Cement setting accelerator, preparation method and application thereof, and set cement

A technology of quick-setting agent and cement stone, which is applied to cement stone. , In the field of cement quick-setting agent and its preparation, it can solve the problems of low strength and difficulty in high-temperature mining of heavy oil, and achieve the effects of high early strength, preventing the formation of micro-cracks, and no decline in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of the above-mentioned cement quick-setting agent, comprising the following steps: mixing polyaluminum chloride, calcium chloride, sodium oxalate, calcium aluminate, calcium formate, sodium sulfate, dispersant and nano-silicon in sequence , to obtain cement quick-setting agent.

[0033] In the present invention, the mixing time is preferably 0.5-2 hours.

[0034] The present invention also provides the application of the above-mentioned cement quick-setting agent in cement stone.

[0035] The present invention also provides a cement stone, which comprises the above-mentioned cement quick-setting agent, water and cement. In the present invention, the added amount of the cement quick-setting agent is preferably 0.5-2% of the cement mass.

[0036] In the present invention, there is no special limitation on the source of the cement, and commercially available products well known to those skilled in the art can be ...

Embodiment 1

[0039] A cement quick-setting agent, comprising the following components in mass percent: 2% polyaluminium chloride; 25% calcium chloride; 20% sodium oxalate; 5% calcium aluminate; 10% calcium formate; 15% sodium sulfate; Agent 5%; nano-silicon 15%;

[0040] The above-mentioned cement quick-setting agent, 800G grade cement and water are mixed, and the cement quick-setting agent is 2% of the mass of the 800G grade cement to obtain cement stone.

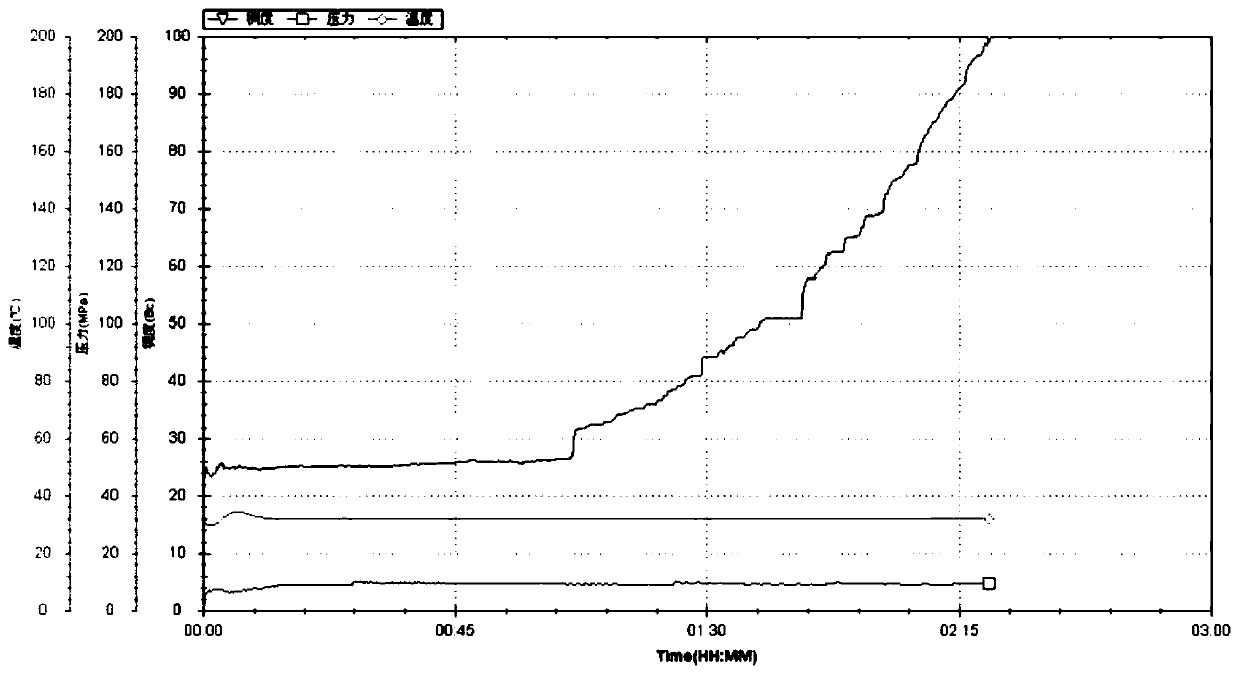

[0041] figure 1 For the cement stone that embodiment 1 makes under certain temperature and pressure, the curve graph of grout consistency changing with time, from figure 1 It can be seen that the cement slurry can thicken in a short time (2h).

Embodiment 2

[0043] A cement quick-setting agent, comprising the following components in mass percent: 8% polyaluminum chloride; 23% calcium chloride; 18% sodium oxalate; 8% calcium aluminate; 8% calcium formate; 13% sodium sulfate; Agent 9%; nano-silicon 13%. ;

[0044] Mix the above-mentioned cement quick-setting agent, 800G grade cement and water, and arrange them according to different proportions to obtain cement stone.

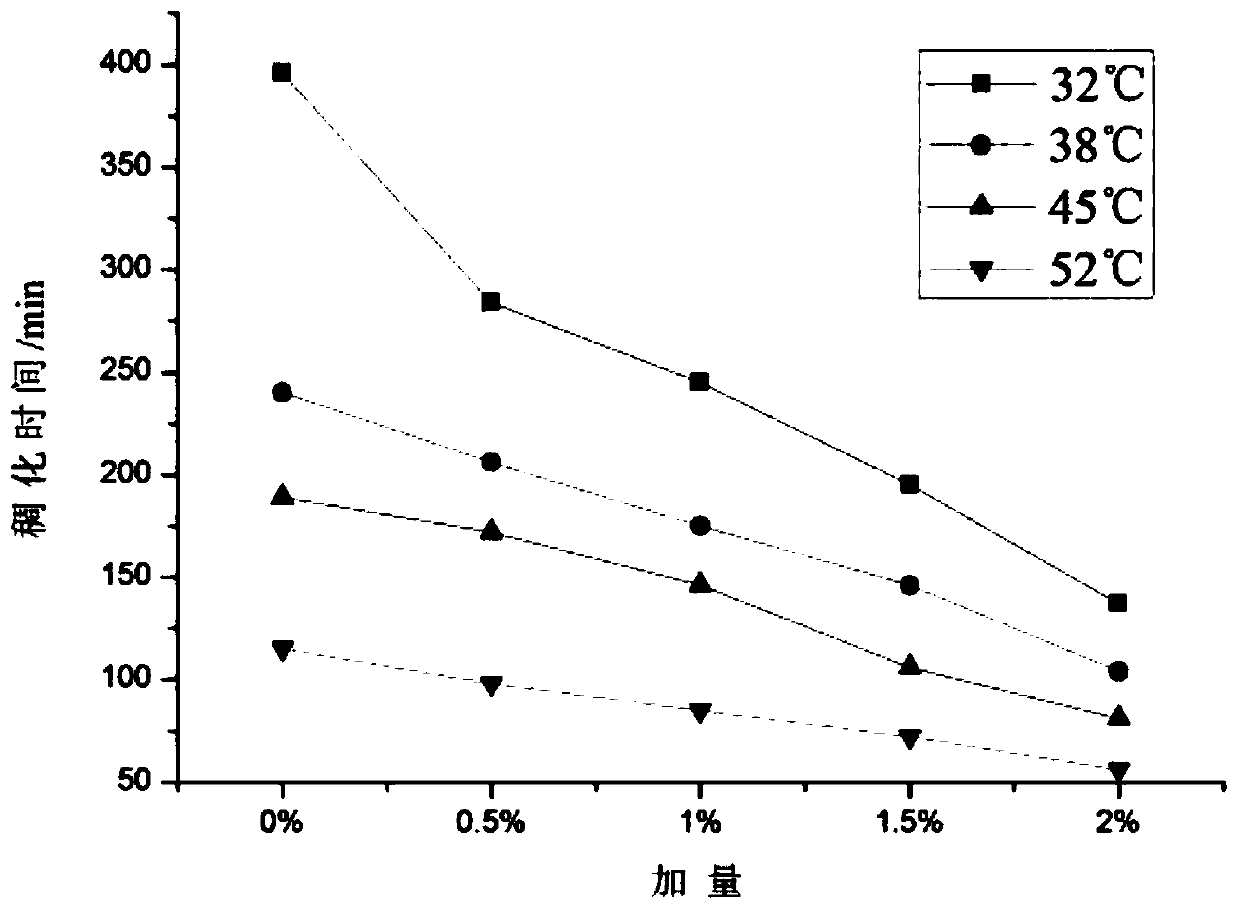

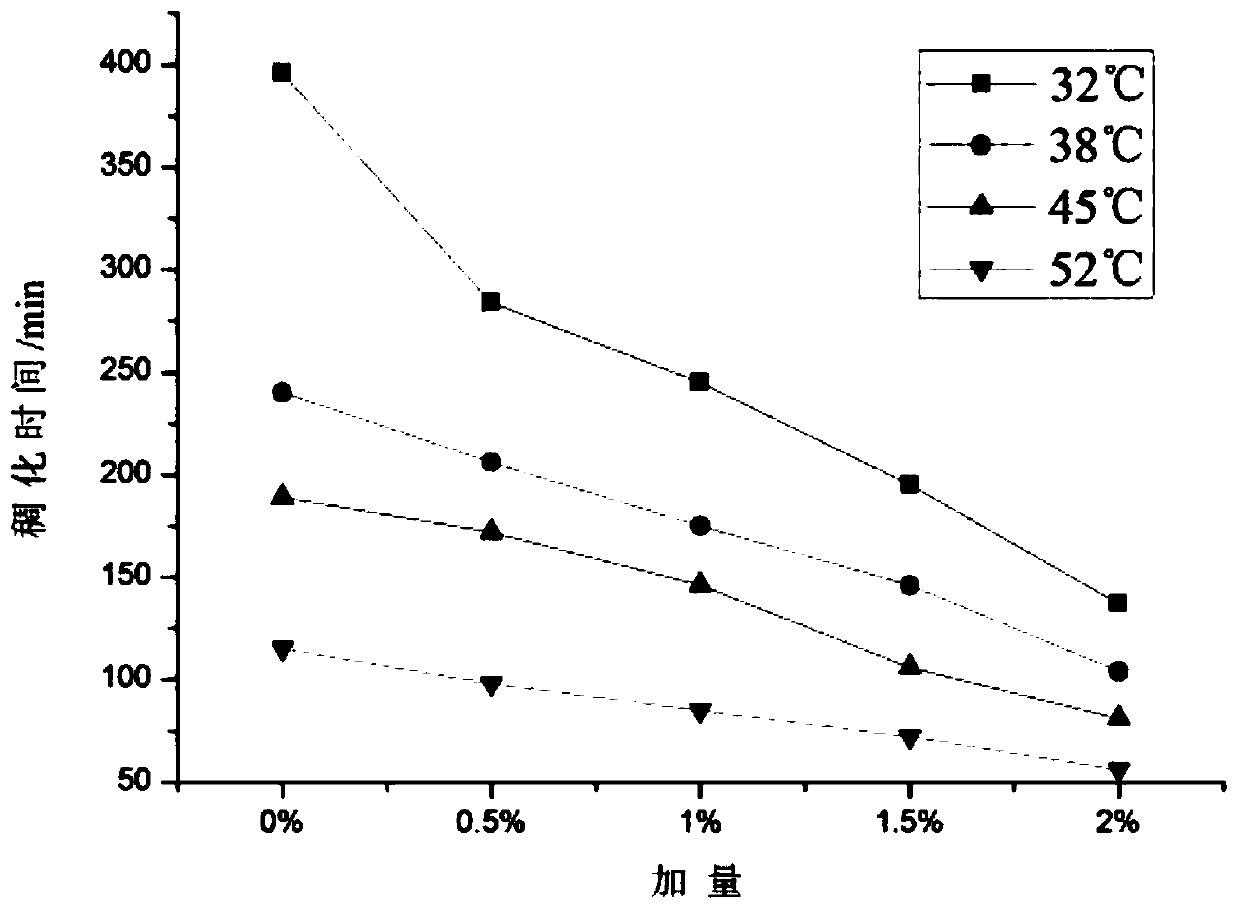

[0045] Table 1 Different content of cement quick-setting agent, at different temperatures for 1.90g / cm 3 Experimental data on the influence of density cement slurry thickening time (min)

[0046]

[0047]

[0048]From the experimental data in Table 1, it can be obtained that the cement slurry prepared in this example, within the range of 32-52 °C, the thickening time shortens continuously with the increase of temperature and addition amount. When the addition amount is 2%, the cement The thickening time of the slurry is 56-137 minutes.

[0049] figure 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com