Rubber cooling fan

A fan and cooling glue technology, applied in the field of cooling glue fans, can solve the problems of inability to clean up, difficult to fully clean up, falling, etc., and achieve the effects of improving work efficiency, avoiding slipping and falling injuries, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, the glue cooling blower of the present invention will be described based on the drawings.

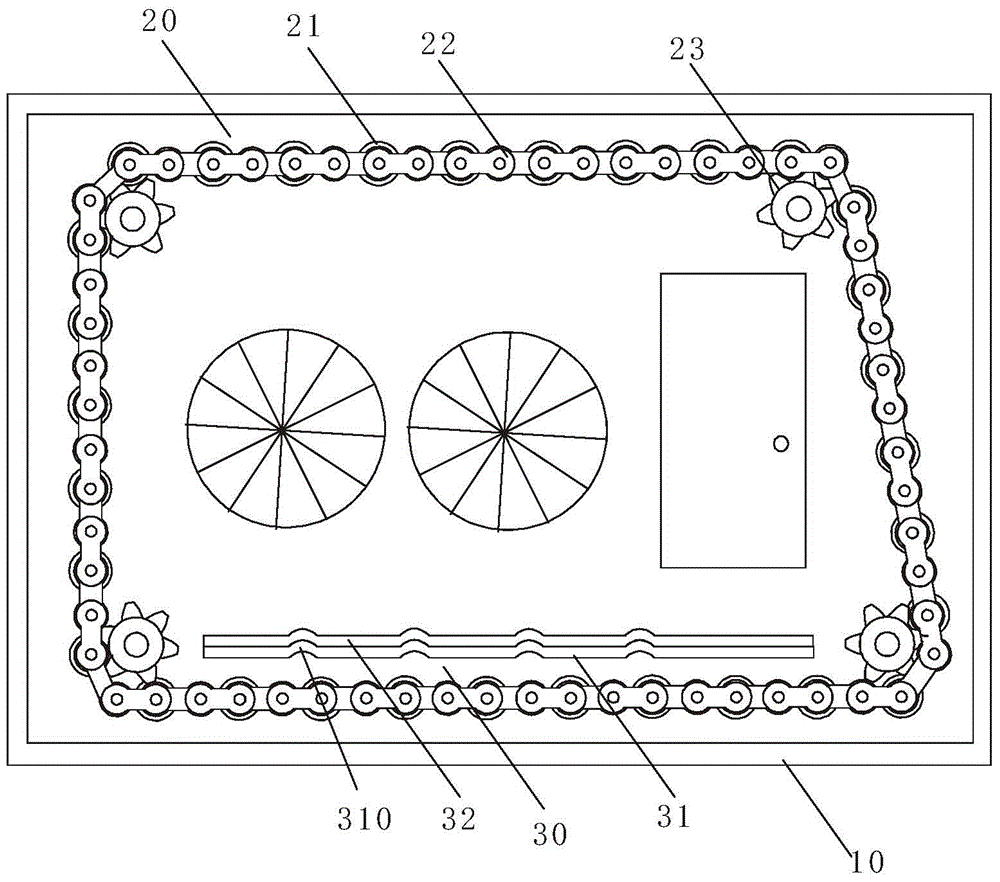

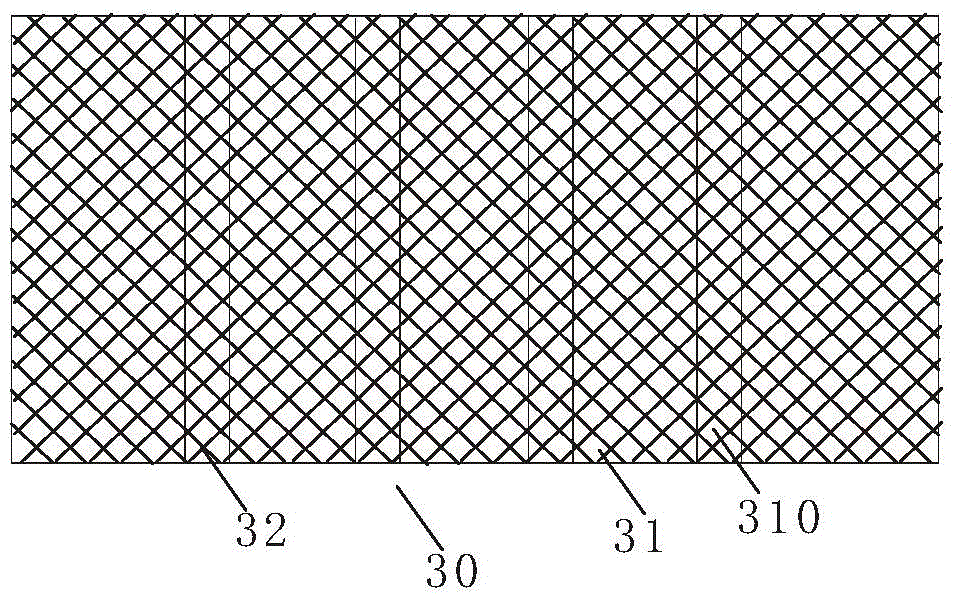

[0016] figure 1 It is a side view sectional schematic diagram showing the glue cooling blower of the present invention. figure 2 It is a schematic plan view of the dust collecting component of the glue cooling blower of the present invention.

[0017] Such as figure 1 , figure 2 As shown, the glue cooling blower of the present invention has a body 10 , a hanging mechanism 20 and a dust collecting member 30 .

[0018] The machine body 10 is formed in a rectangular parallelepiped shape, and a plurality of blowers 11 are formed on the side wall of the machine body 10 .

[0019] The hanging mechanism 20 is formed in the inside of the body 10 and includes a plurality of hanging rods 21 extending in the width direction of the body 10. On the two chains 22 that form a ring shape, the chains 22 are mounted on four sprockets 23 that are rotatably installed on the body 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com