Method and device for producing sodium nitrate

A sodium nitrate and raw material solution technology, which is applied in the direction of alkali metal nitrate, chemical instruments and methods, alkali metal compounds, etc., can solve problems such as reducing the service life of equipment, corrosion of stainless steel equipment, and affecting product quality, so as to eliminate corrosion and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

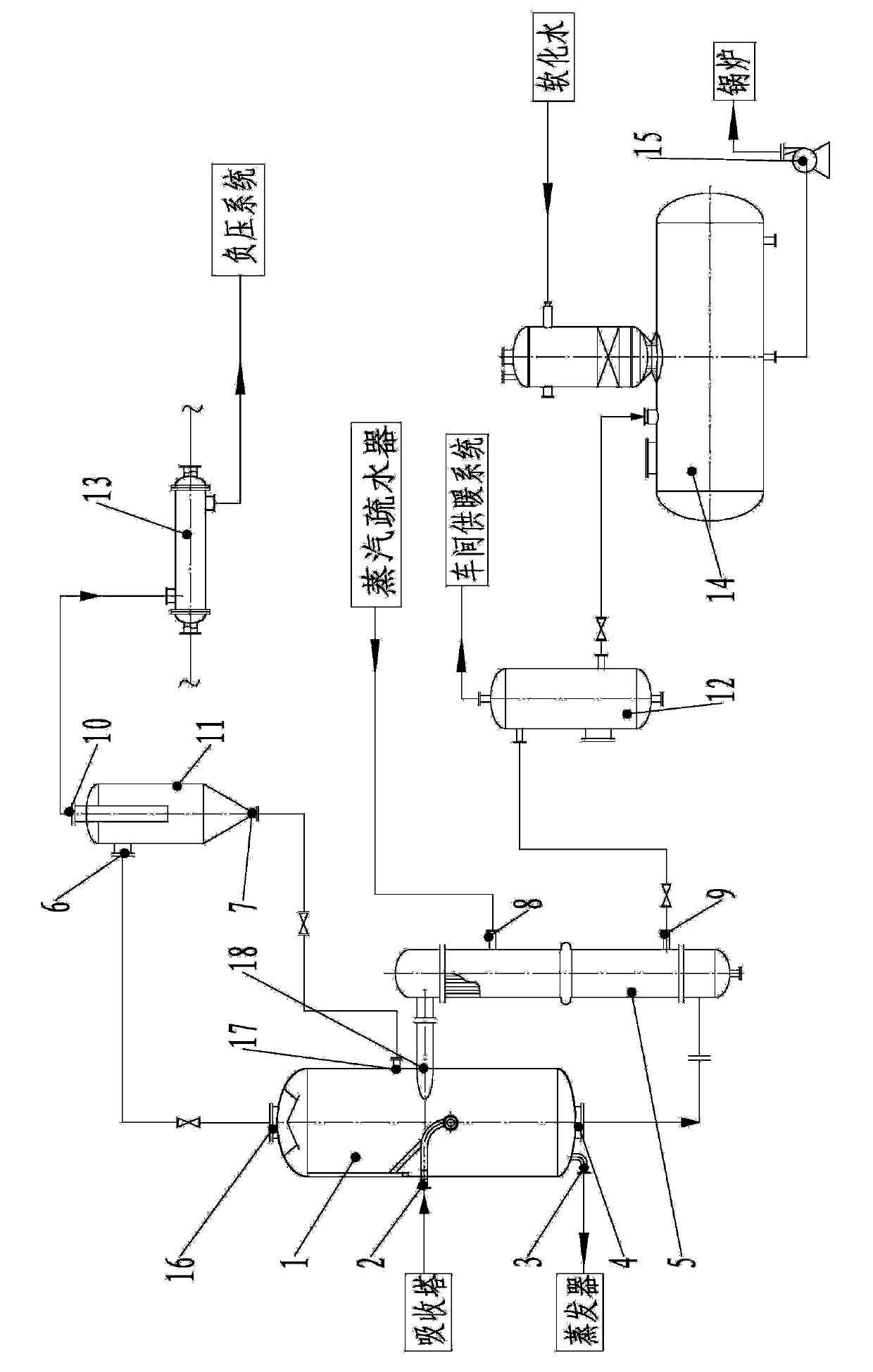

[0017] Below in conjunction with accompanying drawing, the present invention will be further described

[0018] The present invention produces the device of sodium nitrate as figure 1 , figure 2 As shown, it includes ammonia oxidation to prepare nitrogen oxides system, soda ash solution to prepare absorption system, mother liquor conversion system, pre-evaporation system, raw material liquid evaporation, crystallization, centrifugal separation system, drying and packaging system. The mother liquor conversion system consists of a conversion tower, a pre-reform tower, an absorption tower and a mother liquor tank. The pre-evaporation system consists of a pre-evaporator 1 , a separator 11 , a condenser 13 , a closed recovery device 12 and a deaerator 14 . The pre-evaporator is provided with an external circulation heater 5 , a raw material liquid inlet 2 , a raw material liquid outlet 3 , an evaporation steam outlet 16 , a separated liquid inlet 17 , a circulating liquid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com