Preparation process for improving whiteness of kaolin

A preparation process and technology of kaolin, applied in inorganic chemistry, non-metallic elements, silicon compounds, etc., can solve the problem that the whiteness of kaolin cannot be further improved, and achieve the effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

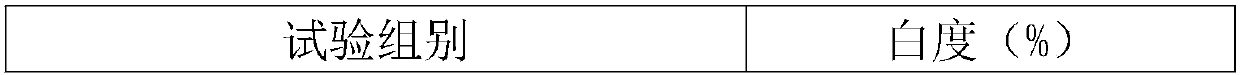

Examples

Embodiment 1

[0045] Embodiment 1: a kind of preparation technology that improves kaolin whiteness comprises the steps:

[0046] Step 1: Mining to remove impurities, mining kaolin mineral materials in Zhangzhou City, and initially separating clay and impurities to obtain base materials;

[0047] Step 2: pulping and desanding, pulping the base material and desanding to obtain the primary pulp material;

[0048] Step 3: Pass the primary slurry material into the No. 1 reaction pool, pass hydrochloric acid into the primary slurry material, adjust the pH of the primary slurry material to 1, and obtain dissolved iron ore slurry;

[0049] Step 4: Introduce hydrogen peroxide with a mass fraction of 35% into the dissolved iron ore slurry in step 2. The weight ratio of hydrogen peroxide to base material is 1:30 to obtain iron ion slurry, and pass the iron ion slurry into No. 2 reaction pool ; Wherein, the base material in this step is the base material described in step one.

[0050] Step 5: Introd...

Embodiment 2

[0053] Example 2: The difference from Example 1 is that the pH of the initial slurry in step three is 2; the weight ratio of hydrogen peroxide to base material in step four is 1:40; the anhydrous hydrofluoric acid and base material in step five The weight ratio of materials is 1:25; the weight ratio of sulfur tetrafluoride solution and anhydrous hydrofluoric acid in step 6 is 1:1.5; the weight ratio of sodium chloride solution and base material in step 7 is 1:40.

Embodiment 3

[0054] Example 3: The difference from Example 1 is that hypochlorous acid is introduced into the primary slurry while hydrochloric acid is introduced in step 3, and the weight ratio of hypochlorous acid to hydrochloric acid is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com