Polymer low-alkaline accelerator used for sprayed concrete and preparation method thereof

A sprayed concrete and polymer technology, applied in the field of building materials, can solve the problems of concrete strength and durability decline, alkali content alkali aggregate reaction, etc., to reduce the rebound rate, solve the later strength and durability decline, and improve the acceleration The effect of coagulation and early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

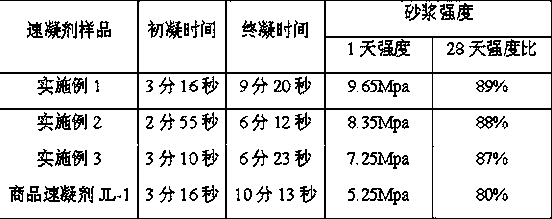

Examples

Embodiment 1

[0027]Take the following raw materials in weight percentage: aluminum hydroxide (industrial first-grade product): 42%, sodium hydroxide: 28%, tap water: 30%; add the above raw materials in the reactor once and stir and heat, and the reaction temperature is controlled at 80 ~120°C, the reaction time is controlled within 1~2h, and the sodium aluminate solution can be obtained.

[0028] Take the following raw materials in terms of weight percentage: phosphoric acid (industrial first-class product): 20%, tungstic acid: 20%, sodium hydroxide: 40%, tap water: 20%; add the above raw materials into the reactor at one time and stir and heat, and react The temperature is controlled at 50-70°C, and the reaction time is controlled at 0.5-1 hour to obtain a sodium phosphotungstate solution.

[0029] Take 20 parts of sodium aluminate solution and 10 parts of sodium phosphotungstate solution prepared above, mix and stir to raise the temperature to 60°C, then add 5 parts of polyacrylamide, 5 ...

Embodiment 2

[0031] Take the following raw materials in weight percentage: aluminum hydroxide (industrial first-grade product): 42%, sodium hydroxide: 28%, tap water: 30%; add the above raw materials in the reactor once and stir and heat, and the reaction temperature is controlled at 80 ~120°C, the reaction time is controlled within 1~2h, and the sodium aluminate solution can be obtained.

[0032] Take the following raw materials in weight percentage: phosphoric acid (industrial first-class product): 30%, tungstic acid: 20%, sodium hydroxide: 40%, tap water: 10%; add the above raw materials into the reactor at one time, stir and heat, and react The temperature is controlled at 50-70°C, and the reaction time is controlled at 0.5-1 hour to obtain a sodium phosphotungstate solution.

[0033] Take 30 parts of sodium aluminate solution and 10 parts of sodium phosphotungstate solution prepared above, mix and stir to raise the temperature to 60°C, then add 5 parts of polyoxyethylene ether, 5 part...

Embodiment 3

[0035] Take the following raw materials in weight percentage: aluminum hydroxide (industrial first-grade product): 42%, sodium hydroxide: 28%, tap water: 30%; add the above raw materials in the reactor once and stir and heat, and the reaction temperature is controlled at 80 ~120°C, the reaction time is controlled within 1~2h, and the sodium aluminate solution can be obtained.

[0036] Take the following raw materials in terms of weight percentage: phosphoric acid (industrial first-grade product): 30%, tungstic acid: 10%, sodium hydroxide: 40%, tap water: 20%; add the above raw materials into the reactor at one time and stir and heat, and react The temperature is controlled at 50-70°C, and the reaction time is controlled at 0.5-1 hour to obtain a sodium phosphotungstate solution.

[0037] Take 30 parts of sodium aluminate solution and 20 parts of sodium phosphotungstate solution prepared above, mix and stir to raise the temperature to 60°C, then add 5 parts of polyoxyethylene e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com