Process for purifying and rectifying sulfur tetrafluoride

A sulfur tetrafluoride and rectification technology, which is applied in the direction of sulfur and halogen compounds, can solve the problems of low-temperature bottling technology, such as danger, high risk, and large damage to steel cylinders, and achieve high safety, increase yield, and reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

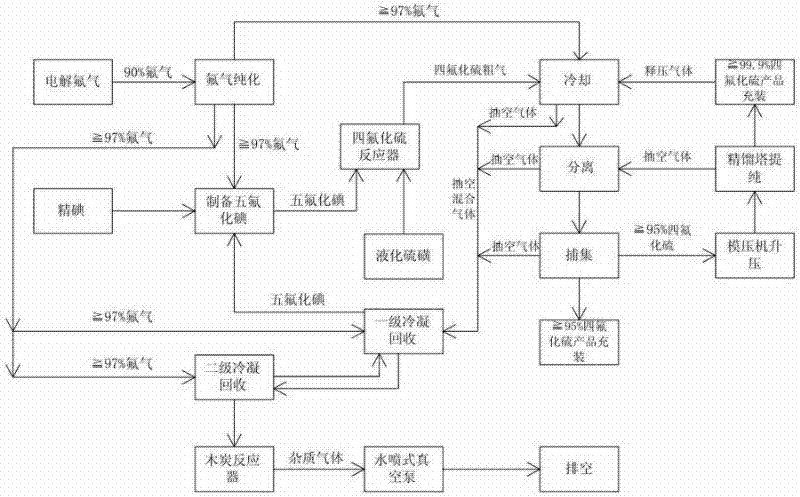

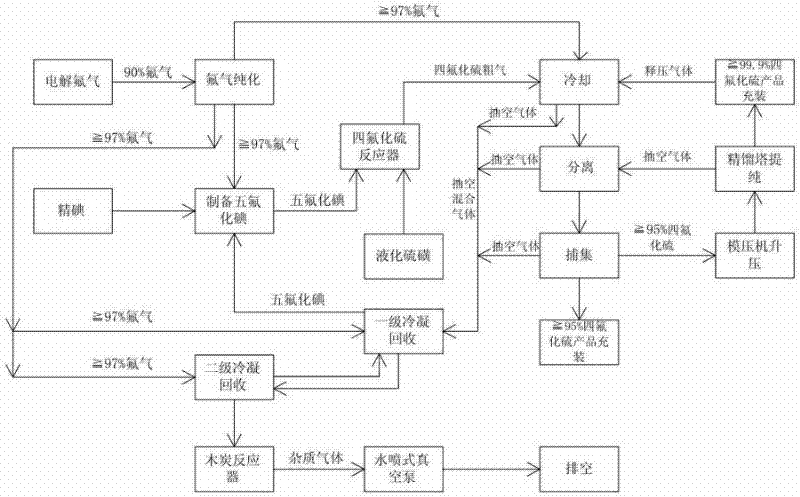

[0024] Purification and rectification process of sulfur tetrafluoride (1)

[0025] A, the crude sulfur tetrafluoride gas synthesized by the reaction passes through a cooler and a condensation separator so that part of the iodine contained in the crude gas is solidified and retained, and iodine pentafluoride is liquefied and retained; the sulfur tetrafluoride mixed gas is separated; the cooling The cooling temperature of the device is 10°C, and the condensation temperature of the condensation separator is -35°C;

[0026] B. The separated sulfur tetrafluoride mixed gas also contains part of fluorine gas, nitrogen gas, hydrogen fluoride gas and trace amounts of impurity gases such as iodine and iodine pentafluoride. Condensate into a liquid state, and then separate the impurity gas through gas phase purification to obtain a liquid primary sulfur tetrafluoride product with a purity of 95%; the condensation temperature of the condensation trap is -100°C;

[0027] C. The primary su...

Embodiment 2

[0029] Purification and rectification process of sulfur tetrafluoride (2)

[0030] A, the crude sulfur tetrafluoride gas synthesized by the reaction passes through a cooler and a condensation separator so that part of the iodine contained in the crude gas is solidified and retained, and iodine pentafluoride is liquefied and retained; the sulfur tetrafluoride mixed gas is separated; the cooling The cooling temperature of the device is 30°C, and the condensation temperature of the condensation separator is 30°C;

[0031] B. The separated sulfur tetrafluoride mixed gas also contains part of fluorine gas, nitrogen gas, hydrogen fluoride gas and trace amounts of impurity gases such as iodine and iodine pentafluoride. Condensate into a liquid state, and then separate the impurity gas through gas phase purification to obtain a liquid primary sulfur tetrafluoride product with a purity of 98%; the condensation temperature of the condensation trap is -40°C;

[0032] C. The primary sulf...

Embodiment 3

[0034] Purification and rectification process of sulfur tetrafluoride (3)

[0035] A, the crude sulfur tetrafluoride gas synthesized by the reaction passes through a cooler and a condensation separator so that part of the iodine contained in the crude gas is solidified and retained, and iodine pentafluoride is liquefied and retained; the sulfur tetrafluoride mixed gas is separated; the cooling The cooling temperature of the device is 20°C, and the condensation temperature of the condensing separator is -3°C;

[0036] B. The separated sulfur tetrafluoride mixed gas also contains part of fluorine gas, nitrogen gas, hydrogen fluoride gas and trace amounts of impurity gases such as iodine and iodine pentafluoride. Condensate into a liquid state, and then separate the impurity gas through gas phase purification to obtain a liquid primary sulfur tetrafluoride product with a purity of 97%; the condensation temperature of the condensation trap is -70°C;

[0037] C. The primary sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com