Overprint varnish-free high wear resistance aluminum foil lined paper water-based ink and preparation method thereof

A water-based ink, high wear-resistant technology, applied in ink, household utensils, applications, etc., can solve the problems of unsatisfactory anti-skid effect, inconvenient use, failure, etc., achieve stable gloss, improve wear resistance, and improve adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

[0027] 1. Embodiment

[0028] In each of the following examples, the water-based acrylic film-forming emulsion is the A-1127 of DSM; the water-based acrylic non-film-forming emulsion is 2956L of the U.S. New Pace Company; the water-based defoamer is BYK019 of BYK; the wetting agent Cytec AEROSOL OT-75 was used; the wax paste was MD-2000 from Onkel Company; the pH regulator was DEMA organic amine; the rest of the components were conventional commercially available products.

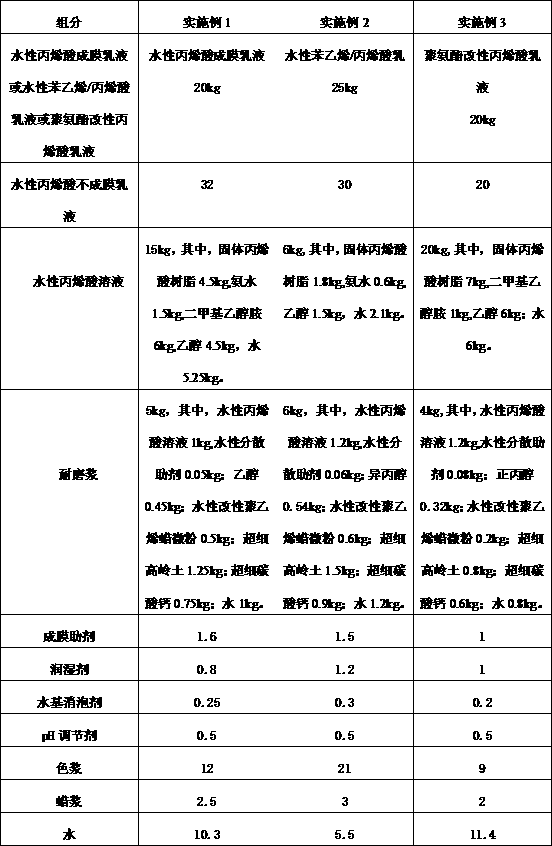

[0029] The following table is the formula table (unit, kg) of 3 examples of the water-based ink of high wear-resistant aluminum foil lining paper without varnish according to the present invention.

[0030]

[0031] The preparation method of 3 embodiments of the high wear-resistant aluminum foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com