Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Sulfur tetrafluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur tetrafluoride is the chemical compound with the formula SF₄. It is a colorless gas. It is a corrosive species that releases dangerous HF upon exposure to water or moisture. Despite these unwelcome characteristics, this compound is a useful reagent for the preparation of organofluorine compounds, some of which are important in the pharmaceutical and specialty chemical industries.

Continuous production of sulfur tetrafluoride

InactiveCN1644490AReduce in quantityContinuous high-efficiency productionSulfur and halogen compoundsHalogenGas phase

Continuous production of sulfur tetrafluoride is carried out by synthetic reacting, cooling to separate SF4 from halogen, returning and reutilizing halogen, gas-phase purifying, liquefying and filling. The halogen fluoride has synthetic reaction with pure industrial brim stone proportionally in a reactor, with reacting temperature of 110deg.C-500deg.C, reacting pressure 0.1-1.0MPs, the mole ratio of halogen fluoride to S = 4-5:5 and the excess of the halogen fluoride = 0-25%. It achieves low cost, simple process and higher efficiency.

Owner:马本辉

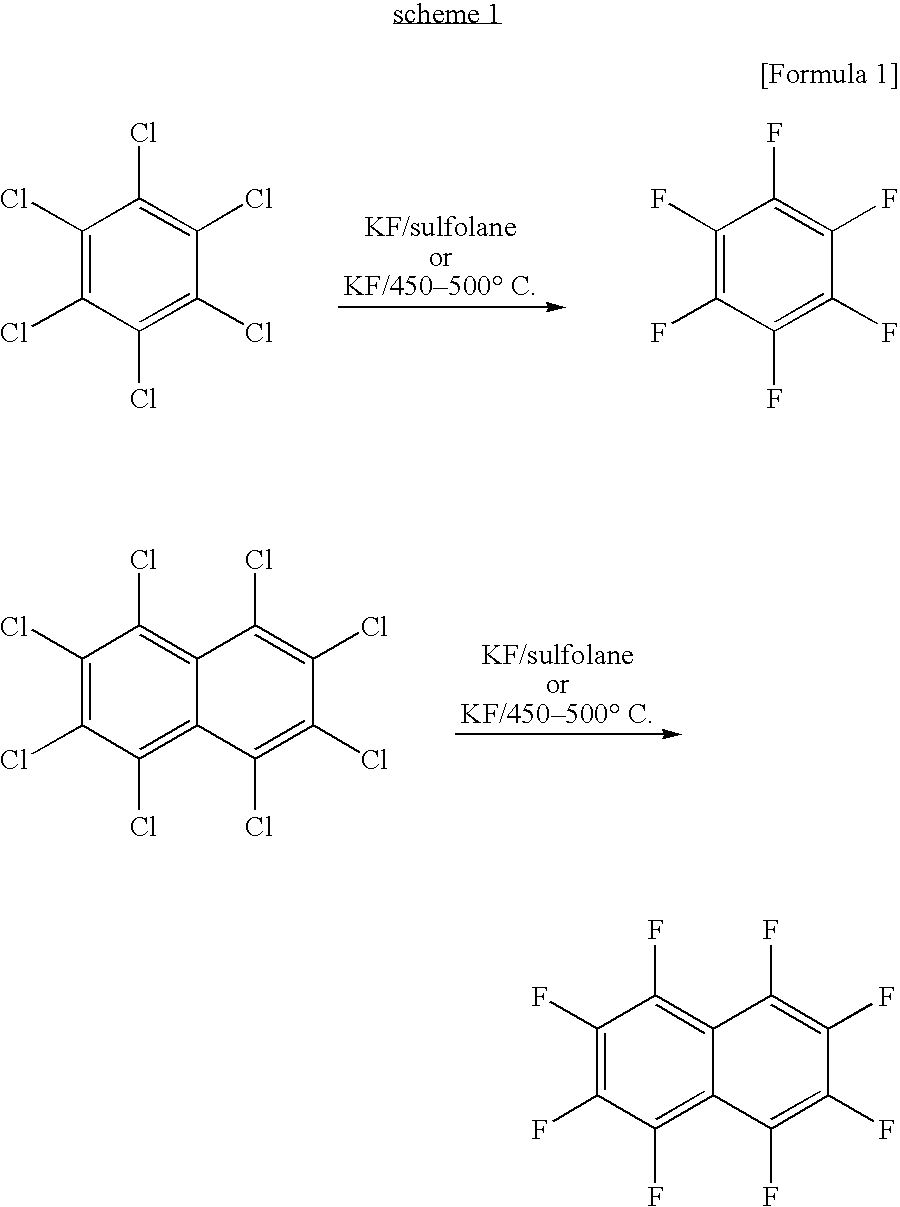

Methods for Producing Arylsulfur Pentafluorides

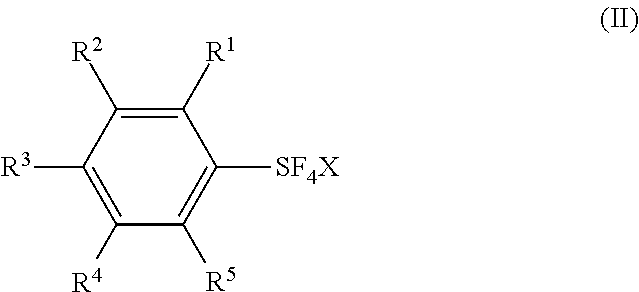

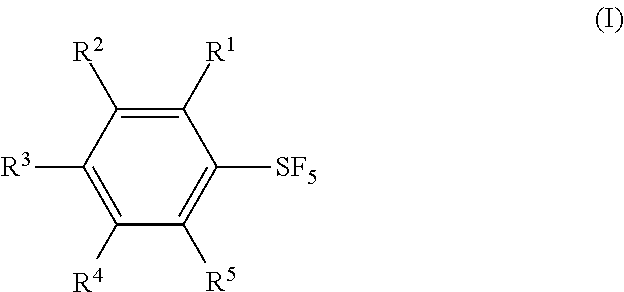

InactiveUS20110306798A1Organic chemistryOrganic compound preparationPentafluoridePurification methods

Novel methods for preparing arylsulfur pentafluorides are disclosed. Arylsulfur halotetrafluoride is reacted with a fluoride source under hydrous conditions to form an arylsulfur pentafluoride. The purification method is also disclosed.

Owner:UBE IND LTD

Method for synthesizing trifluoromethyl amine

ActiveCN102875270ARaw materials are easy to getShort processOrganic compound preparationOrganic halogenationHydrofluoric acidSulfur tetrafluoride

The invention discloses a method for synthesizing trifluoromethyl amine. The method comprises the following steps of: mixing amino acid, anhydrous hydrofluoric acid and sulfur tetrafluoride in a molar ratio of 1:(3-20):(1.8-3.2), and reacting at temperature of between 50 and 150 DEG C for 2 to 10 hours; and cooling, neutralizing, extracting and rectifying to obtain a trifluoromethyl amine product. According to the method, a process is short; and the product is easy to separate, high in yield and stable in quality, the highest yield is 88 percent, and the content of the product is over 97.5 percent.

Owner:JUHUA GRP

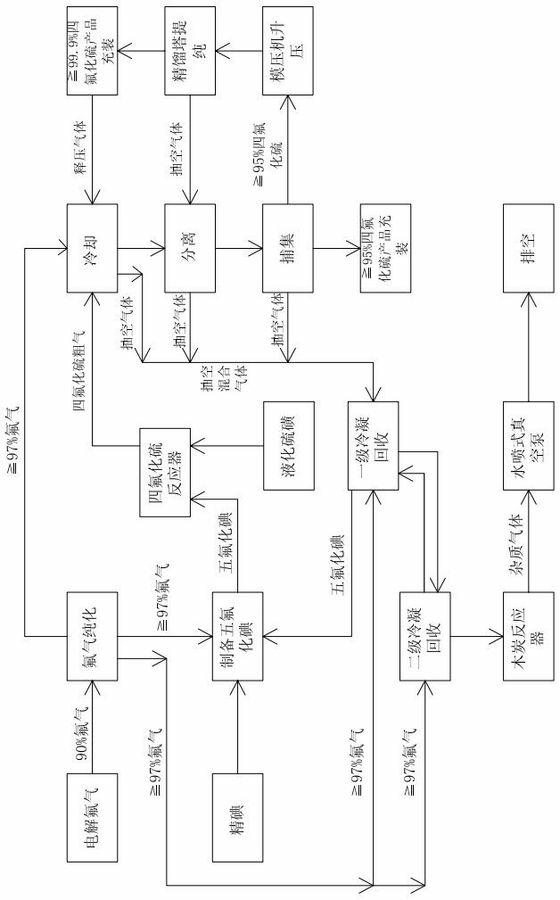

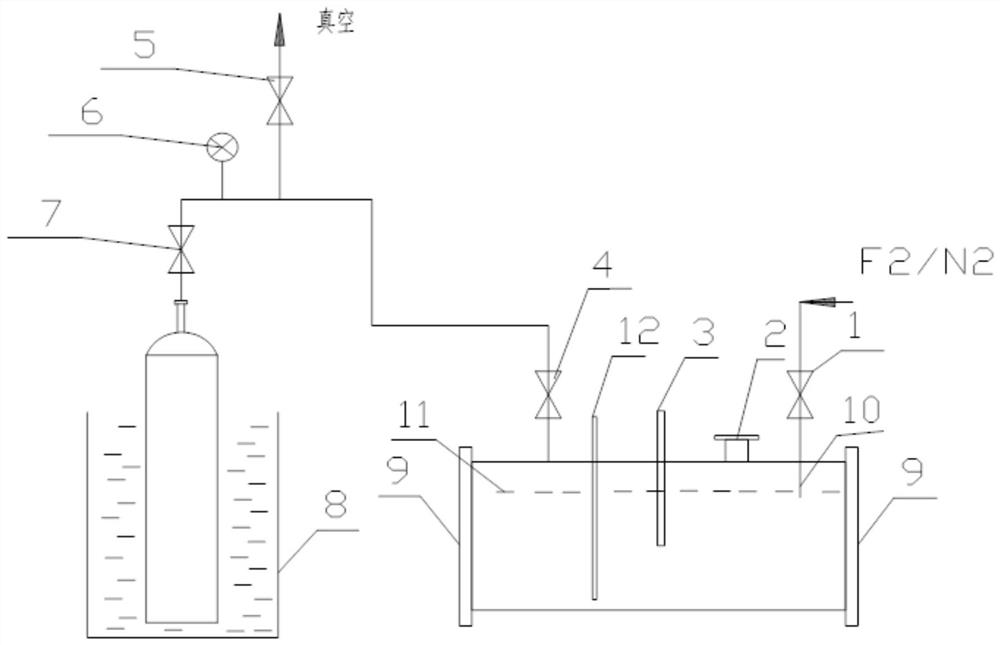

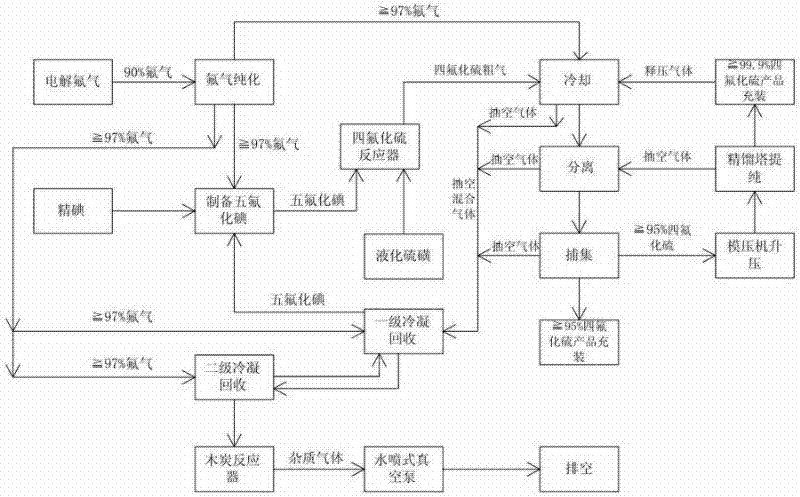

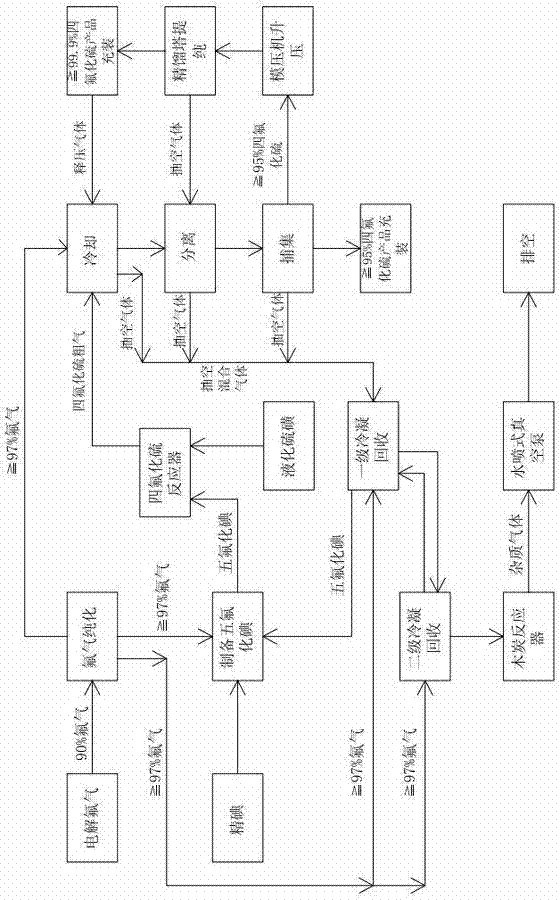

Sulfur tetrafluoride production technique

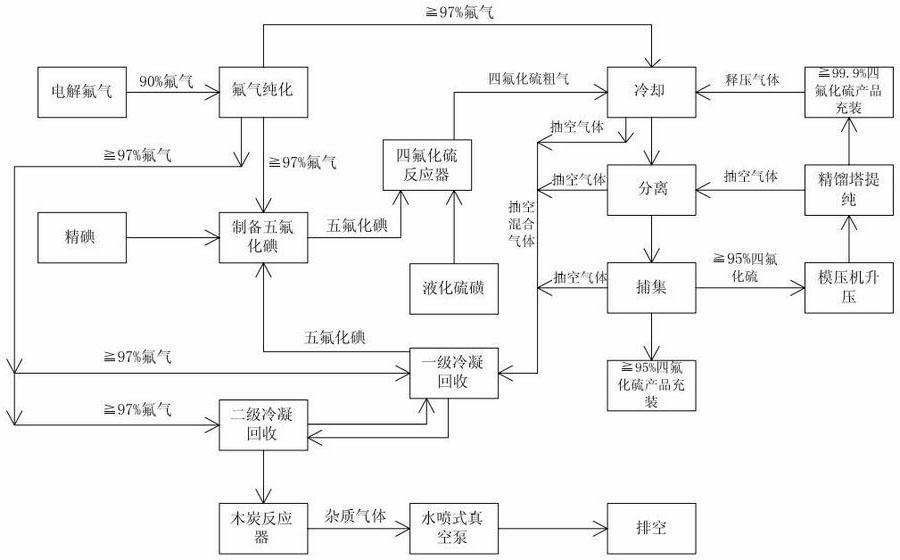

ActiveCN102173393AIncrease concentrationImprove conversion rateSulfur and halogen compoundsHydrogen fluorideTrapping

The invention relates to a sulfur tetrafluoride production technique, belonging to the field of fluorochemicals. The sulfur tetrafluoride production technique comprises fluorine gas purification, iodine pentafluoride preparation, sulfur tetrafluoride reactive synthesis, sulfur tetrafluoride separation and trapping, sulfur tetrafluoride distillation and canning, secondary recycling of iodine pentafluoride as well as discharge of exhaust gas. By using a low-temeprature condensing device, the electrolytic fluorine is purified to remove a great amount of hydrogen fluoride, so the fluorine gas concentration is largely improved. A condensing and recycling device is employed to recycle iodine and iodine pentafluoride for re-use, thus the utilization ratio of iodine can reach above 70% and material losses can be reduced. Due to a constant distillation method, the purity of sulfur tetrafluoride products can reach above 99.9%, and the products can be charged into a steel cylinder more safely. In addition, the entire sulfur tetrafluoride production technique is controlled by a automatic DCS (distributed control system) device, which reduces artificial randomness and experience and improves the stability of product quality.

Owner:山东锐华氟业有限公司

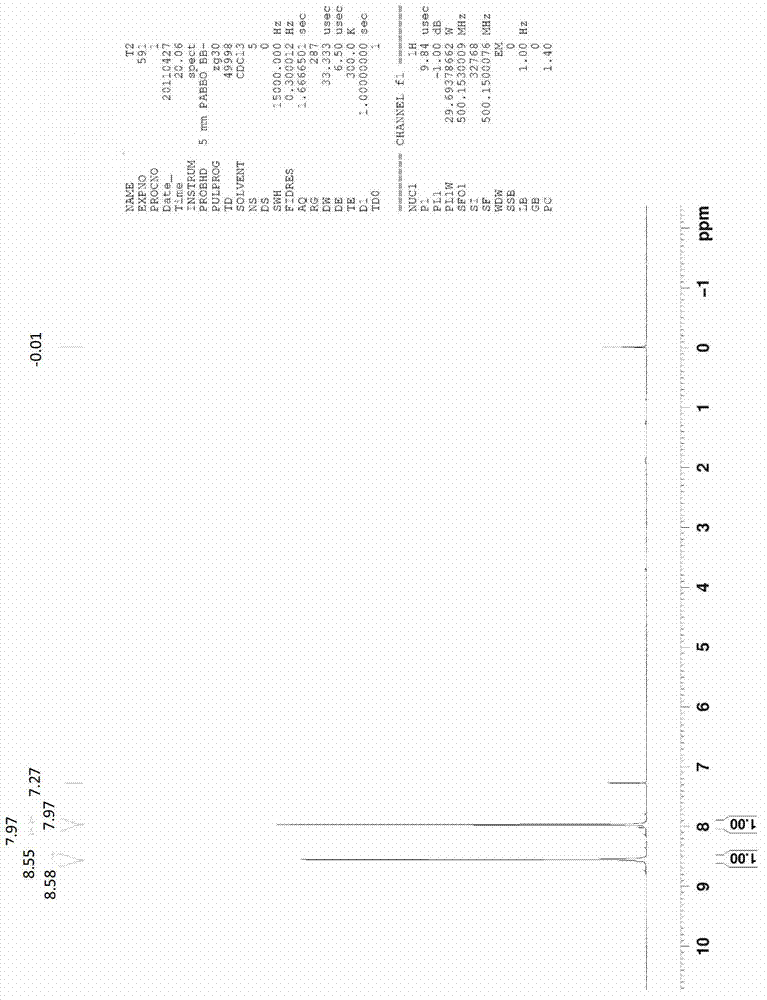

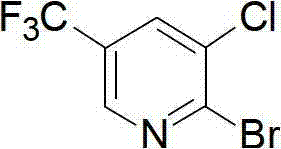

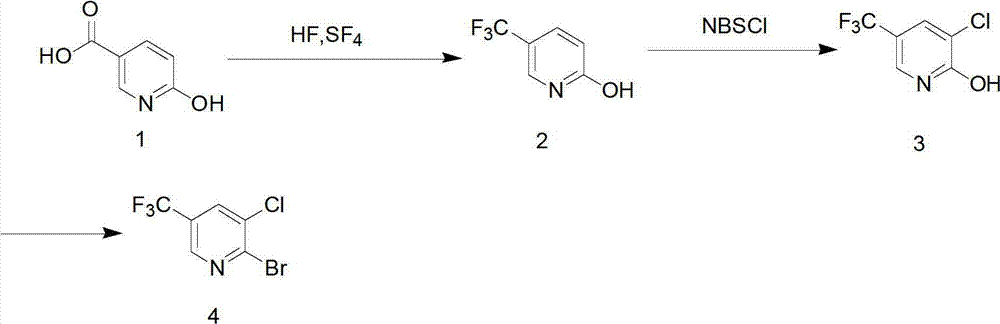

Preparation method for pyridine medical intermediate for synthesizing anti-cancer auxiliary medicines

The invention relates to the field of medical chemistry and discloses a method for synthesizing a pyridine medical intermediate, namely 2-bromo-3-chloro-5-trifluoromethyl pyridine, for synthesizing anti-cancer auxiliary medicines. The method comprises the following steps of: (1) reacting 6-hydroxynicotinic acid, hydrofluoric acid and sulfur tetrafluoride at the temperature of between 100 and 120DEG C and under the pressure of 0.1-0.3MPa, and adding water to obtain 2-hydroxy-5-trifluoromethyl pyridine; (2) reacting with N-chlorosuccinimide, and performing water precipitation to obtain 3-chloro-5-trifluoromethyl-2-hydroxypyridine; and (3) adding excessive phosphorus oxybromide, reacting at the temperature of between 145 and 160DEG C for 5 to 8 hours, cooling, violently stirring at the temperature of between -5 and 0DEG C, extracting, combining organic phases, drying, filtering, performing spin drying, and purifying by using a silica gel column. According to the method, raw materials are readily available, the cost is low, the method is suitable for industrial production and the yield exceeds 38 percent.

Owner:上海泰坦科技股份有限公司

Method for production of sulfur hexafluoride from sulfur tetrafluoride

InactiveUS20120164060A1Increase ratingsFacilitated DiffusionInorganic gasesFluoride preparationStationary phaseSulfur tetrafluoride

Disclosed is a method for an energy-efficient improvement in the production of sulfur hexafluoride, and eliminates the generation of other byproducts. The process is an oxidative fluorination of sulfur tetrafluoride by CoF3 / F2, where CoF3 is solid stationary phase that can be regenerated.

Owner:OMOTOWA BAMIDELE A

Method for production of sulfur hexafluoride from sulfur tetrafluoride

InactiveUS8231855B2Increase ratingsFacilitated DiffusionInorganic gasesFluoride preparationStationary phaseSulfur hexafluoride

Disclosed is a method for an energy-efficient improvement in the production of sulfur hexafluoride, and eliminates the generation of other byproducts. The process is an oxidative fluorination of sulfur tetrafluoride by CoF3 / F2, where CoF3 is solid stationary phase that can be regenerated.

Owner:OMOTOWA BAMIDELE A

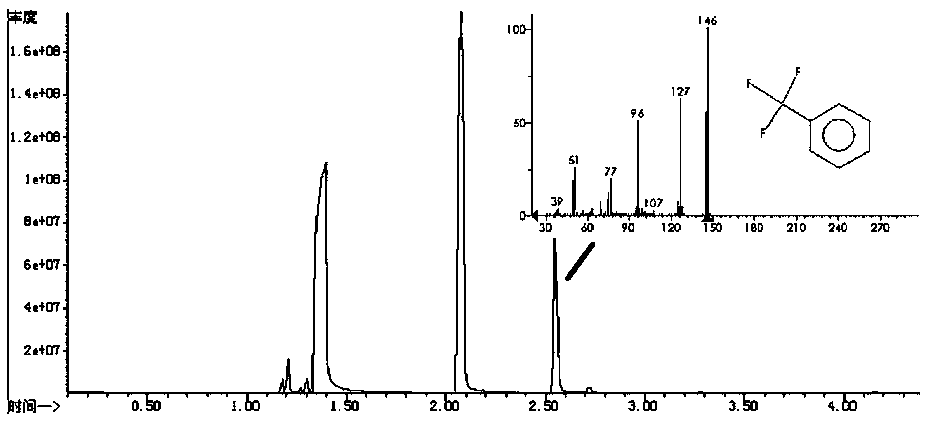

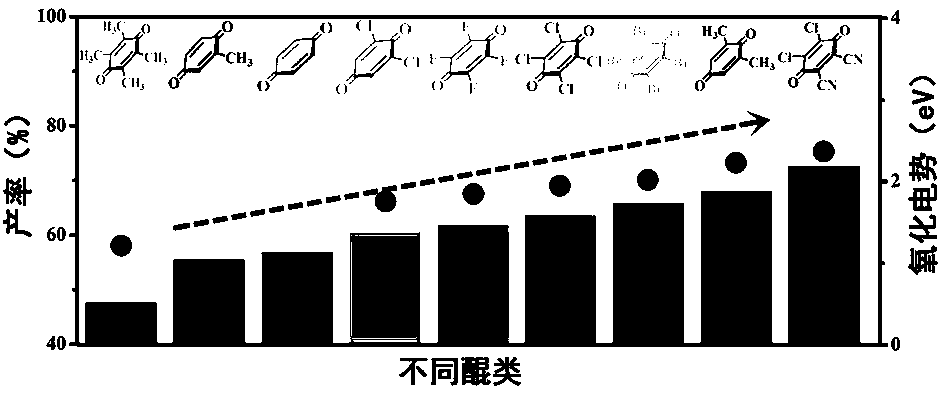

Quinone-catalyzed trifluoromethylation photocatalytic synthesis method

ActiveCN105503510AReduce pollutionEasy to makeOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsTrifluoromethylationQuinone

The invention discloses a quinone-catalyzed trifluoromethylation photocatalytic synthesis method. According to the method, the using problem of highly-corrosive and highly-toxic fluorinating reagents such as hydrogen fluoride and sulfur tetrafluoride in an existing industrial trifluoromethylation reaction is solved, the heavy metal pollution problem of a catalyst in industry is avoided, and the good actual application prospect is achieved. The metal-free photocatalytic trifluoromethylation reaction is achieved by taking simplest and cheapest benzoquinone and derivatives thereof as a photocatalyst and taking a Langlois reagent-sodium trifluoromethanesulfinate (CF3SO2Na) as a trifluoromethyl source under the mild visible light condition, and a complete full-cycle reaction is achieved through a homemade fixed bed reactor. Trifluoromethyl modification can be further performed on organic molecules with the bioactivity and the pharmaceutical activity according to the actual needs. The method has the advantages that the synthesis condition is mild, the raw materials are cheap and easy to obtain, the environmental pollution is low, large-scale industrial production is facilitated, and the significant economic and social benefit is achieved.

Owner:FUZHOU UNIV

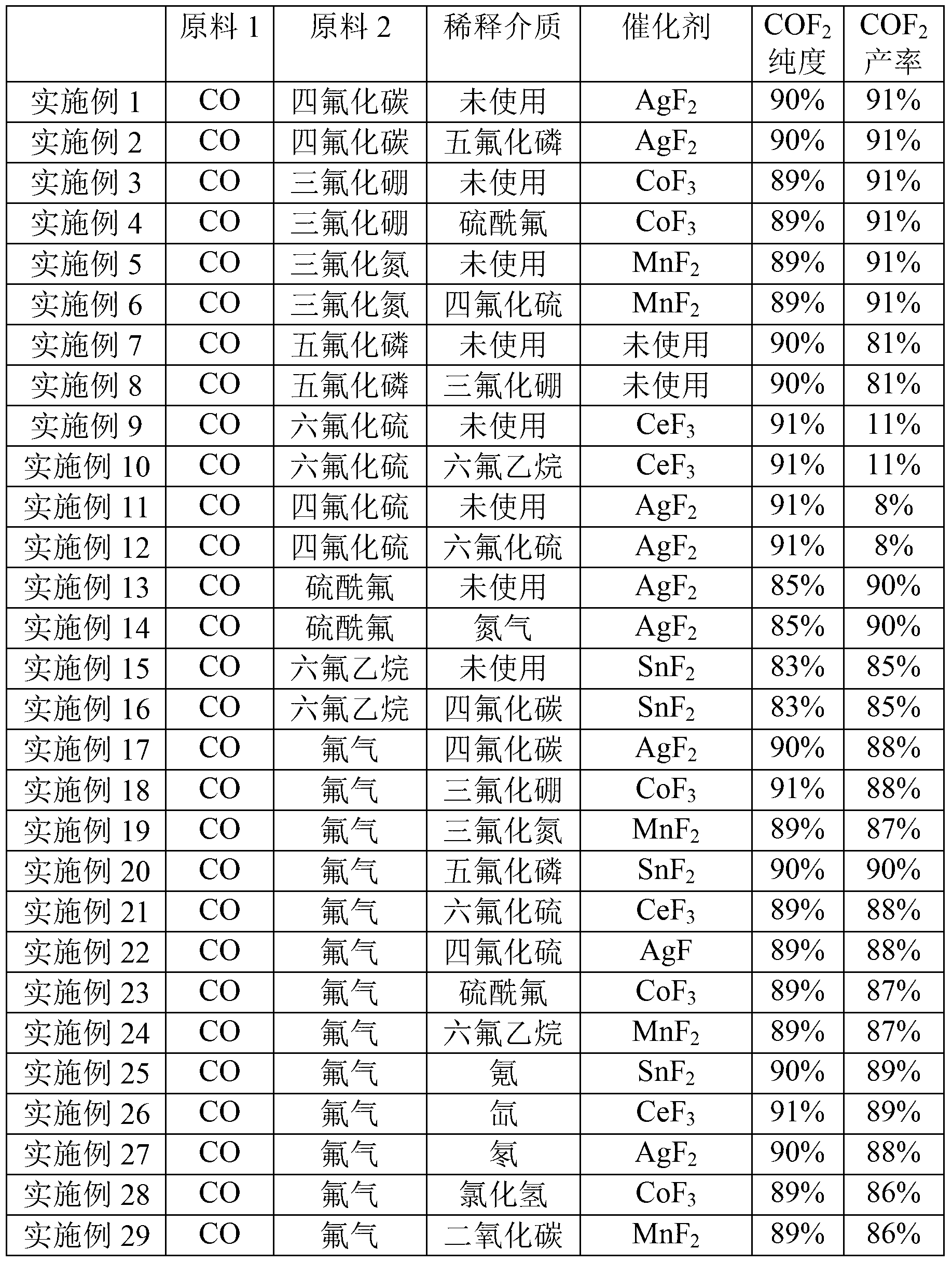

Preparation method of carbonyl fluoride

ActiveCN103213965ASafe preparationEconomical and efficient to prepareCarbon compoundsHexafluoroethanePhosphorus trifluoride

The invention relates to a preparation method of carbonyl fluoride and belongs to the fluorine chemical field and the field of electronic industrial gas. The preparation method is used for preparing carbonyl fluoride through the reaction of carbon monoxide and fluorine-containing substance, wherein the fluorine-containing substance is at least one of carbon tetrafluoride, boron trifluoride, nitrogen trifluoride, sulfur tetrafluoride, sulfur hexafluoride, phosphorus trifluoride, phosphorus pentafluoride, sulfuryl fluoride or hexafluoroethane; the favourable conditions including temperature, pressure, a proportion of fluorine-containing substance to carbon monoxide and gas supply flow rate of the fluorine-containing substance are selected; dilution medium is further added in the method for diluting or carrying out catalytic reaction by virtue of catalyst. The preparation method of the carbonyl fluoride is free of fluorine gas, capable of lowering the corrosion to a reactor, reaction heat, reaction intensity, potential explosive risk and yield drop caused by side reaction, and capable of safely, economically and effectively preparing the carbonyl fluoride. The invention further provides dilution medium which is used in the preparation of the carbonyl fluoride through the reaction of carbon monoxide and fluorine gas.

Owner:PERIC SPECIAL GASES CO LTD

Polyurethane elastomer based on sulfur tetrafluoride modification, and preparation method thereof

The invention discloses a polyurethane elastomer based on sulfur tetrafluoride modification, and a preparation method thereof. The polyurethane elastomer is prepared from the following ingredients at a weight part ratio: 21-43 parts of polyurethane, 16-39 parts of acrylic ester, 12-26 parts of isocyanate, 12-25 parts of hexafluorobutyl acrylate, 7-18 parts of sulfur tetrafluoride, 4-11 parts of hexafluoride propyl alcohol, 7-18 parts of silicon carbide, 6-14 parts of magnesium oxide, 7-18 parts of montmorillonite and 5-12 parts of talcum powder. The polyurethane elastomer has the following advantages: (1) the fluorine content of the polyurethane elastomer based on the sulfur tetrafluoride modification is increased, a contact angle with water is increased, and surface tension is lowered; (2) the thermostability of the polyurethane elastomer disclosed by the invention is improved, and the polyurethane elastomer exhibits excellent water-resistance and solvent-resistance performance; and (3) the polyurethane elastomer keeps good hardness, breaking strength, elongation, storage modulus and surface performance.

Owner:WUXI YONGXING METAL HOSE

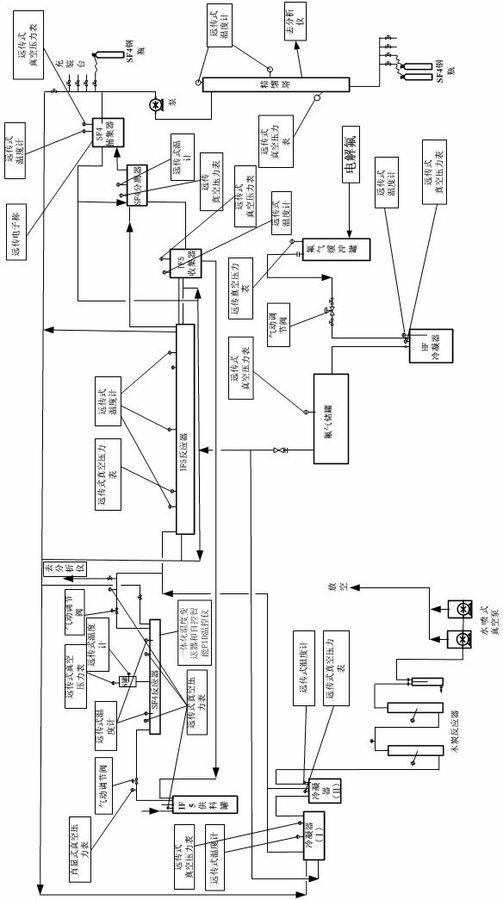

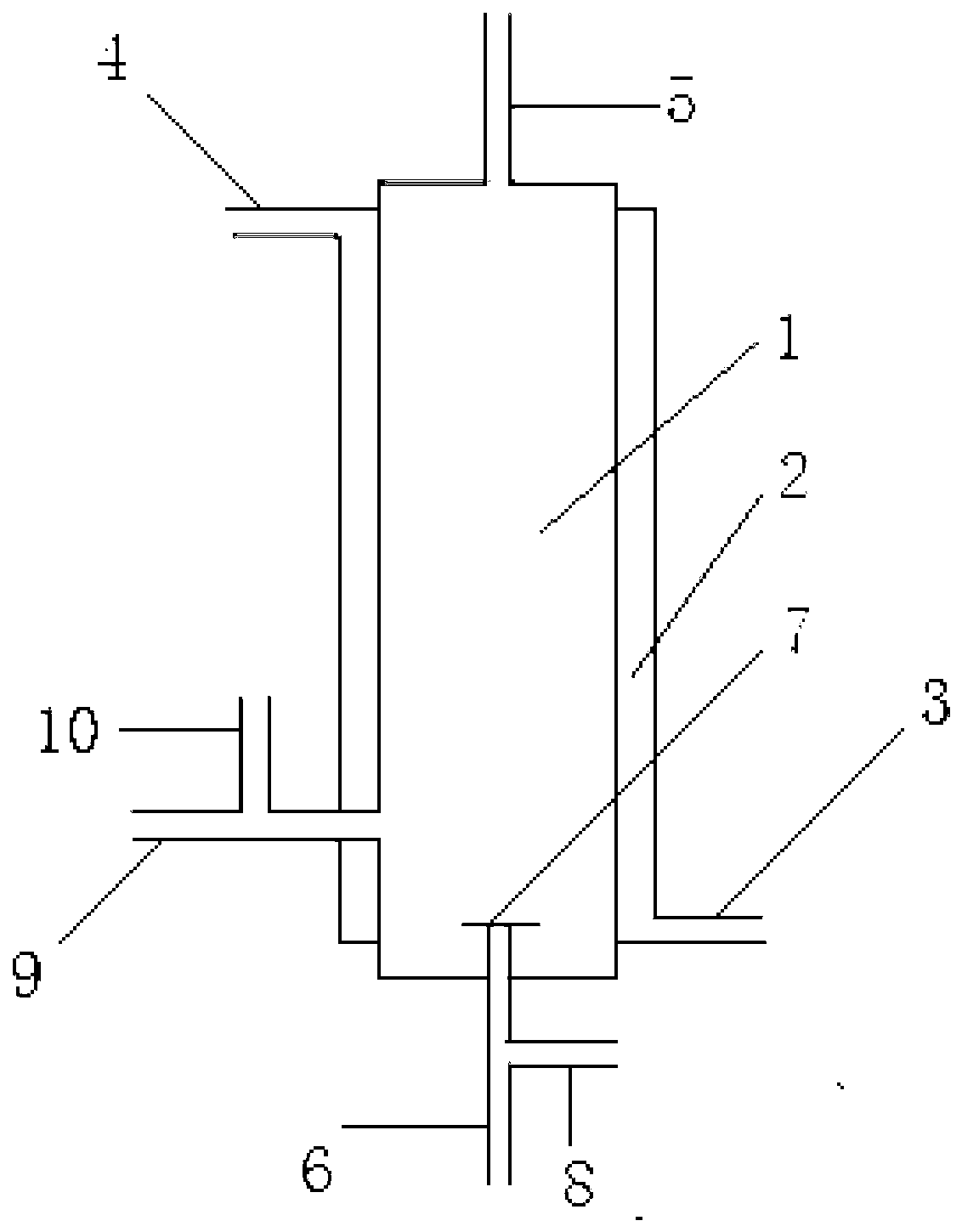

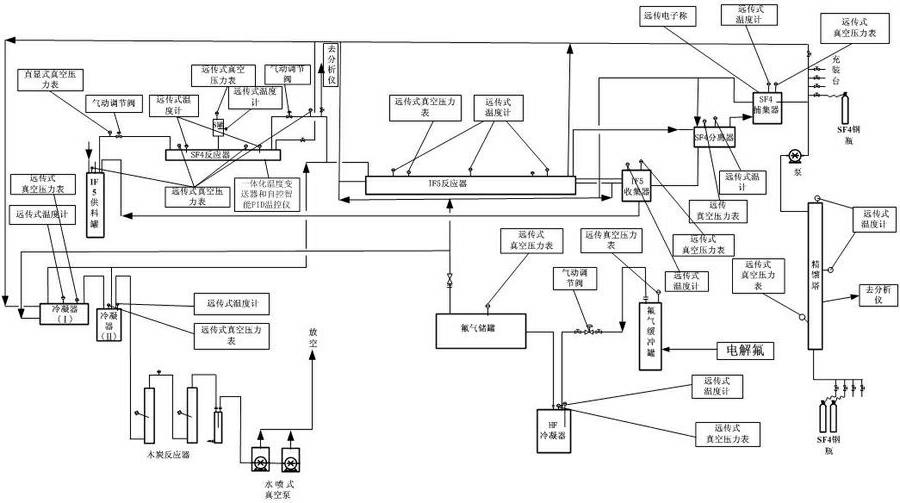

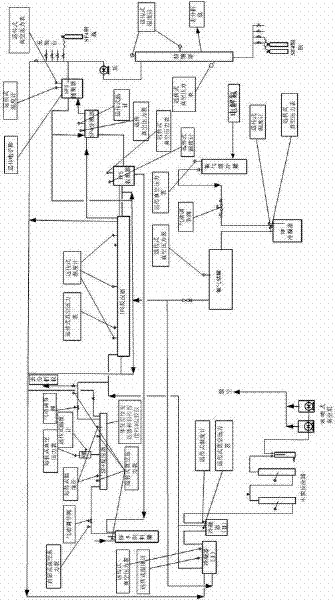

Automatic control of sulfur tetrafluoride production process

ActiveCN102079509AGuaranteed stabilityImprove stabilitySulfur and halogen compoundsAutomatic controlSulfur tetrafluoride

The invention relates to automatic control of a sulfur tetrafluoride production process, comprising the automatic control of sulfur tetrafluoride synthesis reaction, the automatic control of sulfur tetrafluoride cooling, separating and capturing, the automatic control of iodine pentafluoride preparation, the automatic control of fluoride preparation and purification, the automatic control of rectification and purification and the automatic control of recycling. The invention ensures the stability of the quality of the sulfur tetrafluoride product by adopting measures of system process control analysis, product mass spectrum analysis and chemical analysis and also ensures the continuous and stable running of production; the production process for synthesizing sulfur tetrafluoride adopts DCS (Distributed Control System) automation device control in the whole course, reduces artificial randomness and experience, improves the stability of the product quality as well as the purity, the yield and the production efficiency of the product and reduces the raw material waste and the production cost.

Owner:山东锐华氟业有限公司

Method for producing 4,4-difluoro cyclohexyl formic ether by using counter cyclohexanone formic ether through fluorination

InactiveCN102531898AResidue reductionHigh purityOrganic compound preparationCarboxylic acid esters preparationCyclohexanoneChemical industry

The invention discloses a method for producing 4,4-difluoro cyclohexyl formic ether by using counter cyclohexanone formic ether through fluorination, which belongs to the technical field of chemical industry. The method comprises the steps of (1) respectively putting the counter cyclohexanone formic ether, sulfur tetrafluoride and hydrogen fluoride in a pressure kettle, starting blending, enabling the reaction temperature in the pressure kettle to be controlled at 0-80 DEG C, and enabling response time to be 0.5-24.0h; (2) opening an outlet valve of the pressure kettle, enabling surplus gas to be led in alkali liquid, and enabling the gas to be absorbed by the alkali liquid; (3) opening the pressure kettle, enabling reaction liquid to be poured in ice water, starting blending simultaneously, stewing and layering after completing pouring to separate an oil layer; and (4) adjusting the separated oil layer to be neutral by using the alkali liquid, stewing to remove a water layer, adding a desiccating agent to the oil layer, and filtering the desiccating agent to obtain the 4,4-difluoro cyclohexyl formic ether. The method synthesizes target products through a one-step reaction, and is simple in reaction, few in steps, few in secondary products, apt to obtain products with high purity through distillation, high in total recovery, good in safety and favorable for scale production.

Owner:江苏华达化工集团有限公司

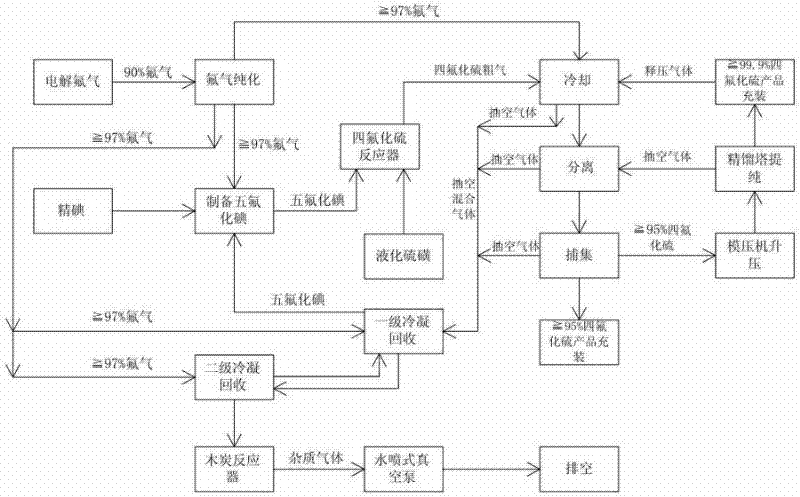

Material recycling technique used during sulfur tetrafluoride production

ActiveCN102173394AReduce lossesReduce the amount of purification treatmentSulfur and halogen compoundsTrappingGas phase

The invention relates to a material recycling technique used during sulfur tetrafluoride production. Firstly, the coarse sulfur tetrafluoride gas is produced through reactive synthesis of iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor and then raw materials are initially recycled through condensation, separation and trapping. The impure gases obtained by gas pahse purification during condensation, separation and trapping of sulfur tetrafluoride are evacuated and recovered again through a secondary condensation recovery device. The condensation recovery devices in the initial and secondary stages are utilized to recycle iodine and iodine pentafluoride, which can increase the utilization rate of iodine by more than 70%. The technique can not only reduce material losses and lower production cost but also cut down the volumes to be purified.

Owner:山东锐华氟业有限公司

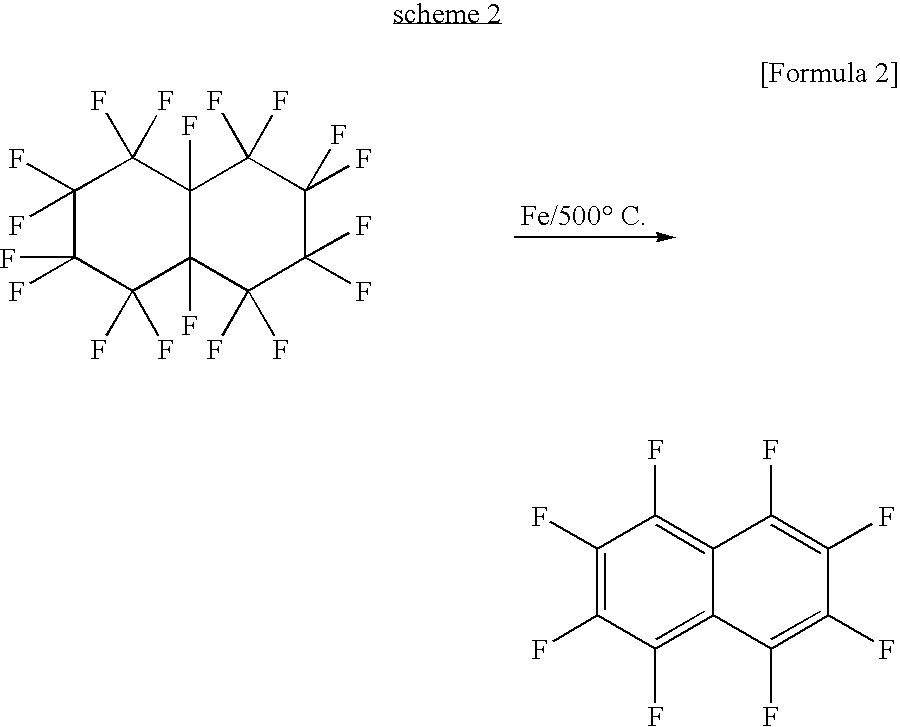

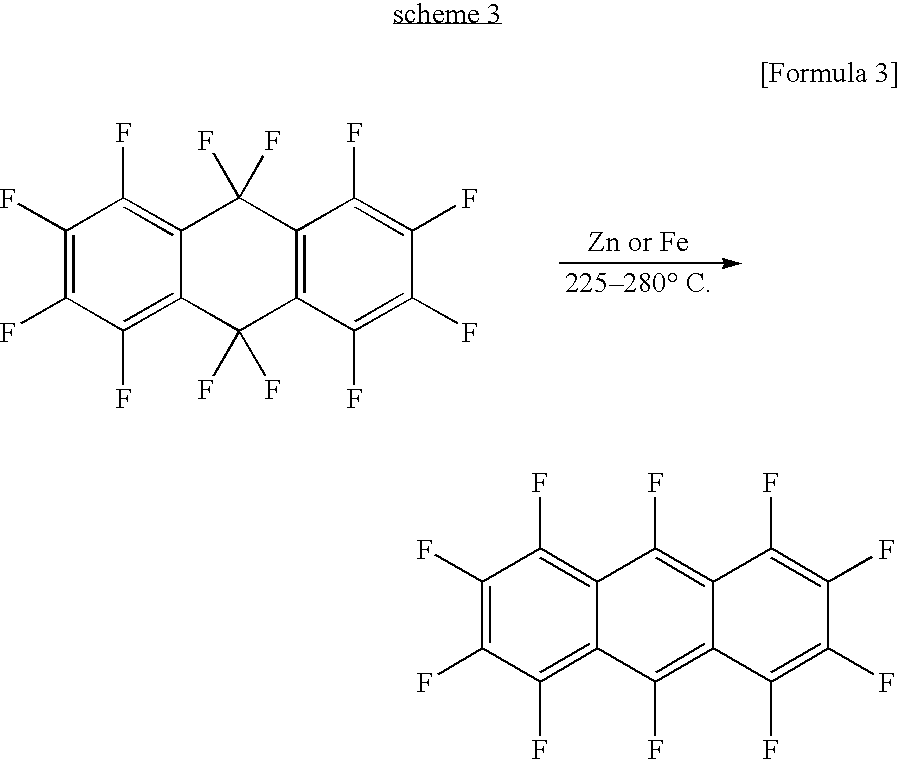

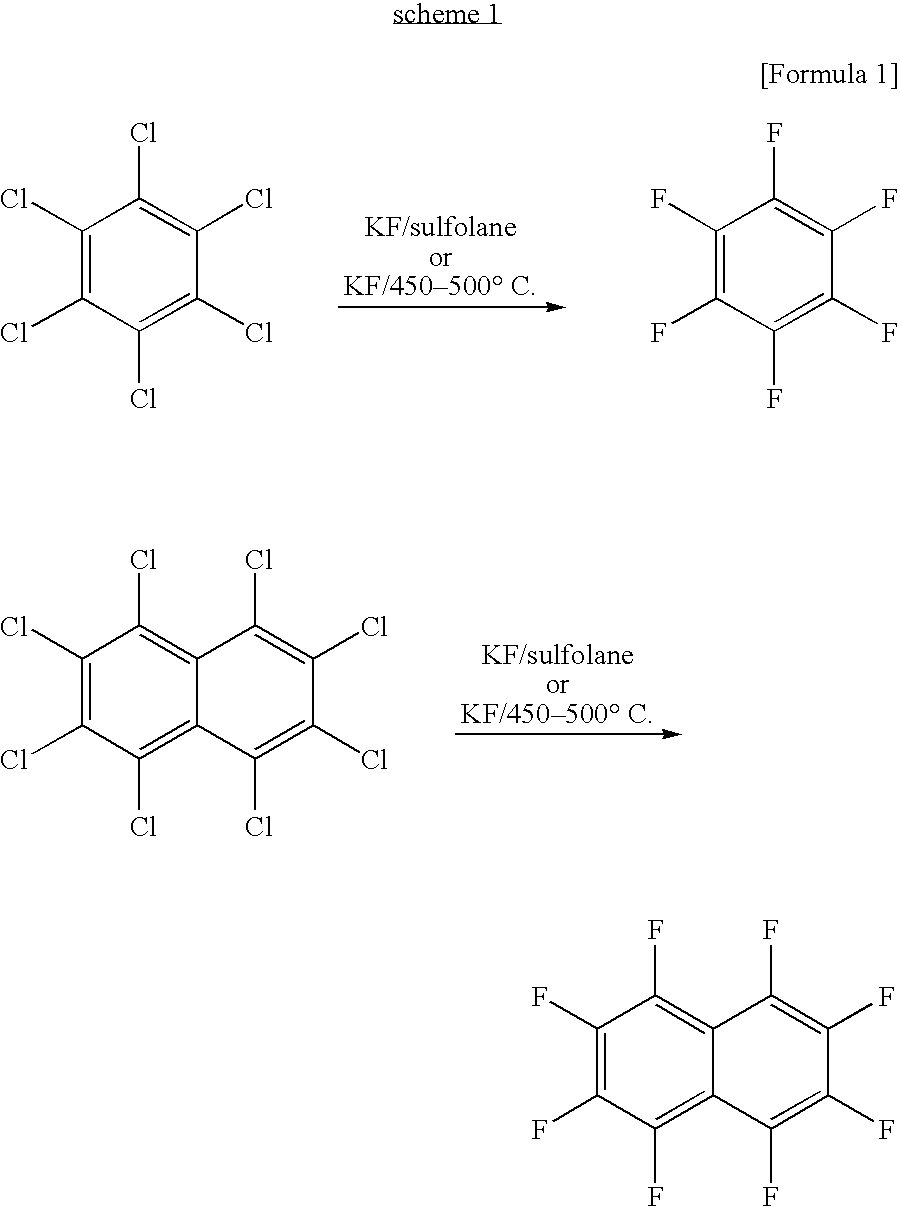

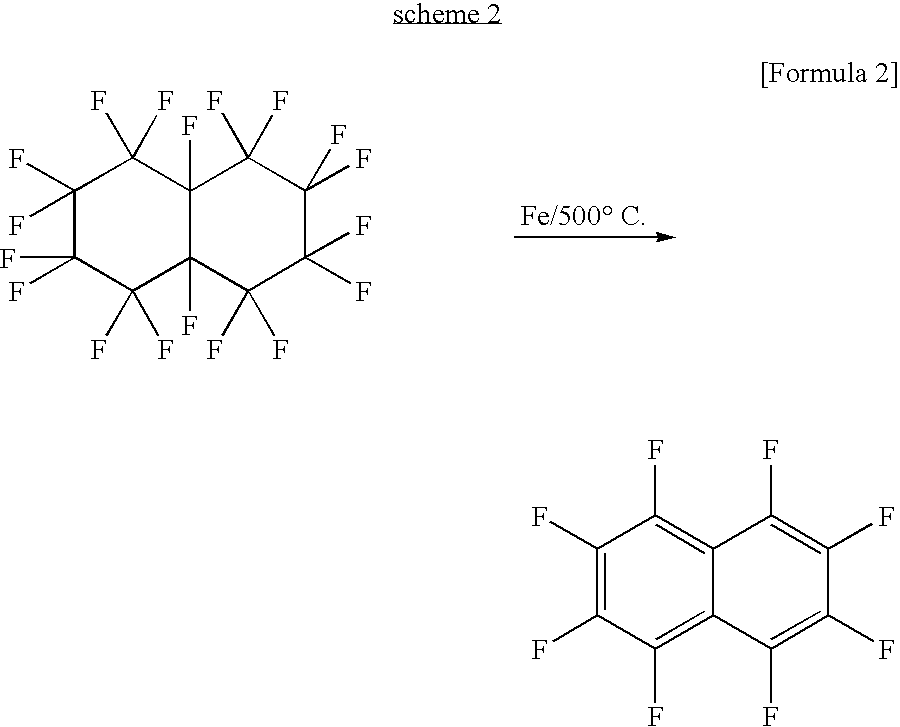

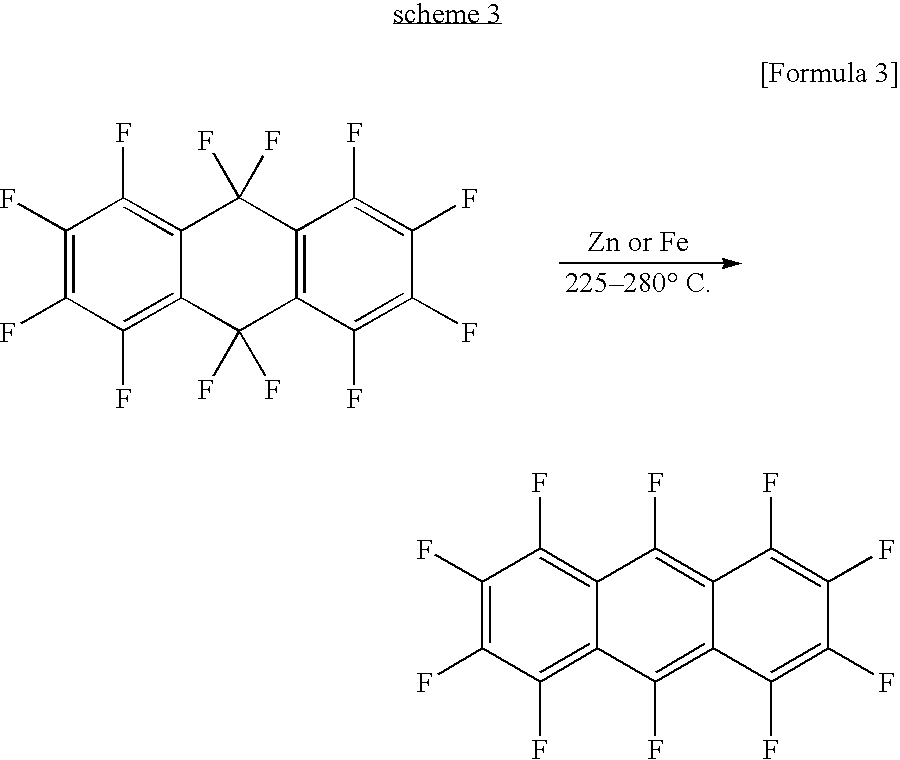

Fluorinated pentacene derivative and method of producing same

ActiveUS20070083067A1Preparation by dehalogenationOrganic compound preparationPentaceneSulfur tetrafluoride

Fluorinated pentacene derivatives, for example, the novel compounds tetradecafluoropentacene, 5,6,7,12,13,14-hexafluoropentacene, 5,7,12,14-tetrafluoropentacene, and 6,13-difluoropentacene, and intermediates therefor are provided. And a method of producing fluorinated pentacene derivatives and intermediates therefor is also provided. Pentacene derivatives fluorinated at desired positions of the pentacene skeleton are obtained by introducing the oxo group, hydroxyl group, or alkoxyl group into the pentacene skeleton followed by fluorination with sulfur tetrafluoride and partial defluorination using a reducing agent.

Owner:KANTO DENKA IND CO LTD

Purification and rectification process of sulfur tetrafluoride

InactiveCN109704291AEasy to manufactureConvenient scientific exportSulfur and halogen compoundsTemperature controlSulfur hexafluoride

The invention discloses a purification and rectification process of sulfur tetrafluoride. The preparation process of sulfur hexafluoride is controlled through inductance elements. The process is carried out by using the following devices: a weighing device, a containing box, a quantitative valve, a sulfur tetrafluoride reactor, a stirrer, temperature sensors, a pressure sensor, an air pump, a cooler, a condensation catcher and a rectification tower. The process comprises the following operation steps: proportioning raw materials, preparing sulfur tetrafluoride, cooling crude gas, purifying thecrude gas and rectifying sulfur tetrafluoride. According to the invention, the condensation temperatures of the temperature control cooler and the condensation catcher are measured by the temperaturesensors, so that preparation of the sulfur tetrafluoride product is facilitated; and pressure in the sulfur tetrafluoride reactor is measured through the pressure sensor, so that scientific export ofthe crude gas is facilitated. The electric appliance elements used in the process do not need manual operation, the effect of full-automatic operation is achieved, the error of preparing the sulfur tetrafluoride product is reduced, purification precision is improved, and the purification precision is improved by 37% compared with purification precision of manual operation.

Owner:绵阳华鑫瑞建筑劳务有限公司

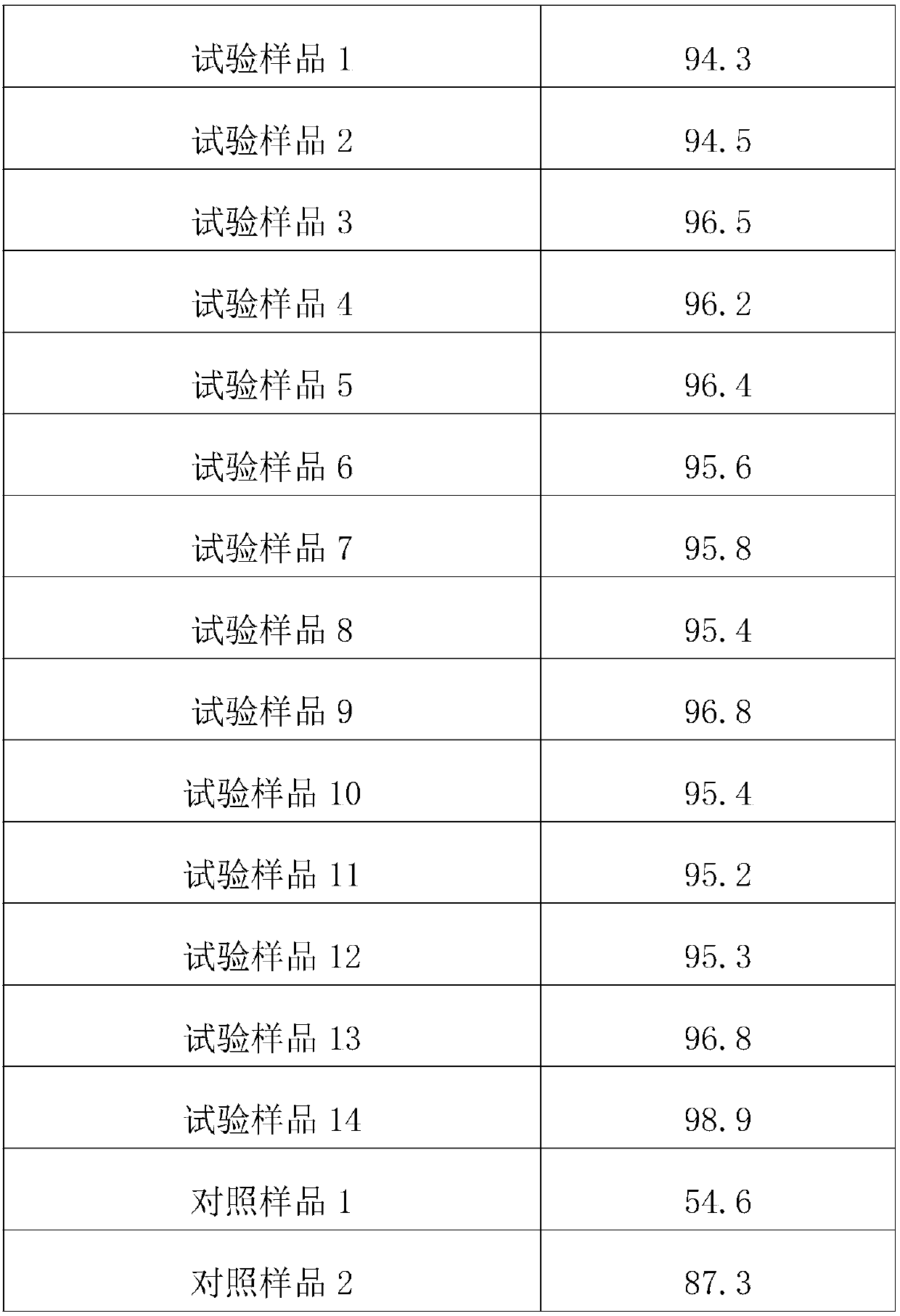

Preparation process for improving whiteness of kaolin

InactiveCN110407219AEliminate the effect of whitenessHigh whitenessSilicon compoundsIonSulfur tetrafluoride

The invention discloses a preparation process for improving the whiteness of kaolin, and relates to the field of removing iron from ore. The preparation process for improving the whiteness of kaolin is characterized by comprising the following steps that 1, mining and impurity removing are conducted, wherein kaolin ore is excavated, clay and impurities are initially separated out, and a base material is obtained; 2, pulping and sand removing are conducted, wherein the base material is subjected to pulping and sand removing, and an ore pulp initial material is obtained; 3, hydrochloric acid isintroduced into the ore pulp initial material, and dissolved iron ore pulp is obtained; 4, hydrogen peroxide is introduced into the dissolved iron ore pulp, and iron ion ore pulp is obtained; 5, anhydrous hydrofluoric acid is introduced into the iron ion ore pulp, and iron fluoride ore pulp is obtained; 6, a sulfur tetrafluoride solution is introduced into the iron fluoride ore pulp, and iron hexafluoride ion ore pulp is obtained; 7, a sodium chloride solution is introduced into the iron hexafluoride ion ore pulp, and after uniform mixing, the mixture is introduced into a filter press for pressure filtration. The preparation process has the advantages of improving the whiteness of the kaolin and expanding the application field of the kaolin.

Owner:福建新汉唐非金属材料有限公司

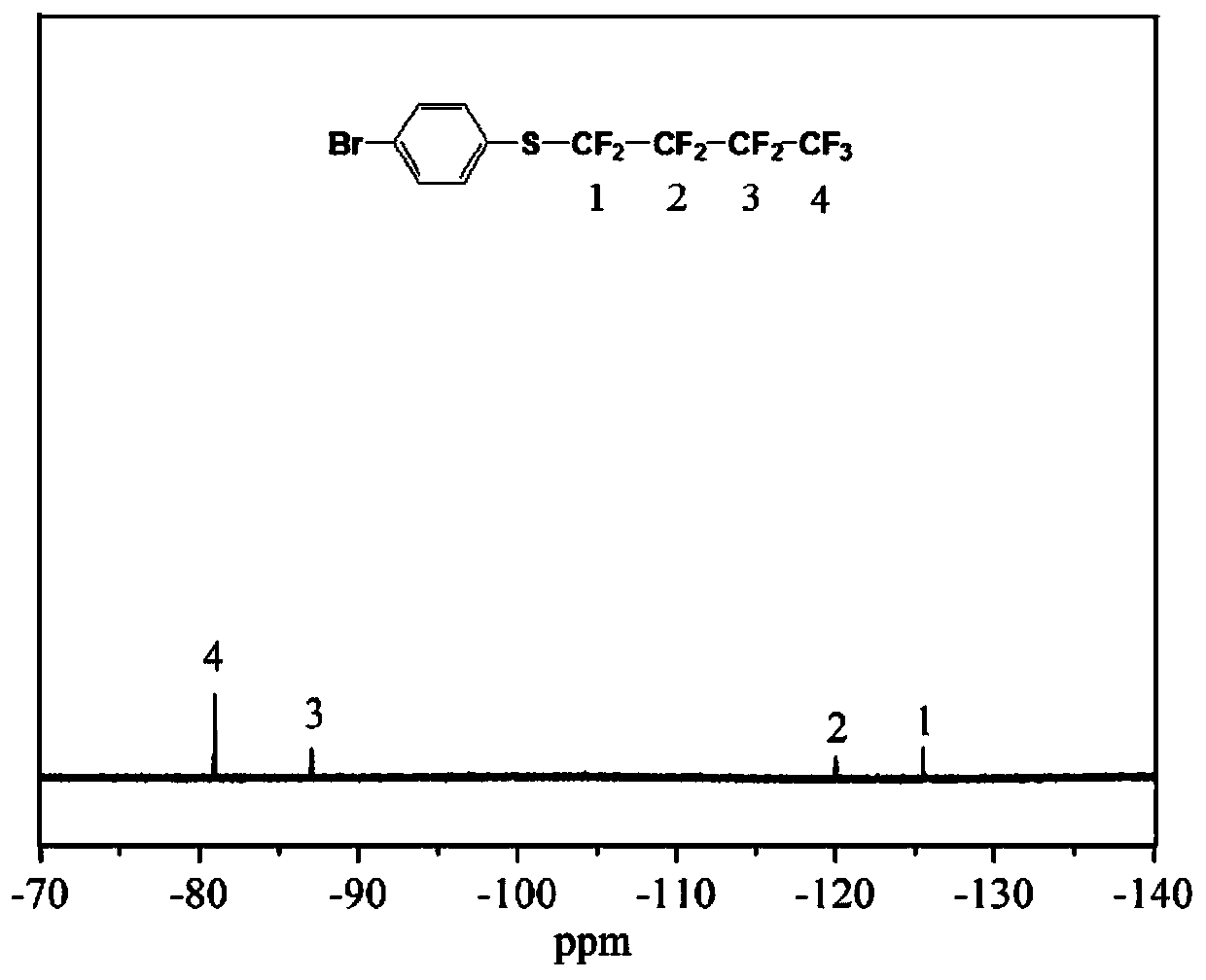

Perfluoroalkyl styrene and application thereof

ActiveCN110294699AExcellent liquid repellencySusceptible to UV degradationOrganic chemistryCoatingsUltraviolet lightsElectron

The invention discloses a perfluoroalkyl styrene monomer and application thereof. The perfluoroalkyl styrene monomer is prepared by the following steps of using monohalogenated thiophenol and perfluoro-iodoalkane as the raw materials, so as to obtain an intermediate, namely perfluoroalkyl thiohalobenzene; further fluorinating, so as to obtain perfluoroalkyl tetrafluorothio methylene halobenzene; finally, reacting with vinyl magnesium bromide, so as to obtain perfluoroalkyl tetrafluorothio methylene styrene. The prepared tetrafluorothio methylene-containing perfluoroalkyl styrene has the advantages that the reaction property is realized, and the tetrafluorothio methylene-containing perfluoroalkyl styrene can be used for preparing fluorine-containing surface treatment materials and liquid-repelling surfaces; because the perfluoroalkyl is bonded with rigid benzene rings, the whole structure of the fluorine-compound has larger crystallizing property, and the excellent liquid-repelling property is obtained; the tetrafluorothio methylene is used as a bridge group, and is directly bonded with the benzene ring, and the good heat-resistant stability is provided by the electron stable reaction of large phi bond of the benzene ring corresponding to the sulfur tetrafluoride; the tetrafluorothio methylene-containing perfluoroalkyl styrene is easy to degrade under the radiation by ultraviolet light, and the obtained fluorine-containing material is environment-friendly.

Owner:东莞市德伦新材料有限公司

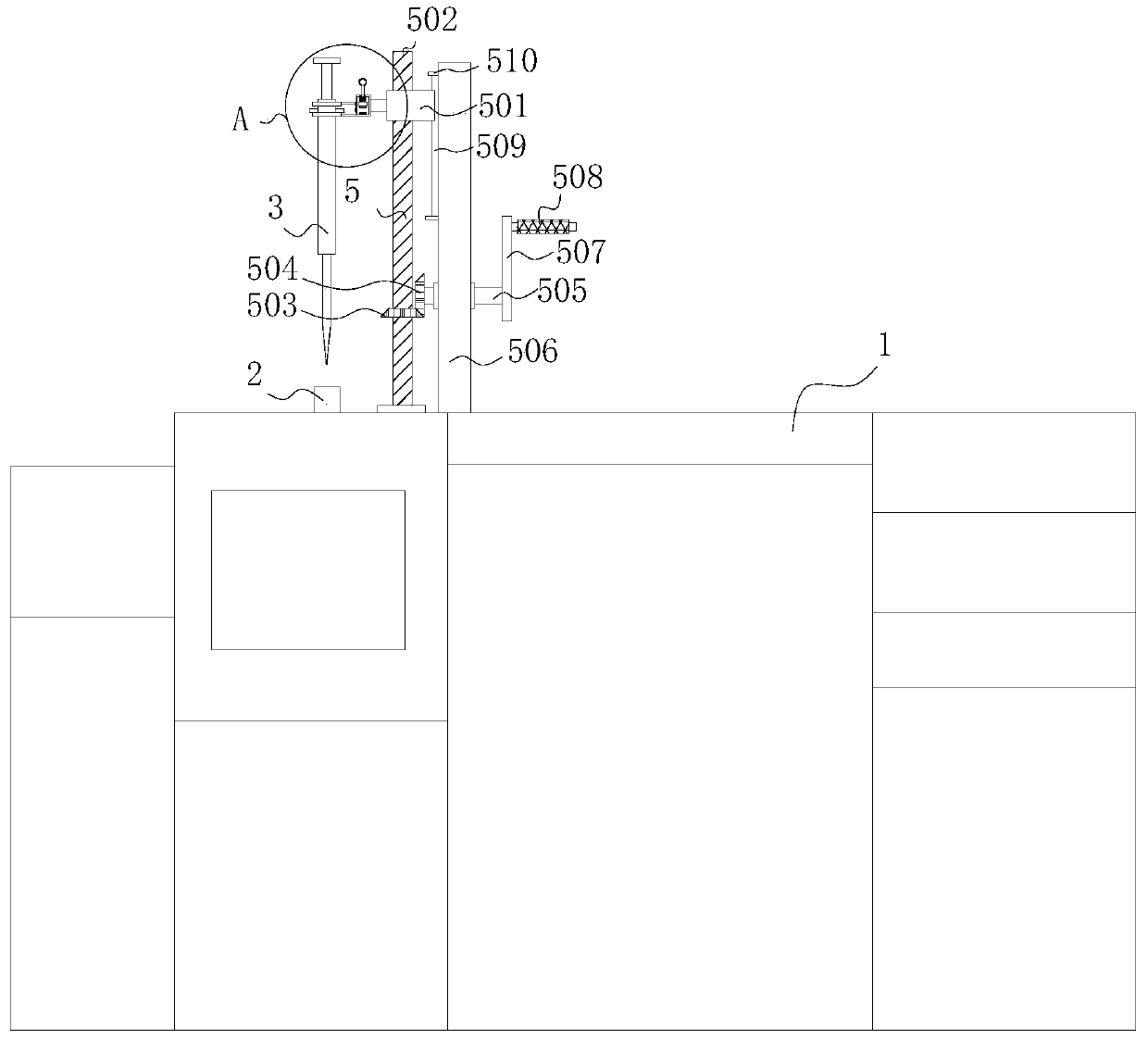

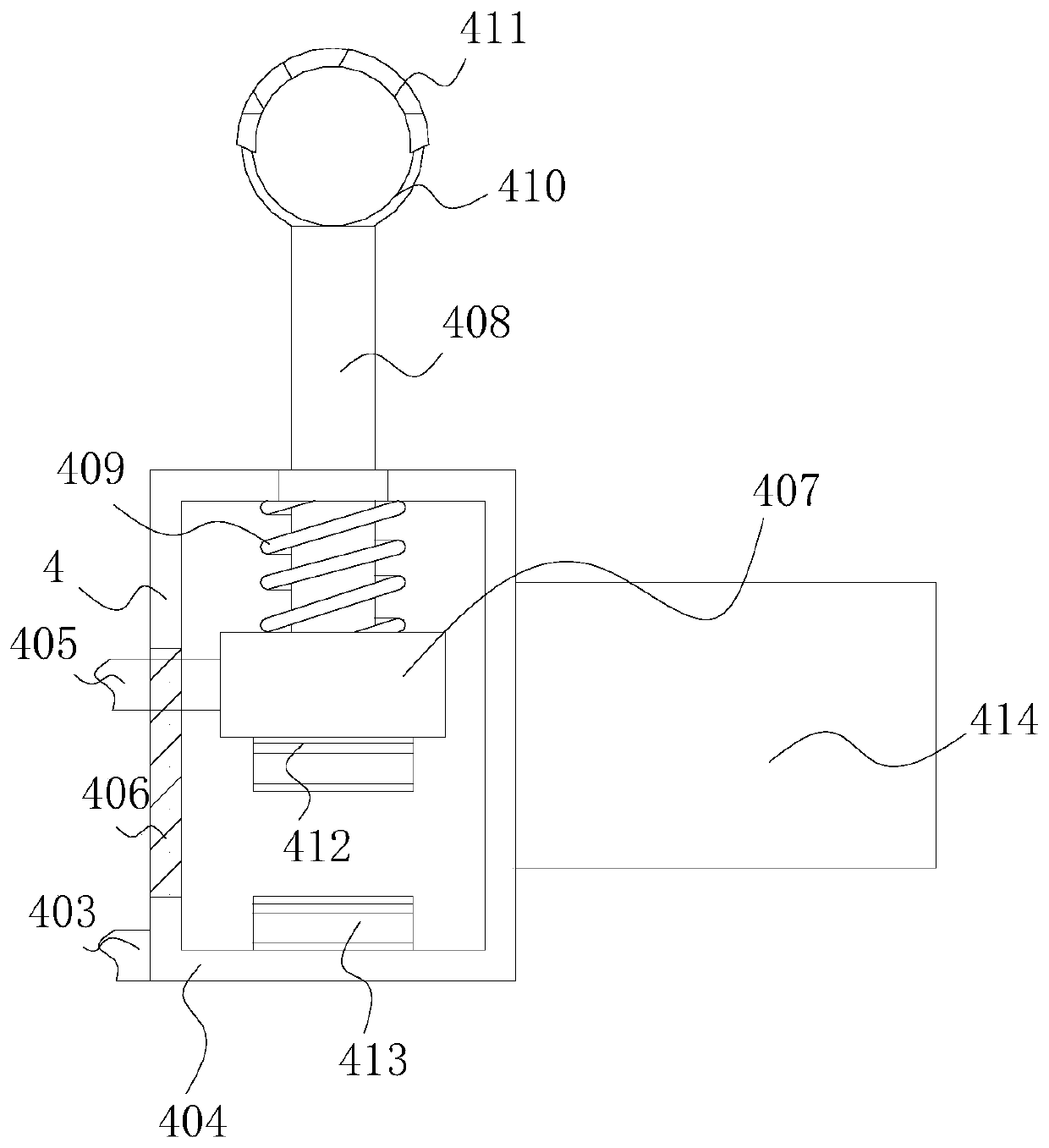

Sulfur tetrafluoride analyzer

PendingCN109781898AEasy to insertAvoid collision damageComponent separationSulfur tetrafluorideEngineering

The invention relates to the technical field of analyzers, in particular to a sulfur tetrafluoride analyzer comprising a gas chromatograph, a feed tube, a micro sample injection needle, a positioningmechanism, a lifting mechanism and a push block. The feed tube is fixedly communicated with the top of the gas chromatograph. The micro sample injection needle arranged above the feed tube is fixedlyconnected with the push block and is connected to the positioning mechanism; and the positioning mechanism is fixedly connected to the lifting mechanism fixedly connected to the top of the gas chromatograph. According to the invention, the positioning mechanism clamps and locates the push block at the micro sample injection needle rapidly and the lifting mechanism lifts the micro sample injectionneedle stably, so that the micro sample injection needle can be inserted into the feed tube conveniently. The lifting is stable; and the collision damage, caused by shaking, of the micro sample injection needle is avoided. The long-time manual holding is avoided; and the sulfur tetrafluoride product is detected conveniently.

Owner:山东锐华氟业有限公司

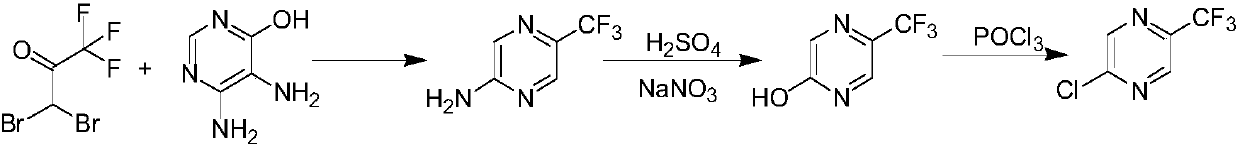

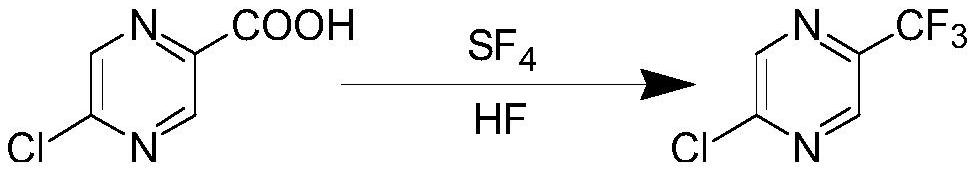

Method for synthesizing 2-chloro-5-(trifluoromethyl)pyrazine

ActiveCN107840828ASimple processRaw materials are easy to getOrganic chemistryHydrogen fluoridePyrazine

The invention provides a method for synthesizing 2-chloro-5-(trifluoromethyl)pyrazine by using 5-chloro-pyrazine-2-carboxylic acid, anhydrous hydrogen fluoride and sulfur tetrafluoride. The method forsynthesizing 2-chloro-5-(trifluoromethyl)pyrazine has the advantages of simple technology, easily available raw materials, and high yield.

Owner:KINGCHEM LIAONING CHEMICAL CO LTD

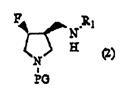

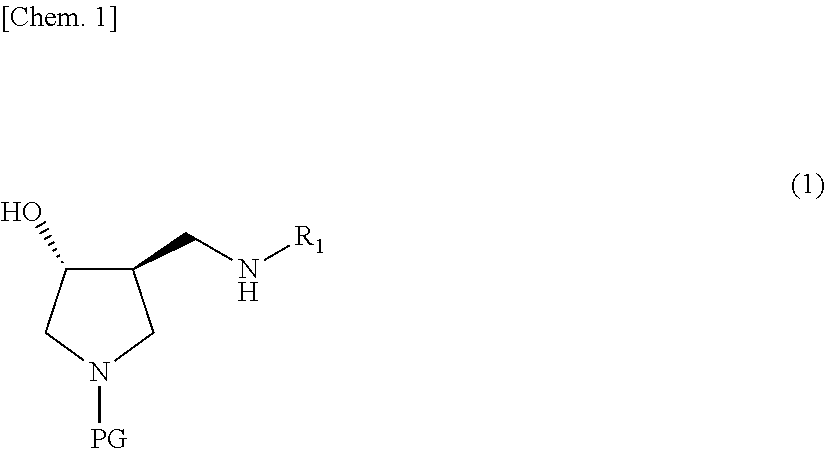

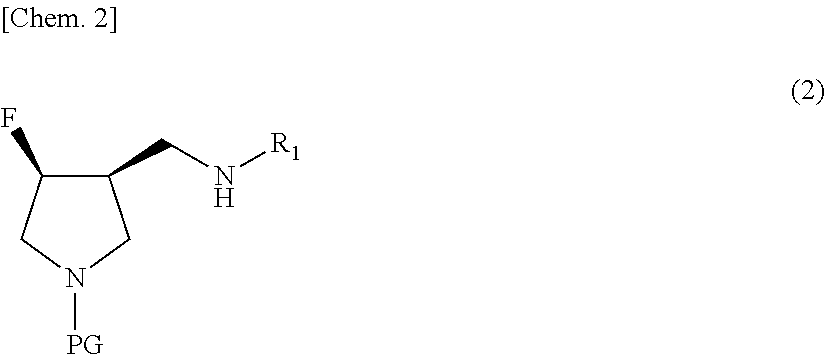

Method for producing 3,4-disubstituted pyrrolidine derivative and production intermediate thereof

InactiveCN102695698AEfficient productionLow costAntibacterial agentsOrganic chemistrySulfur tetrafluorideEnantiomer

Provided is an inexpensive and industrially advantageous method for preparing (3R,4S)-3-(N-substituted aminomethyl)-4-fluoropyrrolidine or an enantiomer thereof which can be an intermediate for producing pharmaceuticals. It relates to a method for preparing (3R,4S)-3-(N-substituted cyclopropylaminomethyl)-4-fluoropyrrolidine derivative or ait's enantiomer, or their salts, comprising a step of fluorinating a 4-hydroxy-3-(N-substituted aminomethyl)pyrrolidine derivative represented by the general formula (1) or an enantiomer thereof using a sulfur tetrafluoride derivative. [In the formula (1), PG represents a protective group for the amino group, and R1 represents a C1 to C6 alkyl group which may be substituted, or a C3 to C8 cycloalkyl group which may be substituted].

Owner:KYORIN PHARMA CO LTD

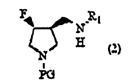

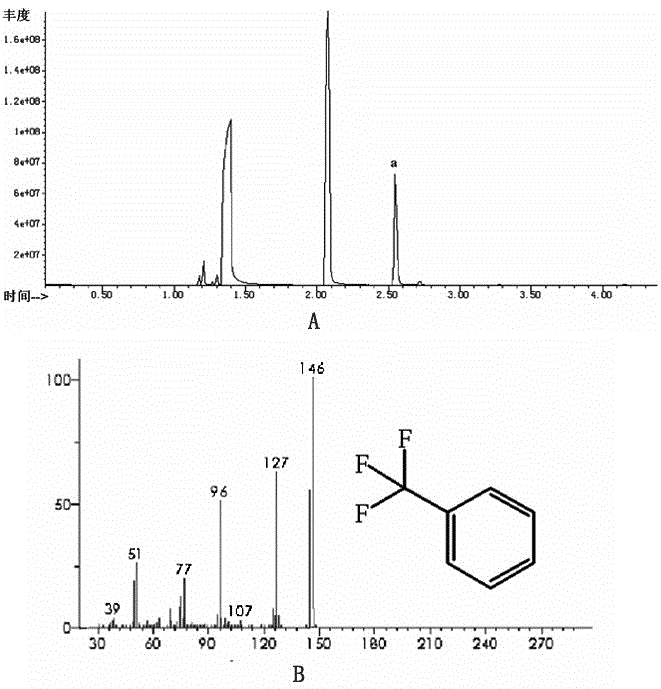

Method for converting benzene into benzotrifluoride through heterogeneous catalysis

ActiveCN105585418ALow costMild reaction conditionsHalogenated hydrocarbon preparationHydration reactionTrifluoromethylation

The invention discloses a method for converting benzene into benzotrifluoride through heterogeneous catalysis. Benzene is catalyzed to generate benzotrifluoride at lower temperature and normal pressure with manganese sulfate monohydrate as a catalyst, sodium trifluoromethanesulfinate as a trifluoromethyl source and acetonitrile as solvent. The raw materials are low in price and easy to obtain, conditions are mild, environment pollution is low, products are easy to separate, hydrogen fluoride, sulfur tetrafluoride and other highly-corrosive and highly-toxic fluorinated reagents used in current industrial trifluoromethylation reactions are avoided, large-scale industrial production is facilitated, and the method can be further used for trifluoromethyl modification of organic compounds with biological activity and medicine activity and has good application prospects and economic benefits.

Owner:FUZHOU UNIV

Fluorinated pentacene derivative and method of producing same

ActiveUS7439407B2Preparation by dehalogenationOrganic compound preparationSulfur tetrafluorideAlkoxy group

Owner:KANTO DENKA IND CO LTD

Sulfur-containing long-heterochain perfluoroalkyl acrylate and preparation method thereof

The invention discloses sulfur-containing long-heterochain perfluoroalkyl acrylate and a preparation method thereof. Nonafluorobutyl halogenated sulfur tetrafluoride serves as an end-capping reagent, and after tetrafluoroethylene is subjected to telomerization, 1H,1H,2H,2H-7-perfluoroundecanoic sulfide-1-halogen is prepared from obtained 5-perfluor nonyl sulfide-1-halogen and ethylene gas through single-electron addition reaction; the product and silver olefine acid have esterification reaction to obtain 1H,1H,2H,2H-perfluoroundecanoic acrylate sulfide. The prepared sulfur-containing long-heterochain perfluoroalkyl acrylate contains carbon-carbon double bonds for easy free radical polymerization, and can be used for preparing fluorine-containing polymer and copolymer. Long-heterochain perfluoroalkyl has crystallinity, so that when the prepared fluorine-containing polymer makes contact with liquid, no surface reconstruction phenomenon exists, and excellent liquid repellency. Meanwhile, perfluoroalkyl long heterochain has carbon-sulfur heterodesmic structures, is easy to degrade, does not have accumulative toxicity and does not belong to the sulfur-containing chemical inhibition range.

Owner:SUZHOU UNIV

Raw material recovery technology in sulfur tetrafluoride production

InactiveCN110078029AHigh purityEfficient removalSulfur tetrafluorideSulfur tetrafluorideChemical products

The invention discloses a raw material recovery technology in sulfur tetrafluoride production, and relates to the technical field of production of fluorine chemical products. The raw material recoverytechnology in the sulfur tetrafluoride production comprises following steps: protective measures before preparation of sulfur tetrafluoride, preparation work of sulfur tetrafluoride, pre-preparationof sulfur tetrafluoride, preparation of sulfur tetrafluoride, standby work after product preparation, primary fractional distillation of sulfur tetrafluoride, secondary fractional distillation of sulfur tetrafluoride, capturing of sulfur tetrafluoride, tail gas treatment of product preparation, recovery of product raw materials and detection of product raw materials. According to the technology, sulfur tetrafluoride is subjected to fractional distillation two times firstly, crude sulfur tetrafluoride can be effectively changed into primary sulfur tetrafluoride, needless impurities are removedby one step, then impurities in tail gas can be effectively removed, a processing instrument is effectively cleaned, so that degree of purification of sulfur tetrafluoride by the instrument is increased, and the raw material recovery rate of sulfur tetrafluoride is further increased.

Owner:绵阳华鑫瑞建筑劳务有限公司

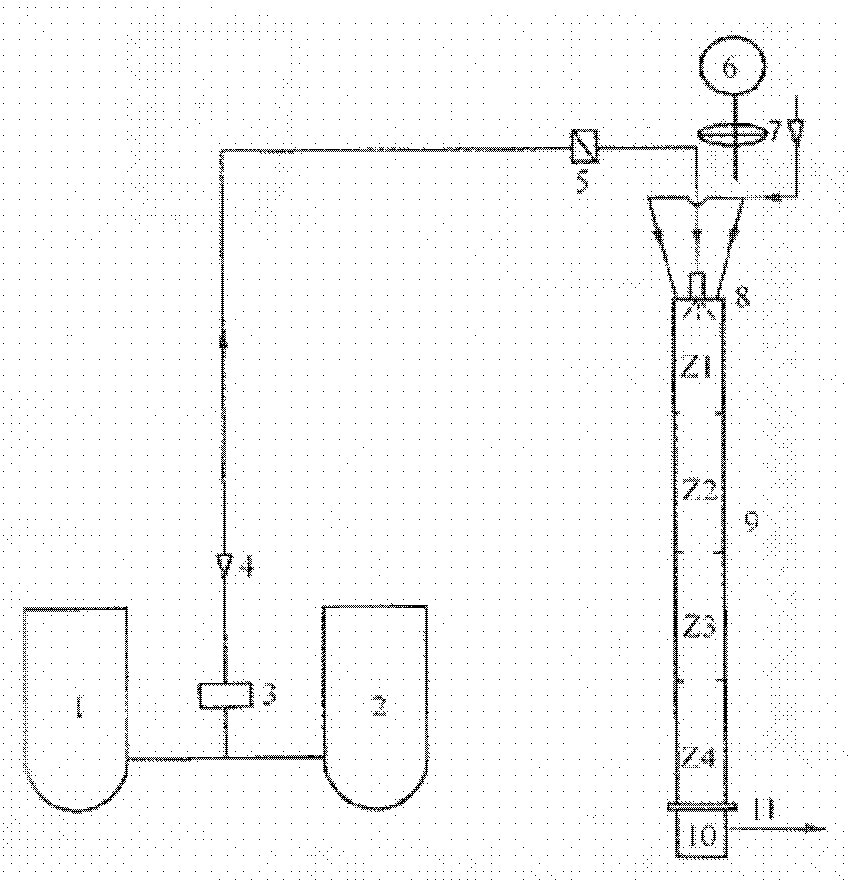

Sulfur tetrafluoride synthesis method and reaction system

ActiveCN113353893AImprove cooling effectAccelerated corrosionSulfur tetrafluorideGas liquid reactionSulfur tetrafluoride

The invention provides a sulfur tetrafluoride synthesis method and a reaction system, and relates to the technical field of chemical engineering. The sulfur tetrafluoride synthesis method comprises the following steps: fluorine gas and liquid sulfur are subjected to a gas-liquid reaction to generate sulfur tetrafluoride, the reaction pressure is 90-120KPa, and the distance between an outlet of the fluorine gas and the liquid level of the liquid sulfur during the reaction is 3-10mm. The method has the advantages that by controlling the reaction temperature, the reaction pressure and the gas-liquid distance, high-quality, stable and high-yield sulfur tetrafluoride can be realized, and the benefit maximization is realized.

Owner:鹤壁德瑞科技有限公司

Process for purifying and rectifying sulfur tetrafluoride

ActiveCN102107857BHigh risk of operationProne to production accidentsSulfur and halogen compoundsSulfur tetrafluoridePhysical chemistry

The invention relates to a process for purifying and rectifying sulfur tetrafluoride, which comprises the following steps of: reacting iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor to synthesize crude sulfur tetrafluoride gas, obtaining a liquid primary sulfur tetrafluoride product with purity of more than or equal to 95 percent through a cooler, a condensation separator and acondensation trap, obtaining a liquid sulfur tetrafluoride product with purity of more than or equal to 99.9 percent by a rectifying process, and continuously charging the product into a steel bottle. The liquid sulfur tetrafluoride product is directly trapped and produced and continuously liquefied and bottled, so damage of low-temperature bottling to the steel bottle is avoided, and the safety is higher. The purity of the sulfur tetrafluoride product is greatly improved by the cooling, separation, trapping and continuous rectification technology adopted in the process.

Owner:山东锐华氟业有限公司

Method for producing sulfur hexafluoride by adopting sulfur tetrafluoride oxidation method

InactiveCN102328914AIncrease productivitySulfur and halogen compoundsSulfur hexafluorideSulfite salt

The invention discloses a technology of producing sulfur hexafluoride by adopting a sulfur tetrafluoride oxidation method. The technology comprises the following steps of: firstly, reacting cupric fluoride, silver fluoride or mercuric fluoride or mixture of the cupric fluoride, the silver fluoride or the mercuric fluoride with molten sulfur to obtain sulfur tetrafluoride and converting metal fluoride into sulphide; secondly, oxidizing the sulfur tetrafluoride with oxygen or air at about 500DEG C to obtain the sulfur hexafluoride and a byproduct of sulfur dioxide; and finally, reacting the metal fluoride fluorine hydride in the presence of oxygen and converting the mixture into fluoride for recycling; and absorbing the byproduct of sulfur dioxide by using a sodium hydroxide solution and converting the mixed solution into sodium sulfite for recycling. The process is reasonable, simple in production and is a most simple and convenient ideal technology for preparing the sulfur hexafluoride.

Owner:TIANJIN TAIYUAN INDAL GAS

Method for producing 3,4-disubstituted pyrrolidine derivative and production intermediate thereof

InactiveUS20120283448A1Low production costEfficient productionAntibacterial agentsOrganic chemistrySulfur tetrafluorideEnantiomer

Provided is an inexpensive and industrially advantageous method for preparing (3R,4S)-3-(N-substituted aminomethyl)-4-fluoropyrrolidine or an enantiomer thereof which can be an intermediate for producing pharmaceuticals. It relates to a method for preparing (3R,4S)-3-(N-substituted cyclopropylaminomethyl)-4-fluoropyrrolidine derivative or ait's enantiomer, or their salts, comprising a step of fluorinating a 4-hydroxy-3-(N-substituted aminomethyl)pyrrolidine derivative represented by the general formula (1) or an enantiomer thereof using a sulfur tetrafluoride derivative.[In the formula (1), PG represents a protective group for the amino group, and R1 represents a C1 to C6 alkyl group which may be substituted, or a C3 to C8 cycloalkyl group which may be substituted.]

Owner:KYORIN PHARMA CO LTD

A kind of synthetic method of 2-chloro-5-trifluoromethylpyrazine

ActiveCN107840828BSimple processRaw materials are easy to getOrganic chemistryHydrogen fluoridePyrazine

The invention provides a method for synthesizing 2-chloro-5-(trifluoromethyl)pyrazine by using 5-chloro-pyrazine-2-carboxylic acid, anhydrous hydrogen fluoride and sulfur tetrafluoride. The method forsynthesizing 2-chloro-5-(trifluoromethyl)pyrazine has the advantages of simple technology, easily available raw materials, and high yield.

Owner:KINGCHEM LIAONING CHEMICAL CO LTD

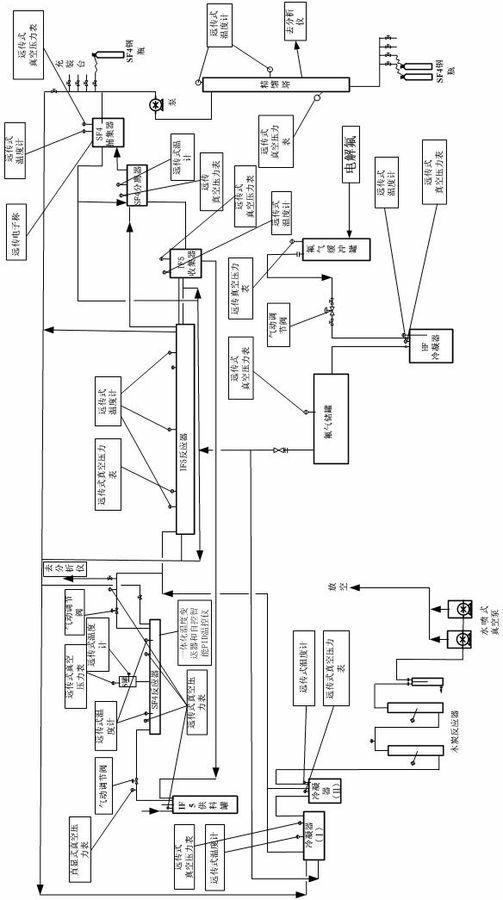

Sulfur tetrafluoride production technique

ActiveCN102173393BIncrease concentrationImprove conversion rateSulfur and halogen compoundsHydrogen fluorideElectrolysis

The invention relates to a sulfur tetrafluoride production technique, belonging to the field of fluorochemicals. The sulfur tetrafluoride production technique comprises fluorine gas purification, iodine pentafluoride preparation, sulfur tetrafluoride reactive synthesis, sulfur tetrafluoride separation and trapping, sulfur tetrafluoride distillation and canning, secondary recycling of iodine pentafluoride as well as discharge of exhaust gas. By using a low-temeprature condensing device, the electrolytic fluorine is purified to remove a great amount of hydrogen fluoride, so the fluorine gas concentration is largely improved. A condensing and recycling device is employed to recycle iodine and iodine pentafluoride for re-use, thus the utilization ratio of iodine can reach above 70% and material losses can be reduced. Due to a constant distillation method, the purity of sulfur tetrafluoride products can reach above 99.9%, and the products can be charged into a steel cylinder more safely. In addition, the entire sulfur tetrafluoride production technique is controlled by a automatic DCS (distributed control system) device, which reduces artificial randomness and experience and improves the stability of product quality.

Owner:山东锐华氟业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com