Sulfur tetrafluoride synthesis method and reaction system

A technology of sulfur tetrafluoride and a synthesis method, applied in the chemical industry, can solve the problems such as hindering the development and growth of the sulfur tetrafluoride industrial chain, the reaction efficiency needs to be improved, and the large-scale industrial production cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

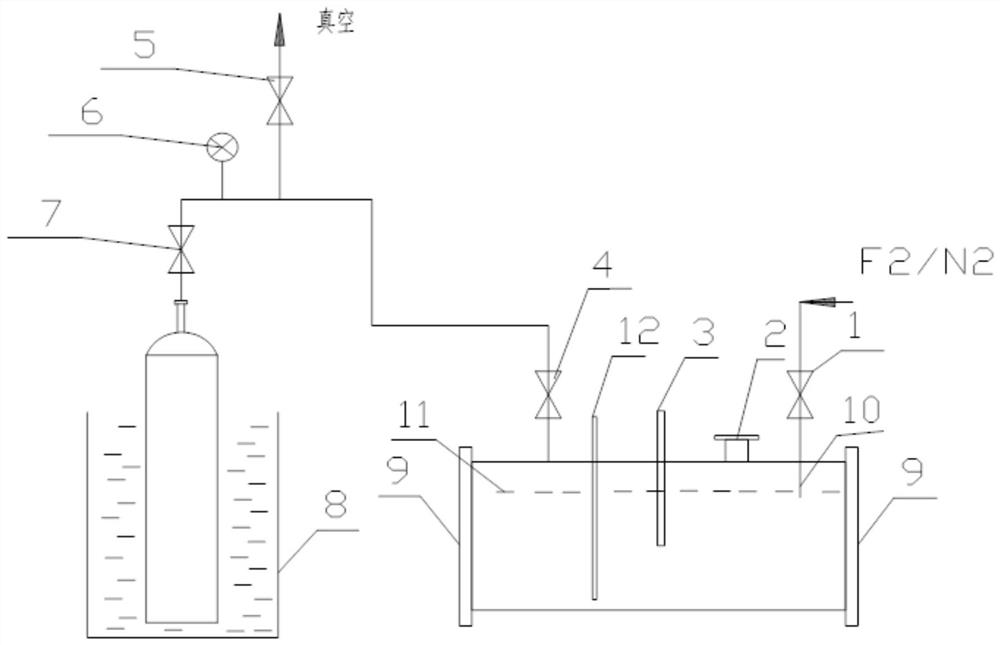

[0035] On the one hand, the embodiment of the present application provides a synthesis method of sulfur tetrafluoride, which includes the following steps: fluorine gas and liquid sulfur undergo a gas-liquid reaction to generate sulfur tetrafluoride, the reaction pressure is 90-120KPa, and the fluorine The distance between the gas outlet and the liquid sulfur surface is 3-10mm.

[0036] In some embodiments of the present invention, in the above-mentioned synthesis method of sulfur tetrafluoride, the distance between the outlet of the fluorine gas and the liquid sulfur surface during the reaction is 3-5 mm, and the working pressure range is 99-105 KPa.

[0037] In some embodiments of the present invention, in the above-mentioned method for producing sulfur tetrafluoride, the reaction temperature is 270-320°C.

[0038] In some embodiments of the present invention, in the above-mentioned synthesis method of sulfur tetrafluoride, the reaction temperature is 280-300°C.

[0039] In ...

Embodiment 1

[0047] The purpose of this embodiment is to provide a kind of synthetic method of sulfur tetrafluoride, comprises the steps:

[0048] The fluorine gas outlet is 5mm away from the sulfur liquid surface, the liquid sulfur temperature is 290°C, the fluorine gas flux is 150 g / h, the fluorine gas is diluted with hydrogen fluoride to a volume concentration of 30%, the reactor pressure is 99KPa, at -85°C (alcohol + liquid nitrogen) Trapped in a 10-liter nickel-plated aluminum alloy gas cylinder in the cold trap 8, reacted for 6 hours, and received 2384 grams of liquefied crude product. The crude gas cylinder was heated at 40°C and 1280 grams of purified product was obtained after the spherical sodium fluoride fully adsorbed hydrogen fluoride, and the SF was detected by gas chromatography. 4 Content 86%, SF 6 8%, s 2 f 2 4%, SOF 2 0.6%, the rest is air and trace CF 4 .

Embodiment 2

[0050] The purpose of this embodiment is to provide a kind of synthetic method of sulfur tetrafluoride, comprises the steps:

[0051] The outlet of fluorine gas is 5mm away from the liquid surface of sulfur, the temperature of liquid sulfur is 300°C, the flow rate of fluorine gas is 140 g / h, diluted with hydrogen fluoride to a volume concentration of 30%, the pressure of the reactor is 110KPa, and it is placed in a cold trap 8 at -80°C (alcohol + liquid nitrogen) Trapped in a 10-liter nickel-plated aluminum alloy cylinder, reacted for 6 hours, and received 2225 grams of liquefied crude product. The crude gas cylinder was heated at 40°C and hydrogen fluoride was fully absorbed by spherical sodium fluoride, and then 1187 grams of purified product was obtained in the cold trap 8, and the SF was detected by gas chromatography. 4 Content 83%, SF 6 6%, S 2 f 2 10%, SOF 2 0.7%, the rest is air and trace CF 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com