Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Nitrosyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrosyl chloride is the chemical compound with the formula NOCl. It is a yellow gas that is most commonly encountered as a decomposition product of aqua regia, a mixture of hydrochloric acid and nitric acid. It is a strong electrophile and oxidizing agent. It is sometimes called Tilden's reagent.

Etching liquid for conductive polymer, and method for patterning conductive polymer

InactiveUS20100089872A1Improve etching effectDecorative surface effectsPrinted circuit aspectsHydrogen halidePermanganic acid

The object is to provide an etching liquid for a conductive polymer having excellent etching capability toward a conductive polymer, and a method for patterning a conductive polymer employing the etching liquid for a conductive polymer. The conductive etching liquid of the present invention is selected from the group consisting of (1) an etching liquid comprising greater than 0.5 wt % but no greater than 70 wt % of (NH4)2Ce(NO3)8 or at least 0.5 wt % but no greater than 30 wt % of Ce(SO4)2, (2) an etching liquid comprising greater than 0.5 wt % but no greater than 30 wt % of (NH4)4Ce(SO4)4, (3) an etching liquid comprising a hypochlorous acid salt aqueous solution having an effective chlorine concentration of at least 0.06 wt % and a pH of greater than 3 but less than 8, (4) an etching liquid comprising nitrosyl chloride which comprises at least 5 wt % of hydrochloric acid and at least 20 wt % of nitric acid, a (hydrochloric acid concentration+0.51×nitric acid concentration) value being no greater than 35 wt %, and a (hydrochloric acid concentration+0.5×nitric acid concentration) value being at least 30 wt %, (5) an etching liquid comprising at least 3 wt % but no greater than 40 wt % of a bromic acid compound and at least 4 wt % of an inorganic acid, (6) an etching liquid comprising at least 6 wt % but no greater than 40 wt % of a chloric acid compound and at least 7 wt % of a hydrogen halide, (7) an etching liquid comprising at least 0.001 wt % but no greater than 20 wt % of a permanganic acid compound, and (8) an etching liquid comprising at least 3 wt % but no greater than 30 wt % of a hexavalent chromium compound.

Owner:TSURUMISODA +1

New method for preparing ruthenium nitrosyl nitrate solution or pure crystal

ActiveCN104556250AHigh purityFully removeRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsNitrateDistillation

The invention discloses a new method for preparing a ruthenium nitrosyl nitrate solution or pure crystal, which comprises the following steps: 1. preparing a pure HNO2 solution; 2. dissolving commercially available RuCl3.nH2O in dilute nitric acid, gradually adding the HNO2 solution prepared in the step 1 under reflux conditions, and stirring until the solution completely becomes rose red, thereby obtaining an intermediate ruthenium nitrosyl chloride; 3. removing excess Cl<-> with an AgNO3 solution, and filtering to obtain a ruthenium nitrosyl nitrate nitric acid solution which conforms to the application requirements; and 4. drying the ruthenium nitrosyl nitrate nitric acid solution obtained in the step 3 by distillation to obtain the pure ruthenium nitrosyl nitrate solid. The method has the advantages of cheap and accessible raw materials, fewer steps and environment friendliness, does not need to design or use any special device, has wide application range (from laboratory small testing to industrial-scale generation), and has very high popularization value.

Owner:昆明铂生金属材料加工有限公司

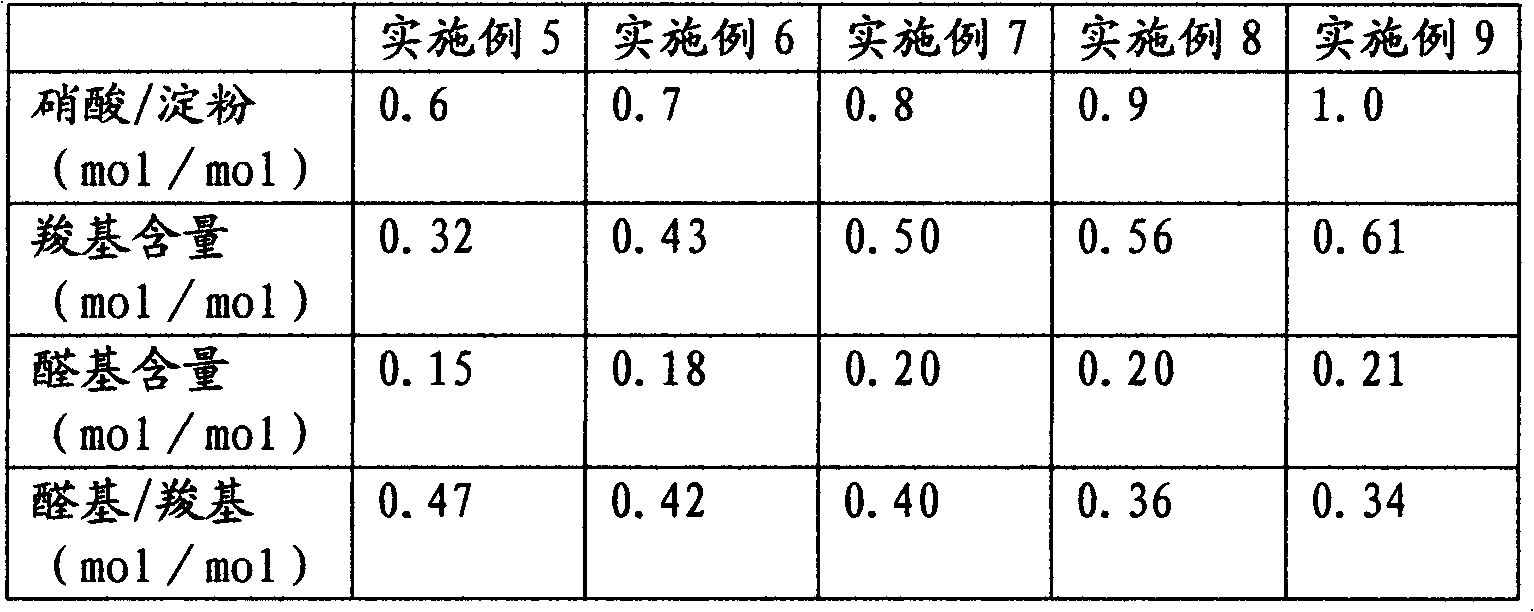

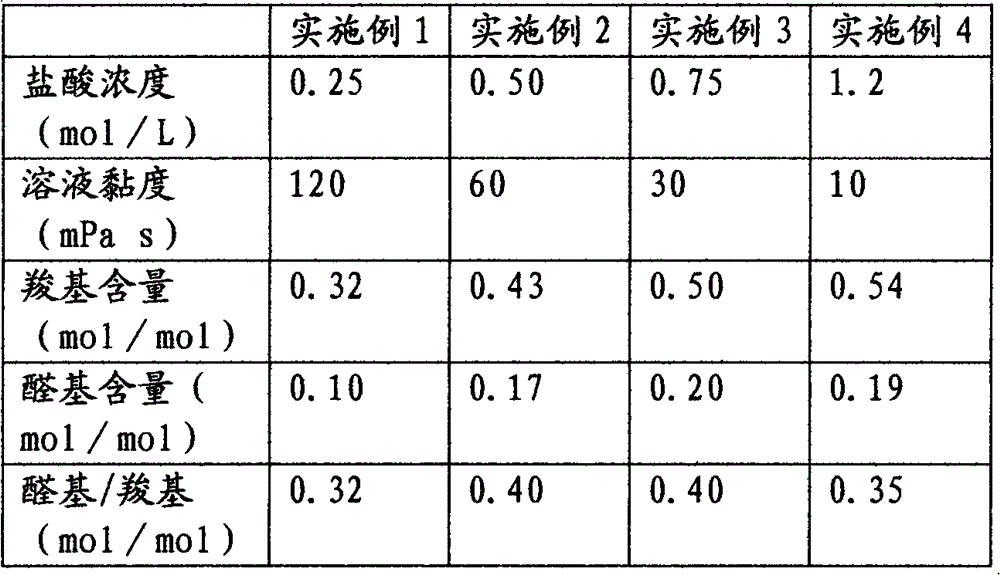

Preparation method of oxidized starch containing aldehyde group on C6 position of glucose unit

The invention discloses a preparation method of oxidized starch containing an aldehyde group in a starch molecule. The preparation method comprises the steps: mixing nitric acid and diluted hydrochloric acid to generate a nitryl chloride strong oxidizer, and oxidizing 40-85% of primary hydroxy on C6 positions of glucose units in the starch molecule with the nitryl chloride strong oxidizer, wherein the mole number of the aldehyde group in the generated oxidized starch is 0.15-0.25, and the mole number of the carboxyl group is 0.25-0.60; and in the oxidation process, air is introduced to a reactor, and nitrosyl chloride generated by reduction of nitryl chloride is oxidized by oxygen to regenerate nitryl chloride, so that starch oxidation process is repeatedly performed. The preparation method has the advantages that the aldehyde group and carboxyl group contents in the oxidized starch can be controlled, the application range of the oxidized starch is widened, the problems of poor oxidation selectivity, large oxidizer consumption and high production cost in the traditional preparation process of the oxidized starch are overcome, and the preparation method has wide application prospects.

Owner:TIANJIN VOCATIONAL INST

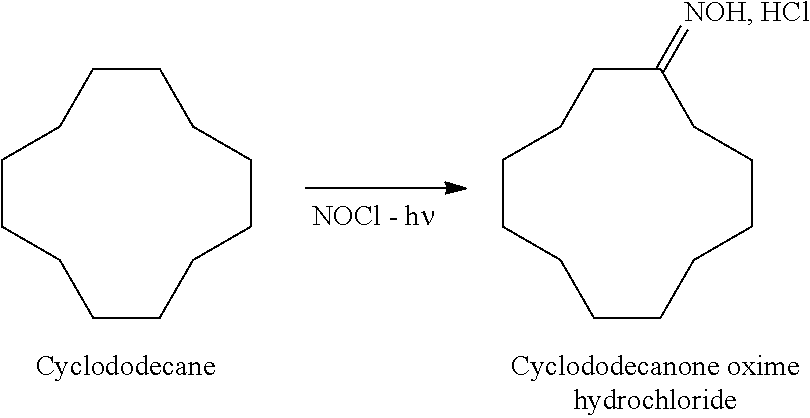

Method for preparing lactames, comprising a photonitrosation step, followed by a beckmann transposition step

InactiveUS20110137027A1Long life-timeLess energy consumptionLactams preparationOrganic compound preparationMicroreactorPhotochemistry

The invention relates to a method for preparing lactames, according to which a photonitrosation of a cycloallcane is carried out using nitrosyl chloride (NOCI). According to the invention, said photonitrosation is carried out by means of LEDs emitting a monochromatic light. The method according to the invention can also include a step comprising Beckmann transposition / dechlorination of the oxime hydrochloride generated during said phonitrosation, preferably carried out in a glass microreactor.

Owner:ARKEMA FRANCE SA

Process for manufacturing potassium nitrate fertilizer and other metal nitrates

InactiveUS20020110512A1Cost effectiveEfficient executionCalcareous fertilisersCobalt ammonia complexesWater vaporCounter current

A process for producing potassium nitrate and other metal nitrates from the chlorides, sulfates, oxides of these metals. The process uses nitrogen dioxide as a true fluidizing medium in shallow beds of the aforementioned solids at moderately elevated temperatures in a continuous counter current process to convert the metal chlorides, sulfates, and oxides, into metal nitrates and effluent gas and water vapor. The process may be carried out in a series of true fluidized beds arranged in a vertical configuration so that the solids flow downward due to the fluidized process and the nitrogen dioxide gas flows counter currently in an upward direction producing pure metal nitrates at the bottom and nitrosyl chloride gas and / or water vapor at the top.

Owner:RIGBY WILLIAM J

A method for removing N-nitroso compounds from pendimethalin

ActiveCN109970573APromote decompositionNo other ingredients addedAmino compound purification/separationNitrosoPendimethalin

A method for removing N-nitroso compounds from pendimethalin is disclosed. The method includes adding hydrochloric acid, ammonium chloride and an auxiliary catalyst into a dichloroethane solution of the pendimethalin containing N-nitroso compounds; heating the mixture to 78-82 DEG C; reacting and stirring the mixture for 6-10 h until the N-nitroso compound content of the reaction system is lower than 0.05%; and subjecting the reaction solution to aftertreatment, and concentration to remove a solvent to obtain a pendimethalin product. According to the method, the ammonium chloride is adopted asan additive for nitroso compound removal under the existence of concentrated hydrochloric acid, and the ammonium chloride reacts with nitrosyl chloride generated during nitroso compound removal to form ammonium nitrite which is unstable and liable to decompose into nitrogen and water, and hydrogen chloride which is dissolved into water to form hydrochloric acid, thus avoiding introduction of organic impurities and avoiding generation of salt-containing waste water.

Owner:JIANGSU YONGAN CHEM CO LTD

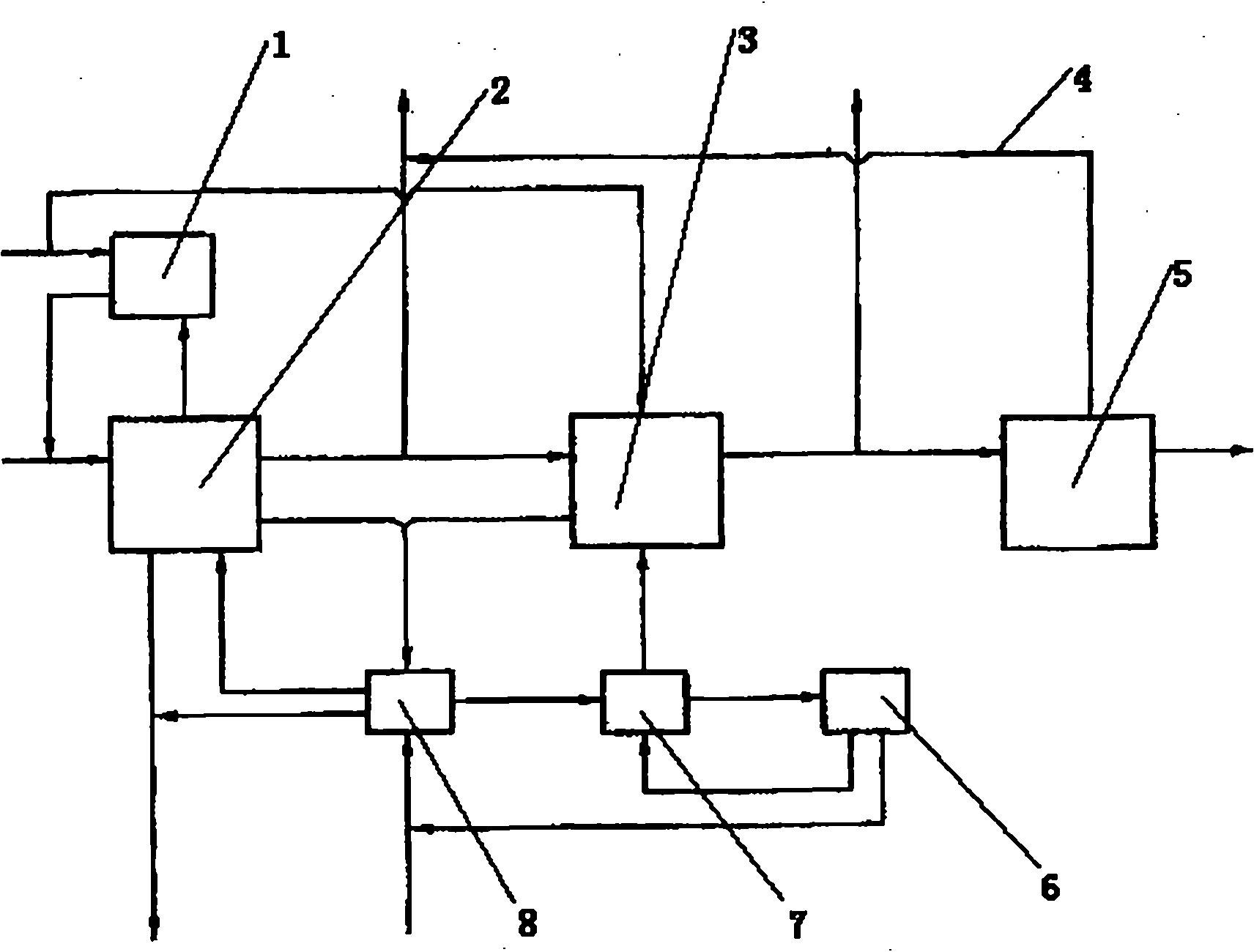

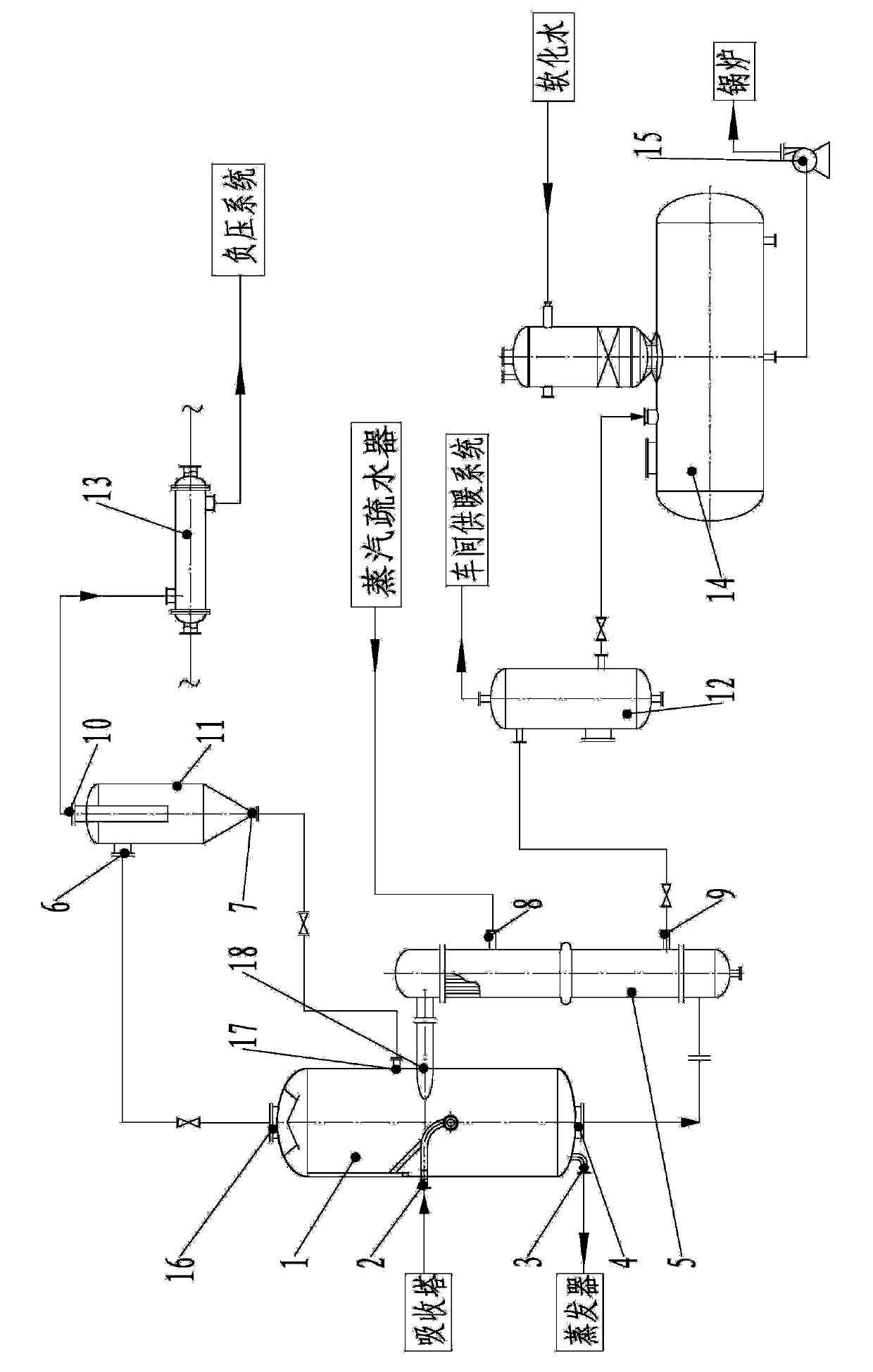

Method and device for producing sodium nitrate

ActiveCN102491375AQuality improvementSave energyAlkali metal nitratesEnergy inputHazardous substanceEvaporation

The invention relates to a method and device for producing sodium nitrate. The device comprises a nitrogen oxide ammoxidation preparation system, a soda solution preparation and absorption system, a mother liquor conversion system and a pre-evaporation system. A pre-evaporator is provided with an outer circulating heater. Steam condensate produced by I efficiency of the evaporator is used for heating raw material fluid in the pre-evaporator by virtue of an outer heater, harmful substances such as chloride ion, nitrosyl chloride in the raw material fluid are removed, pre-evaporation pressure is 0.1-0.3MPa, and temperature is 105-125 DEG C. Raw material departing from the pre-evaporator is subjected to evaporation, crystallization, centrifugal separation and drying to prepare a sodium nitrate product. According to the invention, the pre-evaporator provided with the outer circulating heater is used for recycling waste heat of primary steam condensate produced by utilizing I efficiency of the evaporator, energy source is saved and the quality of the sodium nitrate product is improved, corrosion of harmful gas to equipment is eliminated, and service life of the equipment can be beneficially prolonged.

Owner:SHIJIAZHUANG FENGSHAN CHEM

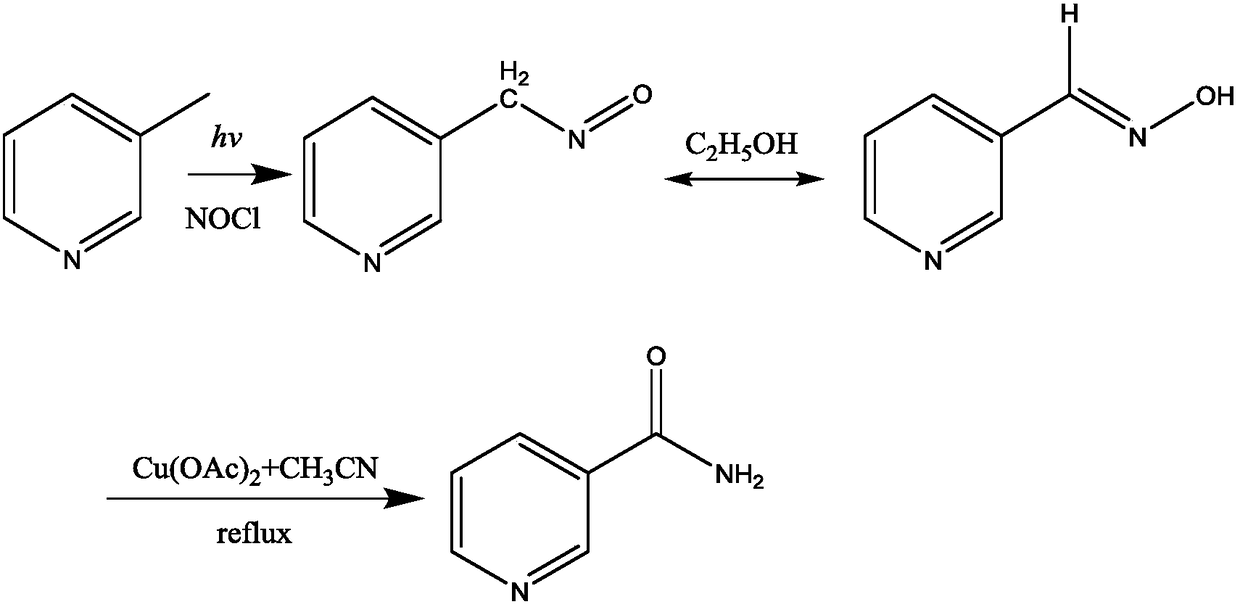

Synthetic method for nicotinamide

ActiveCN108409646AImprove economyMild reaction conditionsOrganic chemistryBeckmann rearrangementIsomerization

The invention belongs to the field of organic chemistry, and discloses a synthetic method for nicotinamide. The method comprises the following steps: using ethanol as a solvent, using 3-methylpyridineas a raw material, introducing a dried nitrosyl chloride gas, performing a photonitrosation-isomerization reaction under irradiation of visible light at temperature of 0-30 DEG C, after the reactionis completed, introducing a nitrogen gas, adding an alkali to adjust pH of the reaction solution to be 6-9, and performing filtration to obtain a filtrate; and adding a copper salt and a nitrile intothe filtrate as a catalyst, performing heating, performing reflux, performing an aldoxime Beckmann rearrangement reaction, after the reaction is completed, adding ethyl acetate crystals into the reaction solution, performing filtration to obtain a crude product of the nicotinamide, and performing recrystallization on the crude product of the nicotinamide to obtain a pure product of the nicotinamide. The synthetic method provided by the invention has mild reaction conditions, a simple process and a high yield, can obtain the high-purity nicotinamide product, has less three waste (waste water, waster gas and solid waste) and high economy, and is suitable for industrialized large-scale production.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

Preparation method of 2-chloro-5-methylpyridine

The invention discloses a preparation method of 2-chloro-5-methylpyridine, and belongs to the field of organic chemistry. According to the method, 2-amino-5-methylpyridine serves as the raw material and reacts with nitrosyl chloride under the existence of acyl chloride, and 2-chloro-5-methylpyridine is obtained. The production process is simple and convenient, the yield is high, and when metered based on 2-amino-5-methylpyridine, the yield can reach 94%.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

Mule meat sausage

InactiveCN102934805ATaste is fresh and sweetCan relax muscles and activate blood circulationMetabolism disorderFood preparationFreeze-dryingLycopodium clavatum

The invention provides a mule meat sausage with the function of preventing hyperlipidemia. The mule meat sausage comprises the following raw materials by weight: 8-10kg of mule meat, 0.5-1kg of lycopodium clavatum liquid extract dry powder, 0.3-0.35kg of salt, 0.005kg of nitrosyl chloride, 0.5kg of white sugar, 1kg of Shaoxing wine, 0.4kg of sesame oil and 0.05kg of five spice powder, wherein the lycopodium clavatum liquid extract dry powder is prepared by preparing liquid extract from lycopodium clavatum, plumeria rubra and liquorice in a ratio of (10-20):(8-20):(3-10) and then freeze-drying and grinding the liquid extract into dry powder. The mule meat sausage has sweet, mellow and fresh taste, additionally has the new taste of the sausage, has the functions of relaxing muscles, stimulating blood circulation, removing turbid phlegm and damp obstruction and reducing blood lipid and is suitable for preventing hyperlipidemia diseases.

Owner:蒋科富

Synthetic method of high-purity and high-yield L-2-chloropropionic acid

InactiveCN107879925AImprove conversion rateHigh yieldOrganic compound preparationCarboxylic compound preparation2-Chloropropionic acidEthyl Chloride

The invention discloses a synthetic method of L-2-chloropropionic acid. The synthetic method comprises the steps of firstly dissolving L-alanine into hydrochloric acid, introducing nitrosyl chloride and hydrogen chloride gas for reaction, after the raw materials are converted, filtering, continuing to stir for 1-2 hours, and an alkaline reagent for neutralization, extracting by virtue of an organic solvent, combining organic phases, drying by virtue of anhydrous calcium chloride, filtering, and carrying out rectification, so as to obtain a product, namely L-2-chloropropionic acid. The method has the advantages that the operation is simple, and the emission of wastewater is reduced; and by taking nitrosyl chloride with relatively high activity as a diazotization regent, aliphatic amino canbe rapidly converted into chlorine, so that the raw material conversation rate and the yield are greatly increased, the yield can reach 90% or above, an original configuration is not reversed in the reaction process, and the optical purity ee value can reach 99.1%.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

Process for preparing 3,4-dihydroxy benzonitrile

InactiveCN1392138ACarboxylic acid nitrile preparationOrganic compound preparationBenzonitrilePhosphorus pentachloride

3,4-dihydroxybenzonitrile useful as a starting compound for synthesis of medicines and agricultural chemicals is produced, with a high yield by chlorinating 3,4-methylenedioxybenzonitrile with sulfuryl chloride or a mixture of molecular chlorine with a chlorination-promoter including phosphorus trichloride, phosphorus pentachloride, sulfuryl chloride, thionyl chloride, and / or nitrosyl chloride, to prepare 2-chloro-benzoA1,3Udioxole-5-carbonitrile, and hydrolyzing 2-chloro-benzoA1,3Udioxole-5-carbonitrile by contacting it with water to produce 3,4-dihydroxybenzonitrile.

Owner:UBE IND LTD

Beef buckwheat sausage and preparation method thereof

The invention discloses a beef buckwheat sausage. The beef buckwheat sausage is prepared from the following raw materials in part by weight: 5kg of beef, 2.5kg of cooked buckwheat grain, 5kg of minced chicken, 2.5kg of chicken skin, 1kg of corn starch, 1kg of modified starch, 6kg of cold water, 0.308kg of table salt, 0.066kg of white sugar, 0.0264kg of white pepper, 0.0897kg of carrageenan, 0.030kg of nitrosyl chloride and 0.075kg of red Konjic rice powder. The beef buckwheat sausage has the beneficial effects that the preparation method can realize factory-like and scale production, the difficult problem of batch production for restaurants is solved, the beef buckwheat sausage can be stored easily, the traditional manual operation is broken, seasoning quantification is realized, a defect that the seasoning amount cannot be controlled is overcome, the requirements of different consumers can be met and the marketing range is expanded.

Owner:陆玉龙

Preparation method of 2-chloro-5-methyl pyridine

The invention discloses a preparation method of 2-chloro-5-methyl pyridine, and belongs to the field of organic chemistry.With 2-amino-5-methyl pyridine as the raw material, under the existence of chloride, 2-amino-5-methyl pyridine reacts with nitrosyl chloride (NOC1) to form 2-chloro-5-methyl pyridine.The production process is simple and convenient, yield is high, and the yield can reach 96% according to 2-amino-5-methyl pyridine.

Owner:NANJING REDSUN BIOCHEM CO LTD +2

Method for regenerating denitrated ferric chloride adsorbent

ActiveCN111151231AAchieve regenerationAvoid decompositionGas treatmentDispersed particle separationIron chlorideHydrogen chloride

The invention discloses a method for regenerating a denitrated ferric chloride adsorbent. Nitrosyl chloride reacts with water to remove water of denitrated ferric chloride; meanwhile, hydrogen chloride generated in the reaction process effectively prevents decomposition of ferric salt in the dehydration process, the decomposition rate of ferric salt is 1% or below, and the method has the advantages of high dehydration speed, easy operation, and high treatment efficiency, and can be carried out at a low temperature.

Owner:ZHEJIANG UNIV OF TECH

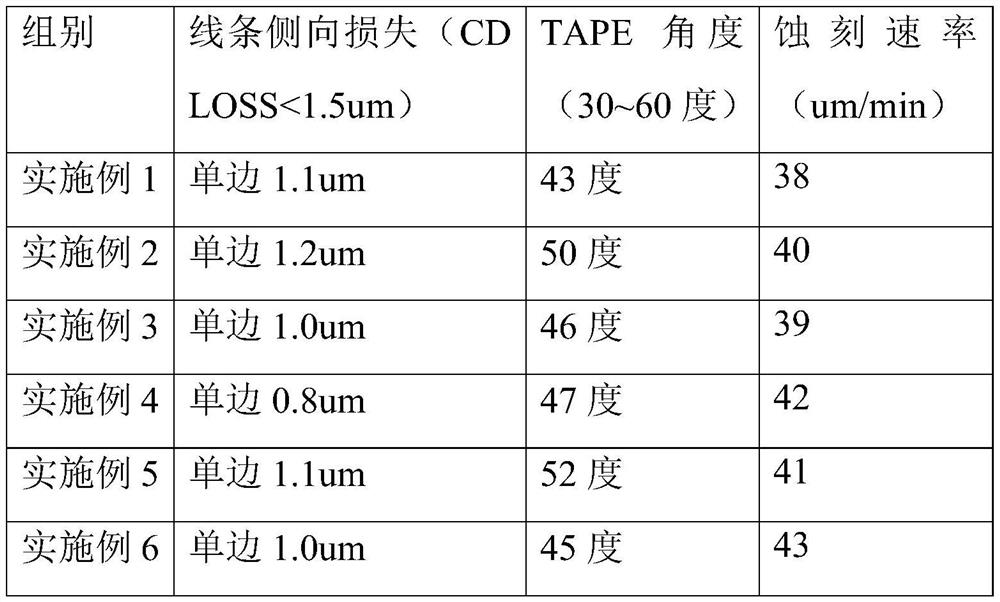

Etching solution for multilayer film of active matrix organic light emitting diode display

InactiveCN111704903AImprove permeabilityImprove etching efficiencySolid-state devicesSurface treatment compositionsO-Phosphoric AcidActive matrix

The invention discloses an etching solution for a multilayer film of an active matrix organic light emitting diode display. The etching solution comprises the following components in percentage by mass: 15 to 45% of phosphoric acid, 1 to 10% of nitric acid, 5 to 25% of malic acid, 0.2 to 0.6% of a penetrating agent, 10 to 14% of nitrosyl chloride, 1 to 8% of dihydric phosphate and the balance of deionized water. The components and the use amounts of the provided etching solution are reasonable, and nitric acid, malic acid and nitrosyl chloride are matched for use, and the etching solution is high in permeability, high in etching efficiency, accurate in etching angle, smooth and uniform in etching line and free of residues. Besides, a mixture prepared in the step 2 is subjected to standingfor 10 seconds or longer, then the mixture is put into a stirring machine with a rotating speed of 1000 r / min and stirred, the penetrating agent and malic acid can be fully mixed into the mixture, andtherefore the uniformity of the etching solution is improved.

Owner:江苏中德电子材料科技有限公司

Synthesis method of dye intermediate

InactiveCN109810008ASimple methodMethod environmentally friendlyOrganic compound preparationAmino-carboxyl compound preparationSynthesis methodsHigh pressure

The invention provides a synthesis method of a dye intermediate. The synthesis method includes the following steps that a sodium nitrite solution is dropwise added into a hydrochloric acid solution togenerate nitrosyl chloride, meanwhile, the generated nitrosyl chloride is introduced into a mixture of 1-nitro-2-methylanthraquinone and fuming sulfuric acid to be subjected to oxidation reaction, and thus a feed liquid A is obtained; the feed liquid A is diluted with water to obtain a diluted feed liquid A; a ferrous sulfate solution is added into the diluted feed liquid A for reduction ring-opening to obtain a feed liquid B; and the feed liquid B is diluted with water, filtered and washed to be neutral and then dried to obtain the dye intermediate. By means of the synthesis method, high temperature and high pressure do not need to be used as reaction conditions, reaction products are free of by-products such as chromium-containing waste acid, and the method is simple, convenient and environmentally friendly and has economic value.

Owner:海门市五洋化工有限公司

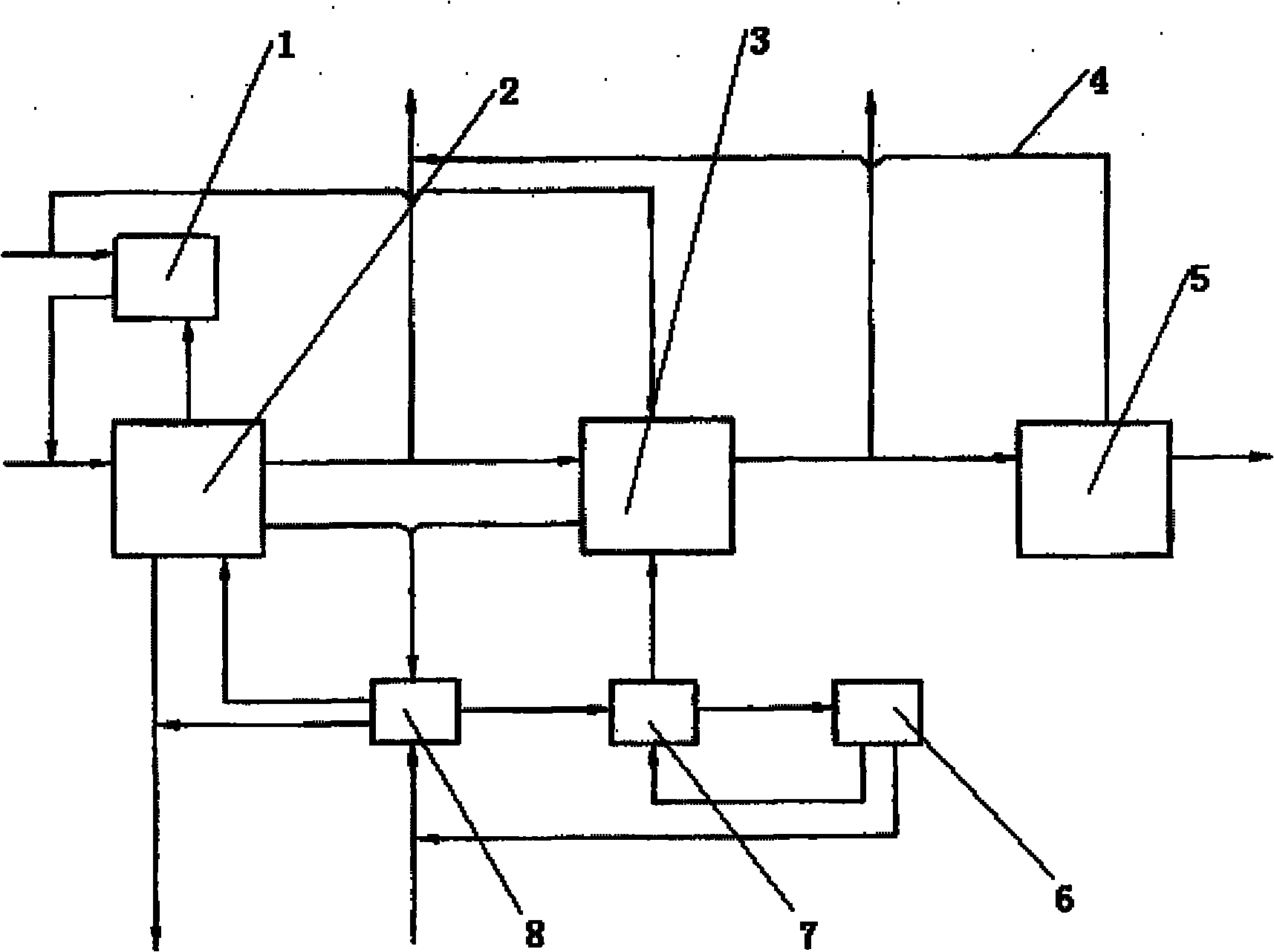

Technology for producing sulfur hexafluoride by reacting nitrosyl fluoride with chlorine and sulfur dichloride

InactiveCN101973528AHigh puritySolve pollutionSulfur and halogen compoundsSulfur tetrafluorideSulfur hexafluoride

The invention discloses technology for producing sulfur hexafluoride by reacting nitrosyl fluoride with chlorine and sulfur dichloride. In the technology, a sulfur dichloride synthesis reactor, a sulfur tetrafluoride synthesis reactor, a sulfur chloride pentafluoride synthesis reactor and a sulfur hexafluoride synthesis reactor are sequentially connected through connecting pipelines, and then are sequentially connected with a complexing reactor, a displacement reactor and a potassium fluoride regenerating device through a connecting pipeline between the sulfur tetrafiuoride synthesis reactor and the sulfur chloride pentafluoride synthesis reactor into a whole. The technology is reasonable and the preparation is simple; the produced sulfur hexafluoride has high purity; and the technology solves the problem of environmental pollution and is ideal technology for preparing the sulfur hexafluoride.

Owner:TIANJIN TAIHENG GASES

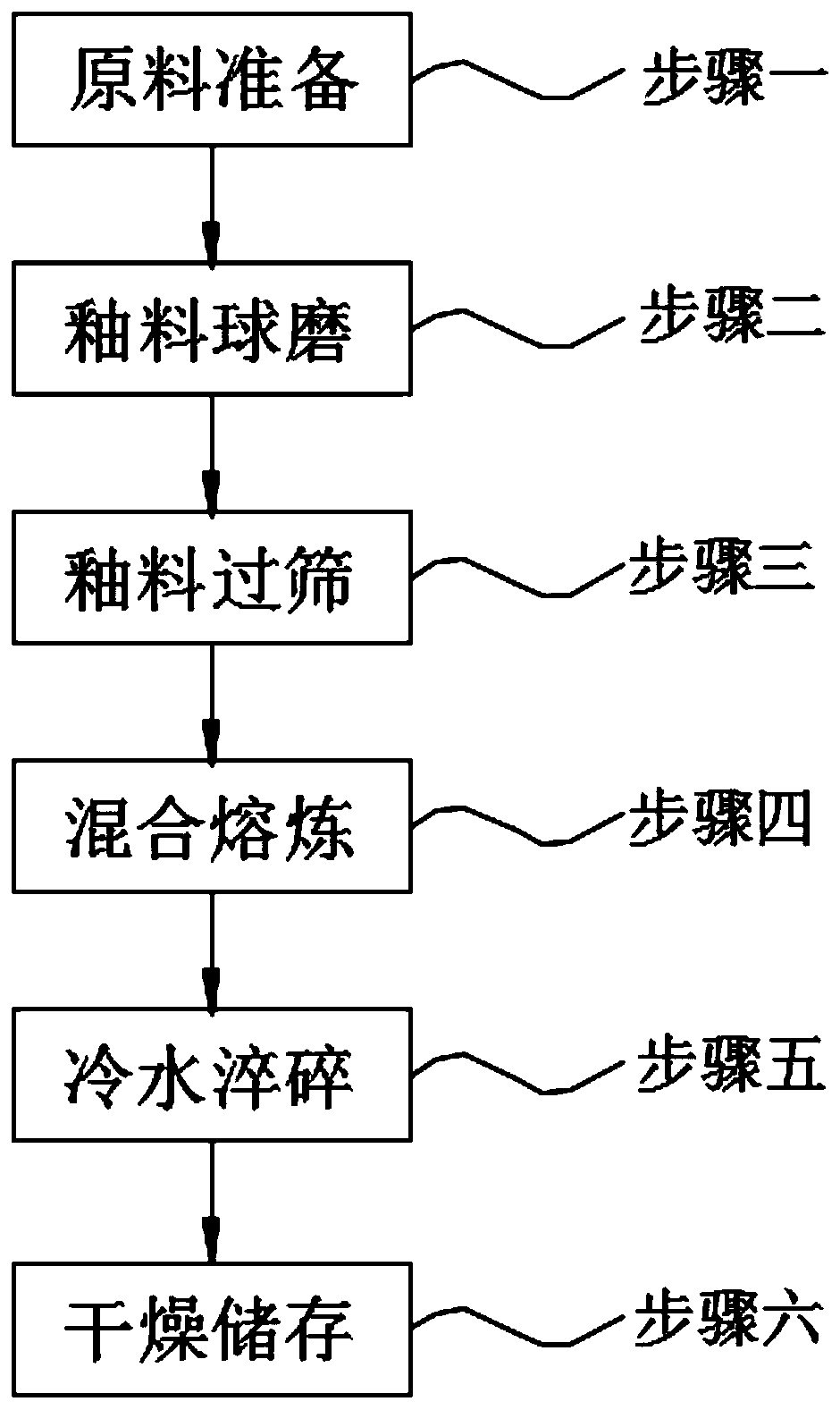

High acid resistant cast iron enamel glaze slurry for furnace frame and preparation method of high acid resistant cast iron enamel glaze slurry

The invention discloses high acid resistant cast iron enamel glaze slurry for a furnace frame and a preparation method of the high acid resistant cast iron enamel glaze slurry. According to the formula, the high acid resistant cast iron enamel glaze slurry is prepared from the components in percentage by mass: 10-15% of tomatec 470#, 10-15% of tomatec 31089#, 35-40% of Fu1414B, 1-3% of clay, 2-5%of quartz powder, 1-3% of AP761 pigment, 0.1-0.3% of sodium tetraborate, 0.1-0.3% of sodium carbonate, 0.1-0.3% of nitrosyl chloride and the balance of water. The preparation method comprises the following steps of step one, raw materials preparation; step two, glaze ball grinding; step three, glaze sieving; step four, mixed smelting; step five, cold water quenching and step six, drying and storage. According to the high acid resistant cast iron enamel glaze slurry, proportion is reasonable, glaze frits obtained by melting at a high temperature have good physical and chemical properties, a densification performance of enamel glaze layer is increased, acid resistance is good, preparation time is short, production efficiency is high, the cost is saved, color is full and not easy to fade, andpromotion is convenient.

Owner:四会市得盈五金制品有限公司

Method and device for producing sodium nitrate

ActiveCN102491375BQuality improvementSave energyAlkali metal nitratesEnergy inputHazardous substanceEvaporation

The invention relates to a method and device for producing sodium nitrate. The device comprises a nitrogen oxide ammoxidation preparation system, a soda solution preparation and absorption system, a mother liquor conversion system and a pre-evaporation system. A pre-evaporator is provided with an outer circulating heater. Steam condensate produced by I efficiency of the evaporator is used for heating raw material fluid in the pre-evaporator by virtue of an outer heater, harmful substances such as chloride ion, nitrosyl chloride in the raw material fluid are removed, pre-evaporation pressure is 0.1-0.3MPa, and temperature is 105-125 DEG C. Raw material departing from the pre-evaporator is subjected to evaporation, crystallization, centrifugal separation and drying to prepare a sodium nitrate product. According to the invention, the pre-evaporator provided with the outer circulating heater is used for recycling waste heat of primary steam condensate produced by utilizing I efficiency of the evaporator, energy source is saved and the quality of the sodium nitrate product is improved, corrosion of harmful gas to equipment is eliminated, and service life of the equipment can be beneficially prolonged.

Owner:SHIJIAZHUANG FENGSHAN CHEM

Method for preparing lactames, comprising a photonitrosation step, followed by a beckmann transposition step

ActiveUS20140246303A1Improve securityHigh yieldLactams preparationOximes preparationMicroreactorCycloalkane

The invention relates to a method for preparing lactames, according to which a photonitrosation of a cycloalkane is carried out using nitrosyl chloride (NOCI). According to the invention, said photonitrosation is carried out by means of LEDs emitting a monochromatic light. The method according to the invention can also include a step comprising Beckmann transposition / dechlorination of the oxime hydrochloride generated during said phonitrosation, preferably carried out in a glass microreactor.

Owner:ARKEMA FRANCE SA

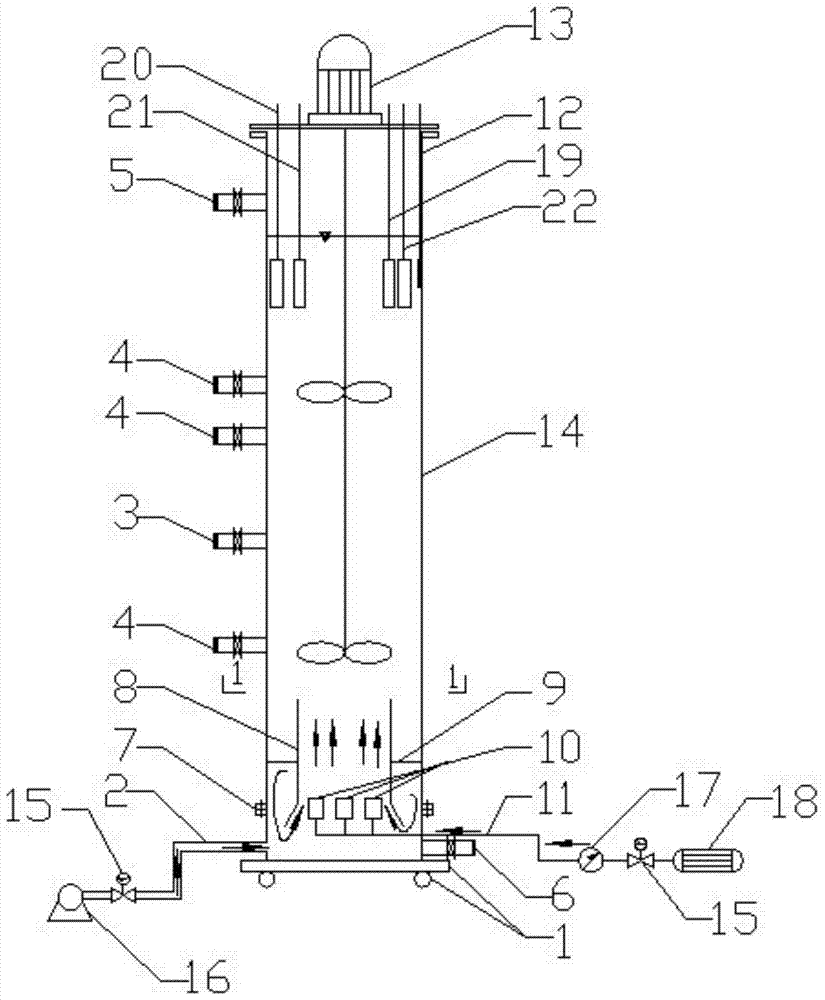

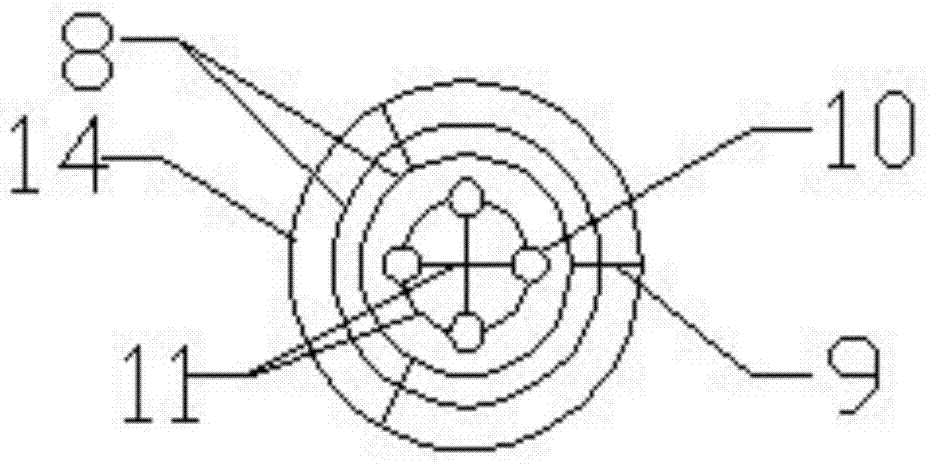

An integrated autotrophic denitrification device and start-up method for treating high-ammonia-nitrogen wastewater

ActiveCN105384237BCompact structureSimple structureTreatment using aerobic processesWater contaminantsHigh concentrationNitrogen removal

The invention provides an autotrophic nitrogen removal integrated device for treating high ammonia-nitrogen wastewater and a starting method, wherein aeration sand heads are adopted for aeration and a gas-collecting hood in the shape of an inverted funnel is arranged above the aeration sand heads. When the device is used for aeration, sludge in the gas-collecting hood is pushed to flow upwards, and sludge outside the hood automatically enters into the hood, so as to form circulating flowing and reach a better mass transfer effect. According to the device, through inoculating a small amount of granule sludge, the aeration rate is gradually increased without accumulation of nitrosyl chloride, so as to culture more and larger granule sludge with higher load. Through 37d, ammonia nitrogen loading reaches 0.47Kg / (m3.d) and reaches the average ammonia nitrogen loading of the inoculated granules. The device is suitable for denitrogenation treatment of middle-high concentration ammonia-nitrogen wastewater, the structure is simple, the degree of automation is high, the denitrogenation effect is good, the running cost is low, and the device can be used for culturing and treating autotrophic nitrogen removal integrated starting of the high ammonia-nitrogen wastewater.

Owner:BEIJING DRAINAGE GRP CO LTD

A method for regeneration of denitrification ferric chloride adsorbent

ActiveCN111151231BAchieve regenerationAvoid decompositionGas treatmentDispersed particle separationSorbentEnvironmental engineering

The invention discloses a method for regenerating a denitrifying ferric chloride adsorbent. The invention removes the moisture of denitrifying ferric chloride through the reaction of nitrosyl chloride gas and water, thereby realizing the regeneration of denitrifying ferric chloride. At the same time, the hydrogen chloride generated in the reaction process The gas effectively prevents the decomposition of iron salts in the dehydration process, and the decomposition rate of iron salts is below 1%. It has the characteristics of fast dehydration speed, easy operation, high processing efficiency, and can be carried out at lower temperatures.

Owner:ZHEJIANG UNIV OF TECH

A new method for preparing ruthenium nitrosyl nitrate solution or pure crystal

ActiveCN104556250BFew synthetic stepsEasy to operateRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsNitrateDistillation

The invention discloses a new method for preparing a ruthenium nitrosyl nitrate solution or pure crystal, which comprises the following steps: 1. preparing a pure HNO2 solution; 2. dissolving commercially available RuCl3.nH2O in dilute nitric acid, gradually adding the HNO2 solution prepared in the step 1 under reflux conditions, and stirring until the solution completely becomes rose red, thereby obtaining an intermediate ruthenium nitrosyl chloride; 3. removing excess Cl<-> with an AgNO3 solution, and filtering to obtain a ruthenium nitrosyl nitrate nitric acid solution which conforms to the application requirements; and 4. drying the ruthenium nitrosyl nitrate nitric acid solution obtained in the step 3 by distillation to obtain the pure ruthenium nitrosyl nitrate solid. The method has the advantages of cheap and accessible raw materials, fewer steps and environment friendliness, does not need to design or use any special device, has wide application range (from laboratory small testing to industrial-scale generation), and has very high popularization value.

Owner:昆明铂生金属材料加工有限公司

A kind of synthetic method of high-purity high-yield 1-2-chloropropionic acid

InactiveCN107879925BImprove conversion rateHigh yieldOrganic compound preparationCarboxylic compound preparationPropanoic acidHigh activity

The invention discloses a synthesis method of L-2-chloropropionic acid. Firstly, L-alanine is dissolved in hydrochloric acid, and nitrosyl chloride is introduced to react with hydrogen chloride gas. ~2 hours, then add alkaline reagents to neutralize, extract with organic solvent, combine organic phases, dry with anhydrous calcium chloride, filter, and rectify to obtain the product L-2-chloropropionic acid. The method of the present invention has the advantages of simple operation and reduced waste water discharge. Using nitrosyl chloride with higher activity as a diazotization reagent can quickly convert aliphatic amino groups into chlorine, which greatly improves the conversion rate of raw materials and the production efficiency. The yield can reach more than 90%. During the reaction process, the original configuration is not reversed, and the optical purity ee value can reach 99.1%.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

Preparation method of oxidized starch containing aldehyde group on C6 position of glucose unit

The invention discloses a preparation method of oxidized starch containing an aldehyde group in a starch molecule. The preparation method comprises the steps: mixing nitric acid and diluted hydrochloric acid to generate a nitryl chloride strong oxidizer, and oxidizing 40-85% of primary hydroxy on C6 positions of glucose units in the starch molecule with the nitryl chloride strong oxidizer, wherein the mole number of the aldehyde group in the generated oxidized starch is 0.15-0.25, and the mole number of the carboxyl group is 0.25-0.60; and in the oxidation process, air is introduced to a reactor, and nitrosyl chloride generated by reduction of nitryl chloride is oxidized by oxygen to regenerate nitryl chloride, so that starch oxidation process is repeatedly performed. The preparation method has the advantages that the aldehyde group and carboxyl group contents in the oxidized starch can be controlled, the application range of the oxidized starch is widened, the problems of poor oxidation selectivity, large oxidizer consumption and high production cost in the traditional preparation process of the oxidized starch are overcome, and the preparation method has wide application prospects.

Owner:TIANJIN VOCATIONAL INST

Method for removing n-nitroso compounds from pendimethalin

ActiveCN109970573BPromote decompositionNo other ingredients addedAmino compound purification/separationNitrosoNitration

The invention discloses a method for removing N-nitroso compounds from pendimethalin, comprising the following steps: adding pendimethalin to a dichloroethane solution containing N-nitroso compounds after the nitration reaction is completed Add hydrochloric acid, ammonium chloride and auxiliary catalyst, heat up to 78~82°C, stir and react for 6~10 h, stop the reaction when the content of N-nitroso compounds in the detection reaction system is less than 0.05%; after the reaction solution is post-treated, Concentration and desolventization give pendimethalin products. The method uses ammonium chloride as an additive for denitration under concentrated hydrochloric acid. Ammonium chloride reacts with nitrosyl chloride formed in the denitration process to form ammonium nitrite and hydrogen chloride. Ammonium nitrite is unstable and easily decomposed. Nitrogen and water, the formed hydrogen chloride dissolves in water to form hydrochloric acid, does not introduce organic impurities, and does not produce saline wastewater.

Owner:JIANGSU YONGAN CHEM CO LTD

Process for manufacturing potassium nitrate fertilizer and other metal nitrates

InactiveUS6475457B2Cost effectiveEfficient executionCalcareous fertilisersCobalt ammonia complexesWater vaporCounter current

A process for producing potassium nitrate and other metal nitrates from the chlorides, sulfates, oxides of these metals. The process uses nitrogen dioxide as a true fluidizing medium in shallow beds of the aforementioned solids at moderately elevated temperatures in a continuous counter current process to convert the metal chlorides, sulfates, and oxides, into metal nitrates and effluent gas and water vapor. The process may be carried out in a series of true fluidized beds arranged in a vertical configuration so that the solids flow downward due to the fluidized process and the nitrogen dioxide gas flows counter currently in an upward direction producing pure metal nitrates at the bottom and nitrosyl chloride gas and / or water vapor at the top.

Owner:RIGBY WILLIAM J

Process for preparing 3,4-dihydroxy benzonitrile

InactiveCN1254466CCarboxylic acid nitrile preparationOrganic compound preparationSulfonyl chlorideHydrolysis

3,4-Dihydroxybenzonitrile, which is used as a starting compound in the synthesis of pharmaceuticals and agrochemicals, is produced in high yield by chlorination with sulfuryl chloride or a mixture of molecular chlorine and a chlorination accelerator 3,4-methylenedioxybenzonitrile to give 2-chloro-benzo[1,3]dioxole-5-carbonitrile, wherein the chlorination accelerator comprises phosphorus trichloride , phosphorus pentachloride, sulfuryl chloride, thionyl chloride and / or nitrosyl chloride; 2-chloro-benzo[1,3]dioxole-5-carbonitrile is contacted with water to make it hydrolyzed 3,4-Dihydroxybenzonitrile is obtained.

Owner:UBE IND LTD

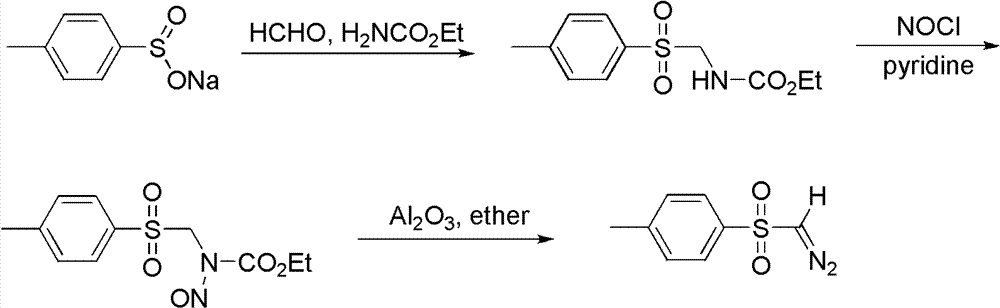

Synthetic method of diazomethane compound

InactiveCN102786373ASimple post-processingAvoid chromatographic separationOrganic compound preparationFunctional group formation/introductionFiltrationSilica gel

The invention provides a synthetic method of a diazomethane compound. Diazotized sulfonyl-3,5,5-trimethyl-2-cyclohexenyl acetate is decarboxylated under the action of neutral alumina to obtain the high-purity and high-yield diazomethane compound. The synthetic method is carried out without using nitrosyl chloride which has the characteristics of high toxicity and easy blasting as a reaction raw material is environmentally-friendly and safe. The reaction yield is good, all the reactions are carried out with the temperature in a range from 0 to room temperature, and requirements on energy are low. The posttreatment process of the final product is simple, so expensive silica gel column chromatography separation is avoided. The reactant alumina has the effects of impurity separation and product purification, so the high-purity sulfonyl diazomethane derivative can be obtained through simple reduced pressure pumping filtration and concentration.

Owner:SHENZHEN Y GENE BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com