Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Slippery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl for manufacturing toy and preparation method of vinyl

The invention relates to vinyl for manufacturing a toy. The vinyl for manufacturing a toy is prepared from the following raw materials in percentage by weight: phthalate, dioctyl phthalate, dibasic lead stearate, PVC (polyvinyl chloride) paste resin, PVC coarse powder, PVC medium powder, talcum powder, PVC hard oil, plasticizer TXIB, acetyl-tri-n-butyl citrate, vanillin, amyl acetate, geranyl butyrate and maltol. The vinyl has good hardness, smooth handfeel, strong plasticity, high re-shaping ability and high stability, and does not deform easily after multiple extrusions; and meanwhile, the vinyl is non-toxic and harmless and has fresh fruit aroma.

Owner:浙江银太郎动漫文化股份有限公司

Preparation method of hydrophilic amino silicone oil

The invention discloses a preparation method of hydrophilic amino silicone oil. The invention is characterized in that the preparation method comprises the following steps: A. the preparation of low-hydrogen silicone oil: siloxane ring body, high-hydrogen silicone oil, blocking agent and acid are mixed for reaction and are cooled, and the pH is adjusted; B. the preparation of epoxy silicone oil: the prepared low-hydrogen silicone oil, alkenyl epoxy compound and catalyst are mixed for reaction and are cooled; and C. the preparation of hydrophilic amino silicone oil: the prepared epoxy silicone oil, organic amine and solvent are mixed for reaction, and the solvent is distilled. The bonding is firmer in the form of a chemical bond when the hydrophilic amino silicone oil prepared by the method reacts with the fabric, and the hydrophilic amino silicone oil is washable, has soft effect of the common amino silicone oil, no yellowing and good smoothness and antistatic property, and can be widely used in fabric finishing.

Owner:HUBEI COLOR ROOT TECH CO LTD

Finishing agent of polyester silk-like fabric and preparation and post-treatment methods of fabric

The invention provides a finishing agent for preparing comfortable and cool polyester silk-like fabric and a post-treatment method of the comfortable and cool polyester silk-like fabric, aiming at overcoming the defects of the finishing agent of the polyester silk-like fabric, such as high processing cost and poor durability in the prior art. The finishing agent provided by the invention is composed of the following components in parts by weight: 5-7 parts of silk peptide, 3-5 parts of polyethylene glycol, 3-5 parts of a cross-linking agent, 1.5-2.5 parts of a cross-linking catalyst, 1-2 parts of acetic acid, 1-2 parts of a softening agent, 0.5-1 part of chitosan and the balance of water. The post-treatment method of the polyester silk-like fabric comprises the following steps: desizing, alkali weight reduction treatment of the base fabric, and pad finishing. By utilizing the finishing agent and the post-treatment method in the invention, the defect, such as hard feel, of the polyester fabric is overcome so that the polyester fabric has the advantages of excellent wrinkle resistance and soft feel, and is air-permeable, cool and comfortable to wear.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

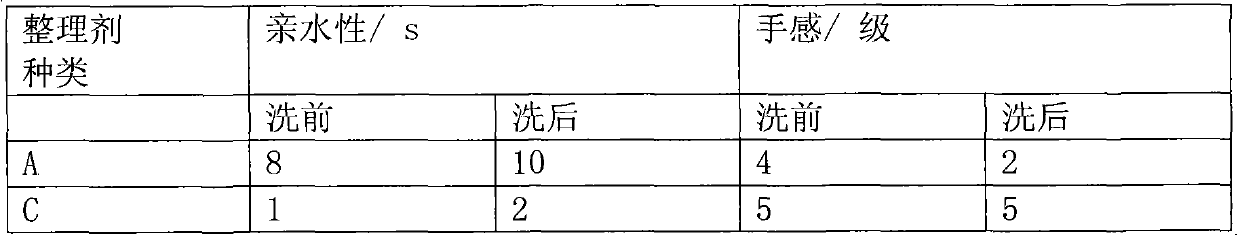

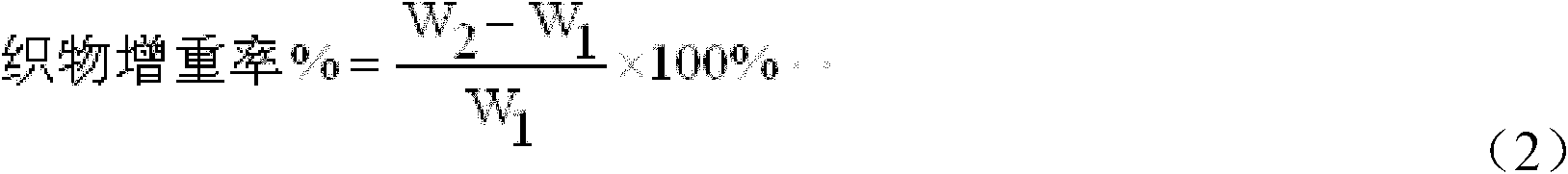

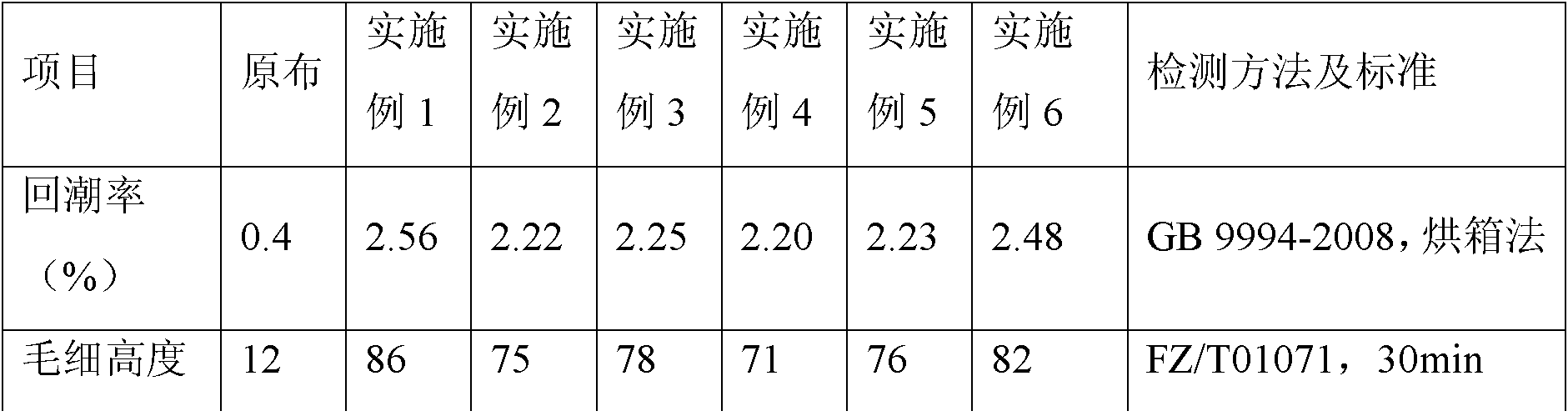

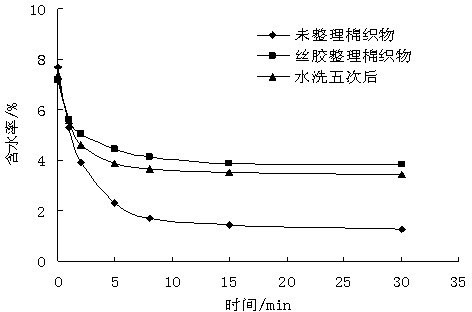

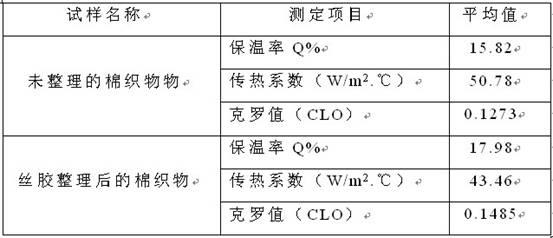

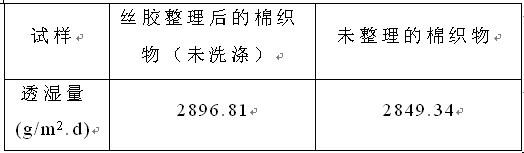

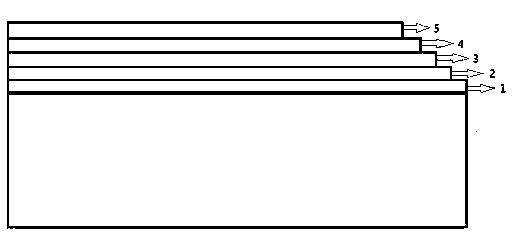

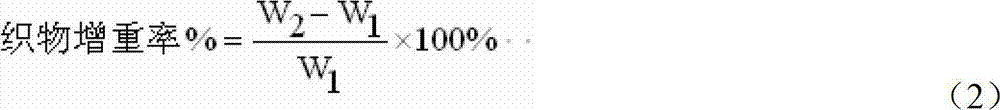

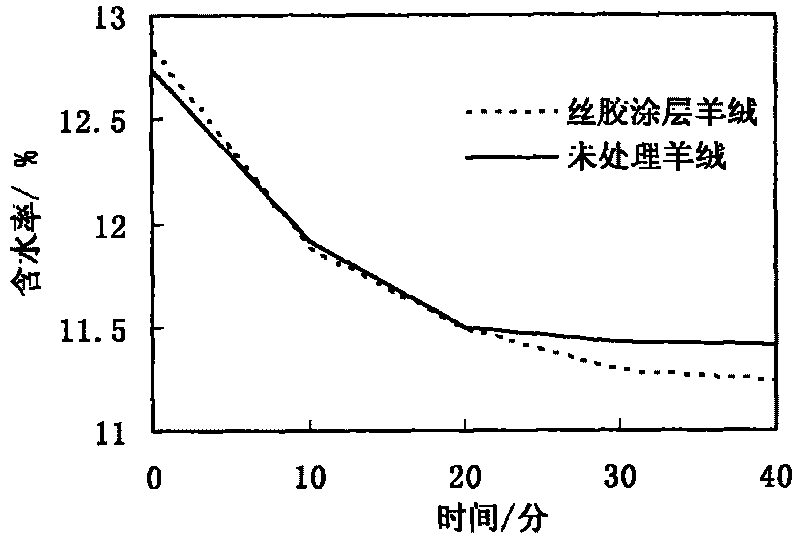

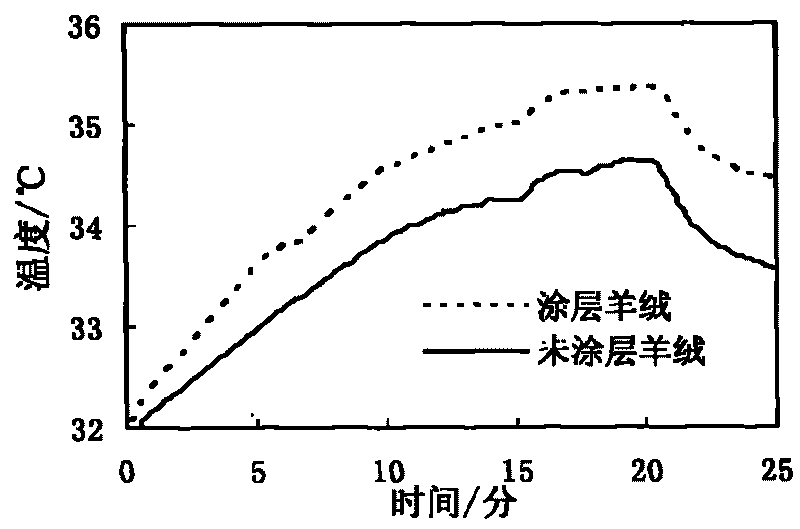

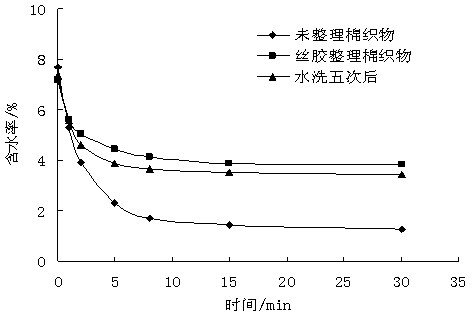

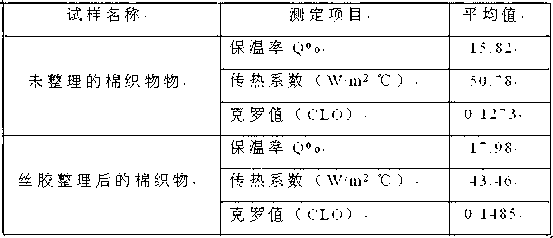

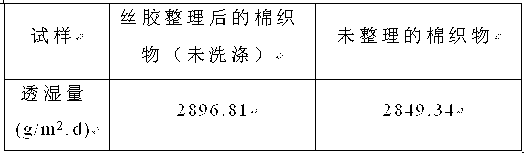

Sericin post-finishing method for cotton fabrics

The invention discloses a sericin post-finishing method for cotton fabrics, which comprises the following steps: (a) configuring settling impregnation liquid: dissolving 3-5% of dissolvable sericin powder counted by mass in hot water, and then adding 1-3% of chitosan quaternary ammonium salt, fully stirring and dissolving, and adding 4-6% of cross-linking agent, and (b) completely steeping the cotton fabrics in the settling impregnation liquid at a solution bath ratio of 1:(30-50), steeping for at least 20 minutes, twice steeping and twice rolling, keeping mangle expression more than 80%, anddrying, thereby obtaining the cotton fabrics. The invention develops the post-finishing method special for the cotton fabrics. The cotton fabrics prepared according to the post-finishing method have better washing fastness and anti-bacteria rate; after the cotton fabrics are washed for five times, a dissolving loss rate is about 0.21% and the anti-bacteria rate is 93.8%; the practical use requirement is fully met; and an extraordinary technical effect is obtained.

Owner:NANTONG LOVER APPL

Paint spraying method for furniture production

ActiveCN103319929AIncrease profitHigh hardnessPretreated surfacesPolyurea/polyurethane coatingsWater basedSand-paper

The invention discloses a paint spraying method for furniture production. According to the method, paint spraying construction is performed by using UV (ultraviolet)-brushing filling putty, UV-spraying sanding priming paint and spraying soft sheen finish paint. The method comprises the following specific steps: sanding an unpainted board with sand paper; manually performing color scraping on the surface of a base material with a UV-water-based color-scraping agent, and drying with infrared, wherein the consumption of the color-scraping agent is 8-12 g / m<2>; manually brushing the UV-brushing filling putty, curing with UV of 180mj / cm<2>, and sanding with the sand paper, wherein the consumption of the UV-brushing filling putty is 30-40 g / m<2>; manually spraying the UV-spraying sanding priming paint, curing with UV of 180mj / cm<2>, and sanding with the sand paper, wherein the consumption of the UV-spraying sanding priming paint is 40-50 g / m<2>; manually spraying the UV-spraying soft sheen finish paint, wherein the consumption of the UV-spraying soft sheen finish paint is 40-50 g / m<2>; and curing with UV of 260mj / cm<2>.According to the invention, the formula of the paint is improved, so that the paint has favorable fullness and adhesive force and has the special effects of moistening, soft sheen and brightening; and the glossiness of a paint film is up to 65 degrees or above.

Owner:JIANGSU HIMONIA TECH

Post-treatment method for comfortable and cool terylene silk-like fabric

The invention discloses a post-treatment method for a comfortable and cool terylene silk-like fabric. The method includes steps of desizing, alkali decrement treatment on a base fabric and padding finishing. In the step of alkali decrement treatment on the base fabric, a treatment solution includes components of, by weight, 2-3% of caustic soda, 0.15-0.25% of penetrating agent, 0.15-0.25% of scouring agent, and the balance of water; a bath ratio is 1:15-20; a treatment temperature is 120+ / -5 DEG C; a treatment time is 40+ / -3min; and a reduction rate is 10-12%. Adoption of the method in the invention to prepare terylene fabric overcomes the hard handle of terylene fabric, improves wearing conformability of polyester fabric; and the product has the advantages of convenient processing and high resource utilization rate.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

After finishing method for sericin of cashmere product

Owner:苏州盛泽科技创业园发展有限公司

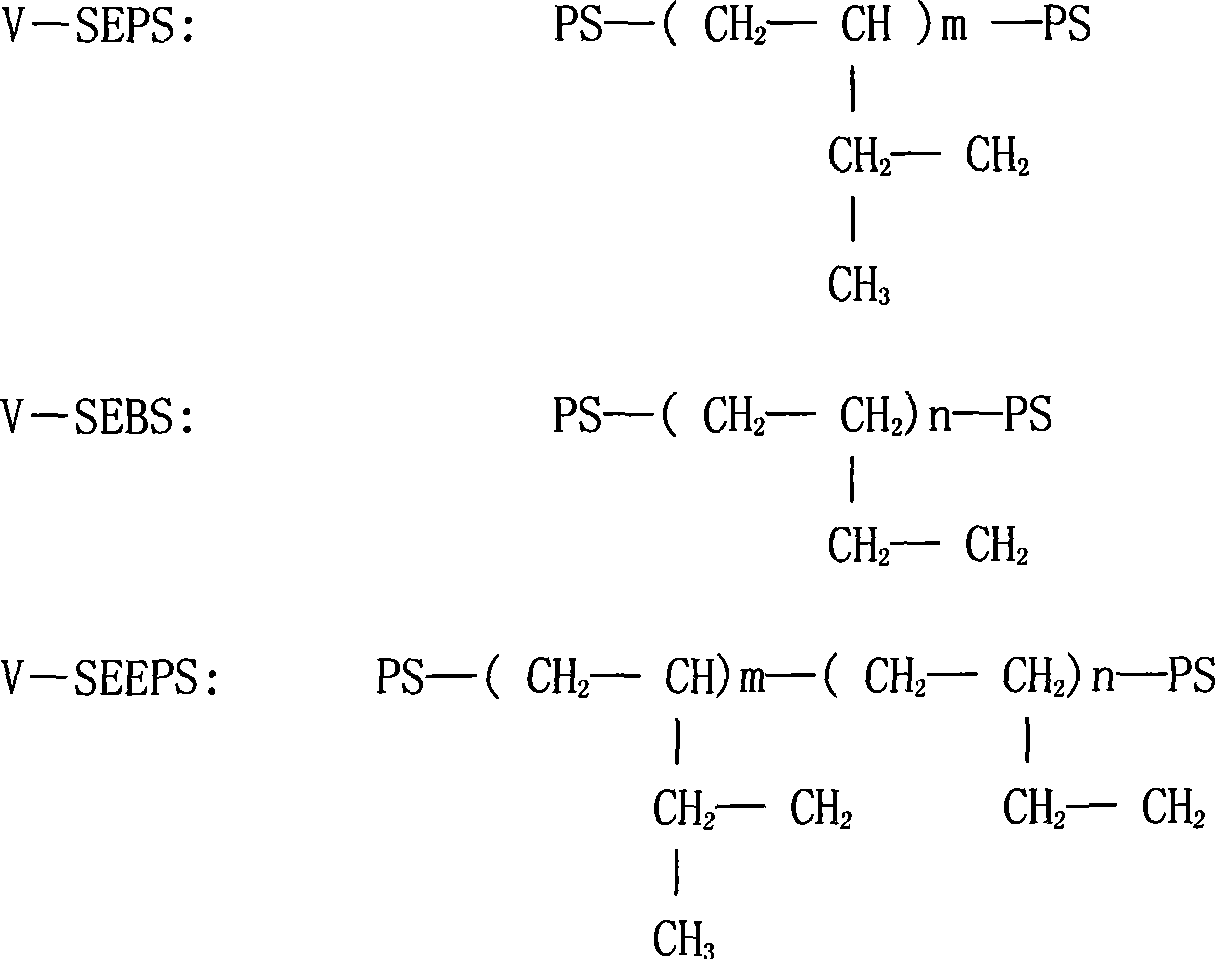

Thermoplastic elastomer, preparation method and use thereof

The invention relates to a thermoplastic elastomer, which comprises the following compositions by gross weight percentage: A. 5 to 85 percent of polypropylene; B. 5 to 90 percent of vinylated styrene hydrogen / conjugated diolefine segmented copolymer; and C. 5 to 90 percent of polyolefin thermoplastic elastomer. The preparation method is to physically mix mixture of various compositions for manufacturing transparent coating materials and so on. The thermoplastic elastomer has the advantages that the thermoplastic elastomer has good transparency, does not contain plasticizer such as processing oil and so on, so that emigration of the thermoplastic elastomer during the use process is avoided, thereby guaranteeing the absolute safety of the thermoplastic elastomer when applied to products such as foodpack, medical appliances and so on; the product is soft; the shore A rigidity is between 0 and 95; the flow rate of fused masses is between 0.1 and 100 grams per 10 minutes; and the thermoplastic elastomer has good weathering resistance, chemical resistance and solvent resistance.

Owner:KURARAY SHANGHAI

UV (ultraviolet)-spraying soft sheen finish paint

InactiveCN103319986AHigh hardnessHigh fullnessPolyurea/polyurethane coatingsEpoxy resin coatingsAcrylic resinUltraviolet

The invention discloses UV (ultraviolet)-spraying soft sheen finish paint which comprises 20-40% of 100% UV cured resin, 0.1-1% of defoaming agent, 0.1-0.5% of leveling agent, 0.5-1.5% of dispersing agent, 0.2-1% of anti-settling agent, 4-8% of photoinitiator, 3-10% of filler, 3-8% of flatting agent and the balance of monomer, wherein the 100% UV-resin is epoxy acrylic resin or modified epoxy acrylic resin, polyurethane acrylic resin, unsaturated polyester acrylic resin or a mixture thereof; the monomer is acrylate, modified acrylate or a mixture thereof; and the filler is inorganic powder. According to the invention, the formula of the paint is improved, so that the paint has favorable fullness and adhesive force and has the special effects of moistening, soft sheen and brightening; and the glossiness of a paint film is up to 65 degrees or above.

Owner:JIANGSU HIMONIA TECH

Furniture wood board surface metallic paint spraying method

InactiveCN108480166AImprove adhesionPrevent disengagementPretreated surfacesCoatingsTouch sensationAcrylic paint

The invention provides a furniture wood board surface metallic paint spraying method. The furniture wood board surface metallic paint spraying method comprises the following steps that mixed priming paint is prepared, specifically, 0.1-0.5% of shish-kebab-structure polymer is added into acrylic paint, and uniform mixing is conducted; mixed finish paint is prepared, specifically, 10-20% of metal powder is added into the acrylic paint, and uniform mixing is conducted; primary polishing is conducted, specifically, the surface of a wood board is polished through a polishing machine, and thus, thesurface of the wood board is smooth; the priming paint is sprayed, specifically, the mixed priming paint is sprayed onto the surface of the wood board through a spraying technology, leveling is conducted, and after baking, a priming paint layer which is 25-40 [mu]m thick is formed; secondary polishing is conducted, specifically, the surface of the priming paint layer is polished through fine sandpaper so as to be smooth; and the finish paint is sprayed, specifically, the mixed finish paint adheres to the priming paint layer through the spraying technology, leveling is conducted, and after baking, a finish paint layer which is 100-120 [mu]m thick is formed. After metallic finish paint is sprayed onto the surface of furniture, the surface of furniture has metallic luster, the paint surface is high in stereoscopic impression and smooth when being touched with a hand, and the good visual effect and touch sensation are achieved.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

Non-yellowing anti-graffiti resin for synthetic leather as well as preparation method of the resin

ActiveCN102168378AComply with environmental standardsHigh glossFibre treatmentShoe polishUltraviolet

The invention relates to non-yellowing anti-graffiti resin for synthetic leather as well as a preparation method of the resin. The non-yellowing anti-graffiti resin for synthetic leather consists of the following components: polyether polyurethane resin, DMF (Dimethyl Formamide), acetone, dimethyl siloxane, organic silicone oil, anti-graffiti additive, uvioresistant absorber and organosilicon leveling agent. After the application of the non-yellowing anti-graffiti resin for synthetic leather, the synthetic leather obtains the advantages as follows: bright gloss, smooth handfeel, good anti-yellowing property, excellent wear-twist resistance, and good pollution prevention property; and stains caused by shoe polish, lipstick paste, marking pen liquid, ball pen liquid, coffee and the like accidentally falling on the leather surface can be easily wiped off by a piece of cloth.

Owner:浙江宝泽高分子材料有限公司

Comfortable high-emulation wool fabric, production technology thereof and textile thereof

ActiveCN103255540AReduces lint and lintFeel goodDyeing processWoven fabricsProcess engineeringHeat setting

The invention relates to comfortable high-emulation wool fabric, a production technology of the comfortable high-emulation wool fabric and a textile of the comfortable high-emulation wool fabric. The production technology of the comfortable high-emulation wool fabric comprises the following steps of warp and weft weaving, gray fabric inspection, singeing, relaxation, refinement, heat setting, water washing, drying, setting, relaxation, kier decatizing, inspection, and coiling. According to the comfortable high-emulation wool fabric, warp-wise and weft-wise blending is applied, the tightness of warp is controlled to be 55%-58%, the tightness of weft is controlled to be 40%-44%, and therefore the frequency of the phenomena of fluffing and wool dropping is reduced. The kier decatizing can make up and correct the defects which are generated in the process of weaving and dyeing and finishing of the textile, can improve handle and appearance of the textile, and enables the textile to be smooth in cloth face, clear in pattern, soft in gloss, and smooth in handle. In addition, the elasticity of the textile is improved, and the wool-type feeling of the textile is improved. The comfortable high-emulation wool fabric can be applicable to clothes, home textile goods, sports goods and medical care.

Owner:ZHEJIANG SIYUAN NEW MATERIAL TECH CO LTD

Non-primer coating method for self-adhesive polyvinylidene chloride emulsion and coating system for implementing non-primer coating method

The invention provides a non-primer coating method for a self-adhesive polyvinylidene chloride (PVDC) emulsion and a coating system for implementing the method. Kiss type coating is adopted for top coating, and an appropriate quantity of wax emulsion and silicon dioxide anti-sticking agent are added into the top coating self-adhesive PVDC emulsion in a top coating process, so that an obtained coating film has the characteristics of high resistance and high heat-sealing property and can compound with a carton through an UV (Ultraviolet) adhesive; the surface of the coating film is smooth, so that the film can easily move on equipment without greater tension; and the film is not subjected to remarkable contraction deformation after being heated through a baking oven, so the product performance is not influenced.

Owner:HAINAN SHINER IND

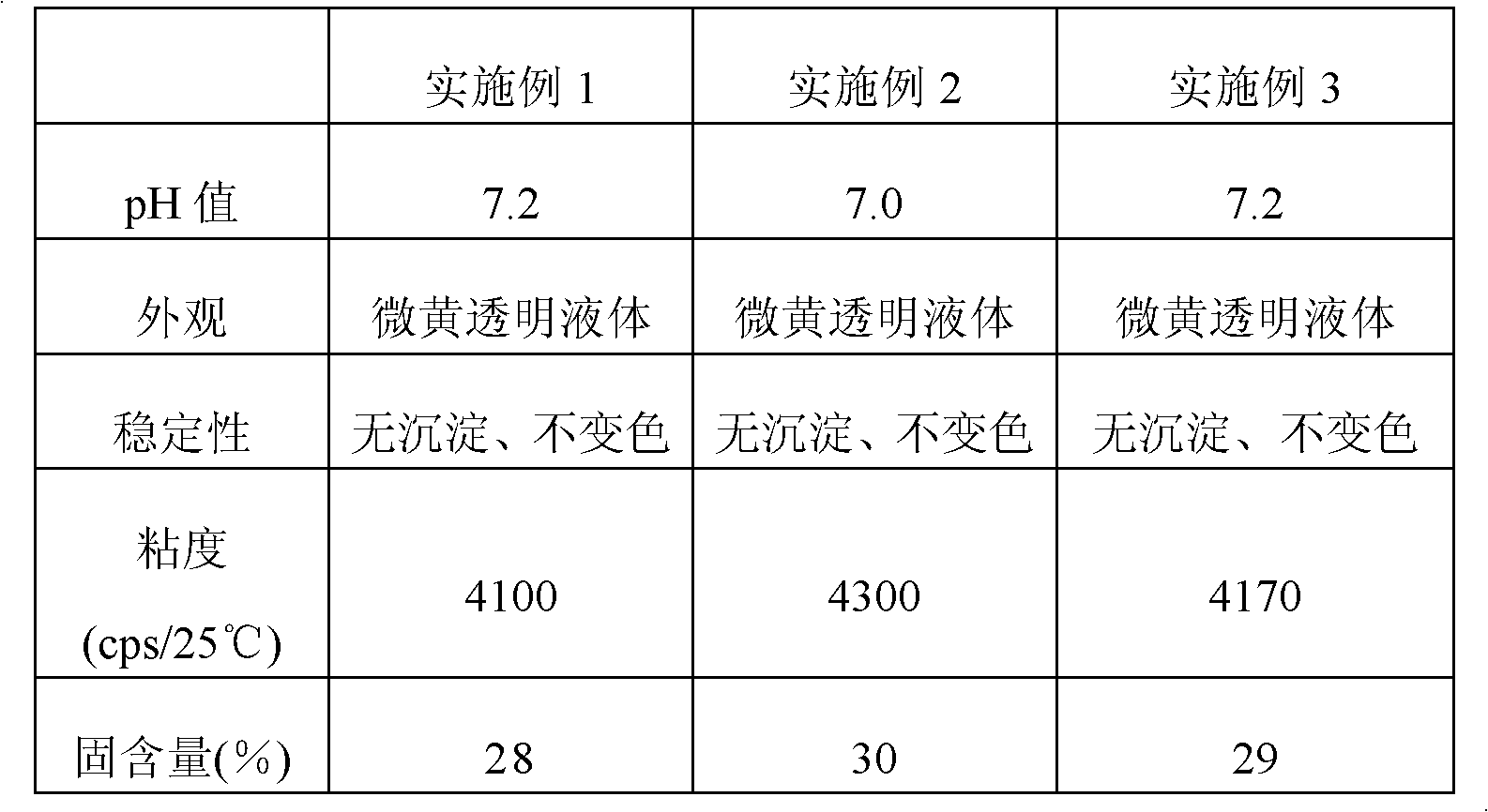

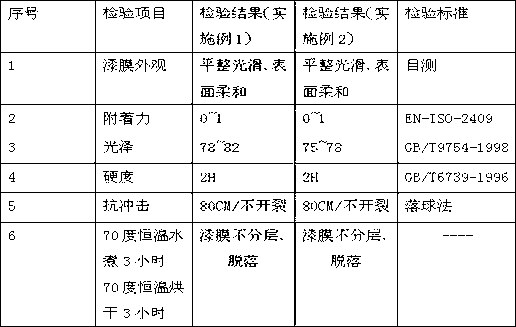

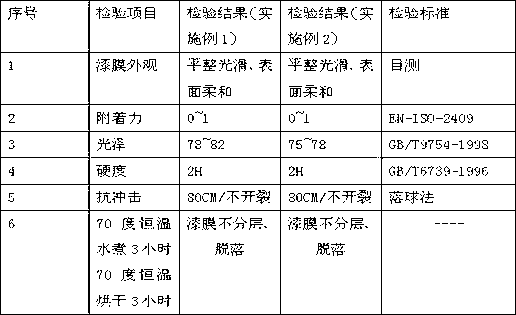

Water boiling-resistant UV (ultraviolet) high-adhesion primer on impregnated laminate flooring

InactiveCN103305098AImprove surface propertiesImprove performancePolyurea/polyurethane coatingsEpoxy resin coatingsUV curingAcrylic resin

The invention discloses a water boiling-resistant UV (ultraviolet) high-adhesion primer on impregnated laminate flooring. The primer comprises the following components in percentage by weight: 30-50% of 100% UV curing resin, 0.1-0.3% of antifoaming agent, 0.1-5% of adhesion promoter, 0.5-1.5% of dispersing agent, 0.5-1% of thixotropic agent, 4-8% of photoinitiator, 10-30% of filler and the balance of monomer, wherein the 100% UV resin is epoxy acrylic resin or modified epoxy acrylic resin, modified polyurethane acrylic resin with an acid group, unsaturated polyester acrylic resin or a mixture thereof; the monomer is acrylic ester, modified acrylic ester or a mixture thereof; and the filler is inorganic powder. The water boiling-resistant UV high-adhesion primer disclosed by the invention has high adhesion and is not delaminated after 3 hours of water boiling at a constant temperature of 70 DEG C and 3 hours of drying at a constant temperature of 70 DEG C.

Owner:JIANGSU HIMONIA TECH

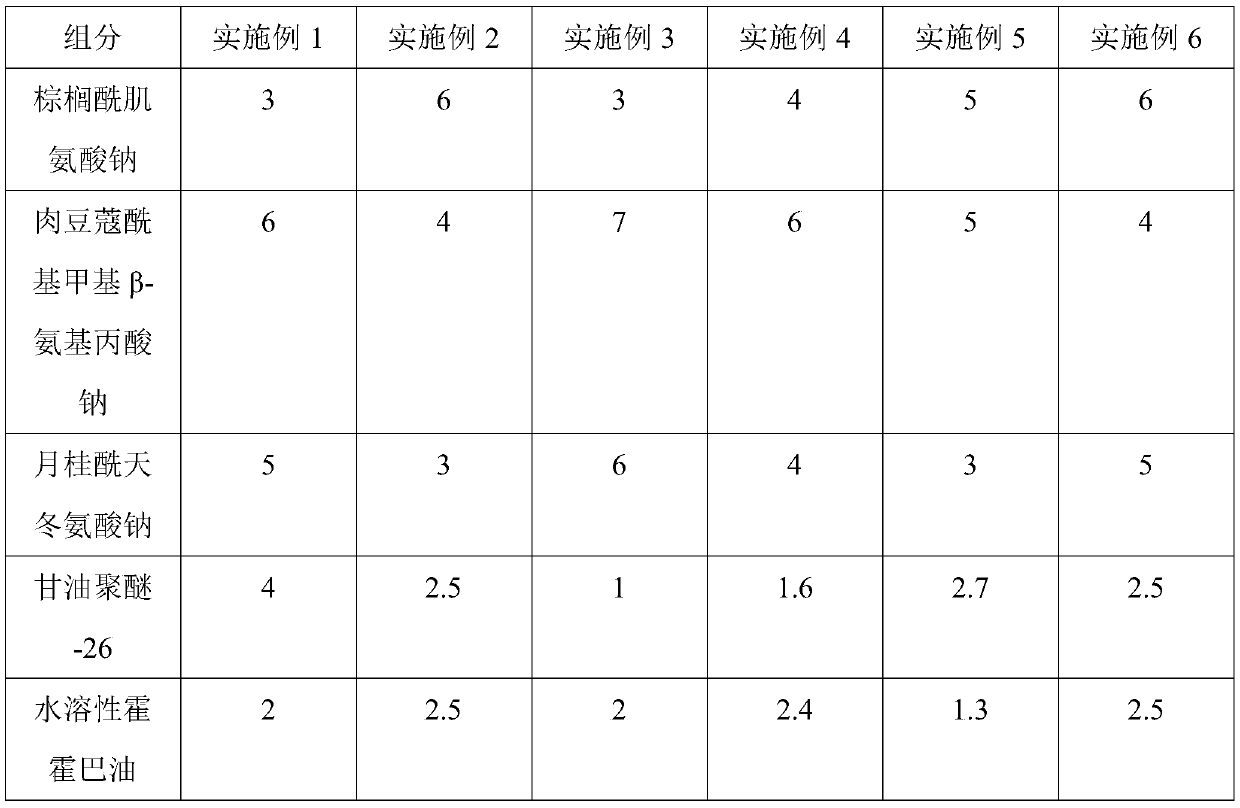

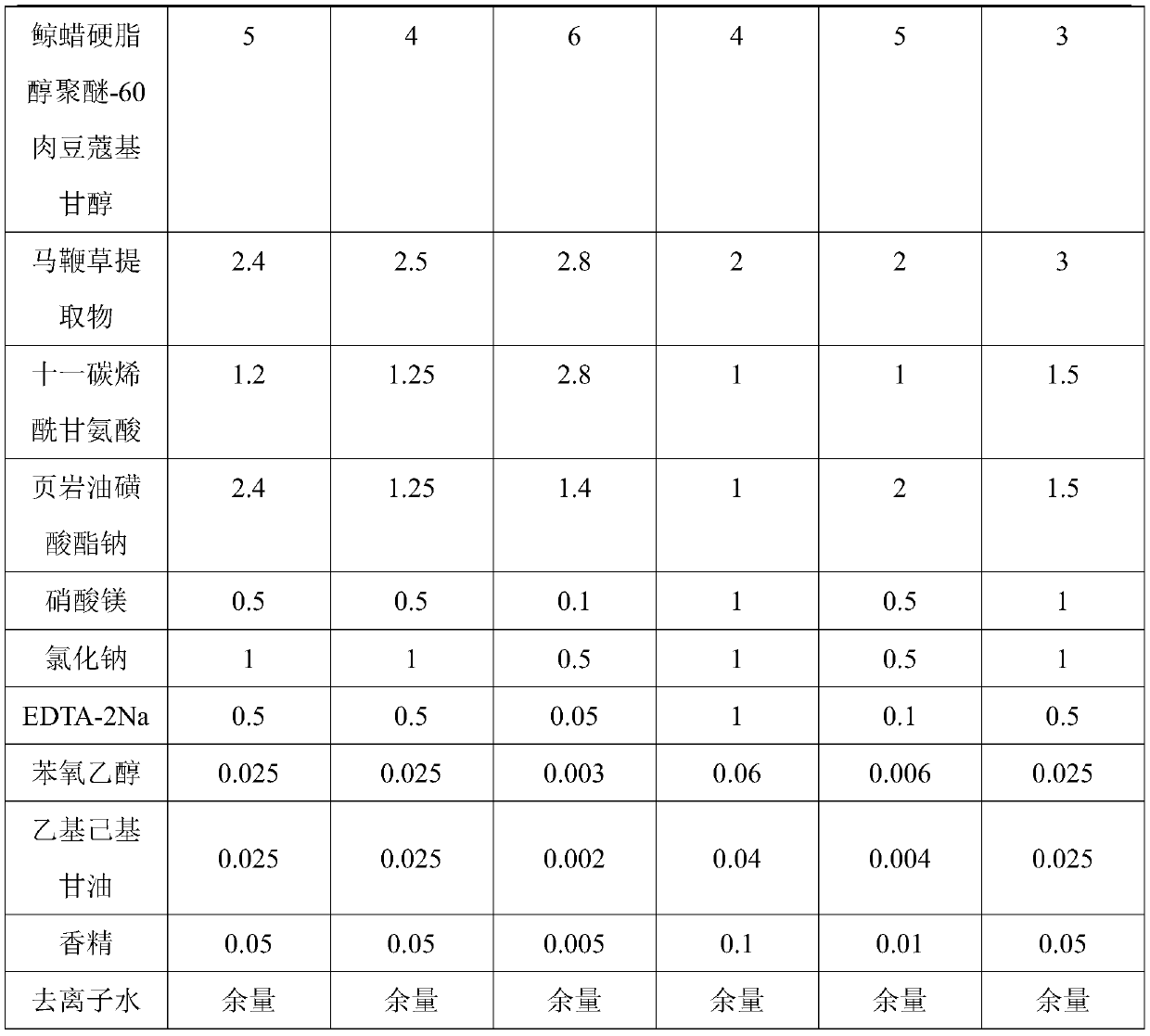

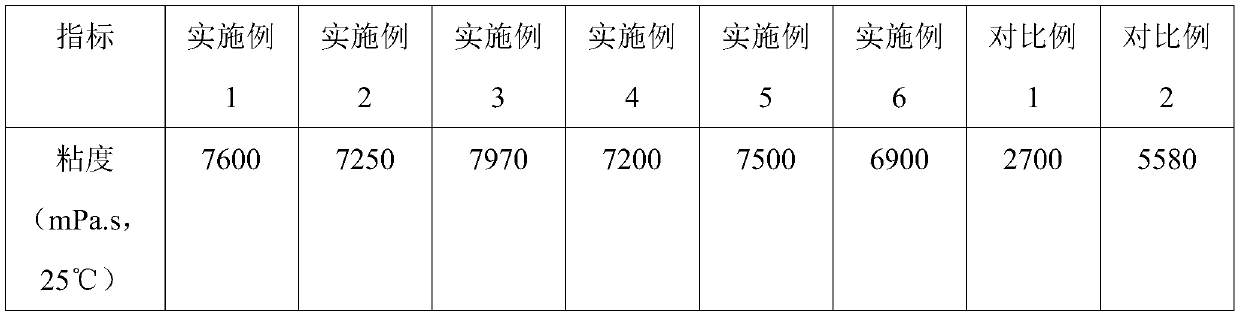

Mild-type mite-killing anti-itching shower gel and preparation method thereof

ActiveCN111110577AEasy to rinseLess irritatingCosmetic preparationsToilet preparationsPropanoic acidShower gel

The invention discloses a mild-type mite-killing anti-itching shower gel and a preparation method thereof. The shower gel contains the following components in percentages by weight: 3-6% of sodium palmitoyl sarcosinate, 4-7% of sodium myristoyl methyl beta-alanine, 3-6% of sodium lauroyl aspartate, 3-6% of an emollient, 3-6% of ceteareth-60 myristyl glycol, 4-7% of a conditioning agent, 0.1-1% ofmagnesium nitrate, 0.5-1% of sodium chloride, 0.05-1% of a chelating agent, 0.005-0.1% of a preservative, 0.005-0.1% of essence, and the balance of deionized water. The shower gel provided by the invention has the advantages of mild nature, low irritation, fine foam, easy flushing and good cleaning power, and has the functions of bacteriostasis, mite killing and skin moisturizing, and enhances skin health while effectively nourishing skin.

Owner:广州玥颜化妆品有限公司

Sericin post-finishing method for cotton fabrics

ActiveCN102605619BImprove washabilityGood antibacterial effectVegetal fibresPolymer scienceSILK SERICIN

Owner:NANTONG LOVER APPL

Vinyl formula

The invention discloses a vinyl formula, comprising the following components by weight percent: PVC (polyvinyl chloride) crude powder, PVC baby powder 810, a plasticizer, hard oil TXIB, hard oil 57 degrees, heat-resistant oil ED-S, a stabilizing agent CE-116 and a release agent. The vinyl prepared by the formula disclosed by the invention is good in hardness, smooth in handfeel, strong in plasticity, good in stability, and closer to a real handle of human skin.

Owner:叶青华

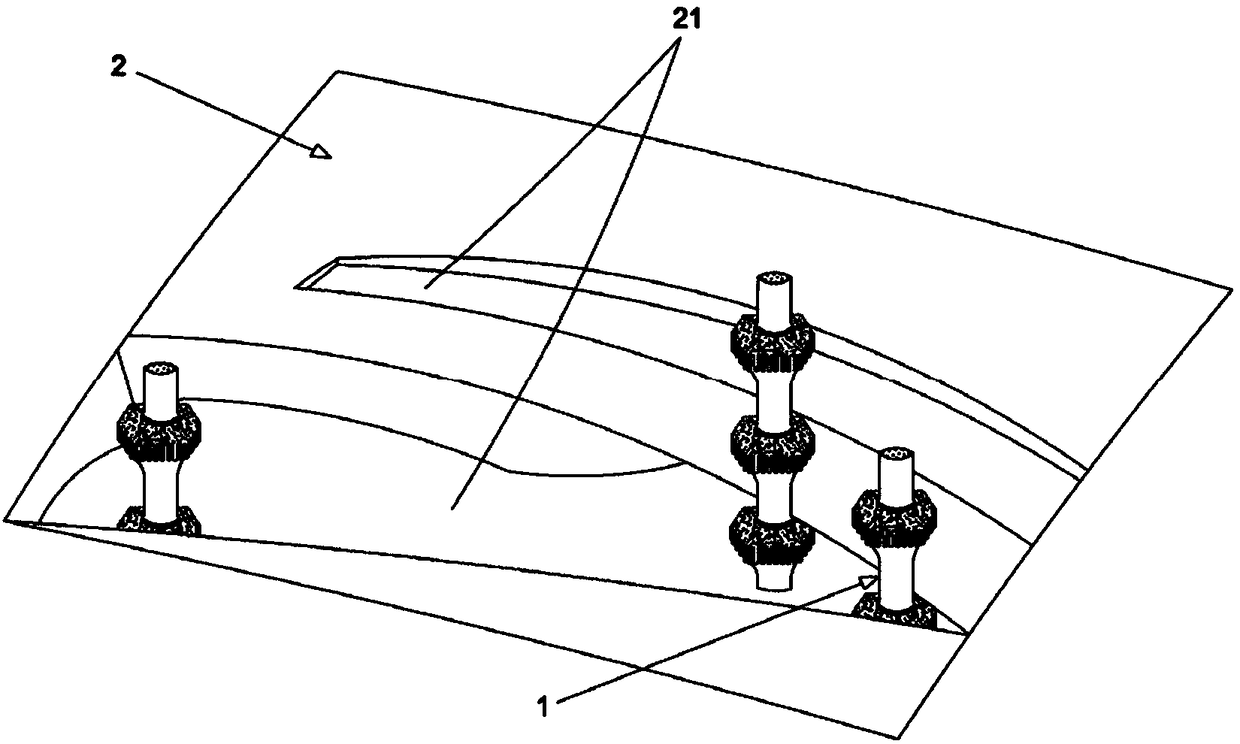

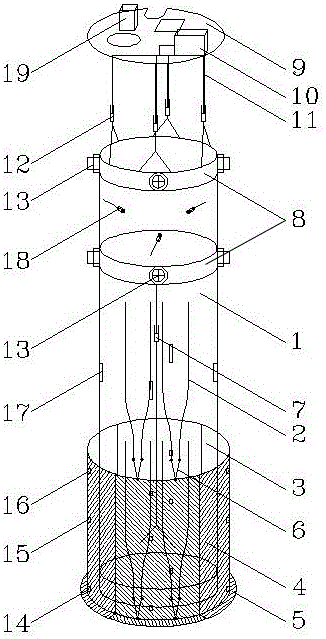

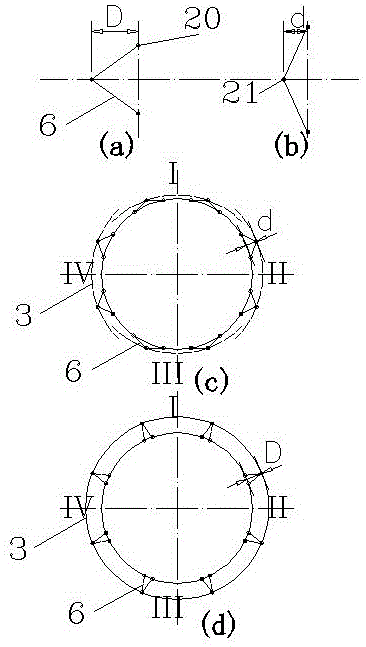

Wall building formwork applicable to intelligent construction of vertical shaft

ActiveCN106351673ASimple structureReduce demoulding resistanceUnderground chambersTunnel liningMeasurement pointStructural engineering

The invention discloses a wall building formwork applicable to intelligent construction of a vertical shaft. The outer surface of the formwork is coated with a Teflon coating; a main body comprises a core frame cylinder, curve sliding rails and segmental sliding forms, and formwork supporting and releasing actions of the segmental sliding forms are realized by the aid of radial contraction indirectly produced by vertical traveling of the segmental sliding forms in the longitudinal direction through the curve sliding rails. Leveling and centering of the formwork are subjected to servo adjustment by corresponding hydraulic oil cylinders after pose determination by sensors, and circularity regulation is not needed. The formwork has basic function of a concrete pouring envelop structure as well as capacity of monitoring and evaluating the quality and an evolution process of cast-in-place concrete by means of setting of pressure, temperature, moisture and ultrasonic measurement points on the outer surface of the formwork. The formwork has the characteristics of being reasonable in structure, reliable in work, quick in action and capable of performing automatic centering and leveling and evaluating the pouring quality of the concrete in real time, and realizes intelligence of the construction process of the vertical shaft.

Owner:CHINA UNIV OF MINING & TECH

Traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream and preparation method thereof

ActiveCN102670479AOvercome the shortcomings of greater irritation and poor smellNon-irritatingCosmetic preparationsToilet preparationsDiseaseCosmetic cream

The invention discloses traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream and a preparation method thereof. The traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream comprises the following traditional Chinese medicine components in parts by weight: 25-35 parts of dandelion, 6-15 parts of goldthread root, 8-15 parts of radix polygonati officinalis, 15-20 parts of Poria cocos, 15-20 parts of red date, 10-20 parts of sophora flower, 10-20 parts of gypsum and 2-8 parts of pearl. The traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream has the effects of powerfully eliminating cortex and in vivo free fatty acids, restraining and killing the activity of propionic acid Corynebacterium acnes, promoting the absorption of nutritional ingredients and promoting skin metabolism, and is capable of treating both principal and secondary aspects of disease. The traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream has no toxic and side effects, is not irritant to skins, and is capable of recovering the elasticity and the vitality of the skins, therefore, the goals of diminishing inflammation, pulling out acnes and beautifying are achieved. According to the preparation method of the traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream, by combining a supercritical extraction method with a water extraction method, the components of effective parts of the traditional Chinese medicines can be effectively extracted, therefore, the functions of the traditional Chinese medicines are improved, and limited traditional Chinese medicine resources with high cost are saved. The traditional Chinese medicine antiphlogistic acne-pullout cosmetic cream has higher economic benefits and social benefits.

Owner:GUANGXI YINGKANG PHARMA

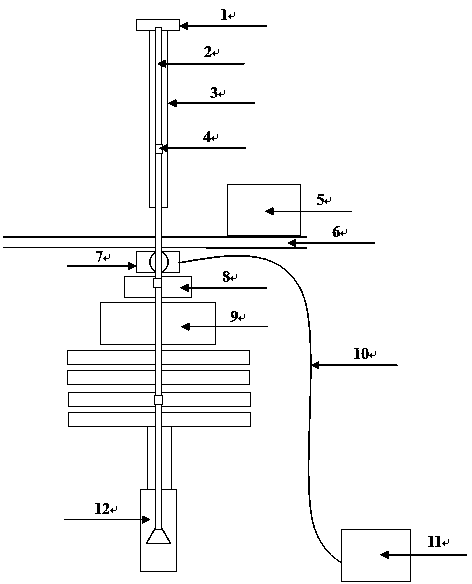

Under-pressure drill tripping method used under top drive drilling machine

ActiveCN103485734ASolve operational problemsSimple processDrilling rodsDrilling casingsTop driveDrill floor

The invention discloses an under-pressure drill tripping method used under a top drive drilling machine and belongs to the technical field of an under-pressure drill tripping tool. The method comprises the following steps that a hydraulic slip is arranged under a drill stand, and in addition, a well mouth requiring the under-pressure drill tripping implementation is subjected to pressure measurement; when the pressure of the tested well mouth is smaller than or equal to 5Mpa, a top drive connecting drill tool is adopted, and when a top drive is adopted for implementing the under-pressure drill tripping, the number of the upwards lifted or downwards placed drill tool(s) is 1 to 3; when the number of the upwards lifted or downwards placed drill tool(s) is 1 to 3, the hydraulic slip arranged under the drill stand is started, the drill tools are clamped by the hydraulic slip, and the clamping force of the hydraulic slip is greater than or equal to 3T; the top drive is started, when the drill tools are upwards lifted, the drill tools clamped in the well mouth are separated, and in addition, the dismounted drill tools are placed on a pipe rack; and when the drill tools are downwards placed, the connected drill tools are conveyed into a well by the downward pressure of the top drive. The method solves the difficult problem that a conventional under-pressure drill tripping device under the top drive drilling machine cannot be mounted or operated on the drill stand.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

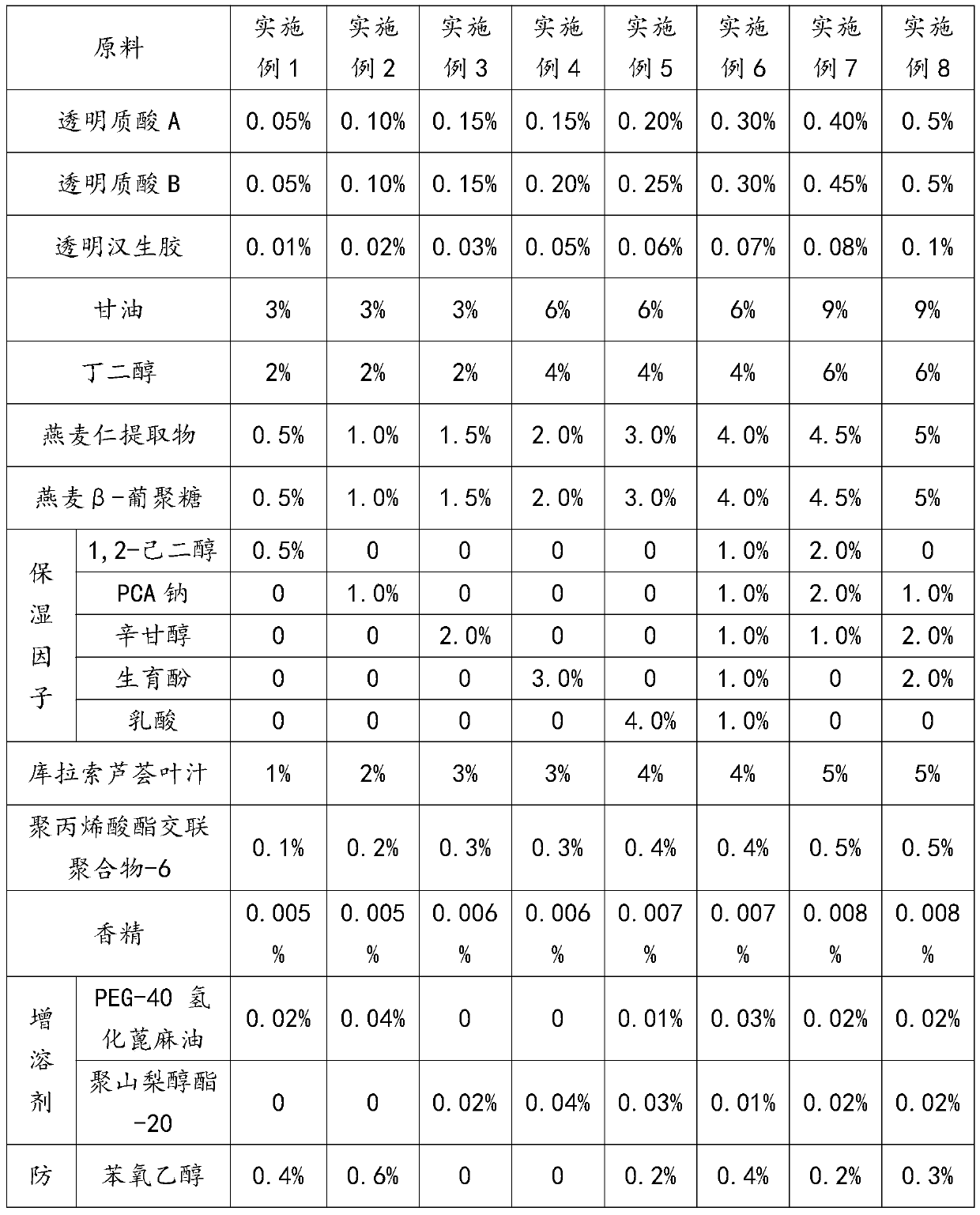

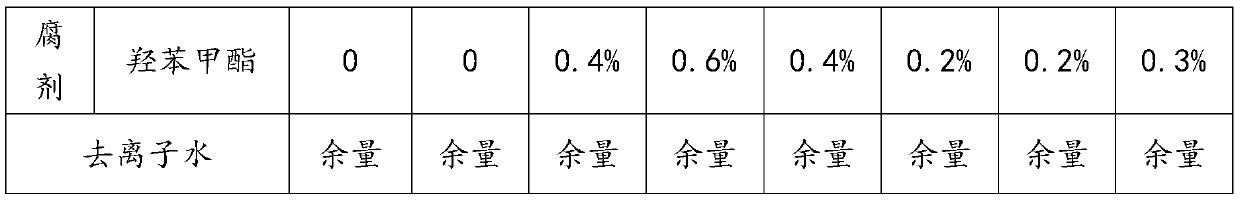

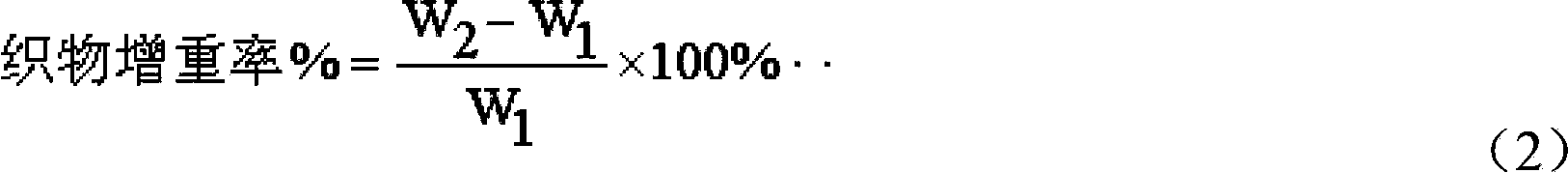

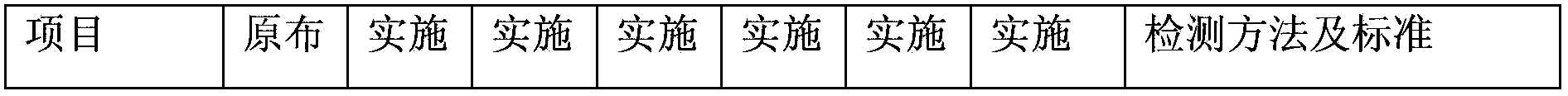

Double hyaluronic acid stock solution and preparation method thereof

InactiveCN110302081AEffectively locks in moistureImprove moisturizingCosmetic preparationsToilet preparationsCross-linkSolvent

The invention relates to the technical field of cosmetics, and discloses a double hyaluronic acid stock solution and a preparation method thereof. The double hyaluronic acid stock solution is preparedfrom the following raw material components in percentage by weight: 0.05%-0.5% of hyaluronic acid A, 0.05%-5% of hyaluronic acid B, 0.01%-1% of transparent Xanthan gum, 3%-9% of glycerin, 2%-6% of butanediol, 0.5%-5% of oat kernel extract, 0.5%-5% of oat beta-glucan, 0.5%-5% of moisturizing factors, 1%-5% of aloe barbadensis leaf juice, 0.1%-0.5% of a polyacrylate cross-linked polymer-6, 0.005%-0.008% of essence, 0.02%-0.04% of a solubilizer, 0.4%-0.6% of a preservative and the balance of deionized water. According to the double hyaluronic acid stock solution and the preparation method thereof, the ratio of two kinds of different molecular weight hyaluronic acid are reasonably adjusted in a ground-breaking mode to form a thin film on the surface of skin, so that moisture in the skin is effectively locked, the effect of long-term moisturizing is achieved, and meanwhile, the skin is smooth but not greasy, no matter in a cold winter or a hot summer, the use experience is good, the cost is lower, and the double hyaluronic acid stock solution is easy to accept by the public.

Owner:广州药妆日用化工有限公司

Post-treatment method for comfortable and cool terylene silk-like fabric

The invention discloses a post-treatment method for a comfortable and cool terylene silk-like fabric. The method includes steps of desizing, alkali decrement treatment on a base fabric and padding finishing. In the step of alkali decrement treatment on the base fabric, a treatment solution includes components of, by weight, 2-3% of caustic soda, 0.15-0.25% of penetrating agent, 0.15-0.25% of scouring agent, and the balance of water; a bath ratio is 1:15-20; a treatment temperature is 120+ / -5 DEG C; a treatment time is 40+ / -3min; and a reduction rate is 10-12%. Adoption of the method in the invention to prepare terylene fabric overcomes the hard handle of terylene fabric, improves wearing conformability of polyester fabric; and the product has the advantages of convenient processing and high resource utilization rate.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Coating method

InactiveCN106311576AEnhance layeringHigh hardnessSpecial surfacesCoatingsEnvironmental resistanceWater based

The invention discloses a coating method for furniture. A water-based coating and a UV coating which are jointly used are adopted in the method. The method comprises the following selected steps that firstly, a base material is provided; secondly, a water-based color wiping agent is applied to the surface of the base material, and the usage amount of the water-based color wiping agent is 8 g / m<2>-12 g / m<2>; thirdly, UV putty is applied, and the usage amount of the UV putty is 30 g / m<2>-40 g / m<2>; fourthly, UV primer is applied, and the usage amount of the UV primer is 30 g / m<2>-50 g / m<2>; fifthly, water-based primer is applied, and the usage amount of the water-based primer is 100 g / m<2>-110 g / m<2>; sixthly, a water-based color modifying agent is applied, and the usage amount of the color modifying agent is 20 g / m<2>-30 g / m<2>; and seventhly, water-based finish paint is applied, and the usage amount of the water-based finish paint is 100 g / m<2>-110 g / m<2>. In the third step, applying is finished through a roller painting manner. In the fourth step and the fifth step, applying is finished through one of a roller painting manner and a spraying manner or the combination manner of roller painting and spraying. In the sixth step, applying is finished through a spraying manner. In the seventh step, applying is finished through a spraying manner. The furniture is provided with a flat surface or a non-flat surface. By means of the coating method, the product performance is improved, environment friendliness is achieved, and implementation is easy.

Owner:GUANGDONG YINGRAN WOOD IND

Overprint varnish-free high wear resistance aluminum foil lined paper water-based ink and preparation method thereof

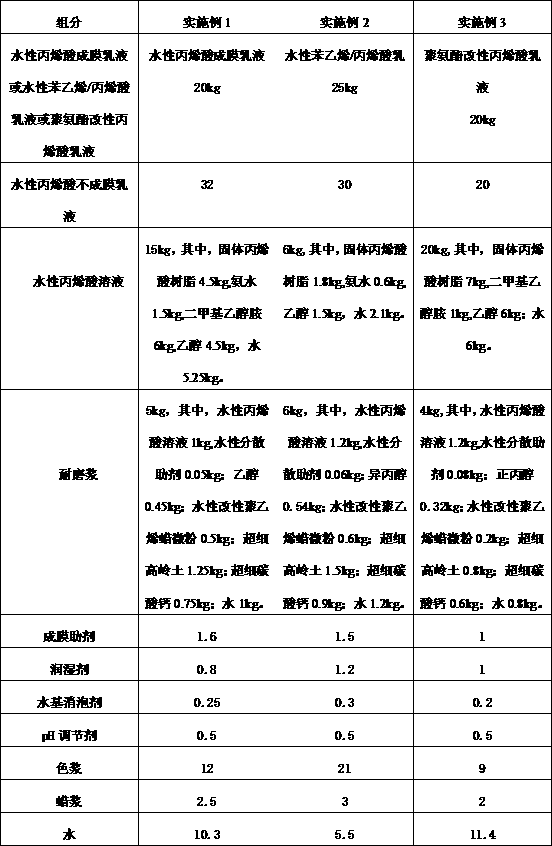

This invention relates to the field of inks, and discloses an overprint varnish-free high wear resistance aluminum foil lined paper water-based ink. The overprint varnish-free high wear resistance aluminum foil lined paper water-based ink comprises 20-25 wt% of an aqueous acrylic film-forming emulsion or an aqueous styrene / acrylic emulsion or a polyurethane modified acrylic emulsion, 20-35 wt% ofan aqueous acrylic non-film forming emulsion, 2-25 wt% of an aqueous acrylic solution, 0.2-2 wt% of a wetting agent, 0.1-0.5 wt% of a defoamer, 0.4-0.6 wt% of a pH adjuster, 10-25 wt% of a color paste, 4-10 wt% of a wax paste, 4-10 wt% of a wear-resistant slurry, 5-15 wt% of water and 0.1-2 wt% of a film forming aid, wherein the wear-resistant slurry comprises 20-30 wt% of an aqueous acrylic solution, 20-25 wt% of water, 5-10 wt% of a water-modified modified polyethylene wax micro-powder, 1-2 wt% of an aqueous dispersion aid, 8-9 wt% of a cosolvent, 20-25 wt% of ultrafine kaolin and 10-15 wt%of ultrafine calcium carbonate. The ink has the adhesion of prime coating, also has the heatproof, waterproof, anti-slip, wear-resistant and scratch-resistant properties of a varnish, is convenient touse, and can simplify aluminum foil pre-coating, monochrome printing and three-time overprint varnish printing into one-time inking printing, so two printing processes are saved, and energy saving and environmental protection are achieved.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

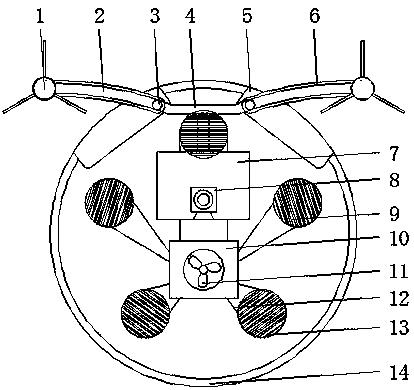

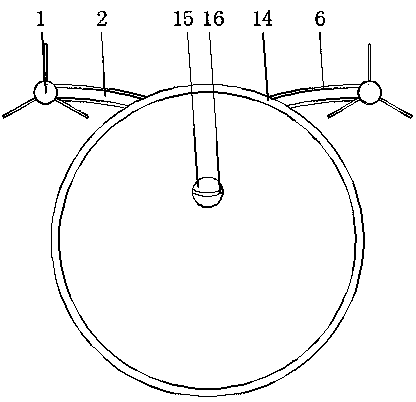

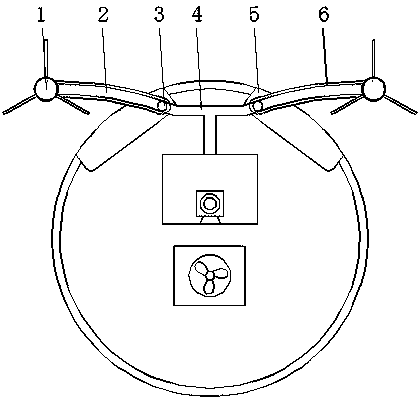

Automatic-cleaning floor sweeping robot

InactiveCN108742325AEasy to useAchieve drying effectMachine detailsCleaning equipmentEngineeringAir blower

The invention discloses an automatic-cleaning floor sweeping robot. The automatic-cleaning floor sweeping robot comprises hairbrushes, an air blower and a floor sweeping robot body, wherein fixed blocks are installed on the lower surface of the floor sweeping robot body, connecting rods are connected to the lower surfaces of the fixed blocks through rotating bearings, the hairbrushes are installedon the lower surfaces of the connecting rods, a water tank is installed inside the floor sweeping robot body, a water pump is installed inside the water tank, a three-way pipe is installed on the upper surface of the water tank, water pipes are installed on the outer end face of one side of the three-way pipe, penetrate through the connecting rods, and are connected with the hairbrushes, an air blower case is installed at the portion, located at the lower portion of the water tank, inside the floor sweeping robot body, the air blower is installed inside the air blower case, connecting pipes are installed on the outer end face of one side of the air blower case, and air blowing pipes penetrating through the floor sweeping robot body are installed on the outer end face, different from one side of the air blower case, of the connecting pipes. The automatic-cleaning floor sweeping robot is more conveniently and rapidly used.

Owner:昆山天卓贸易有限公司

Tough curtain coating soft-light finish paint on impregnated laminate flooring

InactiveCN103305099AImprove surface propertiesImprove performancePolyurea/polyurethane coatingsEpoxy resin coatingsAcrylic resinMoisture

The invention discloses a tough curtain coating soft-light finish paint on impregnated laminate flooring. The finish paint comprises the following components in percentage by weight: 30-50% of 100% UV (ultraviolet) curing resin, 1-3% of antifoaming agent, 0.1-0.5% of leveling agent, 0.5-1.5% of dispersing agent, 0.2-1% of anti-settling agent, 4-8% of photoinitiator, 3-8% of filler and the balance of monomer, wherein the 100% UV resin is epoxy acrylic resin or modified epoxy acrylic resin, modified polyurethane acrylic resin, unsaturated polyester acrylic resin or a mixture thereof; and the monomer is acrylic ester, modified acrylic ester or a mixture thereof. By improving a paint formula, the tough curtain coating soft-light finish paint disclosed by the invention has good toughness, fullness, adhesive and comprehensive water resistance and special effects of moisture, soft light and luster; and the luster of a paint film is over 75 degrees.

Owner:JIANGSU HIMONIA TECH

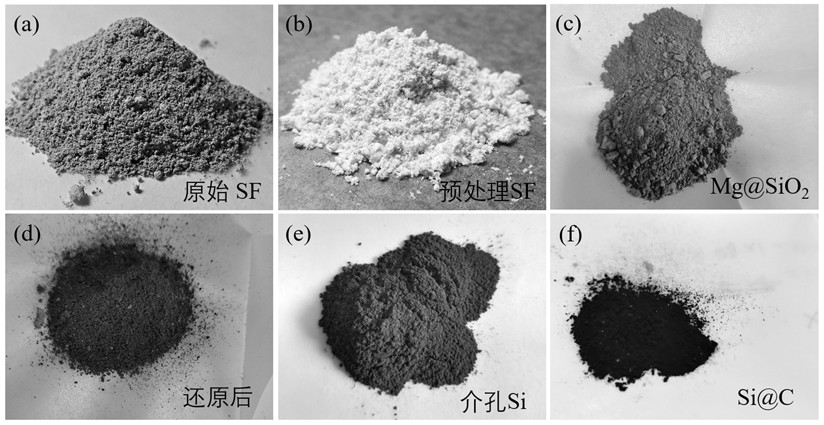

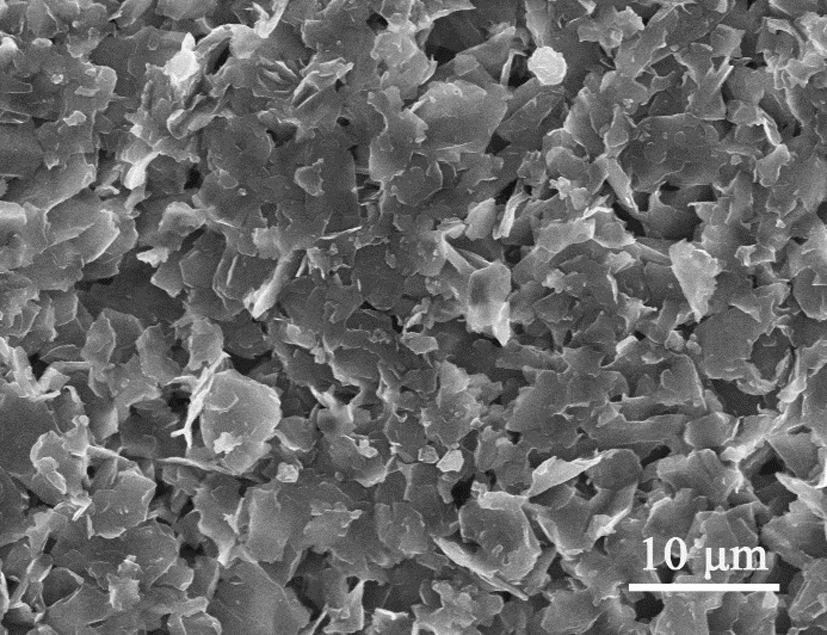

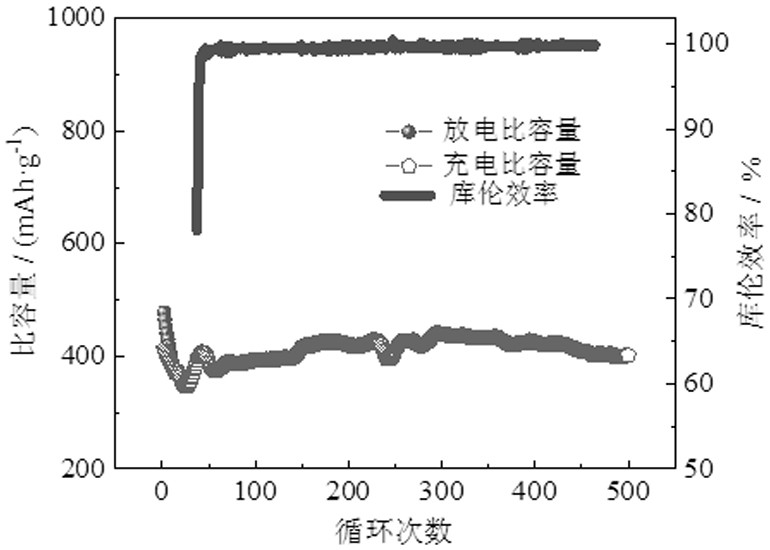

Method for preparing graphite-based Si@C negative electrode material by taking silica fume as Si source

InactiveCN112768672ASlow down body expansionShorten the diffusion distanceCell electrodesSecondary cellsCarbon layerElectrolytic agent

The invention discloses a method for preparing a graphite-based Si@C negative electrode material by taking micro-silicon powder as a Si source. The method comprises the following steps: pretreating the micro-silicon powder, then carrying out ball-milling mixing and reduction reaction on the micro-silicon powder and magnesium powder, and carrying out acid pickling and centrifugal drying to obtain porous crystal Si particles; and uniformly mixing the prepared porous crystal Si with dopamine in a prepared Tris buffer solution with the pH value of 8.5 to deposit polydopamine on the surfaces of Si particles, and coating the Si to prepare the composite material with the Si-C core-shell structure. The composite material has excellent electrochemical performance, relatively high specific capacity, long cycle life, high capacity retention ratio and stable cycle life; the pore structure of the carbon layer and the Si particles wrapped by the carbon layer also shortens the diffusion distance and time for deintercalation and intercalation of lithium ions; the conductivity of Si is enhanced by the coating carbon layer; and the Si@C core-shell structure also prevents the electrolyte from being in direct contact with Si to form an unstable SEI film.

Owner:KUNMING UNIV OF SCI & TECH

A making method for hot blast drying instant noodles

InactiveCN100464645CSlipperyLower requirementBaking processesFood preparationProcess equipmentPotato starch

The present invention relates to instant noodles making process, and is especially making process of hot blast dried instant noodles. The making process of hot blast dried instant noodles includes the steps of adding manioc and potato starch in certain proportion into wheat flour, mixing, leavening, pressing sheet, cutting into noodles, drying and cooling. The hot blast dried instant noodles have short rehydrating time, good smooth taste and simple production process.

Owner:张晋红

Primer-free coating method of self-adhesive acrylate emulsion and coating system implementing primer-free coating method

ActiveCN104353595AGood for healthImprove protectionPretreated surfacesCoatingsEmulsionCoating system

The invention provides a primer-free coating method of a self-adhesive acrylate emulsion and a coating system implementing the primer-free coating method. The coating method is high in coating uniformity, the adhesive force of a coating and a base material is high, defect inspection on the surface of a film is strict, and the quality is better. An obtained coating film is good in heat sealability and high in peeling strength after compounding; moreover, the film can be easily fed on the equipment, and smaller tension is needed, so that the coating process is controlled more easily, and the coating is more uniform and smoother.

Owner:HAINAN SHINER IND

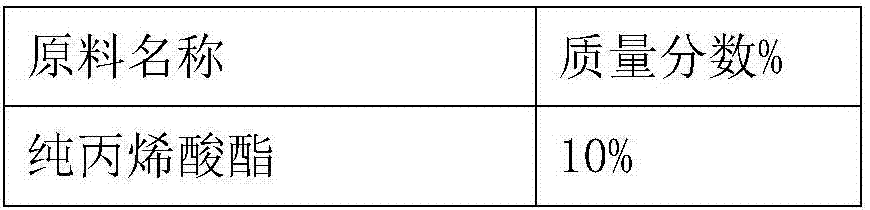

High-adhesion UV (ultraviolet) environment-friendly spraying white primer without sanding and recoating for woodware

InactiveCN107987684AHigh hardnessHigh fullnessEpoxy resin coatingsPriming paintsAcrylic resinDouble bond

The invention discloses high-adhesion UV (ultraviolet) environment-friendly spraying white primer without sanding and recoating for woodware. The high-adhesion UV environment-friendly spraying white primer is prepared from the following raw materials in parts by mass: 10 to 15% of pure acrylic ester, 25 to 30% of modified epoxy acrylate, 20 to 25% of active monomer, 4 to 6% of photoinitiator, 0 to1% of dispersing agent, 0 to 1% of defoaming agent, 15 to 20% of R-706, 10 to 15% of 1250-mesh talcum powder and 0 to 1% of flatting agent. According to the invention, a coating formula is improved,the film hardness and fullness is increased, the polyester resin and acrylic monomers are polymerized together through the double bond of unsaturated polyester, thus the effect of modifying the acrylic resin is realized, the brittleness of the acrylic resin is improved by the flexibility of the polyester resin, the recoatability is obvious, the preparation and use are safe and environmentally friendly. Furthermore, the stereoscopic effect of a film is high, the handfeeling is smooth, the fullness of the white primer can be increased, excellent visual effect and touch feeling are obtained, theaesthetic degree of a product is greatly improved and the protection capability of the product is enhanced.

Owner:上海君子兰新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com