Sulfur tetrafluoride production technique

A sulfur tetrafluoride and production process technology, applied in the production process of sulfur tetrafluoride and the production process of fluorine chemical products, can solve the problem of manual adjustment, artificial randomness, high experience, high risk of low temperature bottling, and hydrogen fluoride. The problem of high impurity content can achieve the effect of reducing the amount of purification treatment, high safety, and increasing the concentration of fluorine gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

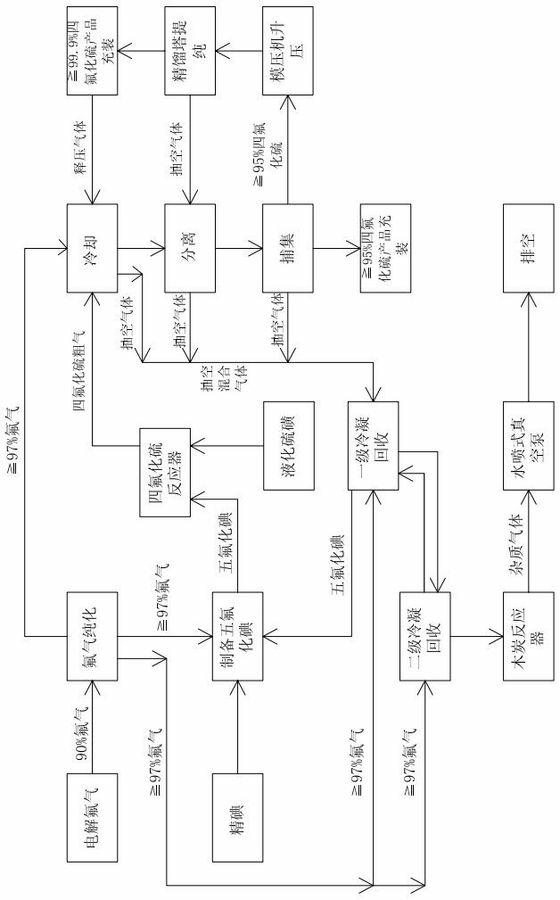

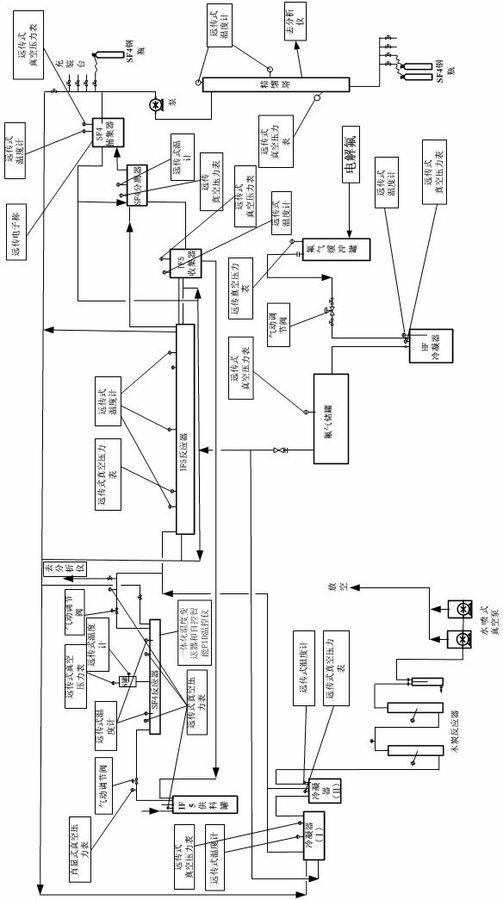

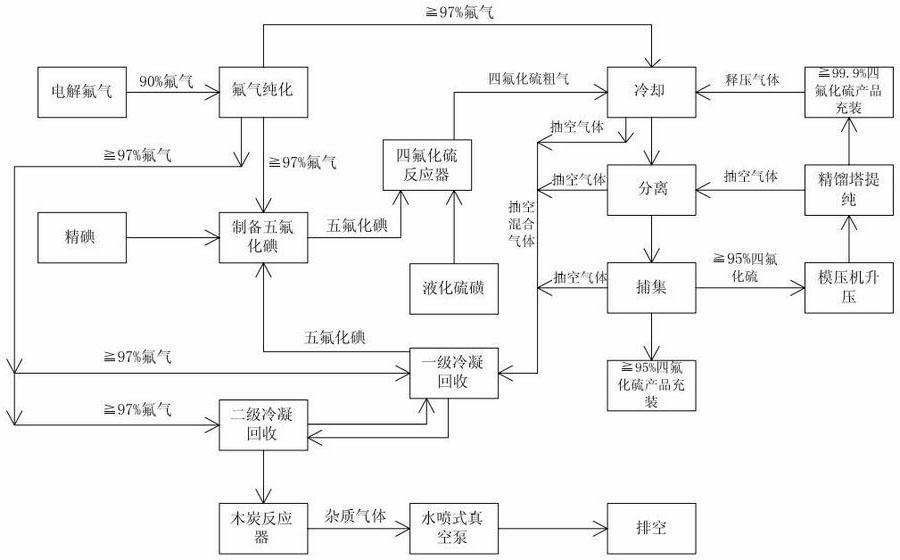

Method used

Image

Examples

Embodiment 1

[0037]Production of primary liquid sulfur tetrafluoride products with a purity of ≥95% (1):

[0038] A. Purification of fluorine gas: fluorine gas is produced by electrolysis, and a large amount of hydrogen fluoride gas in the fluorine gas is removed through condensation at a condensation temperature of -100°C, and the fluorine gas is purified to 97%;

[0039] B, preparation of iodine pentafluoride: prepare liquid iodine pentafluoride with fluorine gas and refined iodine purified in step A, then purify iodine pentafluoride with fluorine gas to obtain liquid iodine pentafluoride with content ≥ 99%; reaction pressure The control is -0.098Mpa, and the reaction temperature is controlled at 30°C;

[0040] C, reaction synthesis of sulfur tetrafluoride: heat and melt the sulfur with S content ≥ 99.5% with the IF prepared in step B 5 The liquid iodine pentafluoride with a content ≥99% is in the sulfur tetrafluoride reactor to produce crude sulfur tetrafluoride gas, of which:

[0041...

Embodiment 2

[0045] Production of primary liquid sulfur tetrafluoride products with a purity of ≥95% (2):

[0046] A. Electrolytic fluorine production: fluorine gas is produced by electrolysis, and a large amount of hydrogen fluoride gas in the fluorine gas is removed through condensation at a condensation temperature of 0°C, and the fluorine gas is purified to 98%;

[0047] B, preparation of iodine pentafluoride: prepare liquid iodine pentafluoride with fluorine gas and refined iodine purified in step A, then purify iodine pentafluoride with fluorine gas to obtain liquid iodine pentafluoride with content ≥ 99%; reaction pressure The control is -0.01Mpa, and the reaction temperature is controlled at 100°C;

[0048] C, reaction synthesis of sulfur tetrafluoride: heat and melt the sulfur with S content ≥ 99.5% with the IF prepared in step B 5 The liquid iodine pentafluoride with a content ≥99% is in the sulfur tetrafluoride reactor to produce crude sulfur tetrafluoride gas, of which:

[00...

Embodiment 3

[0053] Production of primary liquid sulfur tetrafluoride products with a purity of ≥95% (3):

[0054] A. Purification of fluorine gas: fluorine gas is produced by electrolysis, and a large amount of hydrogen fluoride gas in the fluorine gas is removed through condensation at a condensation temperature of -50°C, and the fluorine gas is purified to 98%;

[0055] B, preparation of iodine pentafluoride: prepare liquid iodine pentafluoride with fluorine gas and refined iodine purified in step A, then purify iodine pentafluoride with fluorine gas to obtain liquid iodine pentafluoride with content ≥ 99%; reaction pressure The control is -0.055Mpa, and the reaction temperature is controlled at 60°C;

[0056] C, reaction synthesis of sulfur tetrafluoride: heat and melt the sulfur with S content ≥ 99.5% with the IF prepared in step B 5 The liquid iodine pentafluoride with a content ≥99% is in the sulfur tetrafluoride reactor to produce crude sulfur tetrafluoride gas, of which:

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com