Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Cement accelerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cement accelerator is an admixture for the use in concrete, mortar, rendering or screeds. The addition of an accelerator speeds the setting time and thus cure time starts earlier. This allows concrete to be placed in winter with reduced risk of frost damage. Concrete is damaged if it does not reach a strength of 500 pounds per square inch (3.4 MPa) before freezing.

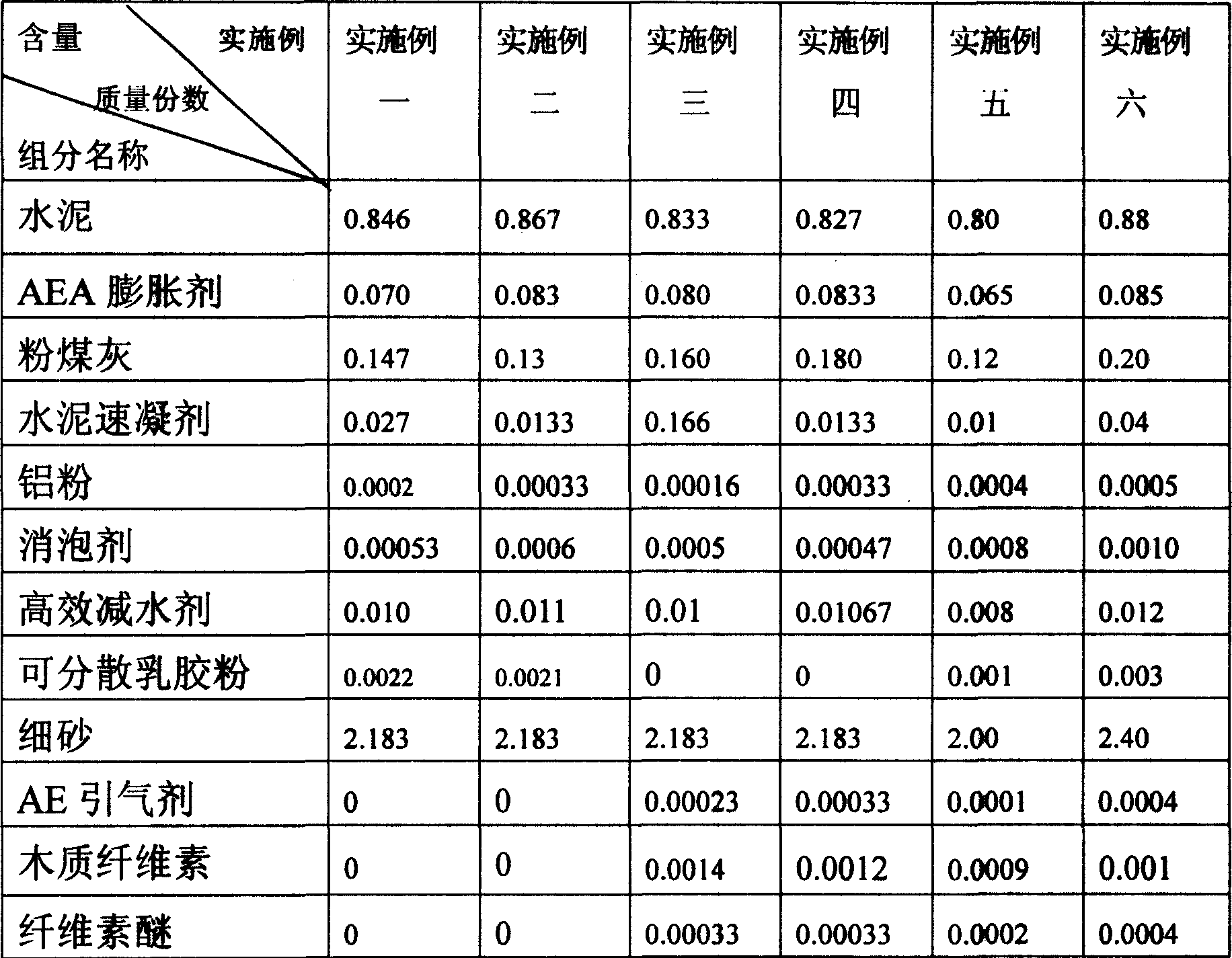

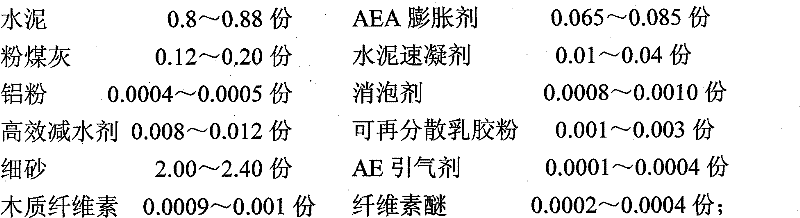

CA mortar dry powder for plate-type slag-free orbit

The invention discloses a CA slurry dried-powder of board-typed non-slag rail, which comprises the following parts: cement, AEA swelling agent, coal ash, cement accelerator, aluminium powder, defoamer, high-effective dehydragent, redispensable emulsion powder, fine sand, AE air-entrainer, ligno-cellulose and cellulose ether. The CA slurry dried-powder adopts industrial manufacturing to produce the product with stable quality, high fluidity and compactness, which is fit for high-speed railroad.

Owner:LIUZHOU OVM MASCH CO LTD

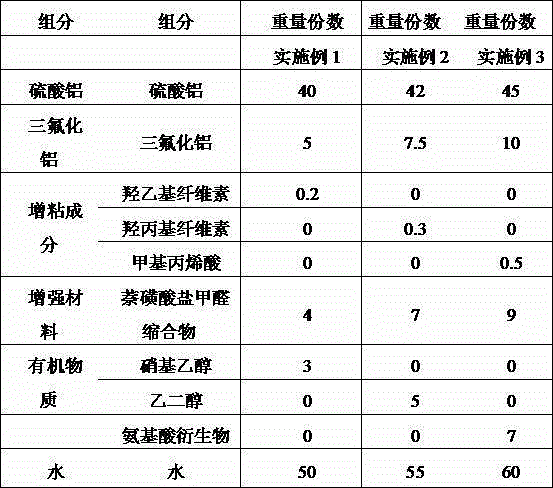

Alkaline-free liquid cement accelerator and using method therefor

The invention belongs to cement auxiliaries and particularly relates to an alkaline-free liquid cement accelerator and a using method therefor. The alkaline-free liquid cement accelerator is prepared from the following components in parts by weight: 40-45 parts of aluminum sulfate, 5-10 parts of aluminum trifluoride, 0.2-0.5 part of a tackifying component, 4-9 parts of a reinforcing material, 3-7 parts of organic matters and 50-60 parts of water. The accelerator for a cement processing process provided by the invention has an adjusting effect on the cohesion time of cement, is free of corrosion and toxicity, causes no corrosive damages on the skin and body of constructors, and has no adverse influence on durability of concrete.

Owner:仇鹏

Concrete spraying additive

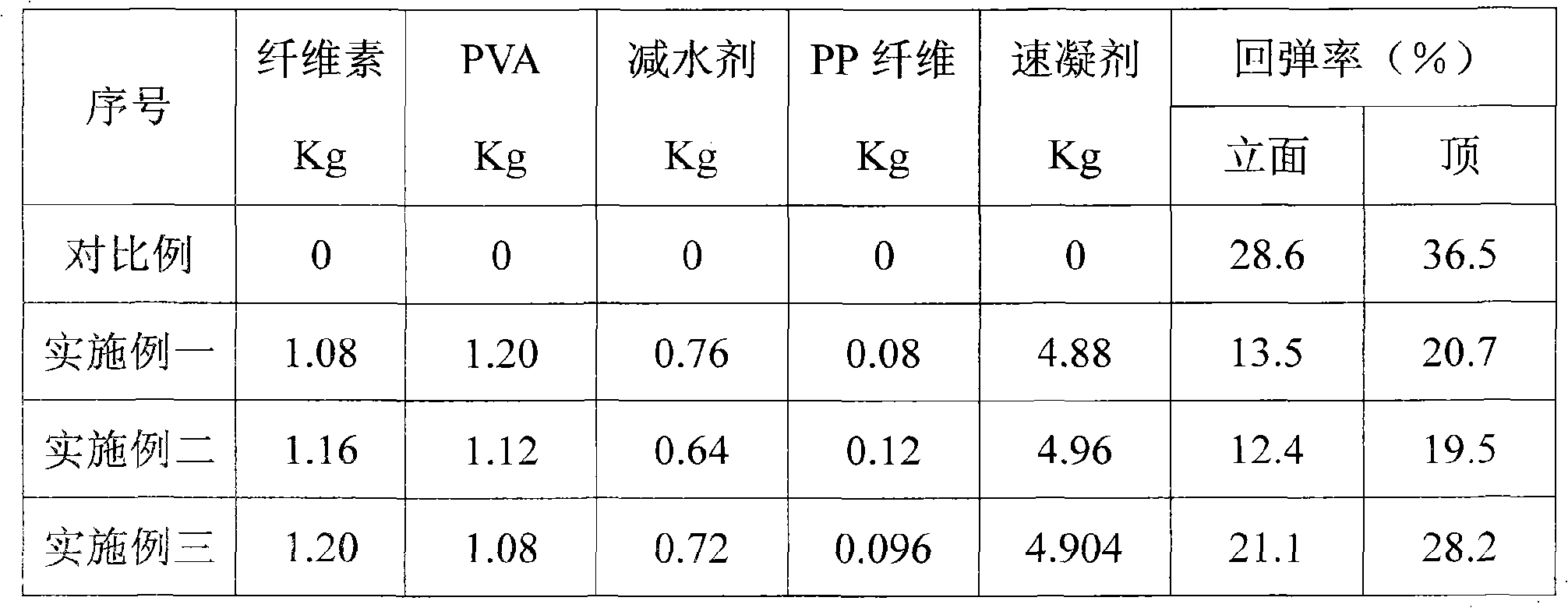

The invention discloses a shotcrete admixture, comprising: 13 to 15 parts by weight of cold water quick dissolving powdery methylcellulose ether or cold water quick dissolving powdery hydroxyethyl cellulose ether, 13 to 15 parts by weight of cold water quick dissolving powdery polyvinyl alcohol, 8 to 11 parts by weight of naphthalene-series powdery water-reducing agent, 1 to 2 parts by weight of mesh polypropylene fiber and 58 to 62 parts by weight of cement accelerator. The shotcrete admixture is prepared by adding the constituents into the concrete together for increasing the cohesion of concrete and viscosity of early-stage slurry, the slurry initial setting time is short, and the resilience amount of concrete can be reduced by 30 to 50 percent.

Owner:山东科技大学教育服务有限公司

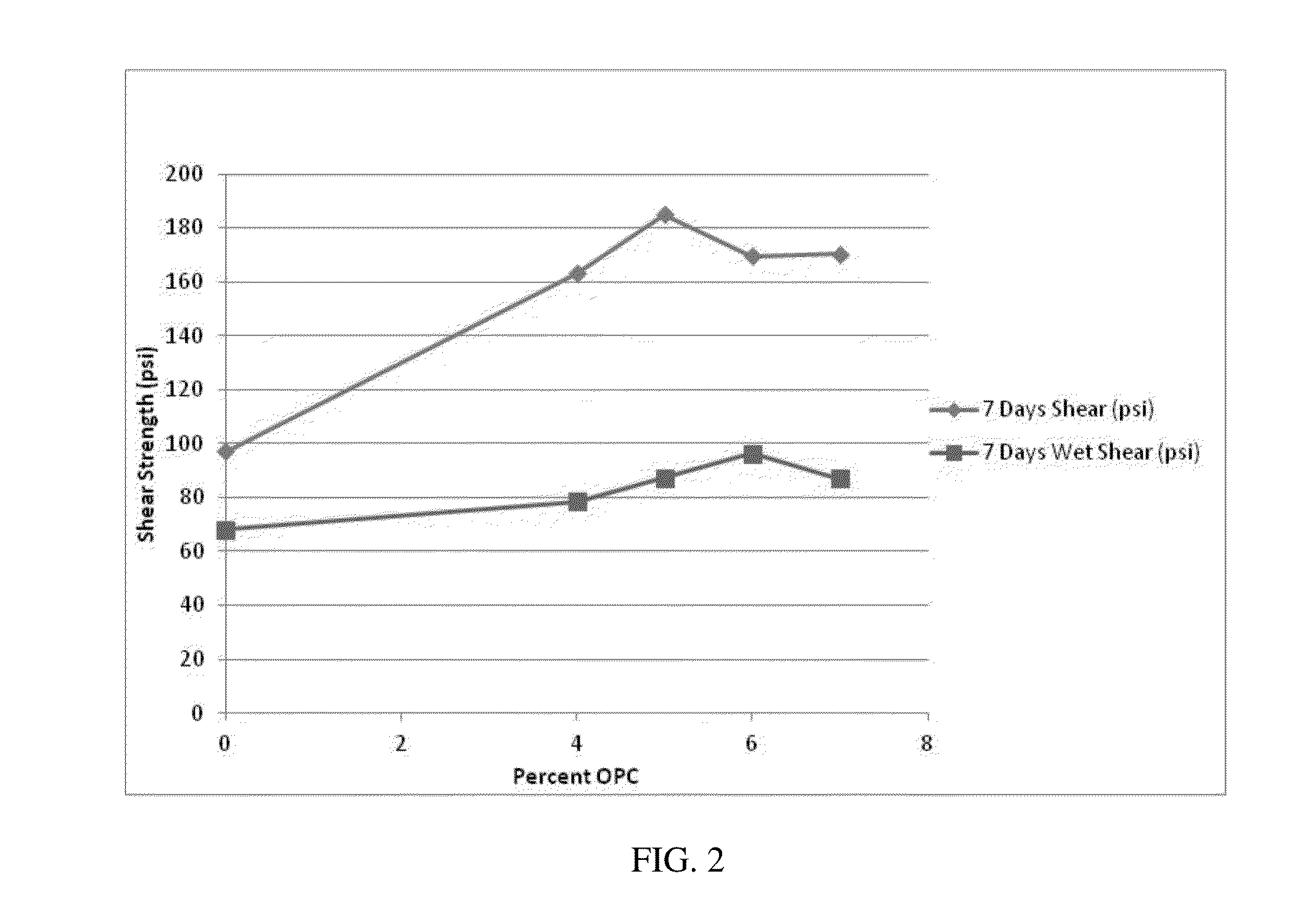

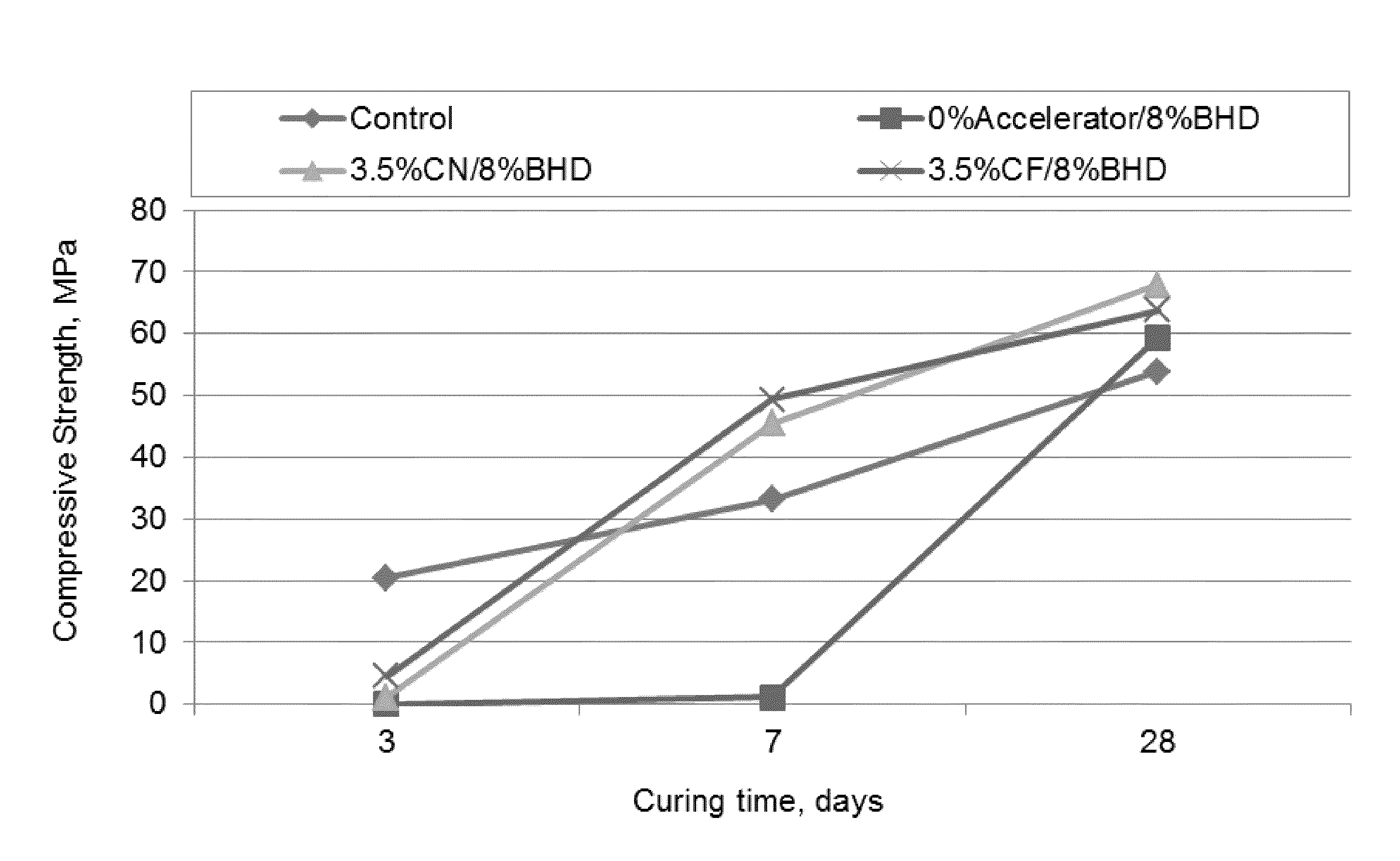

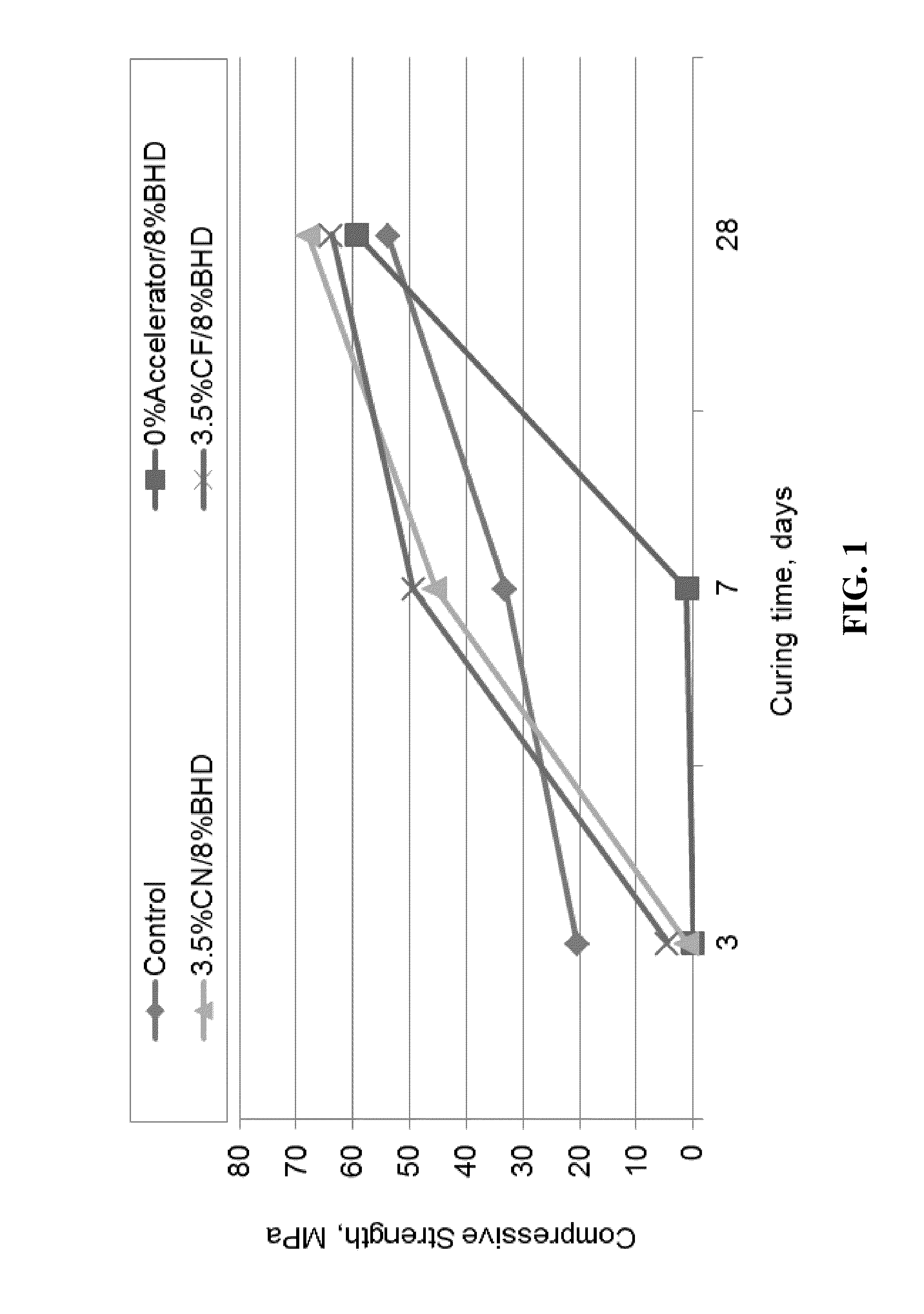

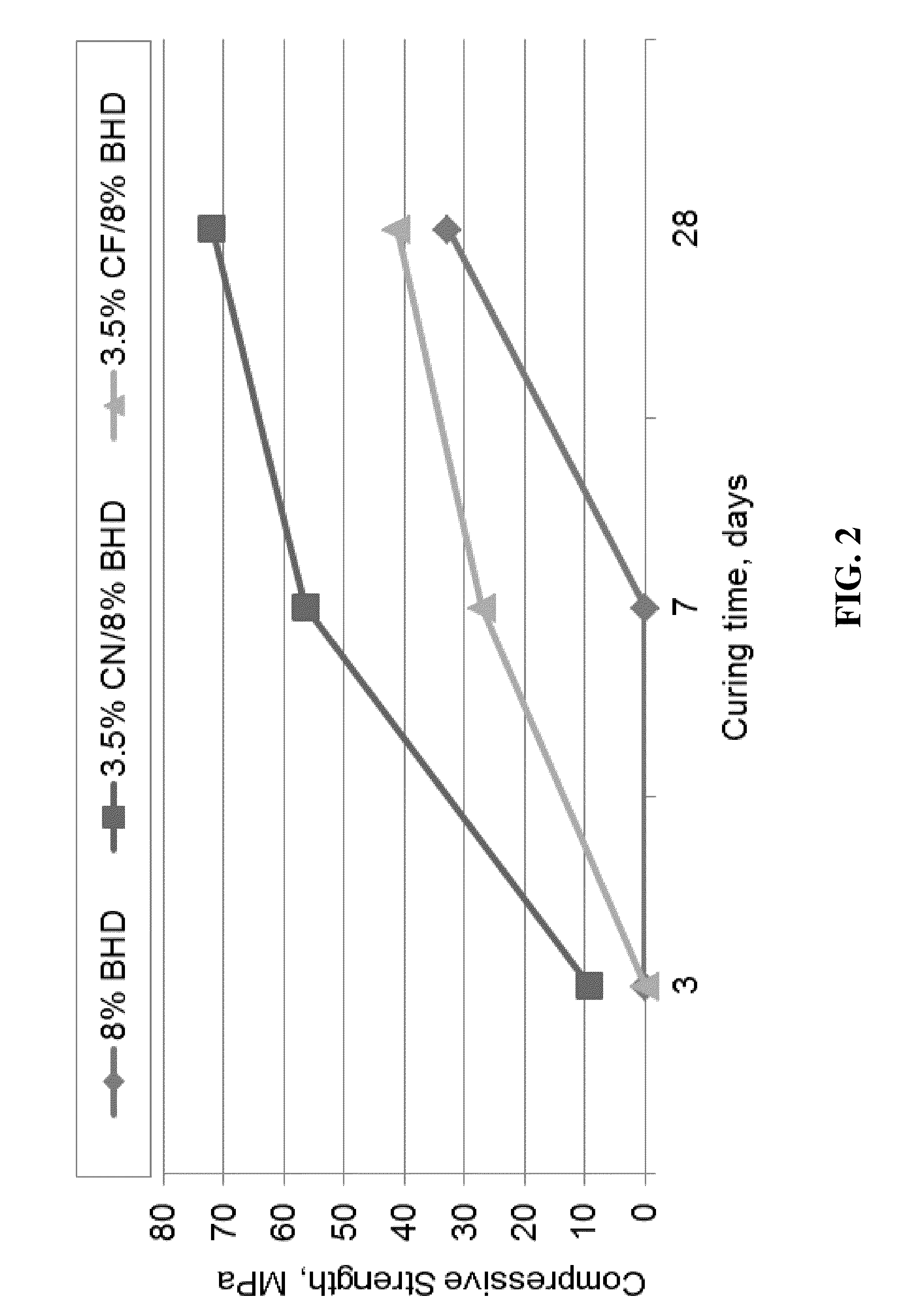

Use of a cement accelerator and electric arc furnace dust in cement

InactiveUS20150291476A1Improve early compressive strengthImprove workabilitySolid waste managementElectric arc furnaceChloride

The present disclosure relates to cement compositions comprising: (a) cement, (b) an electric arc furnace dust (EAFD), and (c) a cement accelerator; wherein the electric arc furnace dust is present in an amount from greater than 8 wt % based on the total weight of the cement (a); and it relates to cement compositions comprising: (a) cement, (b) an electric arc furnace dust (EAFD), and (c) a cement accelerator comprising calcium chloride, calcium nitrate, or sodium nitrate, or a combination thereof; wherein the electric arc furnace dust is present in an amount from greater than 8 wt % based on the total weight of the cement (a). Also disclosed are methods for making the disclosed compositions and products using the disclosed compositions. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:SAUDI BASIC IND CORP SA

Shotcrete admixture

The invention discloses a shotcrete admixture. The shotcrete admixture is prepared from, by weight, 10-15 parts of a water-retaining agent, 15-20 parts of polyvinyl alcohol, 11-15 parts of a water reducing agent, 1-2 parts of polypropylene fibers, 58-62 parts of a cement accelerator, 3-20 parts of active montmorillonite, 10-25 parts of an accelerating agent, 1-12 parts of an acrylic copolymer, 1-2parts of sodium nitrite, 50-80 parts of expanded ultrafine silicon powder and 1-50 parts of calcium hydroxide. Shotcreting on normal seepage rock surfaces can be realized normally to greatly reduce rock surface seepage, the water reducing effect reaches 30% or above, 28-day strength can be improved to 50MPa, preparation of C40 anticorrosion shotcrete can be realized, and the problem of shotcreting in rock burst and water-abundant areas can be completely solved.

Owner:徐州巨龙新材料科技有限公司

Moisture-Curing Compositions, Methods and Products

InactiveUS20150291839A1Reduce usageOvercome disadvantagesSynthetic resin layered productsPretreated surfacesLiquid waterSilanes

Liquid, moisture-curing compositions comprise (a) a silane-terminated moisture-curing polymer, and (b) an inorganic adhesion promoter comprising one or more cements, pozzolan, lime, aluminum trihydroxide, one or more cement accelerators, or a mixture thereof. The composition is curable to form an impermeable barrier to liquid water, and the inorganic adhesion promoter is included in an amount effective to improve adhesion of cement mortar to a cured layer of the composition. Methods employ such compositions to form liquid water-impermeable membranes, and a variety of products employ such membranes.

Owner:CUSTOM BUILDING PRODS

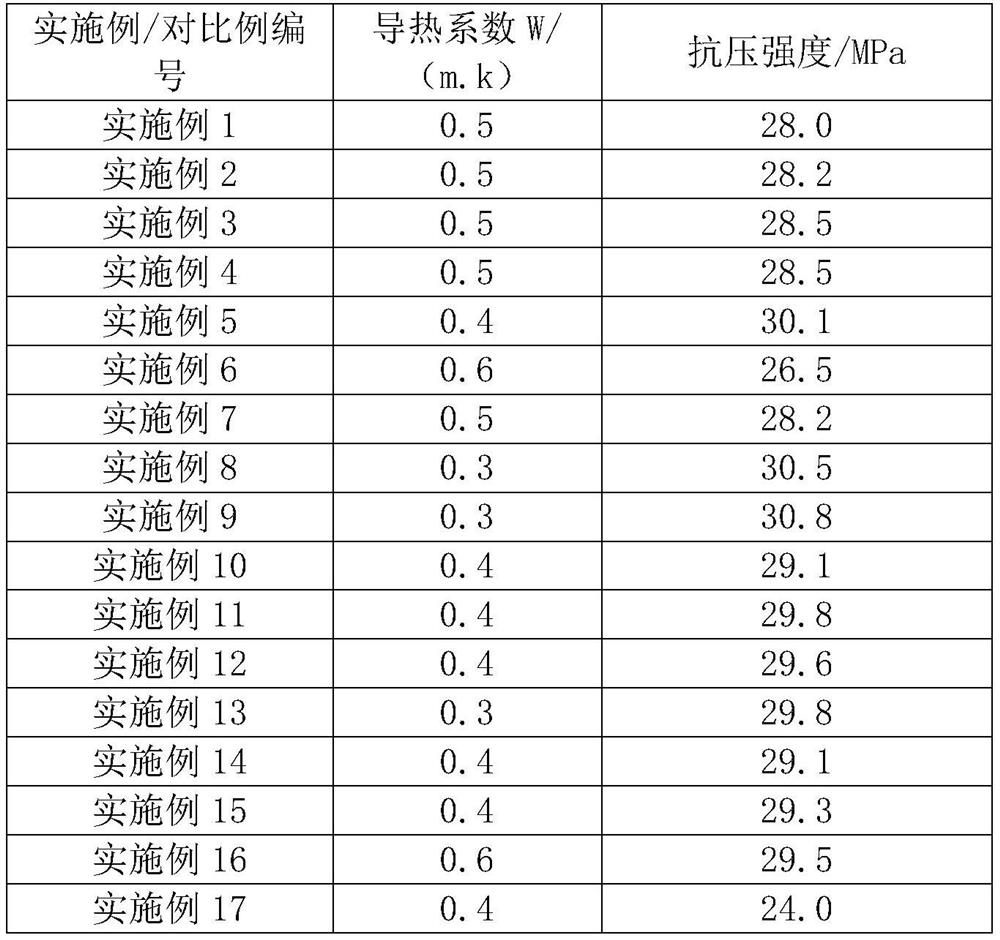

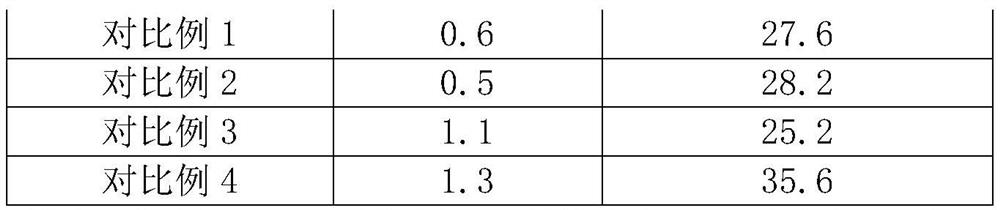

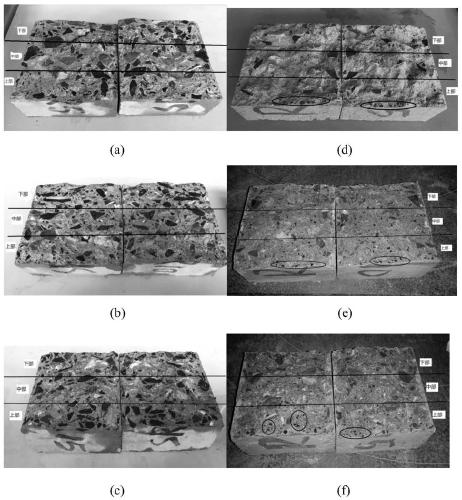

Concrete utilizing industrial solid waste and preparation method thereof

InactiveCN112608085AOvercome the defect of floatingEvenly distributedSolid waste managementCompressive resistanceThermal insulation

The invention relates to the field of concrete, and particularly discloses concrete utilizing industrial solid waste and a preparation method of the concrete, and the concrete utilizing the industrial solid waste is prepared from the following raw materials in parts by weight: 260-270 parts of cement; 45-55 parts of fly ash; 35-45 parts of mineral powder; 710-720 parts of fine sand; 990-1000 parts of broken stone; 10-12 parts of a water reducing agent; 140-160 parts of water; and 100-150 parts of modified waste polyurethane particles; wherein the modified waste polyurethane particles are obtained by coating the surfaces of waste polyurethane particles with modified slurry and curing, and the modified slurry is prepared from cement, a cement accelerator, plant fibers and water. The concrete has the advantage that the thermal insulation property and compressive strength of the concrete are improved.

Owner:陕西天皓万业混凝土工程有限责任公司

Improved manufacture method of cement accelerator

The invention relates to an improved manufacture method of cement accelerator, which comprises the following steps: step I, raw material mix calcination: carrying out mix calcination on 28.8% of bauxite, 40.1% of limestone, 21% of soda ash and 10.1% of raw coal to obtain a aluminum oxygen chamotte; step II, mix grinding: taking calcined aluminum oxygen chamotte and industrial coal cinder to carry out mix grinding to obtain a cement accelerator in the prior art; and step III: adding polyacrylamide and redispersible emulsion powder in proportion in the cement accelerator in the prior art. By adopting the method in the invention, the cement accelerator prepared improves the caking property of the concrete, enables the concrete to have enough moisture for conservation, changes the brittleness of the concrete, and enables the sprayed concrete to have a favorable anti-permeability, meanwhile increases the bond force of the sprayed concrete and the base course, and increases the stretching bonding strength of the base course.

Owner:焦作市新筑王材料科技有限公司

Thermal-insulating cement

InactiveCN105985022AImprove insulation performanceGood heat insulationCement productionSlagCement accelerator

The invention discloses thermal-insulating cement. The thermal-insulating cement comprises the following components by weight percentage: 5-10 parts of vermiculite power, 35-73 parts of cement clinker, 3-5 parts of gypsum, 3-5 parts of slag, 1-8 parts of titanate, 20-45 parts of fluorgypsum, 2-6 parts of a cement accelerator, 6-9 parts of a heat-insulation filling material, 3-6 parts of a thickening agent, and 5-10 parts of bentonite. Compared with common cement, the heat-insulation effect of the thermal-insulating cement is increased by 30%, and the thermal-insulating cement has good heat-insulation effect.

Owner:CHONGQING XIONGCHUANG ARCHITECTURAL ENG TECH

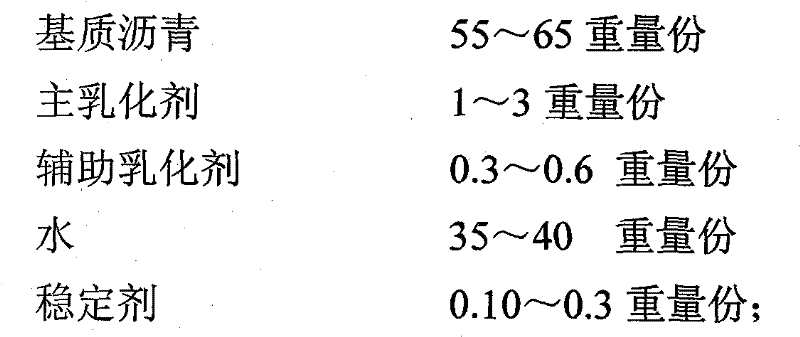

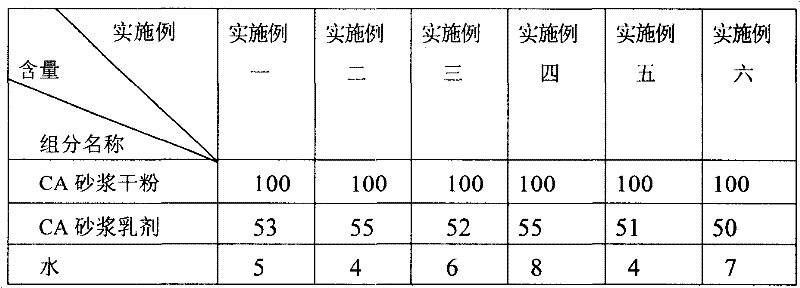

CA mortar for plate-type slag-free orbit and preparation method thereof

The invention discloses a CA slurry and manufacturing method of board-typed non-slag rail to fill the high-speed railroad subgrade, which comprises the following steps: blending dry powder of CA mortar and CA mortar emulsion and water with weight rate at 100:50-55:4-8 to form the CA mortar; allocating the dry powder of the CA mortar with cement, AEA swelling agent, coal ash, cement accelerator, aluminium powder, defoamer, highly effective dehydragent, dispersible emulsion powder, fine sand, AE air-entrainer, wood cellulose and cellulose ether; making slow-breaking slow hardening cation emulsified tar and composite emulsion of polychloroprene latex as CA mortar emulsion; stirring the prepared material, mortar emulsion and water; adding the dry powder of the mortar to stir; manufacturing the dry powder of CA mortar; adopting industrial manufacturing to produce stable-quality product; making the manufacturing and transportation conveniently.

Owner:LIUZHOU OVM MASCH CO LTD

Cement concrete bridge deck pavement surface vibration reduction sealing layer and construction method

ActiveCN111377680AReduce impactReduce driving noiseIn situ pavingsBridge structural detailsBitumen emulsionFirming agent

The invention discloses a cement concrete bridge deck pavement surface vibration reduction sealing layer and a construction method. The material comprises the following components in parts by weight:10-20 parts of emulsified asphalt, 10-20 parts of water-borne epoxy resin emulsion, 10-25 parts of water-borne epoxy resin curing agent emulsion, 100 parts of sand, 3-8 parts of cement, 0.05-0.4 partof cement accelerator, 5-10 parts of waste tire rubber powder and 4-12 parts of water. The construction method sequentially comprises the following steps of designing a construction mix proportion, preparing a solid mixture, a leachate ring mixed solution and a water ring mixed solution, loading and calibrating a slurry seal paver, mixing and paving, trimming, maintaining and opening traffic. Theconstruction thickness of the surface vibration reduction sealing layer is only 3 mm, the maximum particle size of used sand is 3 mm and is the same as the thickness of the surface vibration reductionsealing layer, and therefore tracks cannot be generated. And meanwhile, the surface vibration reduction sealing layer can reduce the driving noise of cement concrete bridge deck pavement, improve thedriving comfort and reduce the impact force of the vehicle load on the bridge, namely, the vibration reduction effect is achieved.

Owner:王壹帆

Function modified cement accelerator

InactiveCN107512858AThe effect of modification is obviousHigh curing strengthPortland cementRoad surface

The invention relates to a function modified cement accelerator. The function modified cement accelerator is characterized in that ordinary Portland cement is endowed with a special function through modification. As for the traditional accelerator, once the traditional accelerator is added into and stirred with the ordinary Portland cement and water, calcium sulphoaluminate is generated and hydrated to release heat, thereby causing workability loss of cement and thus being only suitable for a jetting process; the setting time of the cement cannot be flexibly preset; and the cement curing is only mechanically accelerated, so that the traditional accelerator is unsuitable for various projects and technologies. Different from the traditional accelerator, the function modified cement accelerator has main characteristics that the function modified cement accelerator can be poured, jetted and injected for molding at the aspect of use technology, the setting time can be roughly preset and the workability and liquidity thereof are almost not influenced before the preset setting time; an additive is used for solving the problem of partial functional application of the ordinary Portland cement; the function modified cement accelerator has a wide application prospect in the fields of metro grouting, cement technical components, quick pavement patching, 3D printing of building walls, and the like, in the future.

Owner:广州速力新材料科技有限公司

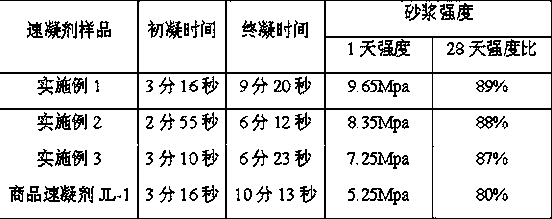

Polymer low-alkaline accelerator used for sprayed concrete and preparation method thereof

The invention provides a polymer low-alkaline accelerator used for sprayed concrete. The polymer low-alkaline accelerator used for sprayed concrete comprises the following components in percentages byweight: 20% to 30% of aluminate, 10% to 20% of phosphotungstate, 5% to 10% of a low molecular weight polymer, 5% to 10% of a high molecular weight polymer and 30% to 50% of water. Moreover, the invention also provides a preparation method of the polymer low-alkaline accelerator used for sprayed concrete. The possibility of generating an alkali-aggregate reaction is greatly reduced, the problem that the long-term strength and durability of concrete are reduced caused by the fact that the alkali-aggregate reaction occurs easily due to high alkali content in an existing cement accelerator is solved, simultaneously, the problems of large dust and great resilience in the injection process are solved through granular composition of the low molecular weight polymer and the high molecular weightpolymer, moreover, the sprayed concrete is used in a wet spraying technology, the stable period exceeds six months, different varieties of ordinary Portland cement can be initially set within three minutes under relatively low amount of admixture and finally set within ten minutes, the 1d strength of cement mortar reaches more than 7 MPa, and the 28d ratio of compressive strength is greater than 85%.

Owner:陕西金石混凝土科技发展有限公司

Cement accelerator

The invention discloses a cement accelerator and belongs to the field of buildings. According to the cement accelerator disclosed by the invention, a substance with a cement accelerating effect is prepared by taking aluminum sulfate octadecahydrate and calcium oxide as raw materials and carrying out high-speed shearing; lithium slag is used as a raw material, is subjected to microwave treatment and is enabled to have more free lithium salts and the like, so that condensation of cement concrete can be promoted and the initial set time is shortened; in addition, alumina and calcium sulfate in the lithium slag also react to generate calcium sulphoaluminate hydrate, so that early strength can be improved; bamboo fibers are added for compounding and raw bamboo fibers are doped, so that the volume shrinkage stress is digested, and further cracks are reduced; the breaking strength of cement-based mortar is improved along with the increase of the doping amount of the raw bamboo fibers; the anti-cracking and compressive strength of the cement slurry at later stage is improved, and further the quality of cement is improved.

Owner:赵顺全

Method for producing cement accelerator through comprehensive treatment of secondary aluminum ash

ActiveCN114477827ARealize resource utilizationImprove technical economyAluminium industrySocial benefits

The invention discloses a method for producing a cement accelerator through comprehensive treatment of secondary aluminum ash, and belongs to the cross technical field of aluminum industry solid waste resource treatment and comprehensive utilization and cement accelerator production. The method comprises the following steps: mixing secondary aluminum ash, a calcium source and an alkaline additive to obtain a mixed raw material, calcining the raw material in gas fuel, and cooling to obtain the cement accelerator, and flue gas generated by calcination is discharged through dust removal and denitration, and dust is recycled. According to the method, the aluminum ash is effectively converted into the accelerator, resource utilization is achieved while treatment is conducted, and remarkable economic benefits are achieved; by regulating and controlling the types of the alkaline additives, a synergistic effect is generated, and the dynamic performance of the cement setting process is improved; especially, green conversion and migration of nitrogen and fluorine elements in the secondary aluminum ash are effectively achieved in the treatment process, and remarkable environmental and social benefits are achieved.

Owner:山西新翔环保科技有限公司

Bayer red mud cement accelerator and production method

The invention discloses a Bayer red mud cement accelerator, which comprises the following raw material by weight ratio, the ratio of Bayer red mud sintering clinker: naphthalene sulfonic acid formaldehyde condensation polymer (FDN): triethanolamine (TEA): Bayer red mud: fly ash: additive is 47-55% to 6-12% to 0.5-1.2% to 15-20% to 10-15% to 5-15%, and an additive is semi-hydrated gypsum and / or lime. The accelerator is prepared according to the following method, drying the Bayer red mud to prepare the Bayer red mud sintering clinker, weighting the components of each raw material according to weight, mixing the weighted raw materials, crushing and grinding, and sieving by a sieve with 200 meshes and packaging to prepare the Bayer red mud cement accelerator. According to the invention, the coagulation time can accord with a national building material current standard, and reduce the production cost of the cement accelerator, compared with a test piece 28d compressive strength with the Bayer red mud cement accelerator, the time intensity of the test piece 28d compressive strength without the Bayer red mud cement accelerator is increased by more than 85%, and the invention provides a feasible approach for comprehensive utilization of the Bayer red mud in an alumina industry.

Owner:贵州亿维海逸环保科技有限公司

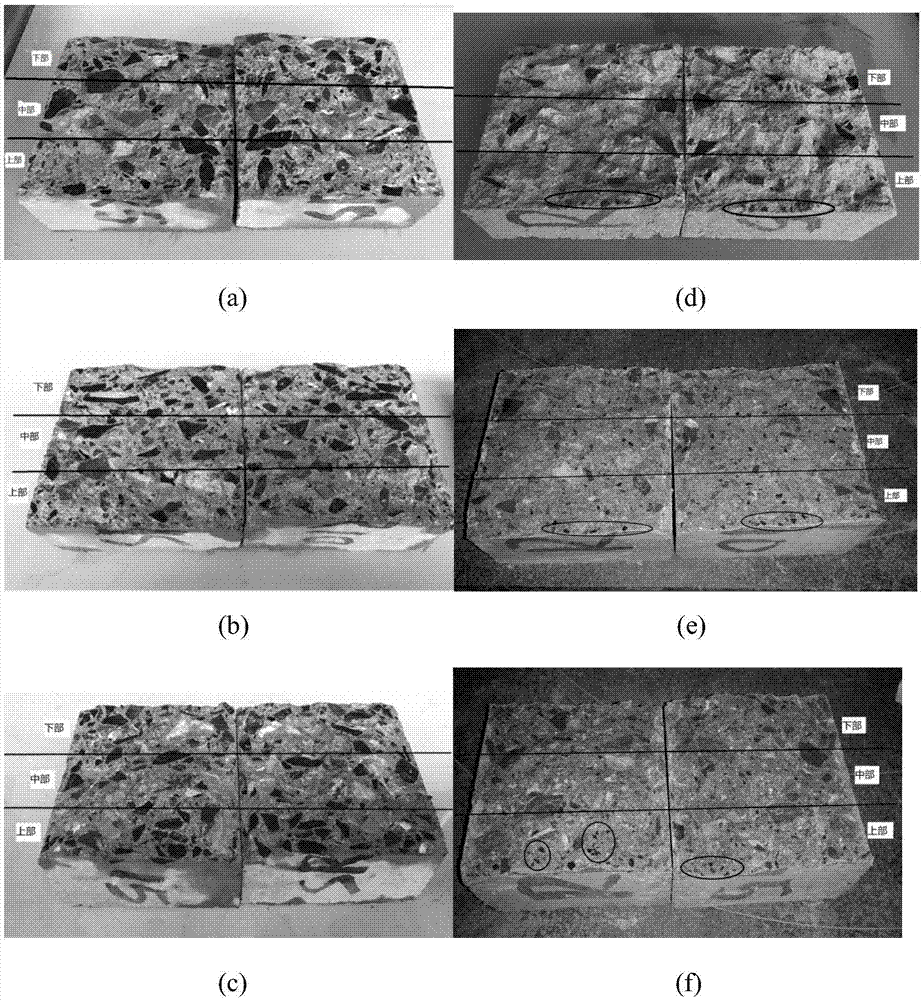

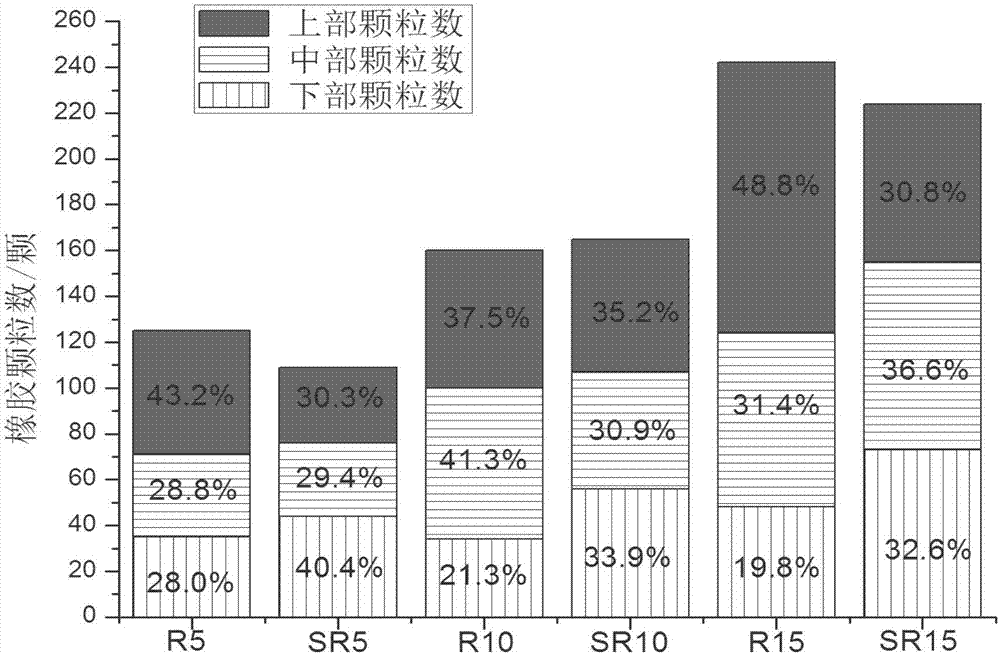

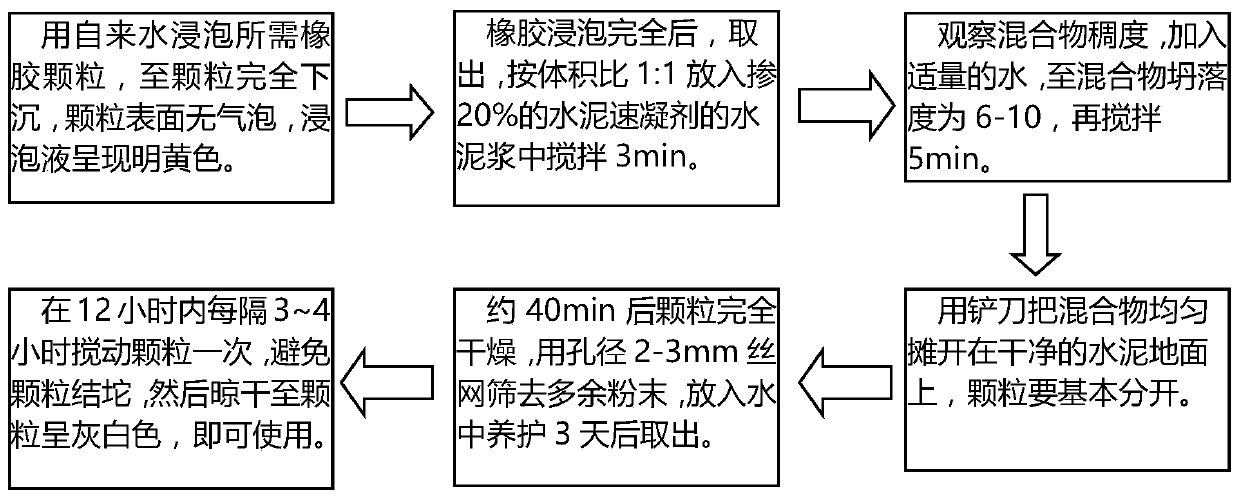

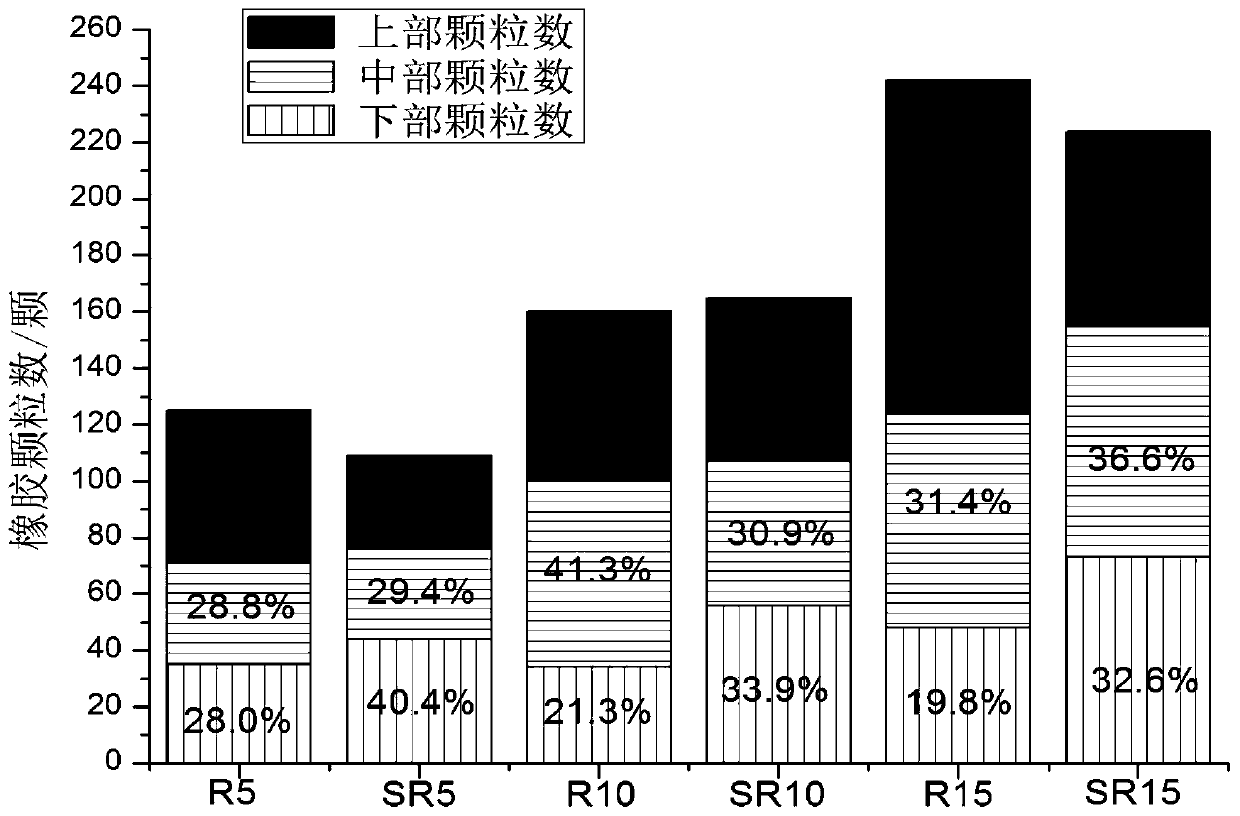

Rubber particle weight increasing method and preparation method of rubber concrete

The invention provides a rubber particle weight increasing method and a preparation method of a rubber concrete. Through the rubber particle weight increasing method, the weight and the density of a rubber particle are increased, the rubber particles are more evenly distributed in the concrete, and the mechanical property of the rubber concrete is improved. The related rubber particle weight increasing method is characterized by comprising the following steps: 1, weighing a certain amount of the rubber particles, soaking with clear water until the particles completely sink down and no bubble exists on the surfaces of the particles; 2, taking out the rubber particles, adding the rubber particles into a cement paste and stirring, wherein the volume ratio of the rubber particles to the cement paste is 1:1 and 20% of a cement accelerator is doped in the cement paste; 3, observing the thickness of a mixture, adding proper amount of water until the slump constant of the mixture is 6-10, stirring for a certain period of time; 4, evenly spreading the mixture by using a shovel blade, basically separating the particles, and airing naturally; 5, screening an excessive powder by using a mesh sieve, maintaining in water for a plurality of days, and taking out; 6, stirring the rubber once every few hours, stirring for times, airing until the particles are grey white, and obtaining the weight increased rubber particles.

Owner:武汉煜卉工程咨询有限公司

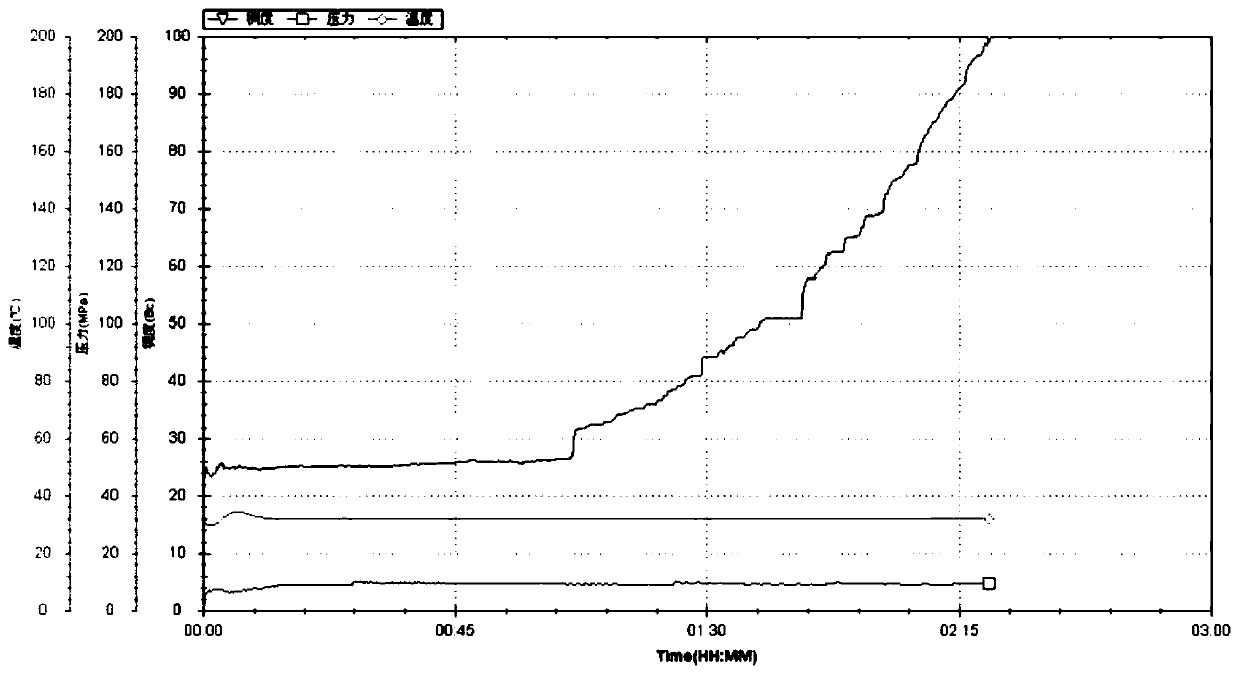

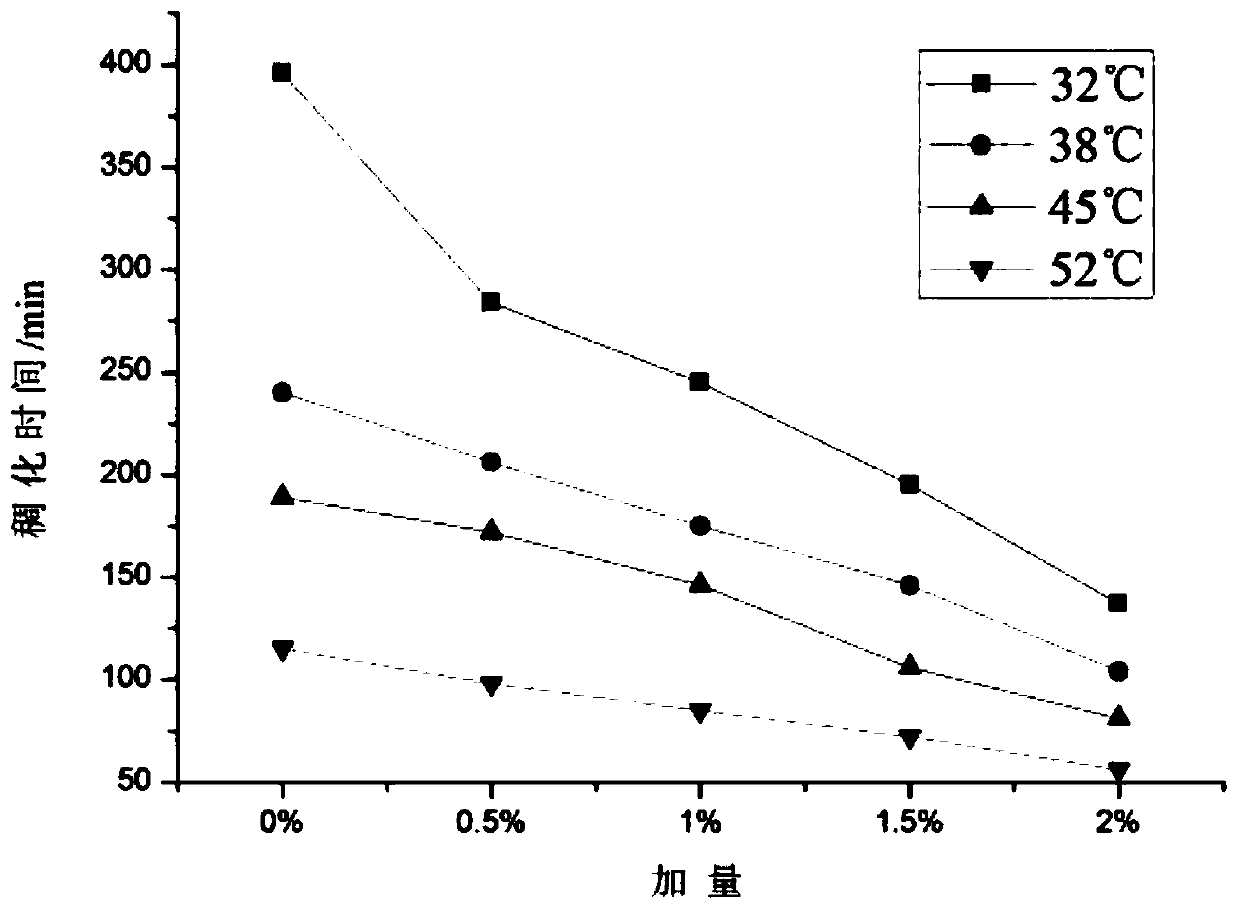

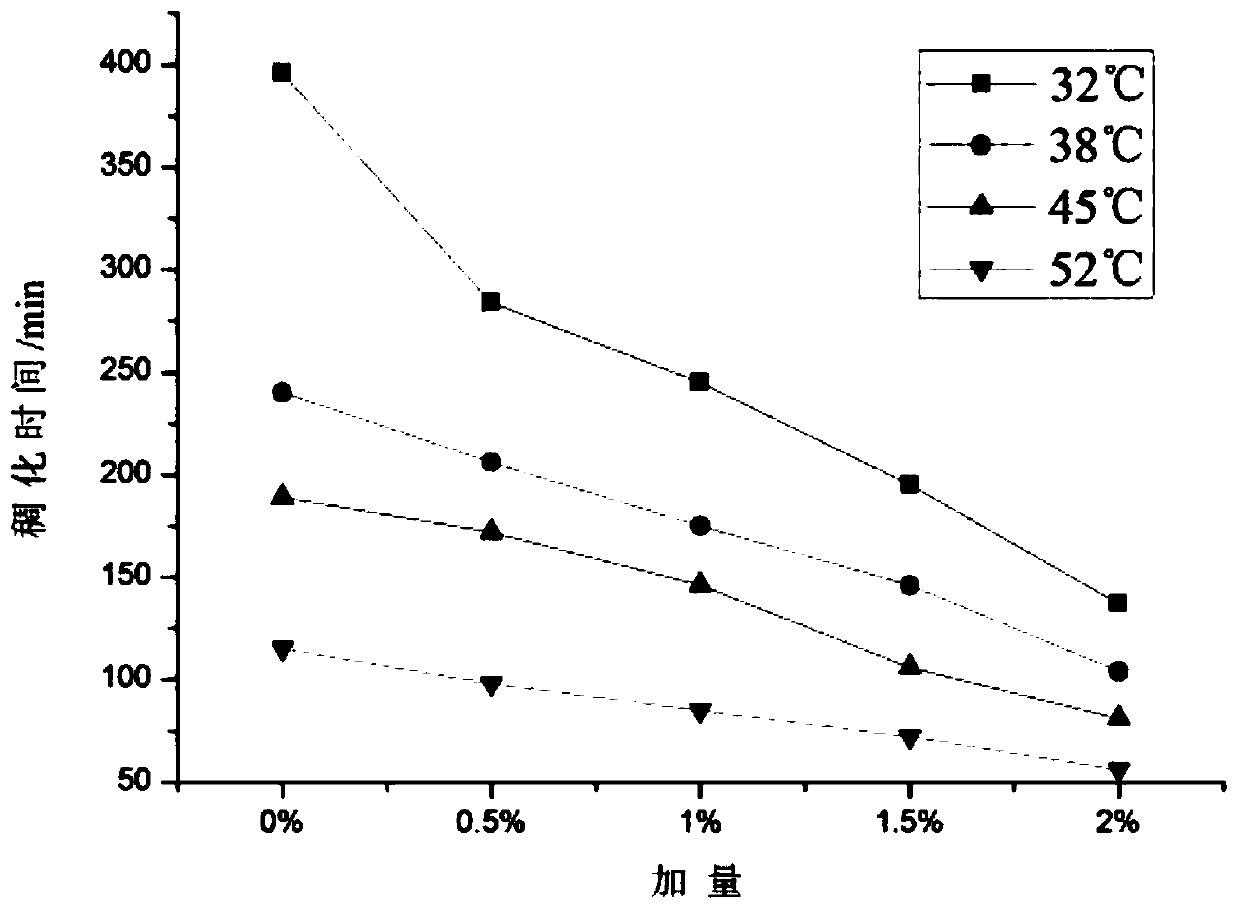

Cement setting accelerator, preparation method and application thereof, and set cement

The invention provides a cement setting accelerator, and a preparation method and application thereof, and belongs to the field of well cementation in thickened oil exploitation. The cement setting accelerator provided by the invention comprises the following components in percentage by mass: 5-10% of polyaluminium chloride, 20-25% of calcium chloride, 15-20% of sodium oxalate, 5-10% of calcium aluminate, 5-10% of calcium formate, 10-15% of sodium sulfate, 5-10% of a dispersing agent and 10-15% of nano silicon. The cement accelerator provided by the invention is prepared by adopting specific components and content, so that setting is fast at low temperature, early strength is high, and the early strength is not reduced at high temperature. The result of the embodiment shows that when the adding amount of the cement accelerator provided by the invention is 2%, the thickening time of cement paste is 56-137 minutes in a temperature range of 32-52 DEG C; the early strength of set cement after 8 hours is 8.1 MPa at a temperature of 36 DEG C; and the early strength after 24 hours is 26.9 MPa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

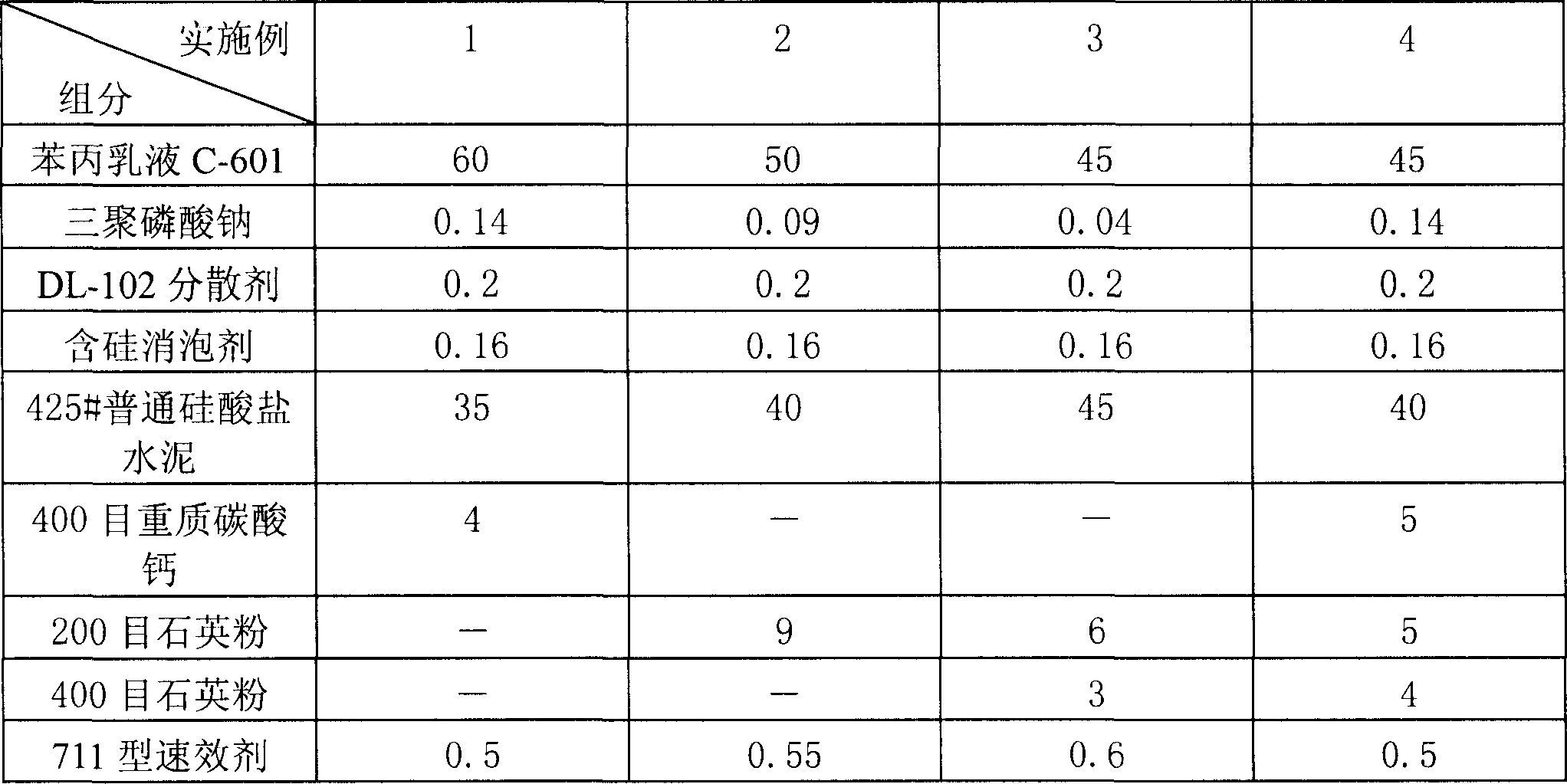

Multi-purpose quick-effective waterproof adhesive

InactiveCN1970669AThe test result is excellentTo achieve the purpose of quick-acting waterproofHydrocarbon polymer adhesivesEmulsionAdhesive

The invention discloses multipurpose quick-effective hydraulic glue, which comprises the following parts: 45-60% synthesized emulsion, 0.1-0.2% inorganic dispersant, 0.1-2% organic dispersant, 0.1-0.3% defoamer, 30-40% common silicate cement, 5-15% heavy calcium carbonate and 0.1-1% cement accelerator. The invention possesses high exending strength and high wet-base binding strength, which displays elastic water-proof coating with relative fracture extending property.

Owner:王永法

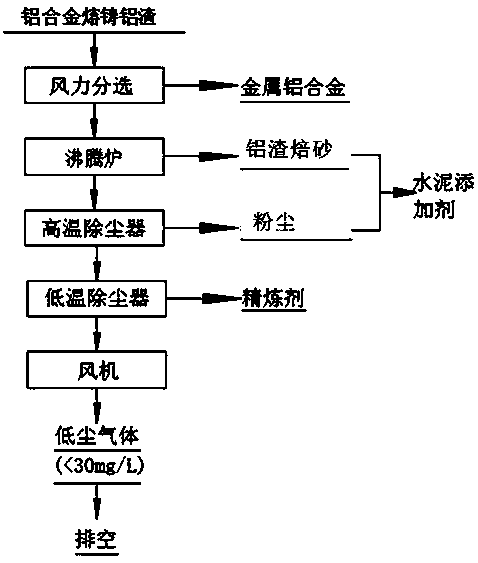

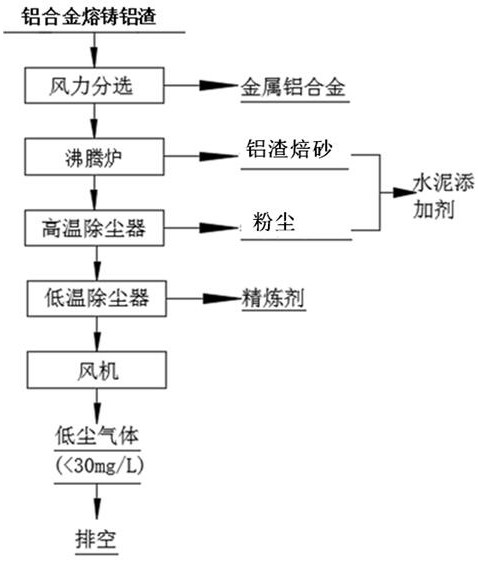

Method for recycling aluminum alloy casting aluminum residue

ActiveCN108754182ARealize recycling of resourcesHarmlessProcess efficiency improvementIngot castingCement accelerator

The invention discloses a method for recycling an aluminum alloy casting aluminum residue. The method comprises the steps of adopting the aluminum residue produced in an aluminum alloy casting processas a raw material, winnowing, sintering at high temperature, collecting dust at high temperature, collecting dust at low temperature, and obtaining a cement accelerator product and a refining agent product for aluminum ingot casting. The invention provides the effective method for effectively and comprehensively recycling the aluminum residue, meanwhile, the cement accelerator product and the refining agent product for aluminum ingot casting can be prepared, hazardous wastes can be recycled harmlessly, the obtained product can be applied to actual production, and the method provided by the invention is simple, easy to operate, green, environmental-friendly, and wide in application prospect.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

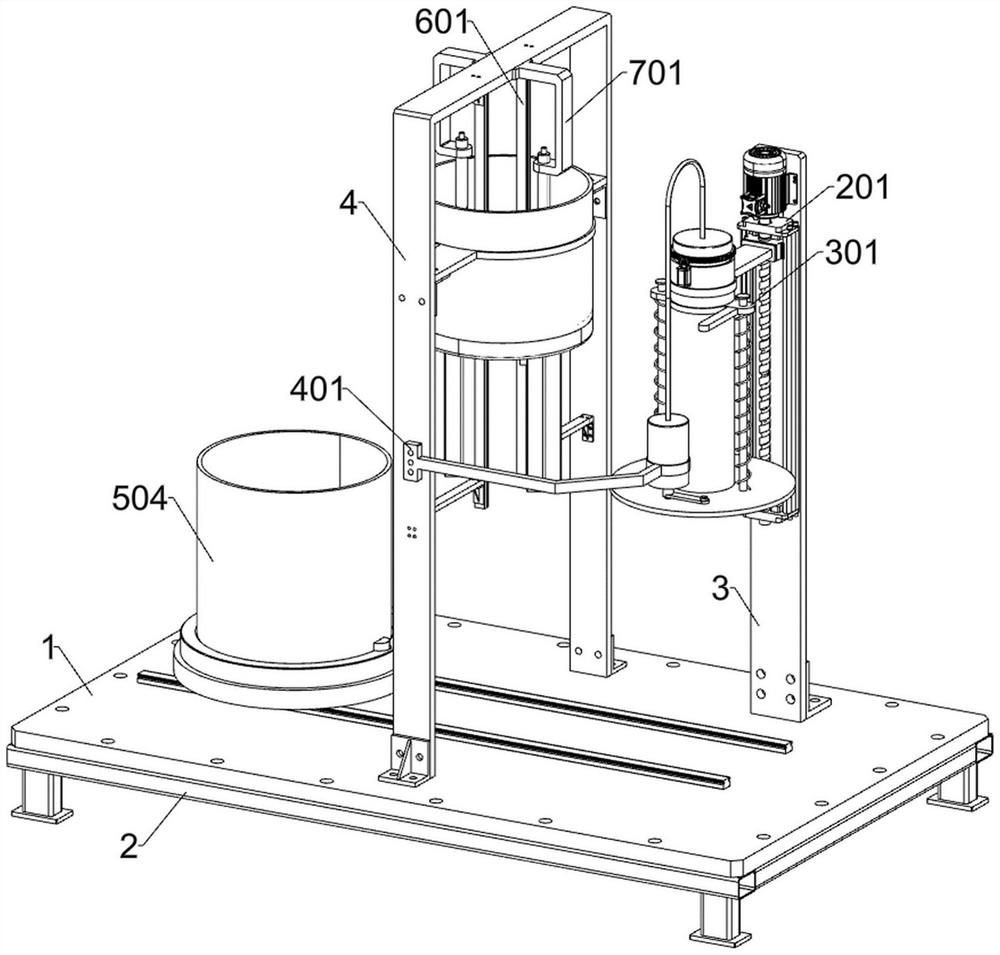

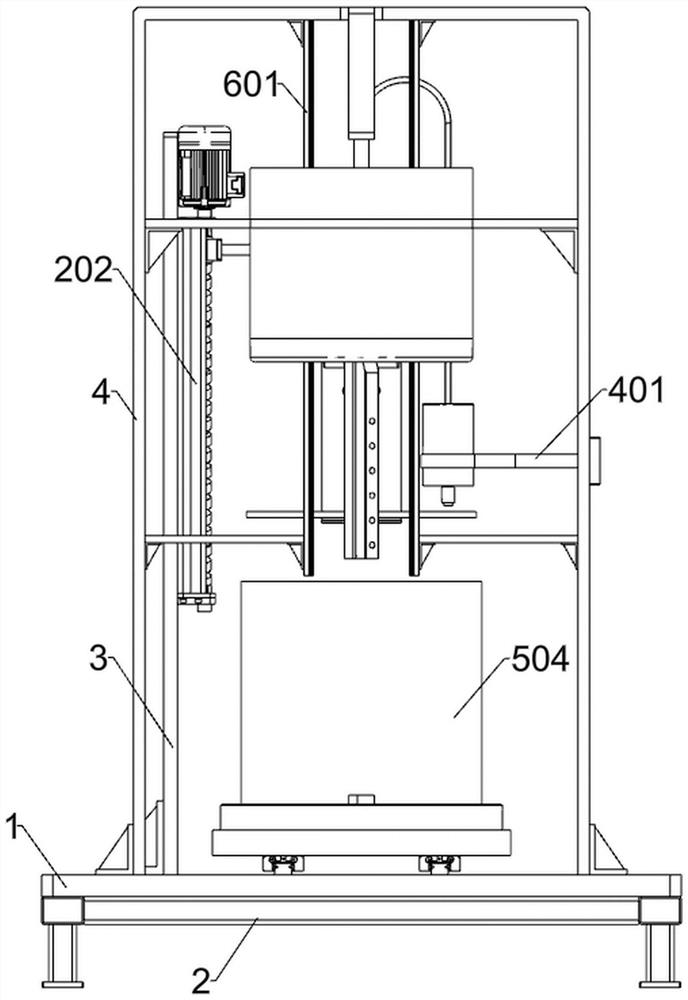

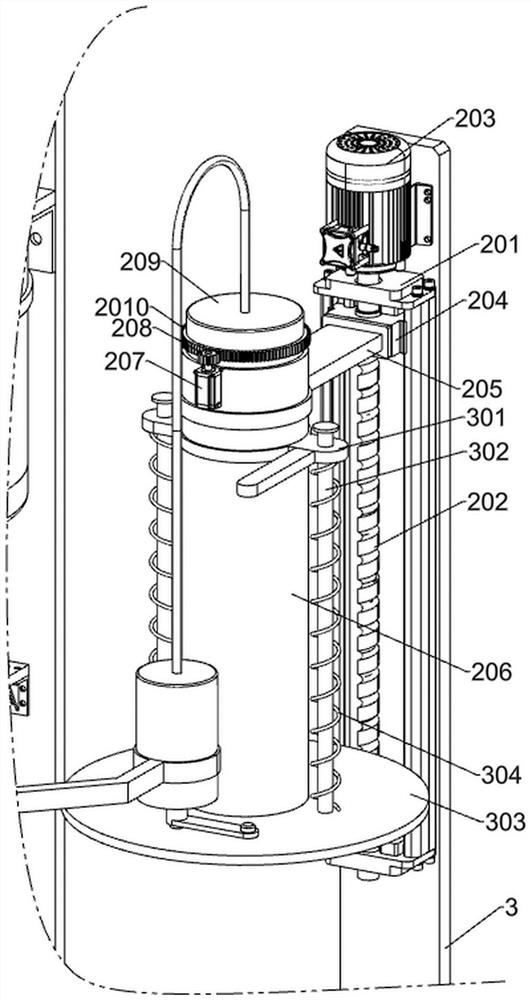

Improved cement accelerator production and processing equipment and process thereof

InactiveCN114471337AImprove elimination efficiencyReduce wasteTransportation and packagingRotary stirring mixersEpoxyProcess equipment

The invention relates to the field of cement accelerators, in particular to improved cement accelerator production and processing equipment and a process thereof. The technical problems that a large number of bubbles are generated in the stirring process due to the fact that epoxy resin glue has certain viscosity, the purity of a mixture is reduced, and the product quality is greatly reduced are solved. According to the technical scheme, the improved cement accelerator producing and processing equipment comprises a second supporting frame, a bubble removing assembly and the like; a bubble removing assembly is installed on the upper portion of the front side of the second supporting frame. During use, bubbles dispersed in a mixture are automatically gathered towards the middle, then the mixture containing the bubbles in the middle is heated in an isolated mode, full heating of all the mixture is not needed, energy waste is reduced, energy conservation and environmental protection are facilitated, the mixture is stirred while heating is conducted, meanwhile, a cavity in the upper portion of the first cylinder is pumped to be in a negative pressure state, and the stirring efficiency is improved. The bubble eliminating efficiency is greatly improved, and meanwhile, a mixture remaining in the stirring blades is automatically removed and collected.

Owner:山西科腾环保新材料股份有限公司 +1

Use of non-chloride cement accelerator and electric arc furnace dust in cement

InactiveUS9278888B1Improve early compressive strengthImprove workabilitySolid waste managementElectric arc furnaceChloride

The present disclosure relates to cement compositions comprising: (a) cement, (b) an electric arc furnace dust (EAFD), and (c) a non-chloride cement accelerator; wherein the electric arc furnace dust is present in an amount from greater than 0 wt % to 8 wt % based on the total weight of the cement (a). Also disclosed are methods for making the disclosed compositions and products using the disclosed compositions. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:SAUDI BASIC IND CORP SA

Three-dimensional reinforced cement light wallboard

InactiveCN101684679ALose weightIncrease the effective use areaSolid waste managementBuilding componentsFiberLand resources

The invention discloses a three-dimensional reinforced cement light wallboard with light weight, great strength, good heat insulation and good sound insulation. The wallboard comprises a polyphenyl board, a sizing agent layer and an alkali-resistant fiber grid, wherein the sizing agent layer is prepared from the following raw material components in part by weight: sawdust, rapid hardening sulphatealuminium cement, fly ash, river sand, reinforcing agent, water and cement softening agent, wherein the reinforcing agent consists of the following raw material components in part by weight: polypropylene fine fiber, sulphoaluminate cement accelerator and silica fume. The three-dimensional reinforced cement light wallboard has the advantages of reducing the dead weight of buildings, increasing the effective use area of the buildings, reducing the structural engineering cost for the buildings, protecting farmland, protecting finite land resources, realizing the factory production of walls, fully and reasonably utilizing industrial and agricultural waste and achieving the aims of protecting earth resources and preventing waste from polluting living environment.

Owner:郭建军

Quick-dry cement

The invention relates to quick-dry cement which comprises the following components in parts: 5-10 parts of a vermiculite powder, 10-15 parts of a cement accelerator, 20-35 parts of fly ash, 10-15 parts of an iron powder, 10-15 parts of a stabilizer, 5-10 parts of fiber and 10-20 parts of bentonite. According to the quick-dry cement, the components are proportionally prepared in advance, and grouting can be performed after stirring with water in a using process, so that the quality of the cement can be sufficiently ensured; the cement has certain flowability, is short in setting time, has early strength, and can meet a requirement of people for the quick-dry cement.

Owner:张升

Thermal insulating cement

InactiveCN107986654AImprove insulation performanceGood heat insulationCement productionSlagPulverized fuel ash

The invention discloses thermal insulating cement which is characterized by comprising the following raw materials in parts by weight: 80 parts of cement clinker, 5-8 parts of gypsum, 10 parts of manganese slag, 5 parts of cement accelerator, 20 parts of vermiculite powder, 3-5 parts of pulverized fuel ash, 0.3-0.4 parts of alum and 12-16 parts of fluorgypsum. The cement is prepared by grinding 80parts of cement clinker, 5-8 parts of gypsum, 10 parts of manganese slag, 5 parts of cement accelerator, 20 parts of vermiculite powder, 3-5 parts of pulverized fuel ash, 0.3-0.4 parts of alum and 12-16 parts of fluorgypsum. A thermal insulating effect of the thermal insulating cement is increased by 40% as compared with the ordinary cement, and the thermal insulating cement has a good thermal insulating effect.

Owner:徐州市龙山水泥有限公司

Cement accelerator, and preparation method thereof

InactiveCN108218280AIncrease the speed of solidificationHigh strengthHydration reactionSodium Bentonite

The invention discloses a cement accelerator, and a preparation method thereof. The cement accelerator is prepared from, by weight, 50 to 100 parts of bauxite slag, 20 to 40 parts of sodium carbonate,10 to 30 parts of bentonite, 5 to 15 parts of sulfonated lignin, 5 to 10 parts of a phosphate, 3 to 5 parts of ether sulfate triethanolamine, 1 to 3 parts of Sodium Lauryl Diphenyl Ether Disulfonate,1 to 3 parts of a methylnaphthalene sulfonic formaldehyde polycondensate, 0.5 to 2 parts of N-acyl potassium glutamate, and 1 to 3 parts of Lauryl methyl aminoethyl sodium phosphate. When the cementaccelerator is mixed with cement, hydration reaction is realized as soon as the cement is mixed with water, cement mortar rapid hardening coagulation is realized, concrete and cement solidification speeds are accelerated greatly; the compatibility of the cement accelerator with cement mortar is excellent, and cement concrete intensity is not reduced.

Owner:广西高企科技有限公司

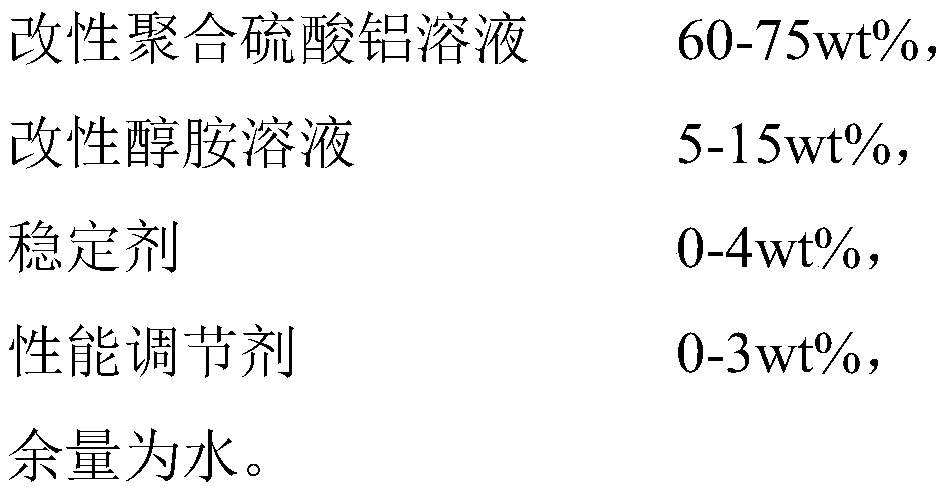

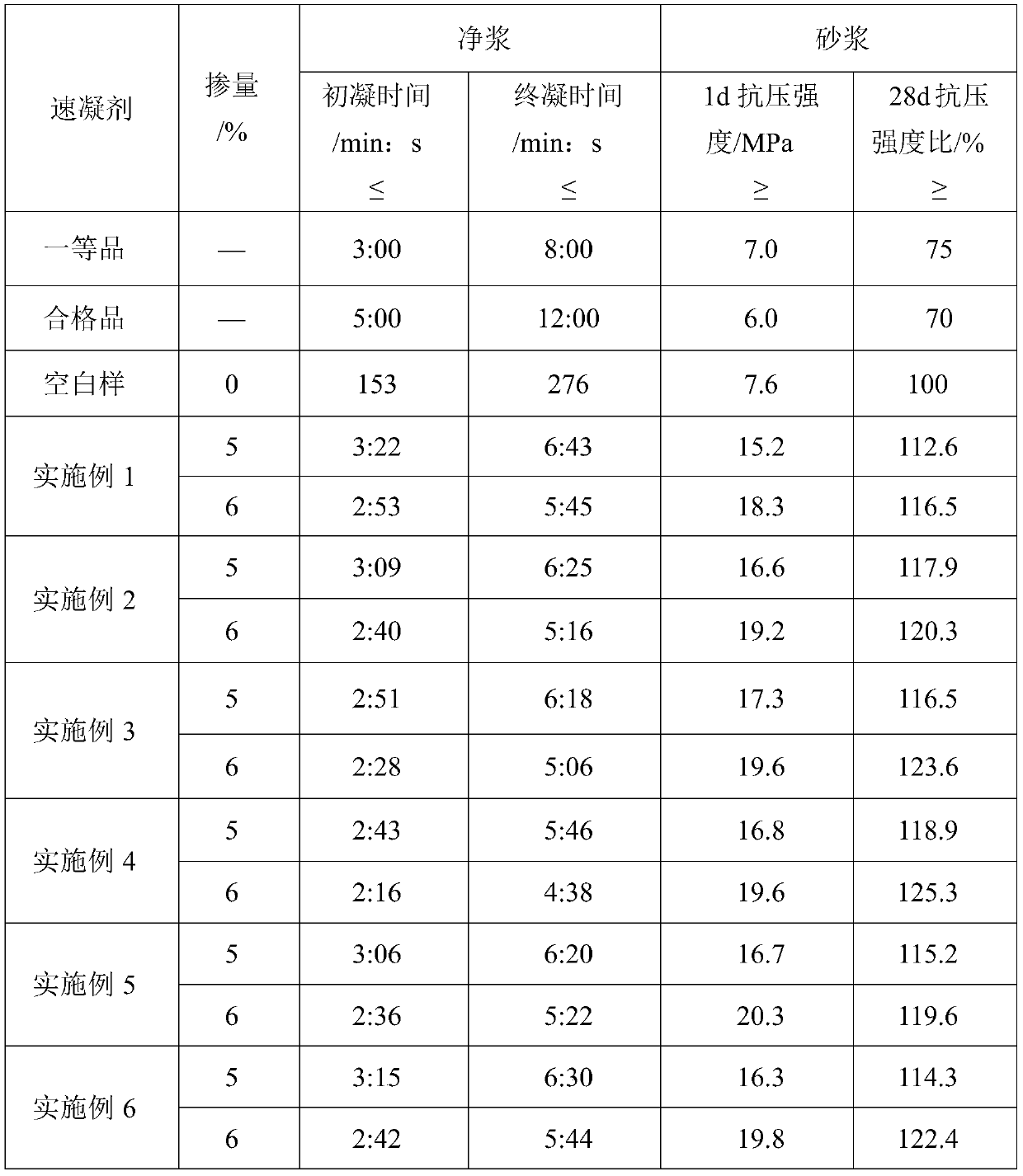

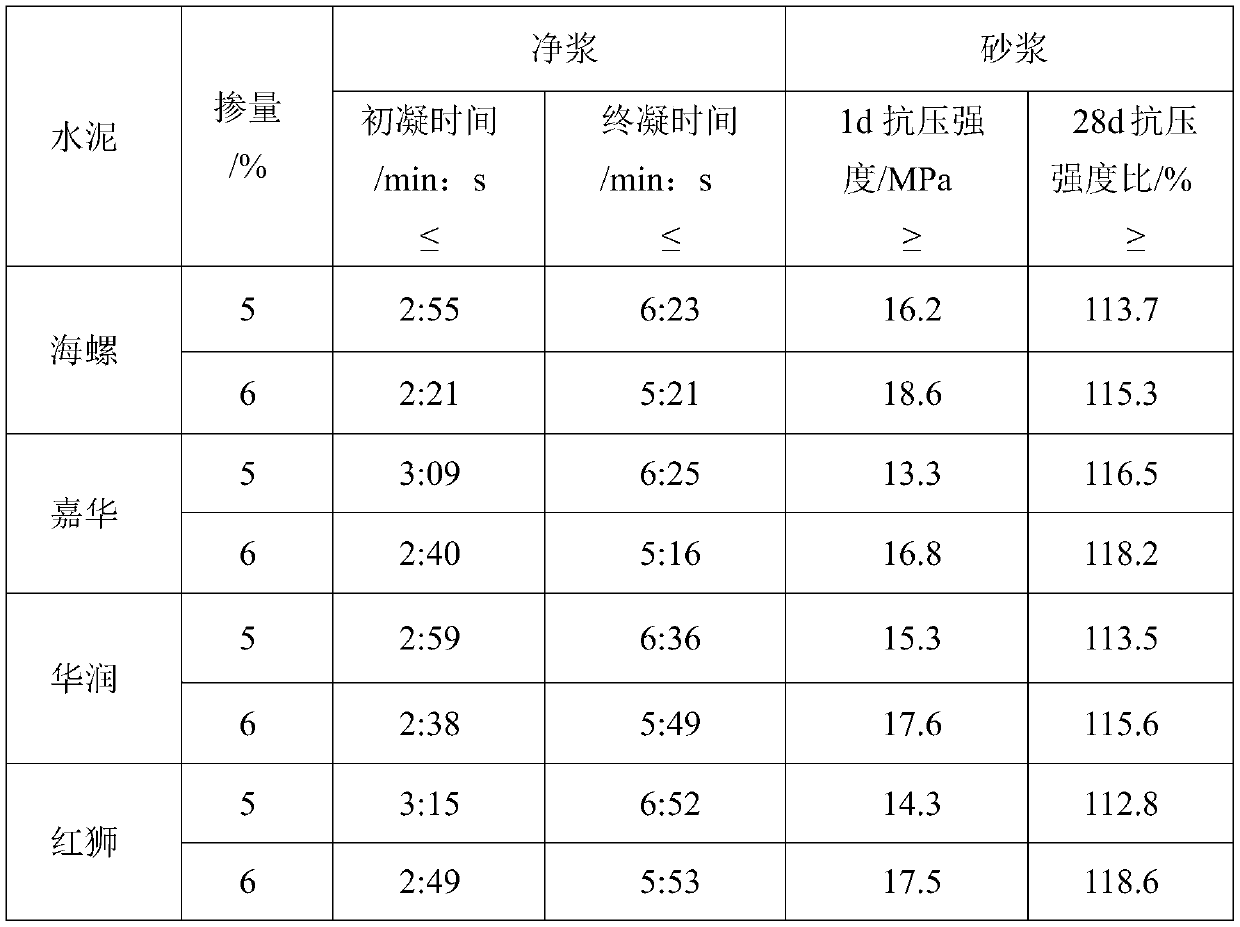

A kind of early-strength liquid alkali-free accelerator for shotcrete and preparation method thereof

The invention relates to an early strong type liquid alkali-free accelerator used for sprayed concrete and a preparation method thereof, solving the problems of reduction of long-term strength and durability of concrete due to easy alkali-aggregate reaction caused by relatively high alkali content of existing cement accelerators. The liquid alkali-free accelerator provided by the invention is prepared from 60-75% of modified polyaluminium sulfate solution, 5-15% of modified alkanolamine solution, 0-3% of a performance modifier, 0-4% of a stabilizer and water. The accelerator belongs to an alkali-free and chloride-free liquid accelerator, is used in a sprayed concrete wet spraying process, has a stationary phase exceeding 6 months, and can realize initial setting of ordinary Portland cementof different varieties in 3 minutes and final setting in 7 minutes; and the cement mortar 1d strength reaches more than 15MPa, and 28d compressive strength ratio is greater than 110%.

Owner:WUHAN UNIV OF TECH

Non-toxic rodenticide Portland cement obstructing agent and preparation method thereof

InactiveCN113475526AAvoid breakingNot easily damaged shapeBiocidePest attractantsEcological environmentAdhesive

The invention relates to a non-toxic rodenticide Portland cement obstructing agent and a preparation method thereof. The non-toxic rodenticide Portland cement obstructing agent comprises paraffin, Portland cement, a cement accelerator, an adhesive, waxberry, Ilex latifolia, pomegranate, grain, an attractant and a preservative. The preparation method comprises the steps of heating the paraffin to prepare a wax liquid, drying and crushing waxberry, Ilex latifolia and pomegranate to prepare dry powder, and uniformly mixing and stirring the wax liquid, Portland cement, the waxberry dry powder, the Ilex latifolia dry powder, the pomegranate dry powder, the cement accelerator, the adhesive, the grain, the attractant and the preservative according to the formula proportion, filling the mixture into forming equipment, and pressing to obtain the non-toxic rodenticide Portland cement obstructing agent. The invention realizes no harm to the ecological environment, the components such as waxberry, Ilex latifolia and pomegranate are natural substances, the non-toxic rodenticide Portland cement obstructing agent is easy to mildew and deteriorate in the natural environment, is safe and harmless to human, poultry and livestock, has high deratization efficiency and obvious effect, and is applied to the technical field of rodent drug prevention and treatment.

Owner:沈阳爱威科技发展股份有限公司

Rubber particle weight gain method and rubber concrete preparation method

The invention provides a rubber particle weight increasing method and a preparation method of a rubber concrete. Through the rubber particle weight increasing method, the weight and the density of a rubber particle are increased, the rubber particles are more evenly distributed in the concrete, and the mechanical property of the rubber concrete is improved. The related rubber particle weight increasing method is characterized by comprising the following steps: 1, weighing a certain amount of the rubber particles, soaking with clear water until the particles completely sink down and no bubble exists on the surfaces of the particles; 2, taking out the rubber particles, adding the rubber particles into a cement paste and stirring, wherein the volume ratio of the rubber particles to the cement paste is 1:1 and 20% of a cement accelerator is doped in the cement paste; 3, observing the thickness of a mixture, adding proper amount of water until the slump constant of the mixture is 6-10, stirring for a certain period of time; 4, evenly spreading the mixture by using a shovel blade, basically separating the particles, and airing naturally; 5, screening an excessive powder by using a mesh sieve, maintaining in water for a plurality of days, and taking out; 6, stirring the rubber once every few hours, stirring for times, airing until the particles are grey white, and obtaining the weight increased rubber particles.

Owner:武汉煜卉工程咨询有限公司

A method for resourceful treatment of aluminum alloy melting and casting aluminum slag

ActiveCN108754182BRealize recycling of resourcesHarmlessSolid waste disposalProcess efficiency improvementIngot castingSlag

The invention discloses a method for recycling an aluminum alloy casting aluminum residue. The method comprises the steps of adopting the aluminum residue produced in an aluminum alloy casting processas a raw material, winnowing, sintering at high temperature, collecting dust at high temperature, collecting dust at low temperature, and obtaining a cement accelerator product and a refining agent product for aluminum ingot casting. The invention provides the effective method for effectively and comprehensively recycling the aluminum residue, meanwhile, the cement accelerator product and the refining agent product for aluminum ingot casting can be prepared, hazardous wastes can be recycled harmlessly, the obtained product can be applied to actual production, and the method provided by the invention is simple, easy to operate, green, environmental-friendly, and wide in application prospect.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com