Furniture wood board surface metallic paint spraying method

A surface spraying and metallic paint technology, applied in the field of spray paint, can solve the problems of easy caking, monotonous color, weak adhesion between the metal paint layer and wood materials, etc., and achieve oily hand feeling, strong three-dimensional effect, good visual effect and tactile feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

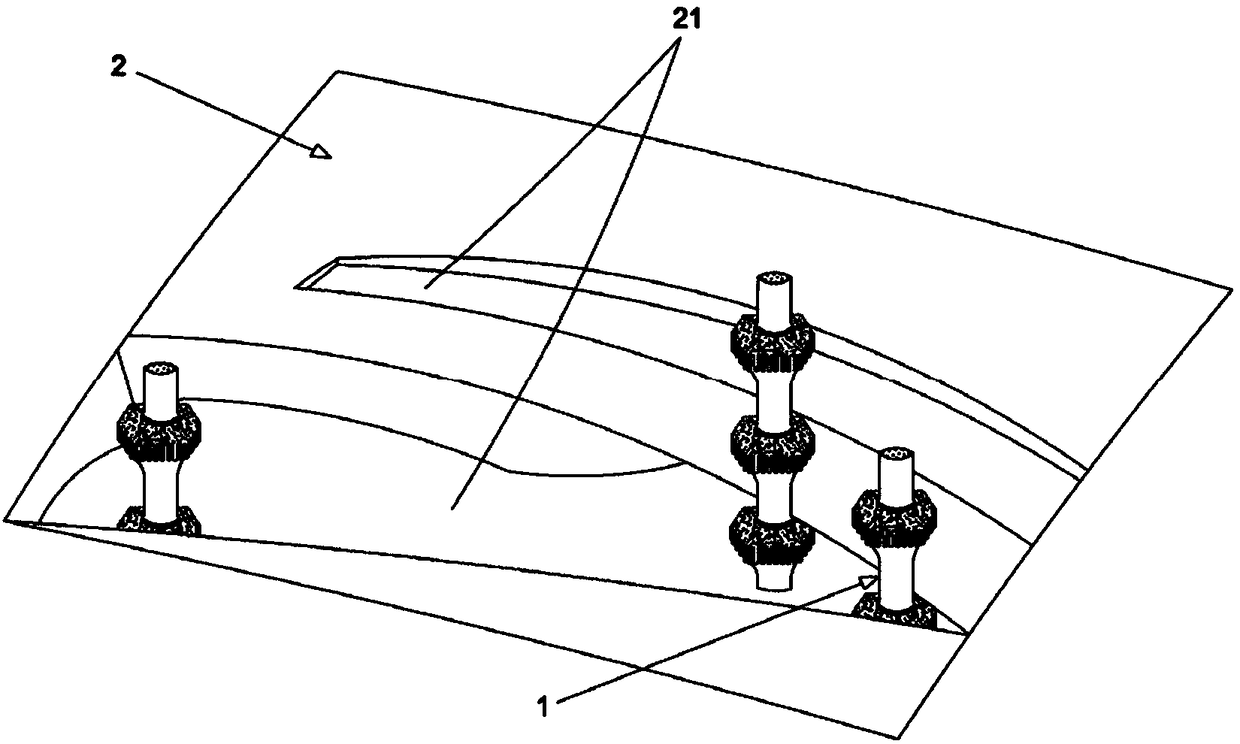

[0024] figure 1 Shown is the three-dimensional structure of the skewered polymer 1, the skewered polymer 1 includes a cylindrical central ridge fiber crystal 11, and a plurality of folded chain attached crystals 12 attached to the surface of the central ridge fiber crystal 11, the skewered Structural polymer 1 forms a "string" structure as a whole;

[0025] figure 2 Shown is the principle of action of the string crystal structure polymer 1, the string crystal structure polymer 1 is mixed in the acrylic paint, after brushing the mixed primer, part of the string crystal structure polymer 1 enters the gap 21 of the wood board 2, and is formed by it The special "string" structure is partially emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com