High acid resistant cast iron enamel glaze slurry for furnace frame and preparation method of high acid resistant cast iron enamel glaze slurry

An acid-resistant cast iron and enamel glaze technology, applied in the field of cast iron enamel, can solve the problems of shortening the service life of the hob, poor glaze gloss and high production cost, and achieve the effects of cost saving, good acid resistance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A highly acid-resistant cast iron enamel slurry for a stove frame, the formula includes: Domade 470#, Domade 31089#, Fu 1414B, clay, quartz powder, AP761 pigment, borax, soda ash, nitrous and water, each component The mass percentages are: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 2% clay, 3% quartz powder, 2% AP761 pigment, 0.1% Borax, 0.1% soda ash, 0.3% nitrous, and the balance is water.

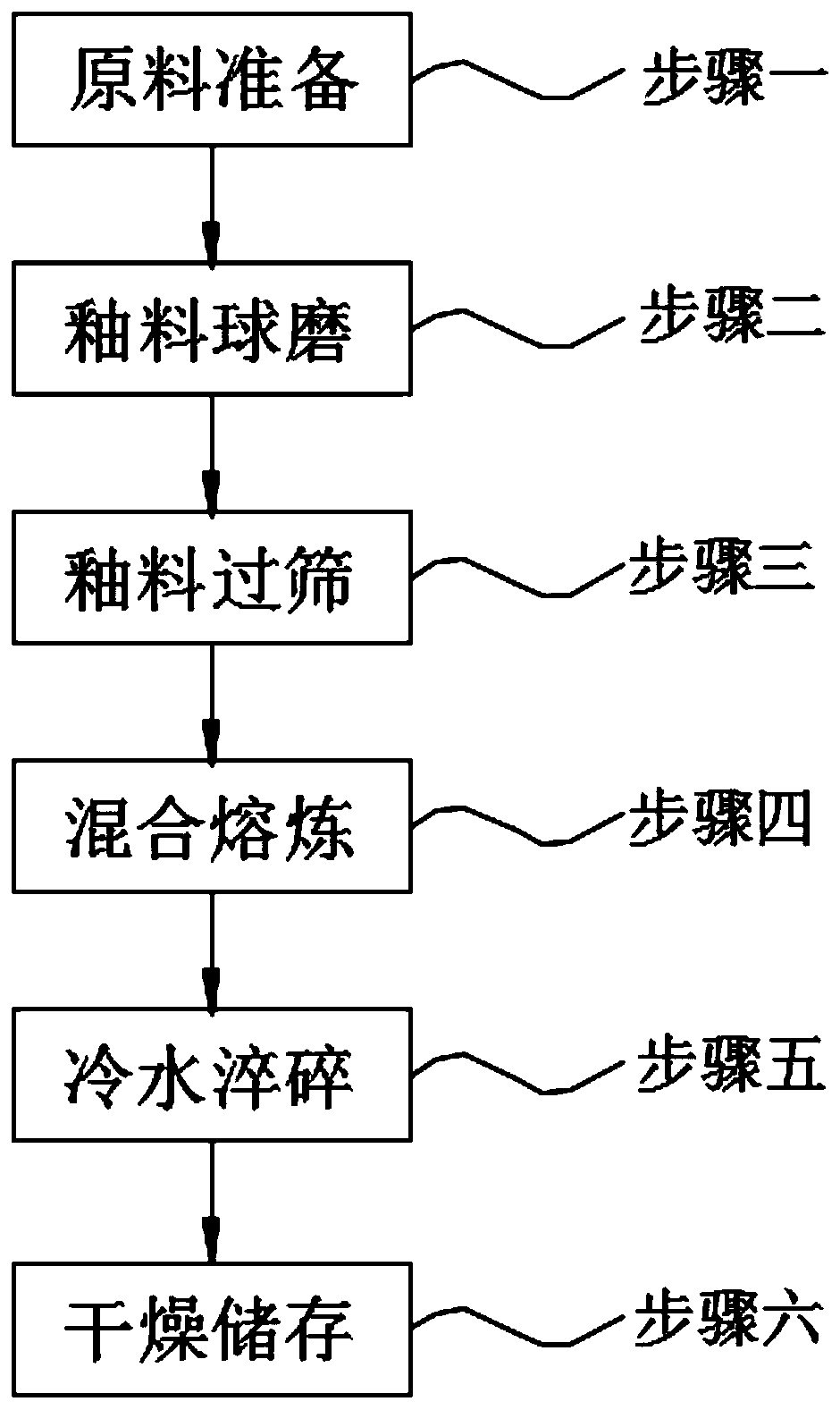

[0029] A method for preparing high acid-resistant cast iron enamel glaze slurry for a furnace frame, comprising the following steps: Step 1, raw material preparation; Step 2, glaze ball milling; Step 3, glaze sieving; Step 4, mixing and melting; Step 5, cold water Quenching; step six, dry storage;

[0030] Wherein in above-mentioned step one, raw material preparation comprises the following steps:

[0031] 1) According to the weight percent of each component, it is respectively: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 2% clay, 3% quartz powder, 2% % of AP761 pi...

Embodiment 2

[0042] A highly acid-resistant cast iron enamel slurry for a stove frame, the formula includes: Domade 470#, Domade 31089#, Fu 1414B, clay, quartz powder, AP761 pigment, borax, soda ash, nitrous and water, each component The mass percentages are: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 3% clay, 5% quartz powder, 3% AP761 pigment, 0.1% Borax, 0.1% soda ash, 0.3% nitrous, and the balance is water.

[0043] A method for preparing high acid-resistant cast iron enamel glaze slurry for a furnace frame, comprising the following steps: Step 1, raw material preparation; Step 2, glaze ball milling; Step 3, glaze sieving; Step 4, mixing and melting; Step 5, cold water Quenching; step six, dry storage;

[0044] Wherein in above-mentioned step one, raw material preparation comprises the following steps:

[0045] 1) According to the weight percent of each component, it is respectively: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 3% clay, 5% quartz powder, 3% % of AP761 pi...

Embodiment 3

[0056] A highly acid-resistant cast iron enamel slurry for a stove frame, the formula includes: Domade 470#, Domade 31089#, Fu 1414B, clay, quartz powder, AP761 pigment, borax, soda ash, nitrous and water, each component The mass percentages are: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 2% clay, 4% quartz powder, 2% AP761 pigment, 0.1% Borax, 0.1% soda ash, 0.3% nitrous, and the balance is water.

[0057] A method for preparing high acid-resistant cast iron enamel glaze slurry for a furnace frame, comprising the following steps: Step 1, raw material preparation; Step 2, glaze ball milling; Step 3, glaze sieving; Step 4, mixing and melting; Step 5, cold water Quenching; step six, dry storage;

[0058] Wherein in above-mentioned step one, raw material preparation comprises the following steps:

[0059] 1) According to the weight percent of each component, it is respectively: 12% Domade 470#, 12% Domade 31089#, 36% Fu 1414B, 2% clay, 4% quartz powder, 2% % of AP761 pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com