Improved cement accelerator production and processing equipment and process thereof

A technology of processing equipment and quick-setting agent, which is applied in the field of production and processing equipment of improved cement quick-setting agent, can solve the problems of lowering product quality, lowering the purity of mixture, etc., so as to reduce energy waste, avoid insufficient stirring, and increase bubbles. Eliminate the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

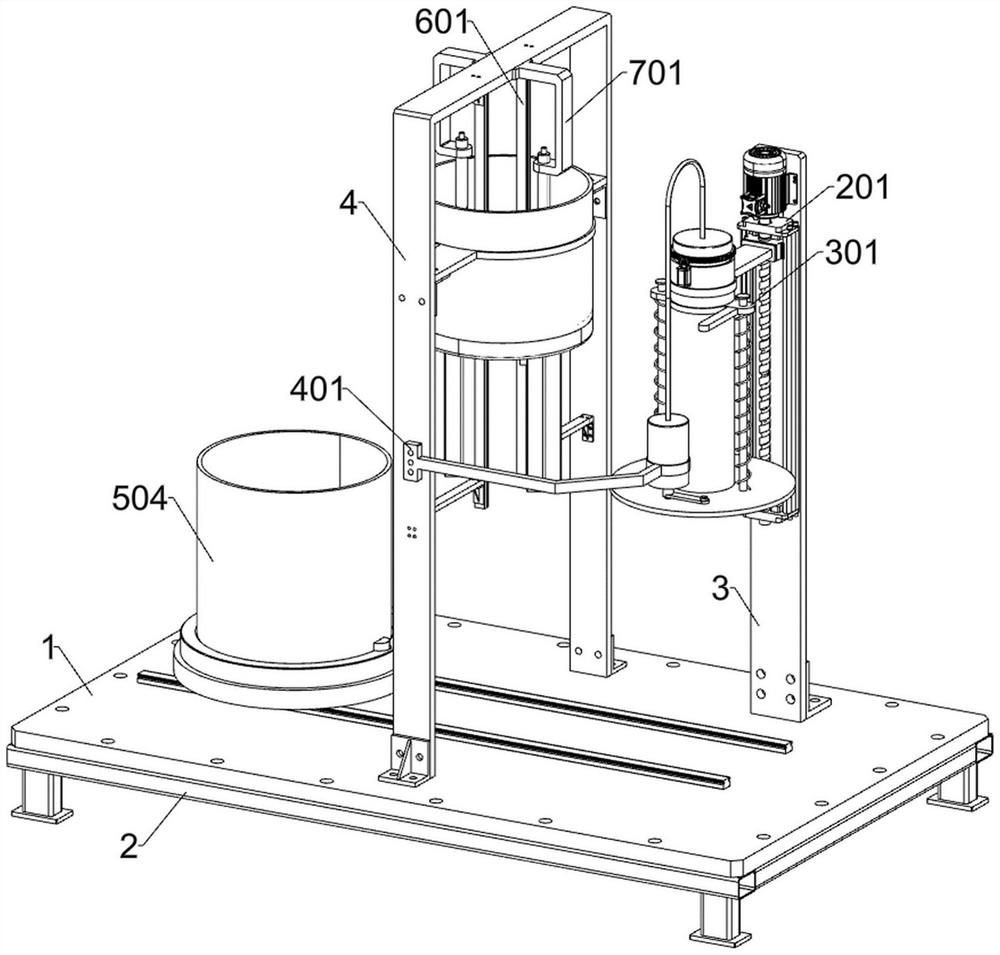

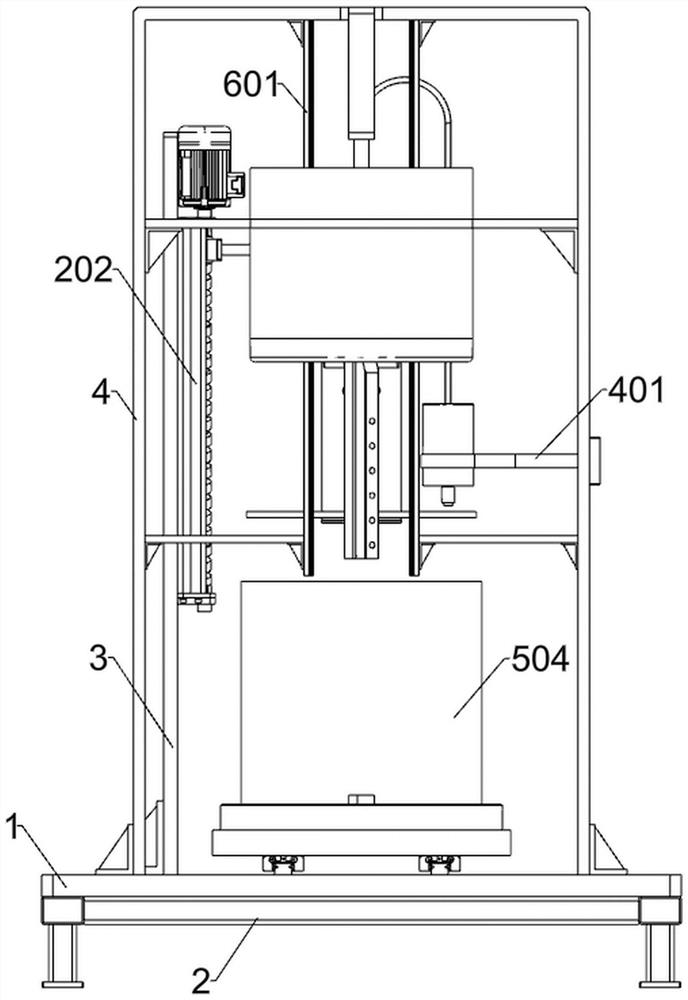

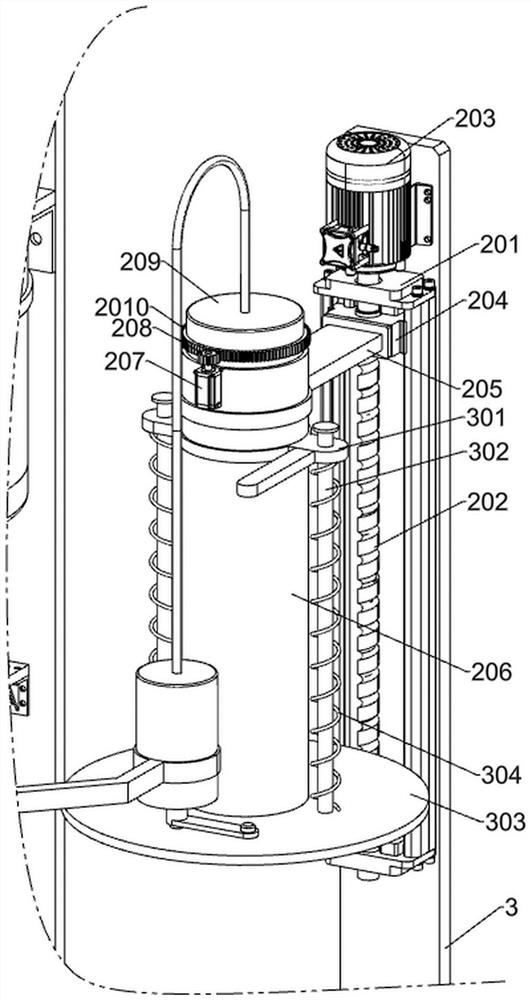

[0039] A kind of production and processing equipment of improved cement quick-setting agent, such as Figure 1-8 As shown, it includes a bottom plate 1, a first support frame 2, a second support frame 3, a third support frame 4, a bubble removal component, an overflow prevention component, a negative pressure component, a transfer component and a stirring component; the bottom side of the bottom plate 1 is connected by bolts There is a first support frame 2; a third support frame 4 is connected by bolts on the upper middle part of the bottom plate 1; a second support frame 3 is connected by bolts on the upper right side of the bottom plate 1; an air-removing component is installed on the upper front side of the second support frame 3; The anti-overflow assembly is installed on the lower part of the air-removing assembly; the negative pressure assembly is installed in the middle of the front side of the third support frame 4; the negative pressure assembly is connected to the ai...

Embodiment 2

[0046] On the basis of Example 1, such as figure 1 and Figure 9-12 As shown, the stirring assembly includes a second electric slide rail 601, a second electric slide block 602, a third linkage frame 603, a third motor 604, a second spur gear 605, a third round rod 606, a third spur gear 607, The third linkage block 608, the stirring blade 609, the second pipeline 6010 and the second piston 6011; the inner side of the upper part of the third support frame 4 is fixedly connected with two second electric slide rails 601; the two second electric slide rails 601 slide A second electric slider 602 is connected; a third linkage frame 603 is fixedly connected between the two second electric sliders 602; a third motor 604 is installed on the front of the third linkage frame 603; the output end of the third motor 604 is fixed The second spur gear 605 is connected; the middle part of the third linkage frame 603 is rotatably connected with a third round rod 606; The lower part of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com