Bayer red mud cement accelerator and production method

A technology of quick-setting agent and Bayer red mud, applied in the field of Bayer red mud cement quick-setting agent, can solve the problems that have not been researched, and achieve the effects of protecting the environment, improving the later strength and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

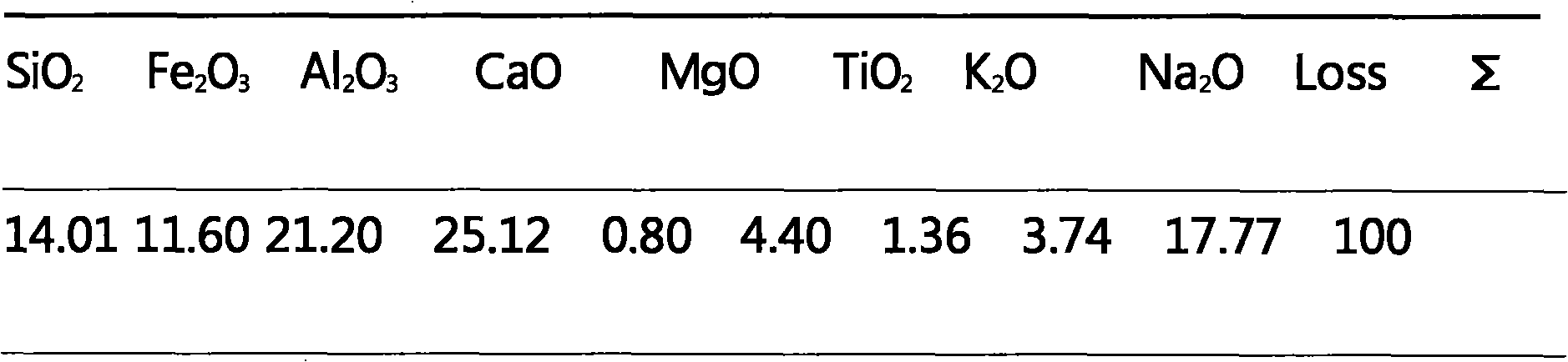

Image

Examples

Embodiment 1

[0067] Embodiment 1, according to this accelerator proportioning: Bayer red mud sintered clinker: naphthalenesulfonic acid formaldehyde condensation polymer (FDN): triethanolamine (TEA): Bayer red mud: fly ash: hemihydrate gypsum=50 %: 10%: 1%: 20%: 14%: 5%.

[0068] Prepare 2 kg of sample, use 5 kg of ball mill to grind until 80% of 200 mesh sieve passes, take 20 g of quick-setting agent and add it to 400 g of cement, and add 168 ml of water according to the water-cement ratio of 0.4, stir rapidly for 25 seconds, immediately Put it into the round mold, manually vibrate several times, cut off the excess cement slurry, and smooth the surface with a clean scraper, use the cement slurry standard consistency and setting time tester to measure the initial setting time of the cement slurry for 4 minutes, and the final setting time for 8 minutes minute.

[0069] The compression test uses a 200kN compression testing machine and a 40mm (length) × 40mm (width) × 160mm (height) test mol...

Embodiment 2

[0070] Embodiment 2, according to this accelerator proportioning: Bayer red mud sintered clinker: naphthalenesulfonic acid formaldehyde condensation polymer (FDN): triethanolamine (TEA): Bayer red mud: fly ash: lime=55%: 8%:0.5%:15%:10%:11.5%. Prepare 2 kg of sample, use 5 kg of ball mill to grind until 80% of 200 mesh sieve passes, take 20 g of quick-setting agent and add it to 400 g of cement, and add 168 ml of water according to the water-cement ratio of 0.4, stir rapidly for 25 seconds, immediately Put it into the round mold, manually vibrate several times, cut off the excess cement slurry, and smooth the surface with a clean scraper, use the cement slurry standard consistency and setting time tester to measure the initial setting time of the cement slurry for 5 minutes, and the final setting time 7 minute.

[0071] The compression test uses a 200kN compression testing machine and a 40mm (length) × 40mm (width) × 160mm (height) test mold. The compressive strength ratio of...

Embodiment 3

[0072] Embodiment 3, according to this accelerator proportioning: Bayer red mud sintered clinker: naphthalenesulfonic acid formaldehyde condensation polymer (FDN): triethanolamine (TEA): Bayer red mud: fly ash: lime: hemihydrate gypsum =47%: 12%: 1%: 15%: 15%: 10%, prepare 2 kilograms of samples, adopt experimental 5 kilograms of ball mills to pass through 80% of 200 mesh sieves, get wherein 20g quick-setting agent and add in 400 grams of cement , and according to the water-cement ratio of 0.4, add 168 ml of water, stir rapidly for 25 seconds, immediately put it into the round mold, manually vibrate several times, cut off the excess cement slurry, and smooth the surface with a clean scraper. The setting time measuring instrument measures the initial setting time of the cement slurry for 3 minutes and the final setting time for 5 minutes.

[0073] The compression test uses a 200kN compression testing machine and a 40mm (length) × 40mm (width) × 160mm (height) test mold, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com