Technology for producing sulfur hexafluoride by reacting nitrosyl fluoride with chlorine and sulfur dichloride

A technology of sulfur dichloride and sulfur hexafluoride, applied in the direction of sulfur and halogen compounds, can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution problems, simple preparation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

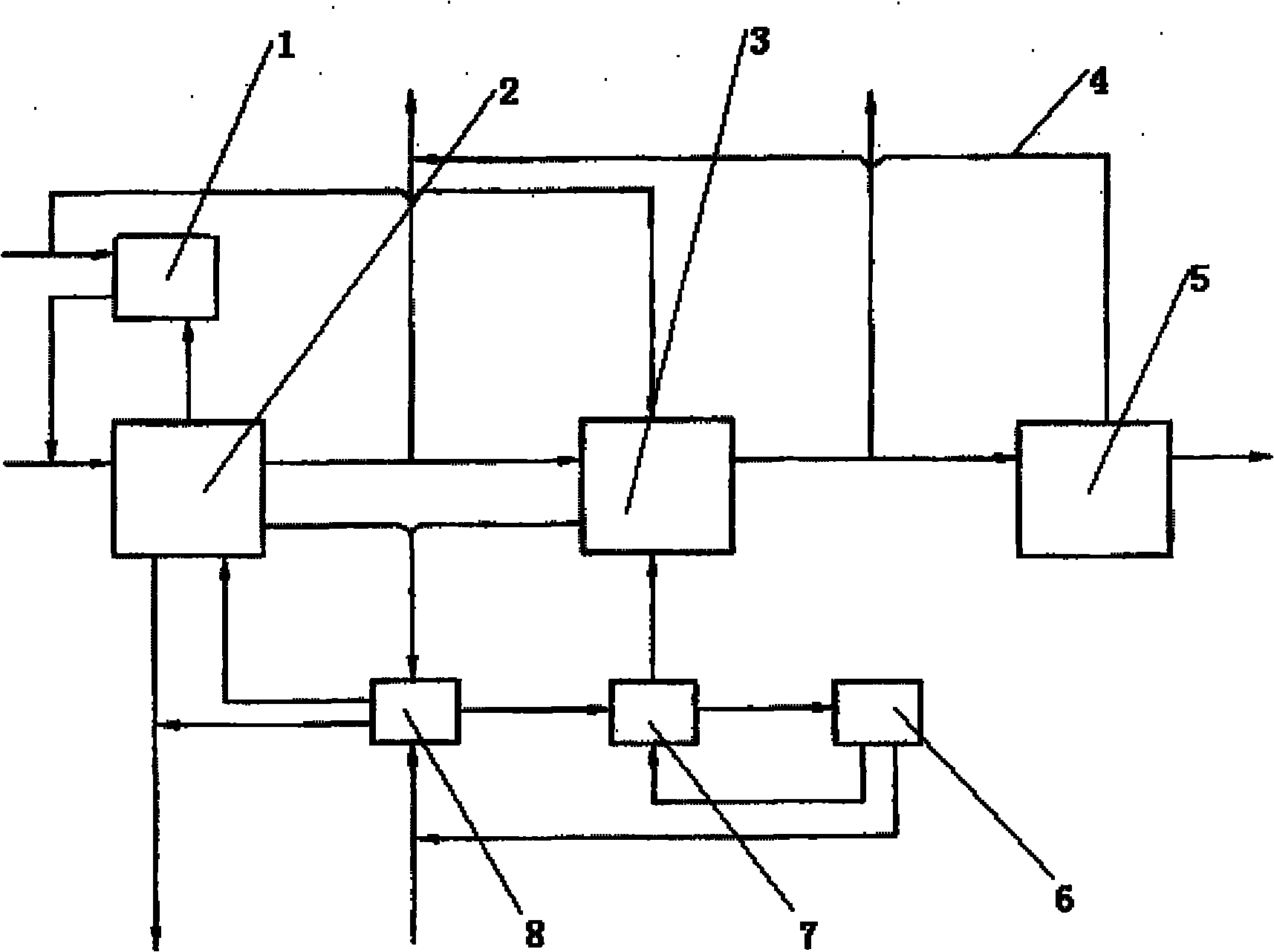

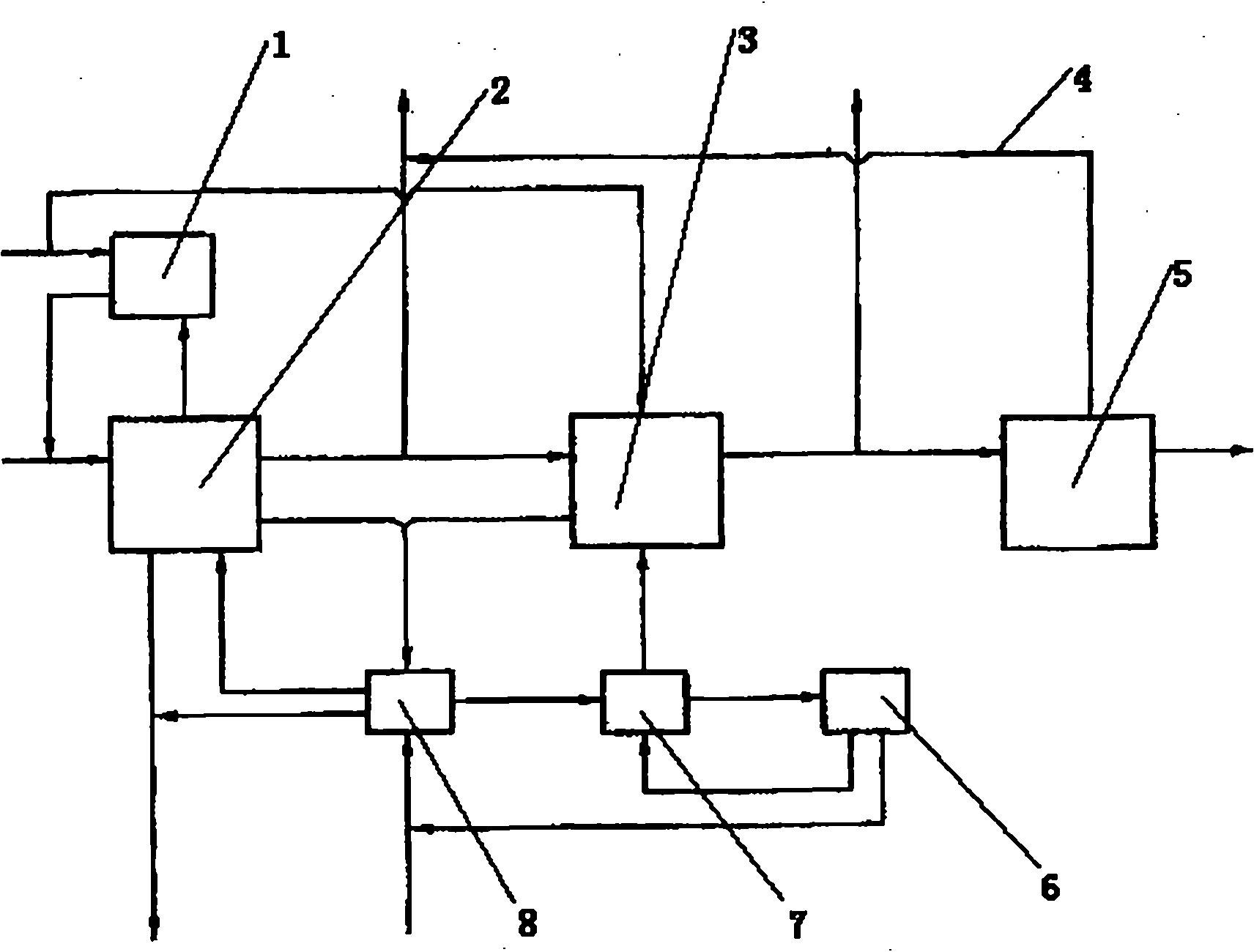

[0009] refer to figure 1 , the sulfur dichloride synthesis reactor 1, the sulfur tetrafluoride synthesis reactor 2, the sulfur pentafluoride monochloride synthesis reactor 3, the sulfur hexafluoride synthesis reactor 5 are sequentially connected through the connecting pipeline 4, through the sulfur tetrafluoride The connecting pipeline 4 between the synthesis reactor 2 and the sulfur pentafluoride synthesis reactor 3 is sequentially connected with the complexation reactor 8, the replacement reactor 7, and the potassium fluoride regeneration device 6, and is constituted by an assembly. When using the technology of the present invention, chlorine gas is added to the sulfur dichloride synthesis reactor 1 through the connection line 4, and the sulfur reaction from the sulfur tetrafluoride synthesis reactor 2 is utilized to generate sulfur dichloride, which enters the sulfur tetrafluoride synthesis reaction Device 2 reacts with the hydrogen fluoride complex compound from complexati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com