Preparation method of oxidized starch containing aldehyde group on C6 position of glucose unit

A technology for oxidizing starch and glucose, which is applied to the preparation of oxidized starch containing aldehyde groups in the 6-position of starch molecules. Reduce the consumption of nitric acid, reduce the generation of nitrogen oxide tail gas, and overcome the effect of poor oxidation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0031] Add 5mL, 10mL, 15mL, and 20mL of concentrated hydrochloric acid to four parts of 30% starch milk (270g) respectively, so that the concentration of hydrochloric acid is 0.25, 0.50, 0.75, and 1.0mol / L respectively, and slowly introduce air at 45°C , 28.5 mL of 65% nitric acid was added dropwise within 3 hours, and the oxidized starch was prepared by reacting for 4 hours. The content of carboxyl and aldehyde groups in oxidized starch and the viscosity of the solution were determined by sampling as shown in Table 1.

[0032] Table 1 Effect of hydrochloric acid concentration on carboxyl and aldehyde content in oxidized starch

[0033]

Embodiment 5-9

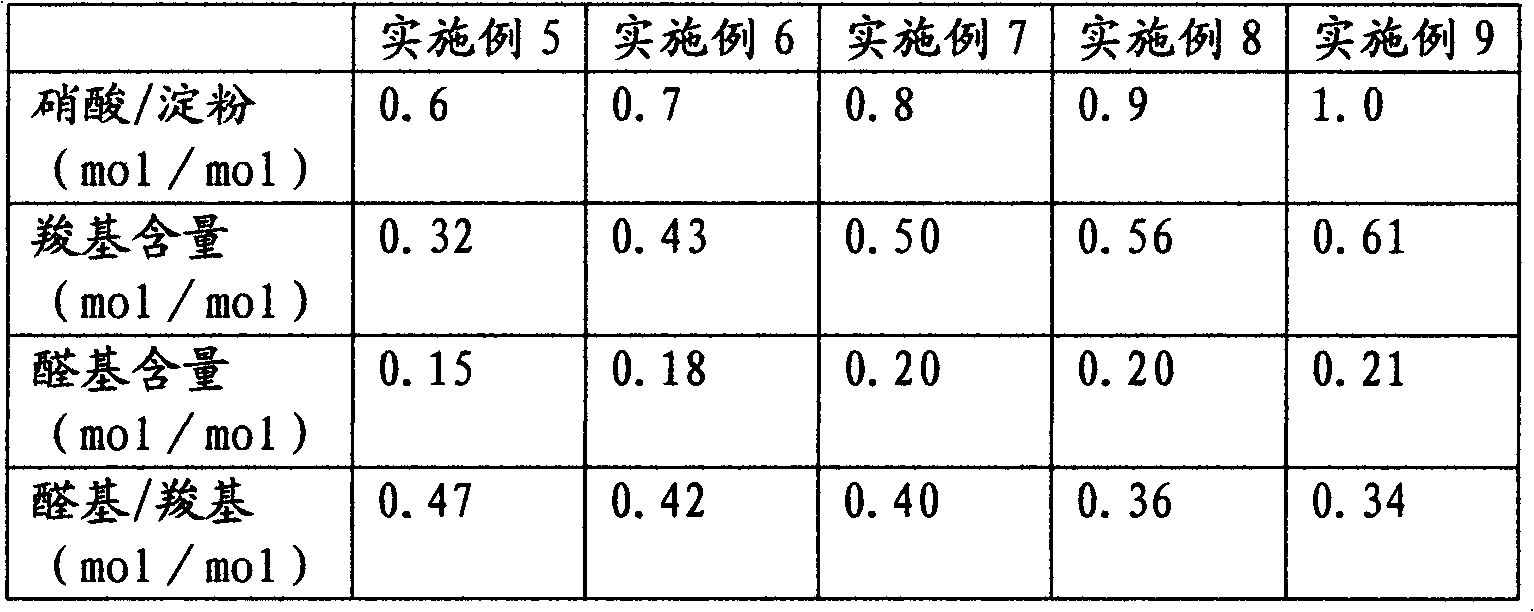

[0035] Add 15mL of concentrated hydrochloric acid to five parts of 30% starch milk (270g) respectively to make the concentration of hydrochloric acid 0.75mol / L, slowly pass air at 45°C, add 65% nitric acid 22mL, 25mL, 28.5mL, 32mL and 35.7mL, so that the molar ratio of nitric acid to starch was 0.6, 0.7, 0.8, 0.9 and 1.0 respectively, reacted for 4h to prepare oxidized starch, and sampled to determine the content of carboxyl and aldehyde groups in oxidized starch as shown in Table 2.

[0036] Table 2 Effect of nitric acid dosage on carboxyl and aldehyde content in oxidized starch

[0037]

Embodiment 10-15

[0039] Add 15 mL of concentrated hydrochloric acid to six parts of 30% starch milk (270 g) to make the concentration of hydrochloric acid 0.75 mol / L, and slowly introduce air at 45 ° C, within 1, 2, 3, 4, and 5 hours respectively 28.5mL of 65% nitric acid was added dropwise, so that the molar ratio of nitric acid to starch was 0.8, and the oxidized starch was prepared by reacting for 4h, and the content of carboxyl and aldehyde groups in the oxidized starch was sampled and determined as shown in Table 3.

[0040] Table 3 Effect of reaction time on carboxyl and aldehyde content in oxidized starch

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com