Rubber particle weight gain method and rubber concrete preparation method

A technology of rubber granule weight gain method, which is applied in the field of rubber granule weight gain method and rubber concrete preparation, which can solve the problems of low rubber particle density, loose bonding, and easy floating when vibrating, and achieve uniform distribution, uniform distribution, The effect of improving water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for increasing the weight of rubber particles and the method for preparing rubber concrete involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

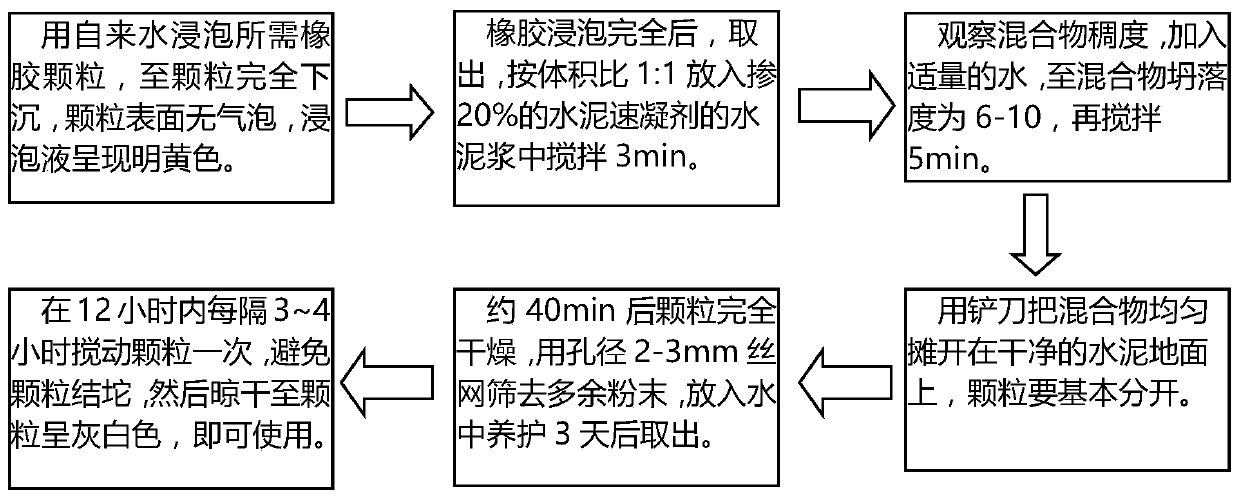

[0025] Such as figure 1 Shown, rubber particle weight gain method comprises the following steps:

[0026] Step 1. Take a certain amount of rubber particles, soak them with tap water until the particles sink completely, and there are no air bubbles on the surface of the particles, and the soaking solution is bright yellow; in this embodiment, the rubber particles used are 3-4mm in size, soak The time is 4-5 days. If there are individual particles that do not sink, just throw them away;

[0027] Step 2. Take out the rubber particles, put them into the cement slurry mixed with 20% cement quick-setting agent according to the volume ratio of 1:1 and stir for several minutes. In the present embodiment, the stirring time is 3min;

[0028] Step 3. Obse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com