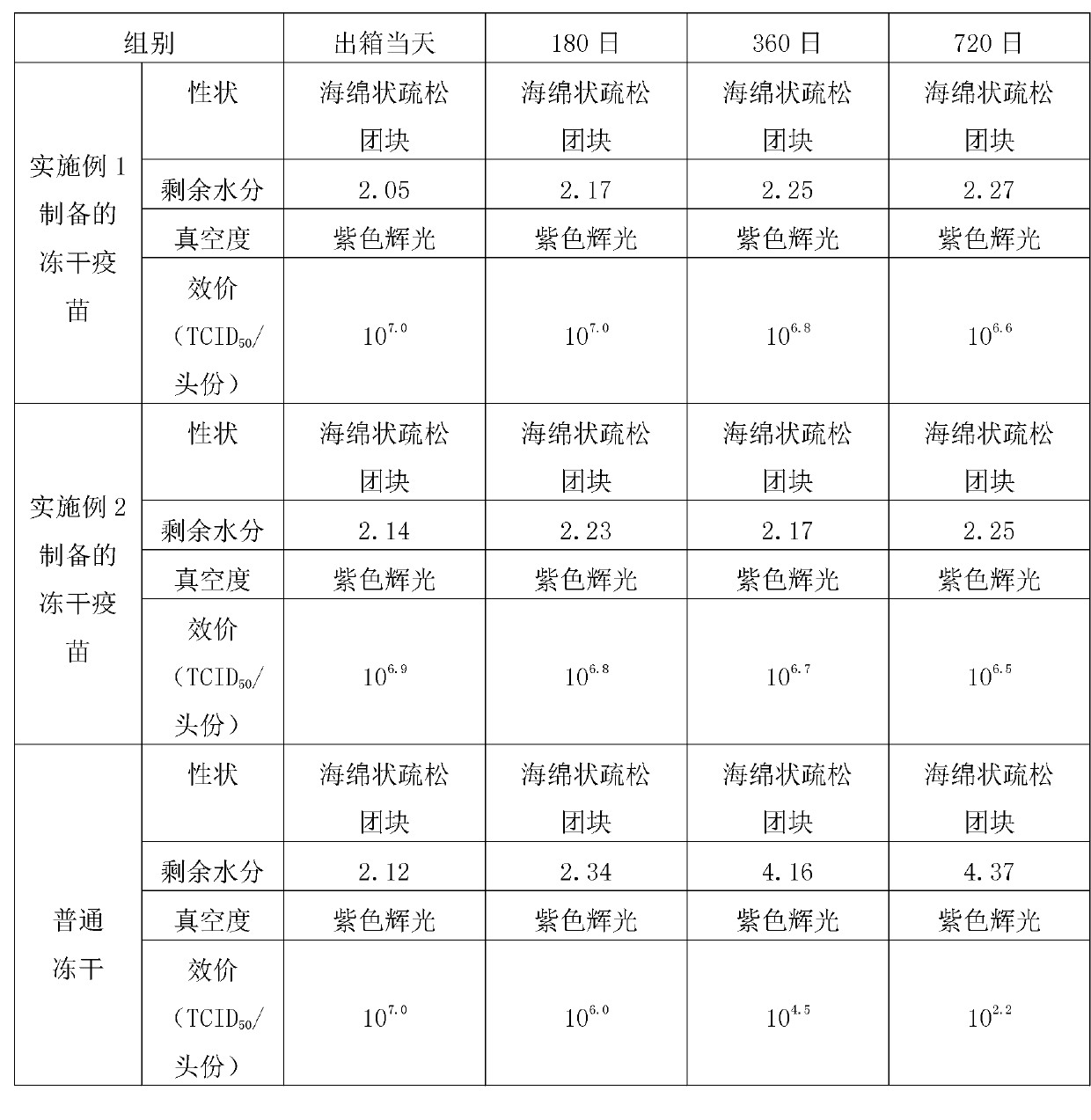

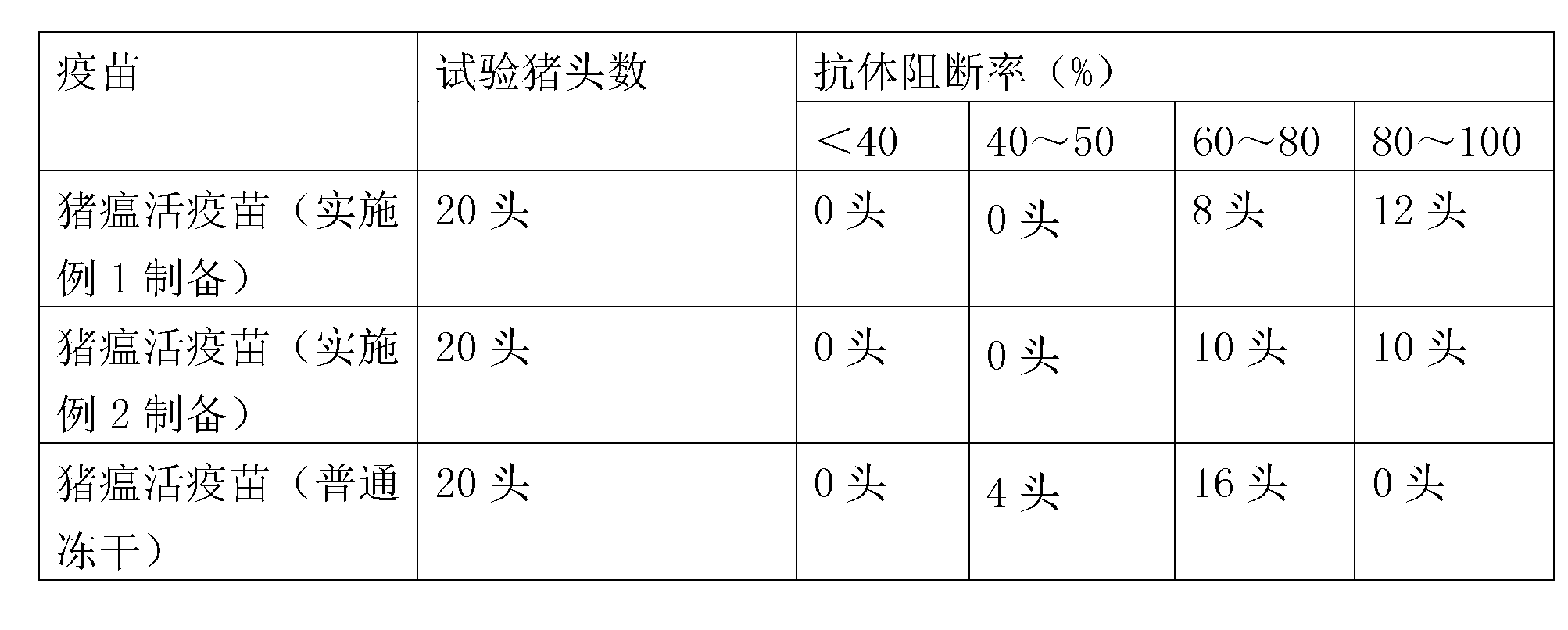

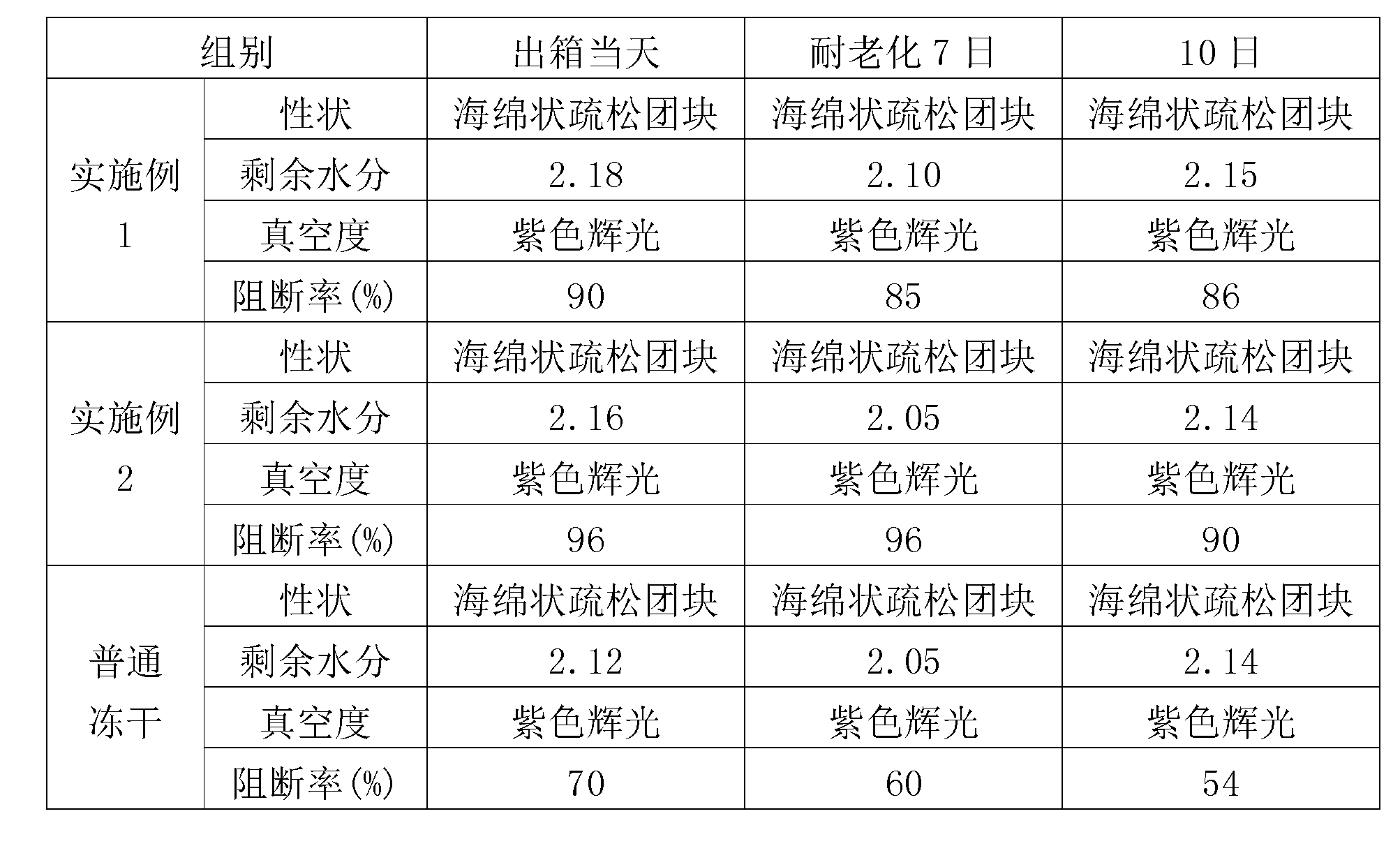

Lyophilized vaccine for classical swine fever

InactiveCN103301454AExtended shelf lifeLow costAntiviralsAntibody medical ingredientsAntigenProtective antigen

The invention relates to a lyophilized vaccine for classical swine fever. The lyophilized vaccine consists of classical swine fever virus serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the protective rate of the vaccine can still reach over 90%, so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

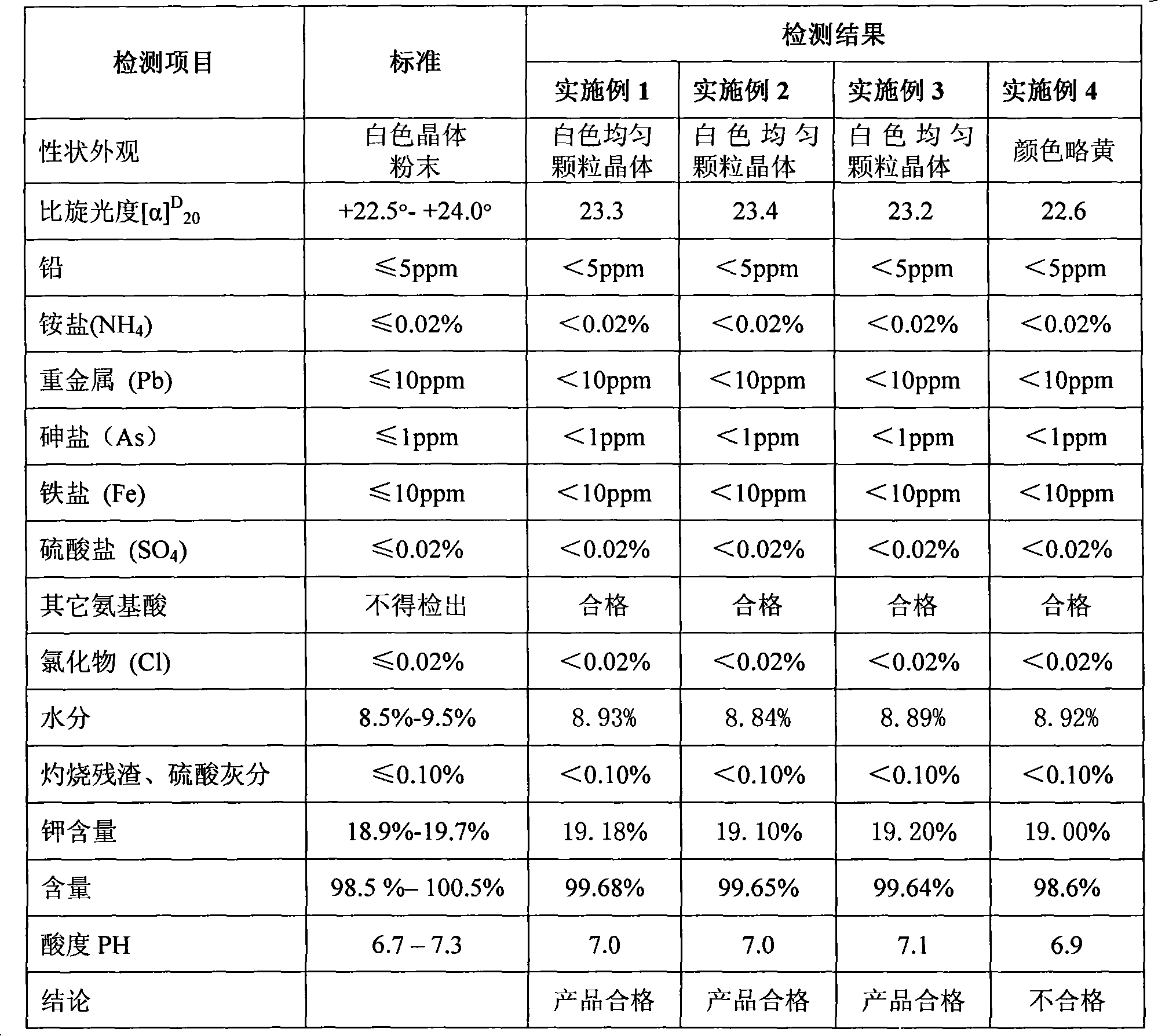

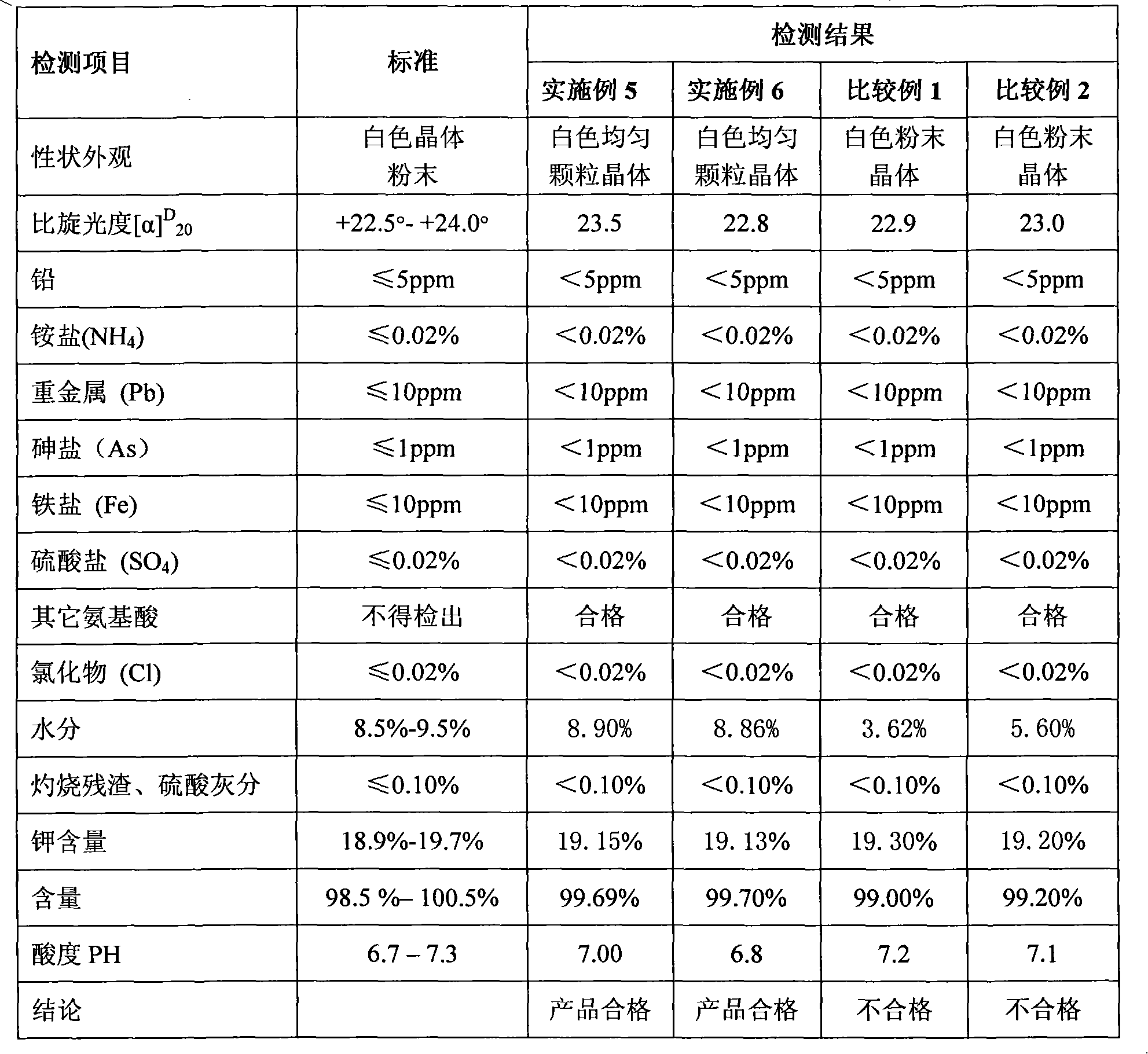

Method for separation and purification of L-potassium glutamate monohydrate

InactiveCN101863789ALarge and uniform particle sizeMoisture stableOrganic compound preparationAmino-carboxyl compound preparationActivated carbonPotassium carbonate

The invention belongs to the chemical field, and discloses a method for separation and purification of L-potassium glutamate monohydrate, which comprises the following specific steps: filling deionized water into a reactor, heating, adding L-glutamic acid and potassium carbonate, correcting the PH value after clarification of reaction solution, adding a proper amount of activated carbon for decolorization, filtering, concentrating to a certain concentration, adding a certain amount of L-potassium glutamate as a seed crystal into the reaction solution, and inducing the L-potassium glutamate in the reaction solution for crystallization, thereby forming an L-potassium glutamate monohydrate crystal. The L-potassium glutamate monohydrate crystal obtained in the method has the advantages of large and uniform particle size and stable water contents in each batch of products. Moreover, the invention can greatly reduce the cost, lower the energy consumption, increase the yield, improve the production environment, and reduce the pollution.

Owner:宜兴市前成生物有限公司

Composite seasoning capable of realizing calcium supplement

InactiveCN103598558AChange the tasteImprove freshnessFood preparationAdditive ingredientSodium Glutamate

The invention belongs to the field of food, and specifically relates to a composite seasoning capable of realizing calcium supplement. The composite seasoning comprises following ingredients, by weight, chicken meal, sodium chloride, potassium glutamate, chilli powder, sodium glutamate, foeniculum vulgare, cinnamon, pepper, shrimp shell meal, bovine bone power, potherb mustard, pseudosciaena polyactis powder, ginger powder, and green Chinese onion powder. The ingredients such as shrimp shell meal, bovine bone power, potherb mustard and pseudosciaena polyactis powder are added into the composite seasoning so as to change taste of the composite seasoning, increase freshness of the composite seasoning, and increase calcium content; calcium supplement is realized by dining; and side effect is not caused.

Owner:ANHUI QIANGWANG FLAVORING FOOD

Formula of non-sodium salt with good salty feature

InactiveCN104026551AGood salty propertiesEliminate bitternessFood preparationSodium inosinatePotassium Glutamate

The invention discloses a formula of non-sodium salt with a good salty feature. The non-sodium salt comprises the following components in parts by weight: 94 to 96.85 parts of potassium chloride, 1.0 to 1.1 parts of calcium phosphate, 0.8 to 3.1 parts of sodium glutamate, 0.05 to 0.3 part of one or a mixture of more of liquiritin, licorice glycosides sodium, licorice glycosides disodium and stevioside, 0.5 to 1.6 parts of one or a mixture of more of malic acid, citrate and succinate, 0.2 to 1.05 parts of one or a mixture of more of sodium inosinate and disodium guanylate. The non-sodium salt disclosed by the invention has a good salty feature; the bitter taste and the chemical state of substitutes, such as potassium chloride, magnesium chloride and magnesium sulfate, in the prior art are eliminated; the flavor enhancing effect is obviously higher than that of potassium glutamate.

Owner:潘井生

Blood-lipid lowering low-sodium salted egg curing solution

The invention discloses a blood-lipid lowering low-sodium salted egg curing solution, which comprises the following raw materials by weight: 1-5 parts of potassium chloride, 3-15 parts of sodium chloride, 0.5-1.5 parts of potassium glutamate, 1.5-3.5 parts of sorbic acid, 2-4 parts of xylitol, 2-6 parts of cinnamon, 1-4 parts of star anise, 3-5 parts of Chinese prickly ash, 1-4 parts of clove, 2-5 parts of glucose, 3-5 parts of water soluble vitamin, 4-8 parts of a Chinese herbal additive, and 5-15 parts of 38-degree Baijiu. The salted egg curing solution provided by the invention has low sodium content, and has the efficacy of lowering blood lipid.

Owner:SUSONG XIANGYUAN POULTRY TRADE

Medicament for rapidly dredging collaterals and eliminating stasis and preparation method thereof

InactiveCN102178846AOrganic active ingredientsPharmaceutical delivery mechanismPercent sodium chlorideVitamin B12

The invention discloses a medicament for rapidly dredging collaterals and eliminating stasis and a preparation method thereof. Three groups of medicaments are prepared by mixing the following raw materials in parts by weight: the first group of medicament comprises the following raw materials in parts by weight: 100-130 parts of 5 weight percent glucose solution, 100-130 parts of 0.9 weight percent sodium chloride solution, 4.5-5.5 parts of arginine hydrochloride, 5.5-6.0 parts of sodium glutamate, 3.0-4.0 parts of potassium glutamate, 1.0-1.5 parts of magnesium sulfate, 0.015-0.025 part of disodium adenosine triphosphate and coenzyme A, wherein the coenzyme A and the 5 weight percent glucose solution are added according to a proportion of 0.8-1.2 unit / g. The second group of medicament comprises the following raw materials in parts by weight: 210-250 parts of 0.9 weight percent glucose solution, 0.015-0.025 part of disodium adenosine triphosphate, 1.0-1.5 parts of magnesium sulfate, 0.07-0.1 part of Chuanxiongqin injection, 35-45 parts of astragalus injection, 0.04-0.055 part of vitamin B6, 0.0018-0.0022 part of vitamin B12 and coenzyme A, wherein the coenzyme A and the 5 weight percent glucose solution are added according to a proportion of 0.4-0.6 unit / g; and the third group of medicament comprises the following raw materials in parts by weight: 210-250 parts of 0.9 weight percent glucose solution and 35-45 parts of Mailuoning. The medicament is suitable for symptoms of various kinds of cardiovascular and cerebrovascular thrombus congestion.

Owner:李英

Lyophilized vaccine for porcine rotavirus (PRV)

ActiveCN103301471AExtended shelf lifeLow costViral antigen ingredientsDigestive systemAntigenSaccharum

The invention relates to a lyophilized vaccine for porcine rotavirus (PRV). The lyophilized vaccine consists of the PRV serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the potency of the vaccine is not smaller than 10<5.7>TCID50 / head (Chinese Standard), so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

Oral liquor composition with reduced bitter taste

InactiveCN1222316CReduce bitternessGood sense of useOrganic active ingredientsPharmaceutical non-active ingredientsMethacrylateL-Glutamin

The present invention relates to a bitterness-abated oral preparation composition formed by adding aminoalkyl methyl acrylate copolymer and / or glutamic acid compound in egg propadiene sodium. Said aminoalkyl methyl acrylate copolymer, optimum, is aminoalkyl methyl acrylate copolymer E and / or aminoalkyl methyl acrylate copolymer RS, and the glutamic acid compound optimally uses at least one of L-glutamine, L-sodium glutamate and L-potassium glutamate. It can greatly abate bitterness, and can be obtain egg propadient sodium oral preparation composition with good taking sense.

Owner:KOTOBUKI PHARMA CO LTD

Lyophilized vaccine for swine encephalitis B and preparation method thereof

ActiveCN103301452BAvoid damageReduce titer lossViral antigen ingredientsAntiviralsProtective antigenAntigen

The invention relates to a lyophilized vaccine for swine encephalitis B. The lyophilized vaccine consists of Japanese encephalitis virus serving as an antigen, and a protective agent, wherein the protective agent is prepared from the following substances in percentage by mass: 2.4-4% of NZ-amine, 0.3-0.5% of mono-potassium glutamate, 16-20% of sucrose, 6-20% of lactoalbumin hydrolysate, 1-1.6% of gelatin and the balance of water. According to the vaccine disclosed by the invention, the used lyophilized protective agent is made from raw materials which are low in cost, and the operation is simple, so that the vaccine can be produced in a large scale. After the vaccine prepared from the protective agent is stored for 24 months at the temperature of 2-8 DEG C, the potency of the vaccine is not smaller than 10<5.7>TCID50 / head (Chinese Standard), so that the storage life of the vaccine is prolonged effectively.

Owner:YEBIO BIOENG OF QINGDAO

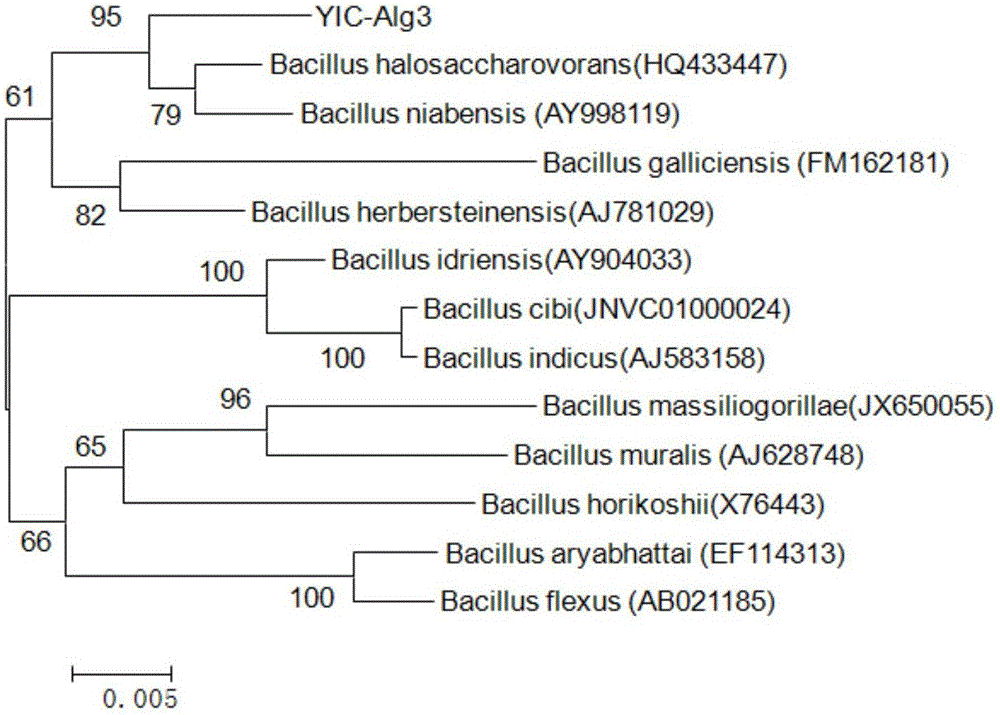

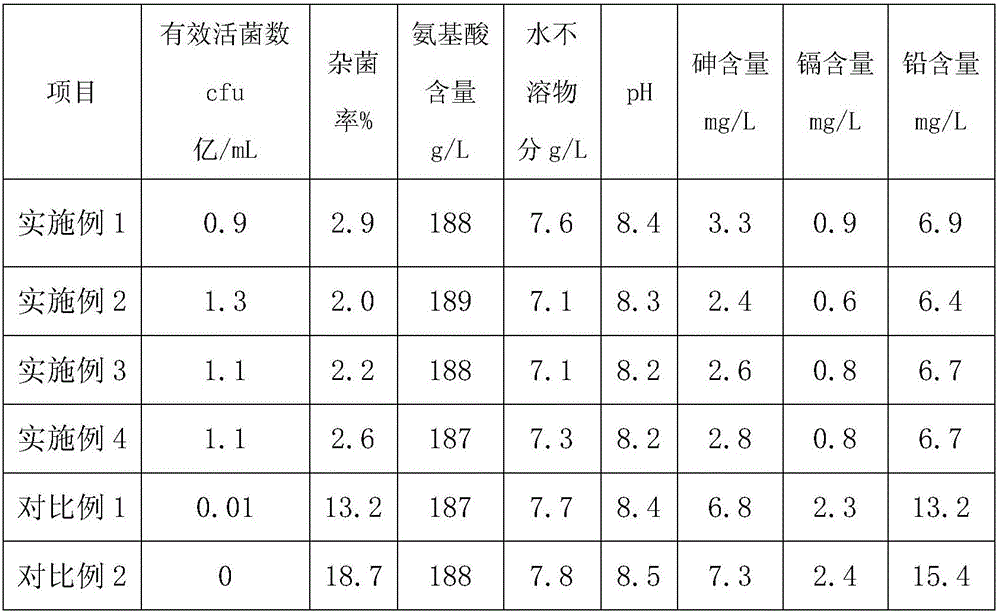

Production method of liquid water-soluble fertilizer containing saccharophilia bacillus agent and amino acid

InactiveCN106220416AIncrease productionPromote growthBio-organic fraction processingBacteriaLiquid mediumLiquid water

The invention relates to a production method of a liquid water-soluble fertilizer containing a saccharophilia bacillus agent and amino acid. The method comprises: grinding dried seaweed into powder, adding the seaweed powder into water according to a certain ratio, putting the obtained product in a fermentation tank, and performing sterilization at a certain temperature for certain time; preparing a seed solution, which includes performing screening to obtain YIC-ALG3 saccharophilia bacillus as a fermentation strain for degrading alginic acid, inoculating a liquid medium with the YIC-ALG3 saccharophilia bacillus and performing cultivation for certain time; adding the seed solution into the fermentation tank according to a certain mass ratio; performing fermentation at a certain condition; adjusting the fermentation condition after the fermentation and performing preservation for certain time; adjusting the fermentation condition again and performing replenishment with the seed solution; performing filter pressing after the adjustment is carried out for three times to obtain a saccharophilia bacillus filtrate; and adding water, the saccharophilia bacillus filtrate and potassium glutamate in a stirring tank, and performing stirring till the mixture is completely dissolved to obtain the liquid water-soluble fertilizer containing a saccharophilia bacillus agent and amino acid. The method is stable and controllable in fermentation process, short in fermentation period, and obvious in product effect, and is suitable for large-scale production.

Owner:WUZHOUFENG AGRI SCI & TECH

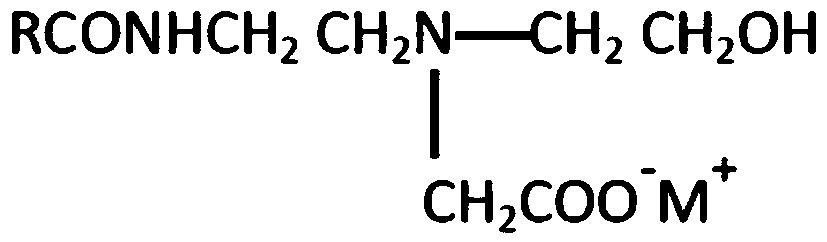

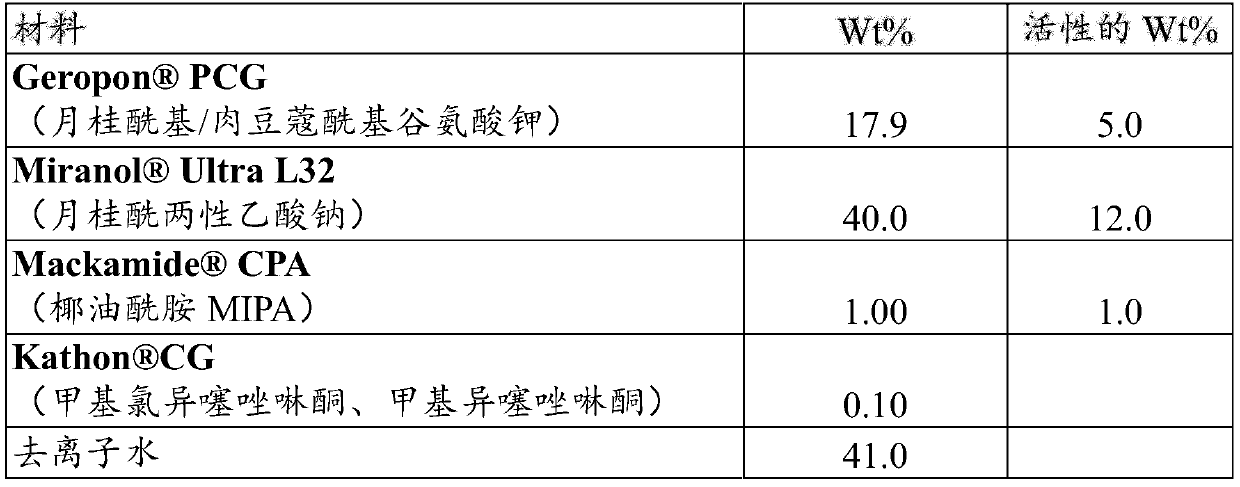

Sulfate-free formulations

ActiveCN110300572ADoes not affect sensory characteristicsCosmetic preparationsNon-ionic surface-active compoundsMonosodium glutamatePersonal care

An aqueous personal care composition comprising: one or more amphoacetates; one or more glutamate surfactants selected from sodium lauroyl glutamate, dipotassium cocoyl glutamate, potassium lauryl / myristoyl glutamate and combinations thereof; and cocamide MIPA; wherein the composition is free of sulfates and ethoxylates.

Owner:RHODIA OPERATIONS SAS

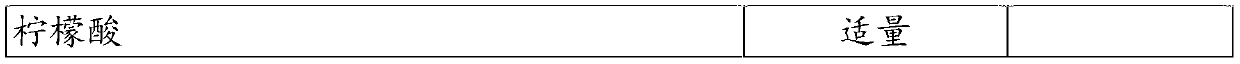

Hepatic cell culture medium having ammonia reducing capacity and application of hepatic cell culture medium

InactiveCN105524876ASolve the problem of generating large amounts of ammoniaReduce ammonia productionCulture processArtificial cell constructsArginineCell culture media

The invention discloses a hepatic cell culture medium having ammonia reducing capacity and application of the hepatic cell culture medium. The culture medium, on the basis of an RPMI 1640 liquid culture medium, is added with one or more of a hepatic cell growth factor, L-ornithine-alpha-ketoglutarate, sodium glutamate, potassium glutamate, arginine, insulin and an antioxidant, so that the problem that a great amount of ammonia is generated in the culture process of L-02 cells is solved and the ammonia output generated from the culture process of the L-02 cells is reduced; the obtained cell culture medium is capable of continuously reducing ammonia, and the culture medium is capable of enhancing the activity and the function of the L-02 cells and regulating the proliferation and the movement of the L-02 cells, so that the large-scale industrial production of the L-02 cells is achieved. In addition, the culture medium is simple in preparation method, easily available in raw material and is relatively strong in practicability.

Owner:WUHAN TOGO MEDITECH CO LTD

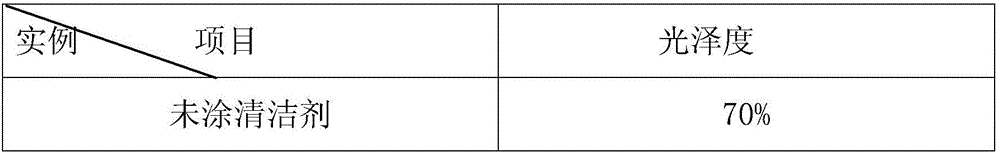

Improved commemorative coin solid detergent

InactiveCN106675854AEfficient removalPrevent oxidationDetergent compounding agentsOrganic non-surface-active detergent compositionsCarboxymethyl cellulosePolyethylene glycol

The invention discloses an improved commemorative coin solid detergent which is prepared from the following components in parts by weight: 10-20 parts of calcium carbonate powder, 5-10 parts of kieselguhr, 5-10 parts of smectite powder, 15-20 parts of pumice powder, 6-15 parts of zeolite powder, 5-10 parts of talcum powder, 10-15 parts of aluminum hydroxide, 10-20 parts of silicon dioxide, 3-8 parts of sodium benzoate, 5-10 parts of polyethylene glycol, 5-10 parts of glycerin, 3-5 parts of sorbitol, 3-5 parts of N-acyl potassium glutamate, 5-10 parts of carboxymethyl cellulose and 7-15 parts of sodium alginate. Compared with the prior art, the improved commemorative coin solid detergent has the significant characteristics that dirt on the surface of a commemorative coin can be effectively eliminated, the commemorative coin is prevented from being further oxidized, the glossiness of the surface of the commemorative coin is kept, and the preparation technology is simple and low in cost.

Owner:佛山慧创正元新材料科技有限公司

Seasoning with calcium supplement function

The invention belongs to the field of foods, and particularly relates to seasoning with a calcium supplement function. The seasoning with the calcium supplement function comprises the components, by weight: 20-30 parts of chicken powder, 5-10 parts of salt, 10-15 parts of potassium glutamate, 1-3 parts of chill powder, 5-10 parts of sodium glutamate, 1-3 parts of fennel, 1-3 parts of cassia, 1-2 parts of Chinese prickly ash, 6-15 parts of shrimp shell powder, 10-15 parts of fishbone powder, 5-8 parts of fresh ginger powder and 1-2 parts of green onion powder. The flavor of the seasoning is changed by adding the shrimp shell powder and the fishbone powder into the seasoning, wherein the shrimp shell powder and the fishbone powder are rich in calcium, the freshness of the seasoning is improved, the content of the calcium is also improved, calcium supplementation is carried out on the body when meals are had, and side effects cannot be generated.

Owner:娄志

Production method of abelmoschus manihot and tartary buckwheat wine

ActiveCN107312692AClarificationUnique tasteMetabolism disorderAlcoholic beverage preparationGerminationPotassium Glutamate

The invention relates to a production method of abelmoschus manihot and tartary buckwheat wine and aims to combine wine fragrance, flower fragrance and wheat fragrance. The production method comprises the following steps: firstly performing fixation and drying treatment on abelmoschus manihot flowers and leaves; then performing tartary buckwheat germination and alcohol stress treatment; soaking tartary buckwheat seeds with warm water and germinating; soaking the germinated tartary buckwheat seeds with an ethanol and potassium glutamate mixed solution, performing activating treatment, drying with hot air for later use and controlling the moisture below 10 percent; then compounding, crushing and leaching an abelmoschus manihot flower and leaf compound and the tartary buckwheat germination seeds; compounding and crushing the germinated tartary buckwheat and the abelmoschus manihot flower and leaf compound after drying treatment; packing the crushed compound into a bag through gauze, then adding 45-75 percent of edible wine for soaking and extracting, controlling the leaching temperature to be 30-60 DEG C and controlling the vibration speed to be 90-120 r / min and the leaching time to be 60-120 min; and finally filtering and blending, and preserving the abelmoschus manihot and tartary buckwheat wine after the alcoholic strength is 45-50 degrees .

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Cement accelerator, and preparation method thereof

InactiveCN108218280AIncrease the speed of solidificationHigh strengthHydration reactionSodium Bentonite

The invention discloses a cement accelerator, and a preparation method thereof. The cement accelerator is prepared from, by weight, 50 to 100 parts of bauxite slag, 20 to 40 parts of sodium carbonate,10 to 30 parts of bentonite, 5 to 15 parts of sulfonated lignin, 5 to 10 parts of a phosphate, 3 to 5 parts of ether sulfate triethanolamine, 1 to 3 parts of Sodium Lauryl Diphenyl Ether Disulfonate,1 to 3 parts of a methylnaphthalene sulfonic formaldehyde polycondensate, 0.5 to 2 parts of N-acyl potassium glutamate, and 1 to 3 parts of Lauryl methyl aminoethyl sodium phosphate. When the cementaccelerator is mixed with cement, hydration reaction is realized as soon as the cement is mixed with water, cement mortar rapid hardening coagulation is realized, concrete and cement solidification speeds are accelerated greatly; the compatibility of the cement accelerator with cement mortar is excellent, and cement concrete intensity is not reduced.

Owner:广西高企科技有限公司

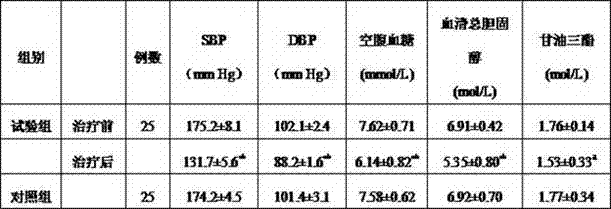

Production method of healthy monosodium glutamate

InactiveCN107801971AKeep healthyKeep freshInorganic compound food ingredientsFood ingredient functionsMonosodium glutamatePotassium hydroxide

The invention relates to a production method of healthy monosodium glutamate. The method includes: Step1: sending a fermentation broth containing glutamic acid or ammonium glutamate into a membrane separator, blocking mycelia, solid protein and colloid of the fermentation broth in the membrane separator; Step2: using washing water to clean residue staying in the membrane separator, and combining the cleaning water with the filtrate obtained in Step 1 to obtain a mixed solution 1; Step3: adding a sodium hydroxide and potassium hydroxide mixed lye slowly into the mixed solution 1 obtained by Step2, performing stirring continuously, at the same time using a pH tester to test the pH value of the mixed solution till the pH vale is 7, and stopping adding of the lye, thus obtaining a mixed solution 2; and Step4: transferring the mixed solution 2 into a vacuum distiller for concentration, thus obtaining a finished product crystal. The monosodium glutamate produced by the method contains sodiumglutamate and potassium glutamate as the main component, and under the premise of ensuring certain freshness, reduces sodium intake, thereby reducing the probability of people suffering from high blood pressure, cardiovascular diseases, nephritis and other diseases.

Owner:NINGBO YUANLI CHEM

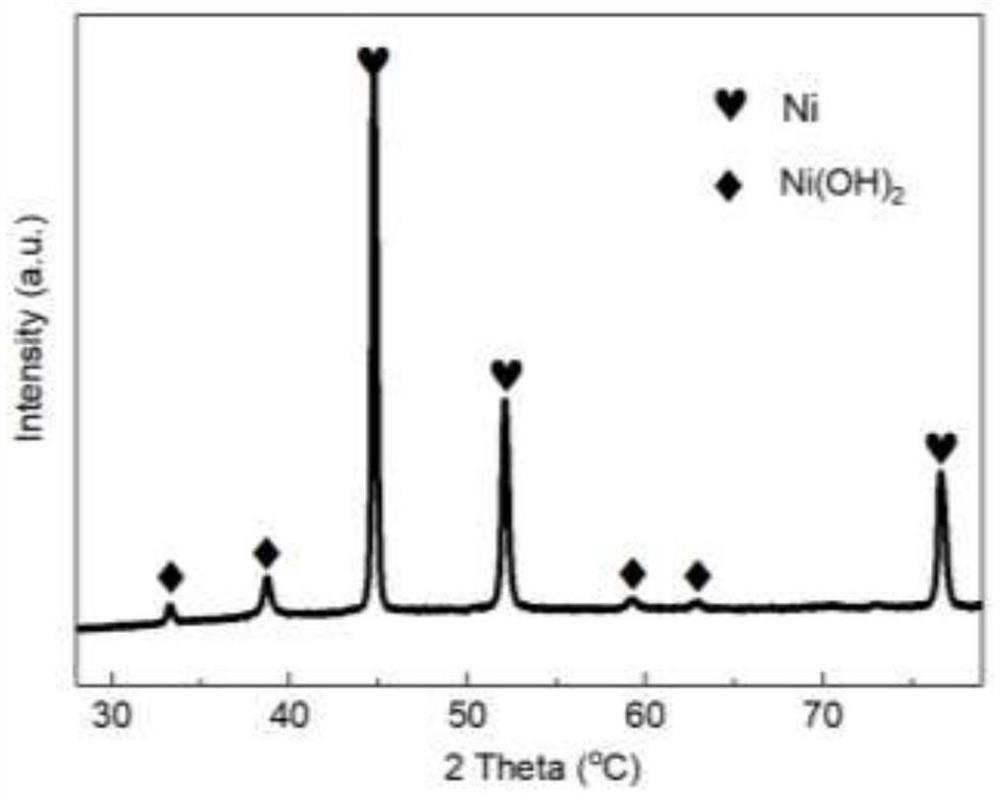

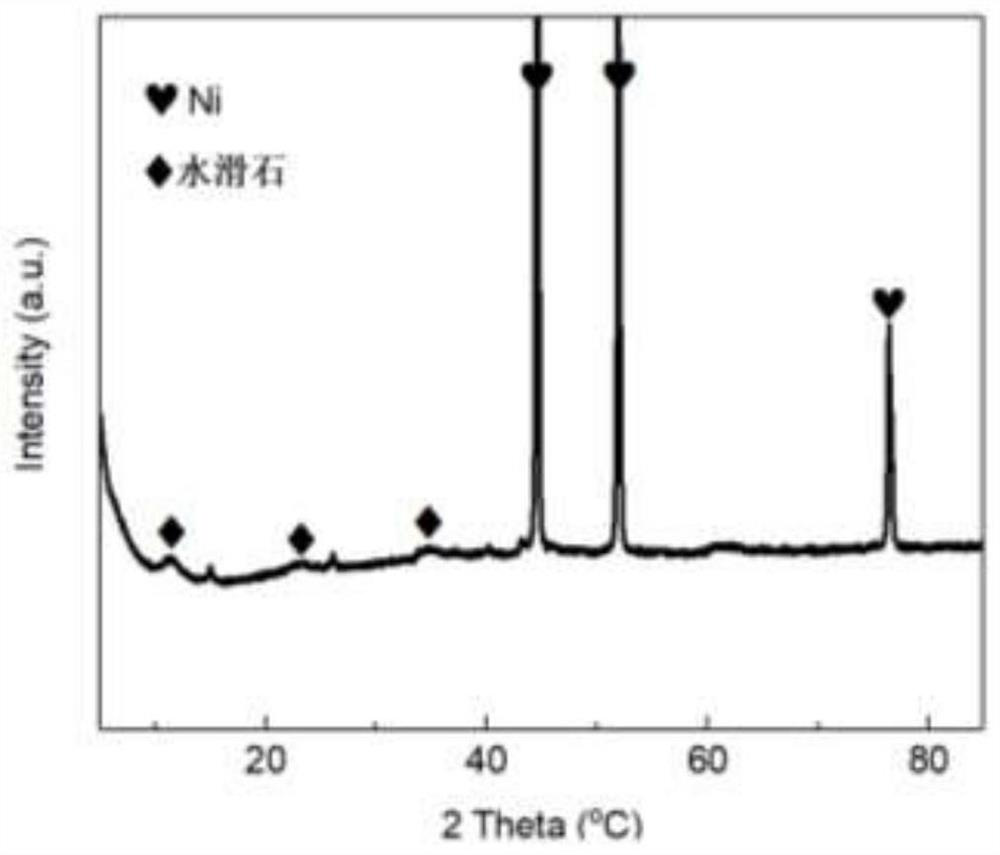

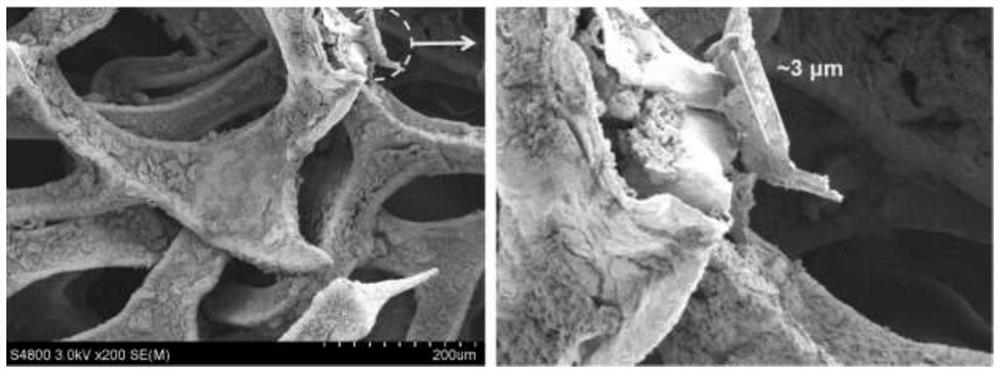

Nickel-based catalyst derived from self-supporting layered double hydroxides as well as preparation method and application of nickel-based catalyst

PendingCN114870894AImprove conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydrogenationPtru catalystKetone

The invention discloses a nickel-based catalyst derived from self-supporting layered double hydroxides as well as a preparation method and application of the nickel-based catalyst. The preparation method comprises the following steps: growing nickel hydroxide on a metal matrix, adding an aluminum salt, an organic acid or an organic acid salt and an alkali, reacting to prepare a self-supporting layered double-metal hydroxide, and reducing the self-supporting layered double-metal hydroxide, the metal matrix contains nickel; the organic acid is selected from one or a combination of more of citric acid, glutamic acid, aspartic acid and tartaric acid, and the organic acid salt is selected from one or a combination of more of sodium citrate, sodium glutamate, sodium aspartate, sodium tartrate, potassium citrate, potassium glutamate, potassium aspartate and potassium tartrate. The nickel-based catalyst is applicable to hydrogenation reaction of carbon-carbon double bonds, hydrogenation reaction of benzene rings or hydroamination reaction of ketone compounds, and is high in conversion rate.

Owner:ZHEJIANG XINHUA CHEM +1

Novel compound seasoning

The invention provides a novel compound seasoning. The seasoning is mainly formed by mixing potassium glutamate, yeast powder, I+G (nucleus amino acid) and maltodextrin in a certain proportion. The seasoning does not contain substances containing sodion added artificially, can be used for reducing the acceptable daily intake of sodion for people, can be used for reducing the probability for suffering from diseases of hypertension, cardiovascular sclerosis, heart disease and the like.

Owner:福建省建阳武夷味精有限公司

A condiment with hypolipidemic effect

ActiveCN103598557BChange the tasteImprove freshnessMulti-step food processesFood ingredient functionsBiotechnologyMonosodium glutamate

The invention belongs to the field of food, and specifically relates to a seasoning capable of reducing blood lipid. The seasoning comprises following ingredients, by weight, chicken meal, sodium chloride, potassium glutamate, chilli powder, sodium glutamate, shiitake, red date, pepper, cucumber, haw, carrot, ginger powder, green Chinese onion powder, and celery. Ingredients capable of reducing blood lipid, such as semen cassia, radix polygoni multiflori, rhizoma alismatis, shiitake, red date, carrot and cucumber are added into the seasoning, so that taste of the seasoning is changed, freshness of the seasoning is improved, and treatment and prevention on hyperlipidemia are realized with dinning.

Owner:ANHUI QIANGWANG FLAVORING FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com