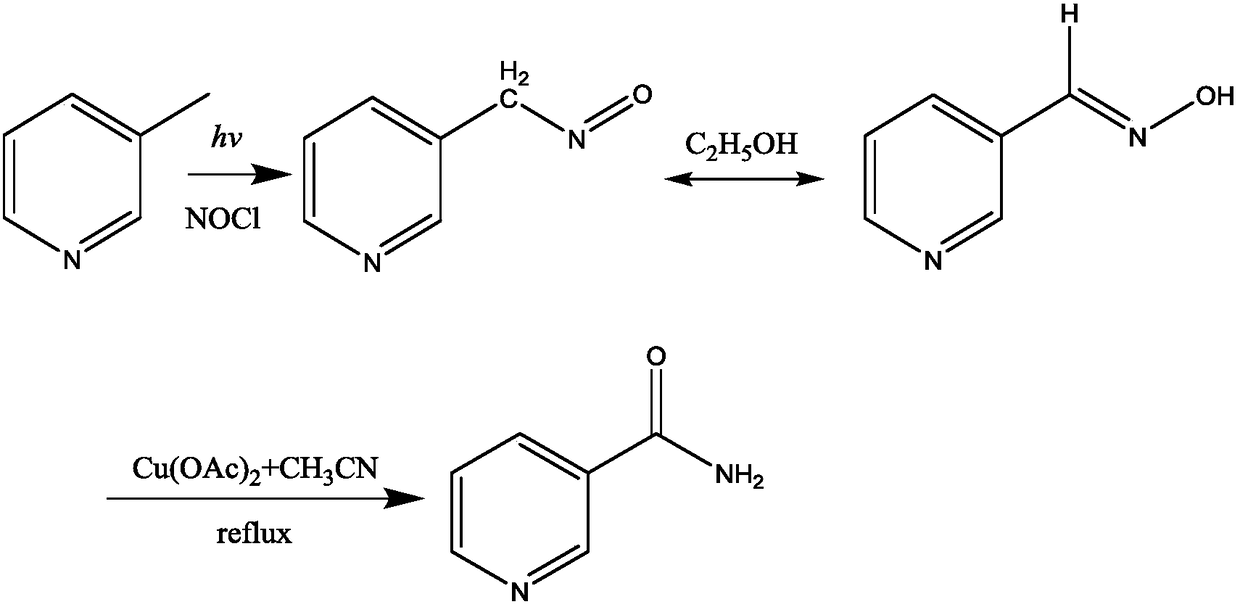

Synthetic method for nicotinamide

A synthesis method and nicotinamide technology, applied in the field of chemistry, can solve problems such as the further improvement of selectivity, and achieve the effects of less three wastes, mild reaction conditions and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 18.8g of 3-picoline (0.2mol, purity 99%, water content 0.37%), absolute ethanol 47g in 100mL ordinary photochemical reactor, turn on the cooling circulation system, turn on the 420nm purple light lamp (power 10W), start to The flow rate of 4.8g / h is passed into nitrosyl chloride to form a good turbulence state in the reactor, the temperature control reaction temperature is between 15 and 18°C, the reaction is about 3h, and the qualitative raw material 3-picoline is converted in the middle control complete. Stop feeding nitrosyl chloride, switch to blowing nitrogen gas for 0.3h, slightly reduce the flow rate and add about 20g of sodium carbonate at the same time, adjust the pH to 7.6, stop ventilation, filter the precipitated sodium chloride 12g, and the filtrate is pyridine-3- 66 g of ethanol solution of formaldehyde oxime, the content of pyridine-3-formaldehyde oxime determined by liquid phase is 33.64%, and the molar yield is 90.95% based on 3-picoline.

[0030] ...

Embodiment 2

[0032] Add 3-picoline 103g (1.1mol, purity 99%, water content 0.42%), dehydrated ethanol 206g in 500mL ordinary photochemical reactor, turn on cooling circulation system, turn on 480nm blue light (power 30W), start with 20g The flow rate of / h is fed into nitrosyl chloride to make the liquid in the reactor form a better turbulent state. The temperature control reaction temperature is between 15 and 18 ° C. The reaction is about 4.5 hours, and the conversion of the qualitative raw material 3-picoline is completed. . Stop feeding nitrosyl chloride, switch to blowing nitrogen gas for 0.9h, slightly reduce the flow rate and add about 40g caustic soda, adjust the pH to 7.2, stop ventilation, filter the precipitated sodium chloride 68g, and the filtrate is pyridine-3- The ethanol solution of formaldehyde oxime is 360g, the content of pyridine-3-formaldehyde oxime is 34.72% as determined by liquid phase, and the molar yield is 93.44% based on 3-picoline.

[0033] Add 360g of the eth...

Embodiment 3

[0035] Add 3-picoline 188g (2mol, purity 99%, water content 0.29%), dehydrated ethanol 400g in 1000mL ordinary photochemical reactor, turn on cooling circulation system, turn on 540nm green light (power 90W), begin to use 30g The flow rate of / h is passed into nitrosyl chloride to make the liquid in the reactor form a better turbulent state. The temperature control reaction temperature is between 15 and 18 ° C. The reaction is about 5 hours, and the conversion of the qualitative raw material 3-picoline is completed. . Stop feeding nitrosyl chloride, switch to blowing nitrogen gas for 1.5h, slightly reduce the flow rate, and add about 150g of sodium bicarbonate solid at the same time, adjust the pH to 6.8, stop ventilation, filter 130g of precipitated salt, and obtain pyridine-3-carbaldehyde oxime 741g of ethanol solution, the content of pyridine-3-carbaldehyde oxime determined by liquid phase is 30.53%, based on 3-picoline, the molar yield is 92.66%.

[0036]Add 741g of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com