An integrated autotrophic denitrification device and start-up method for treating high-ammonia-nitrogen wastewater

An autotrophic denitrification and high ammonia nitrogen technology, which is applied in the fields of water supply and drainage engineering and environmental engineering, can solve the difficulties in the enrichment and cultivation of anammox bacteria, the difficulty in improving the processing capacity of the reactor, and the long time for anammox bacteria to hang on the film and other problems, to achieve the effect of quick start and stable operation, compact structure, and shortened start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

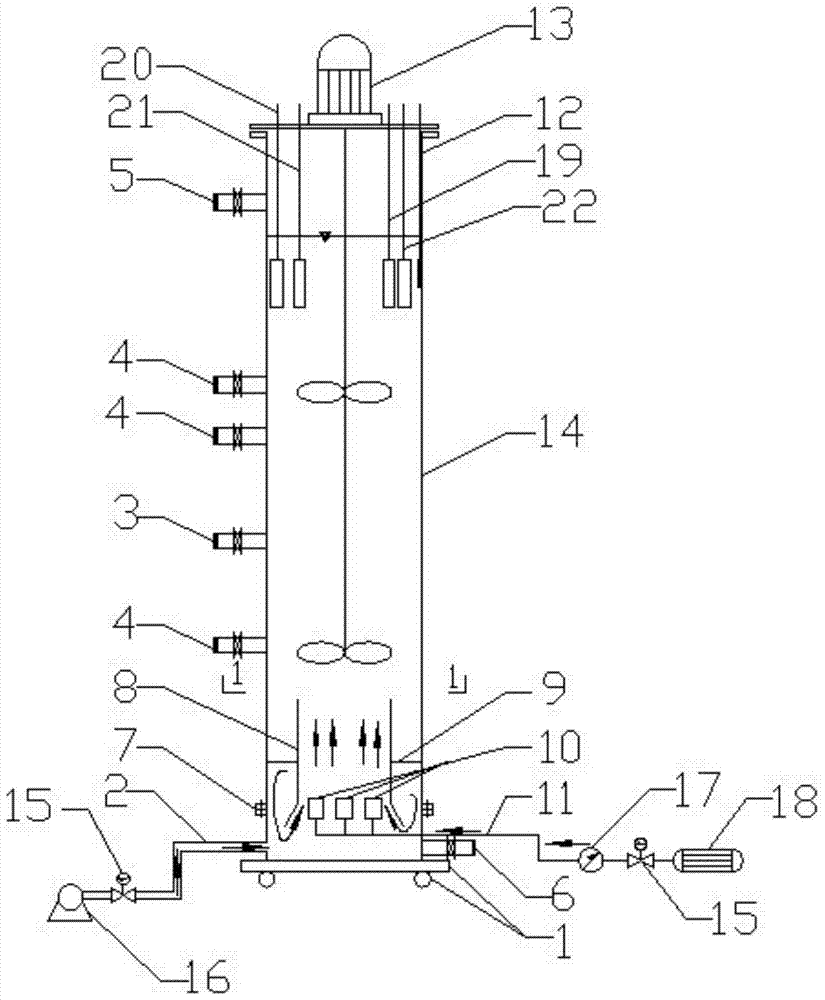

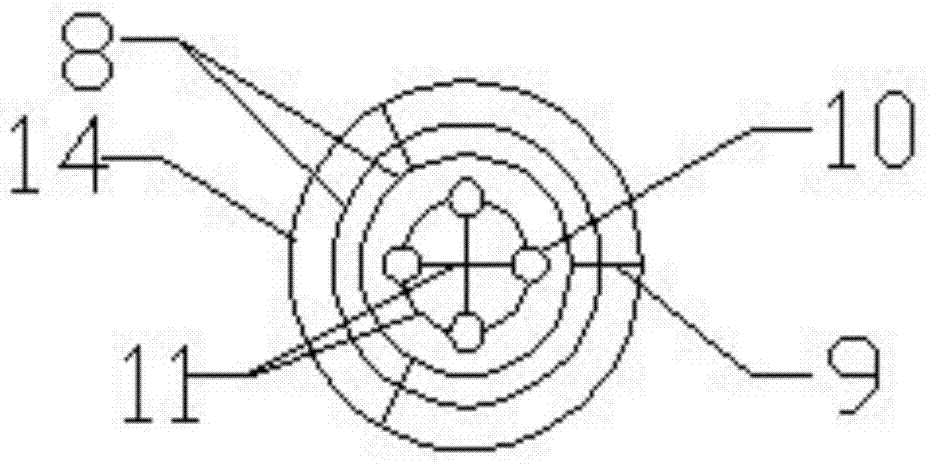

[0029] See attached figure 1 , the main body of the present invention is a cylindrical SBR reactor 14 with a total height of 1400mm, a radius of 150mm, a total volume of 100L and an effective volume of 90L. The device is equipped with a stirrer 13, an aerator 10, a thermometer 12, and is equipped with a pH value online detector 19, a dissolved oxygen online detector 20, a nitrite nitrogen online detector 21, and an ammonia nitrogen online detector 22; The device is connected with a water inlet pipeline 2, a drainage pipeline 3, a mud discharge pipeline 6, an air pipeline 11, an overflow pipeline 5, and a sampling pipeline 4. The gas collecting hood 8 is fixed on the inner wall of the SBR reactor 14 through three annular brackets 9 . The water inlet pipe 2 is provided with an electric valve 15 and a water inlet pump 16 . The electric valve 15 is an electric regulating butterfly valve or a rhombic valve, and is equipped with a PLC controller, and the water inlet pump 16 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com