Lyophilized vaccine for classical swine fever

A vaccine and freeze-drying technology, which can be applied to medical preparations with inactive ingredients, inactive ingredients of polymer compounds, and medical components of antibodies. The effect of time limit, low cost of raw materials and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

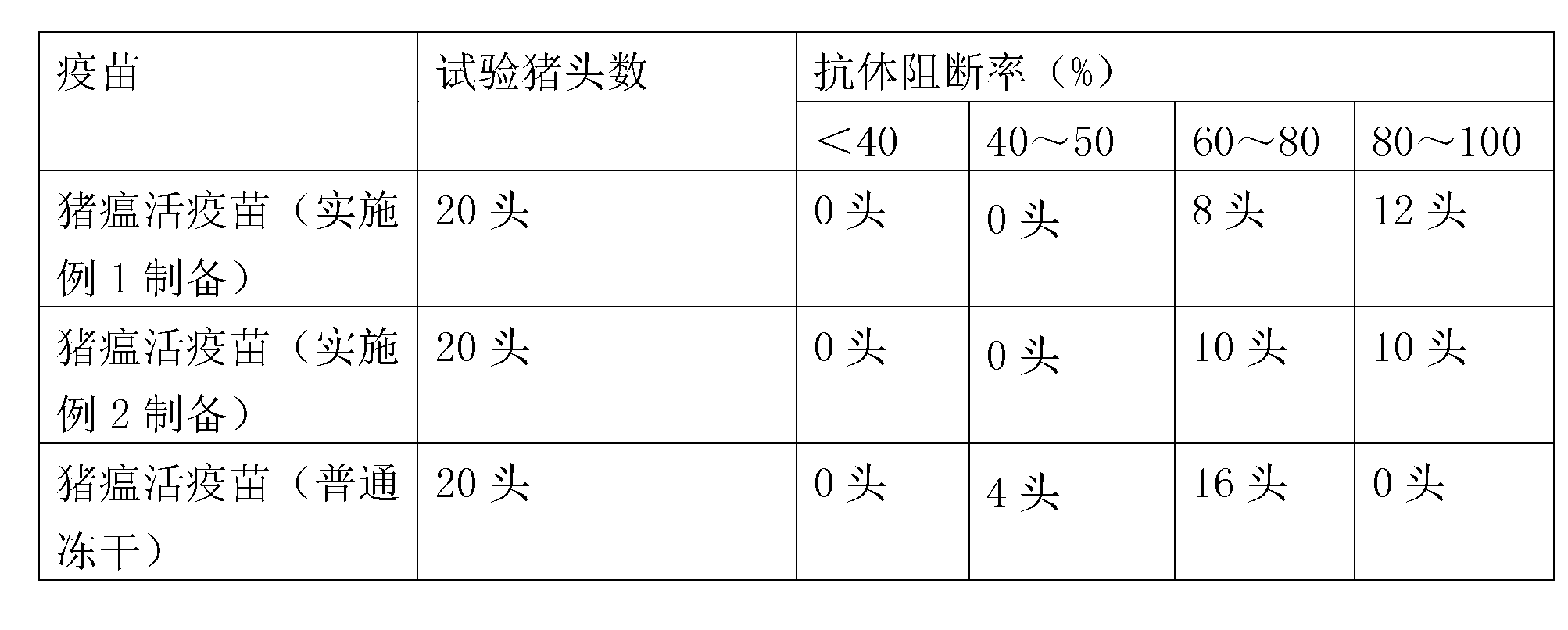

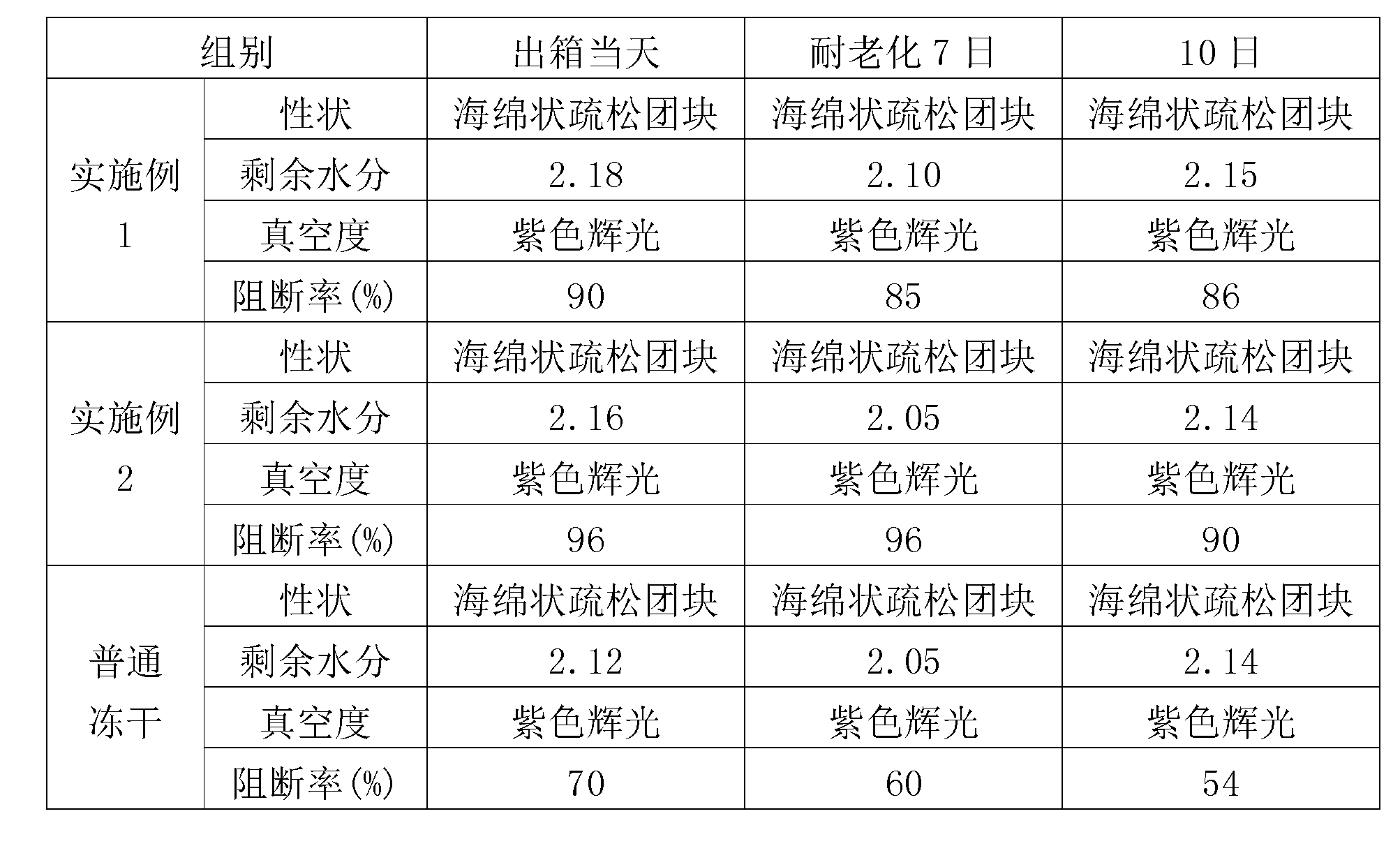

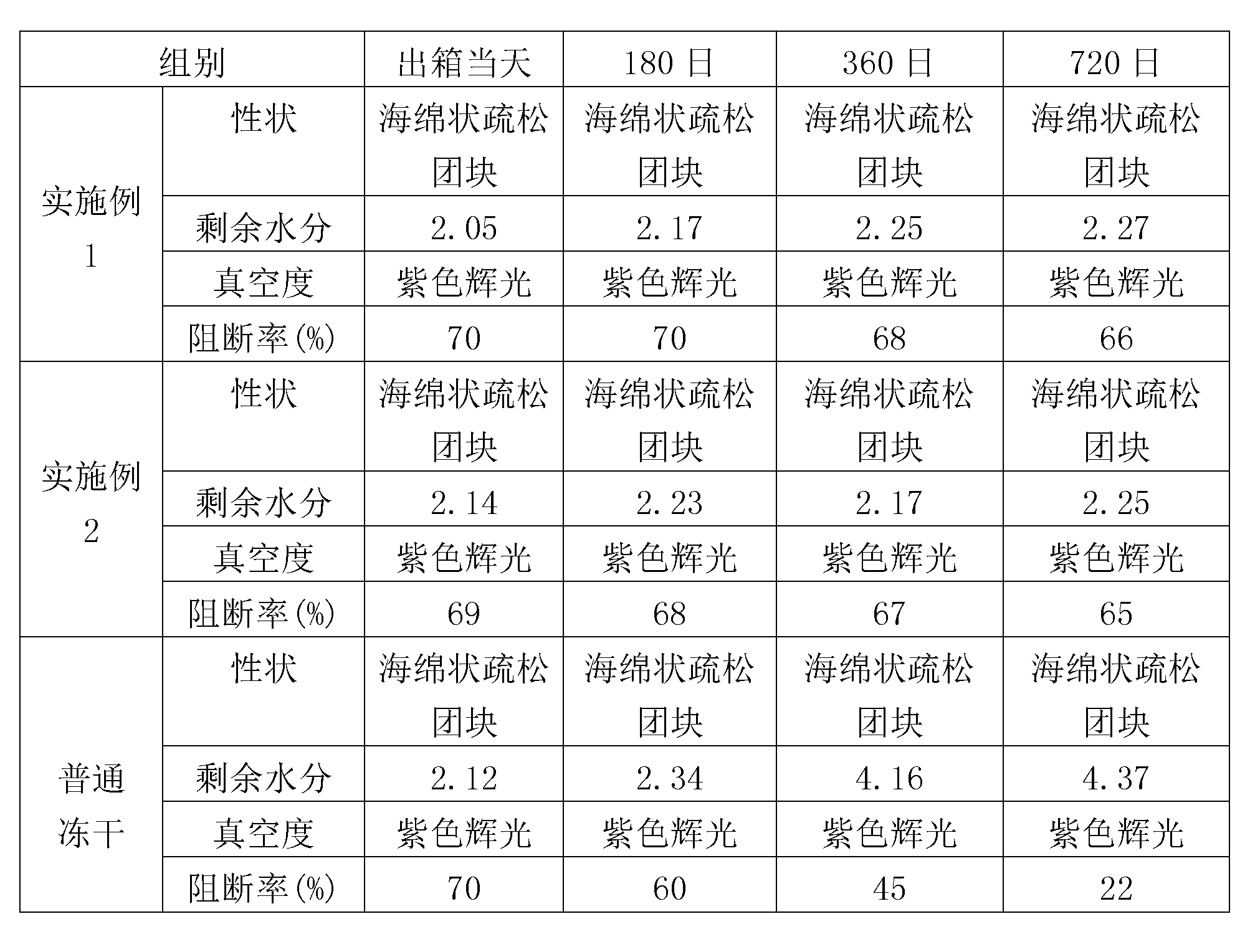

Examples

Embodiment 1

[0025] 1. Preparation of lyoprotectant: divided into two parts, liquid A and liquid B.

[0026] 1) Preparation of liquid A: Weigh 48g of NZ-amine, 6g of monopotassium glutamic acid, 400g of sucrose, and 30g of hydrolyzed milk protein; dissolve the above ingredients in 800ml of water for injection in order, shake well after fully dissolving, and add water for injection After reaching 1000ml, shake well, filter and sterilize with a 0.22μm filter membrane, and store in a 37°C greenhouse for future use.

[0027] 2) Preparation of liquid B: Take 80g of gelatin, fully dissolve it with 800ml of water for injection at 70-80°C, add water for injection to 1000ml, stir well, autoclave at 121°C and 15 pounds for 30 minutes, and store at 37°C after sterilization.

[0028] 3) Proportion according to the volume ratio of liquid A: liquid B = 1:1, and mix well to get the heat-resistant freeze-drying protective agent.

[0029] The lyoprotectant prepared by the invention has undergone long-term...

Embodiment 2

[0038] 1. Preparation of lyoprotectant:

[0039] 1) Preparation of liquid A: Weigh 80g of NZ-amine, 10g of monopotassium glutamic acid, 500g of sucrose, and 50g of hydrolyzed milk protein; dissolve the above ingredients in 800ml of water for injection in order, shake well after fully dissolving, and add water for injection to 1000ml, sterilized by filtration with a 0.22μm filter membrane, and stored in a 37°C greenhouse for future use.

[0040] 2) Preparation of liquid B: Take 120g of gelatin, fully dissolve it with 800ml of water for injection at 70-80°C, add water for injection to 1000ml, autoclave at 121°C and 15 pounds for 30 minutes, and store at 37°C after sterilization.

[0041] 3) According to the ratio of liquid A: liquid B = 1:1, it can be used as a heat-resistant protective agent after mixing evenly.

[0042] 2. Vaccine preparation

[0043] 1. The cultured swine fever virus was tested for sterility and virus content, and the qualified virus solution was mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com