Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "N-hexadecane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

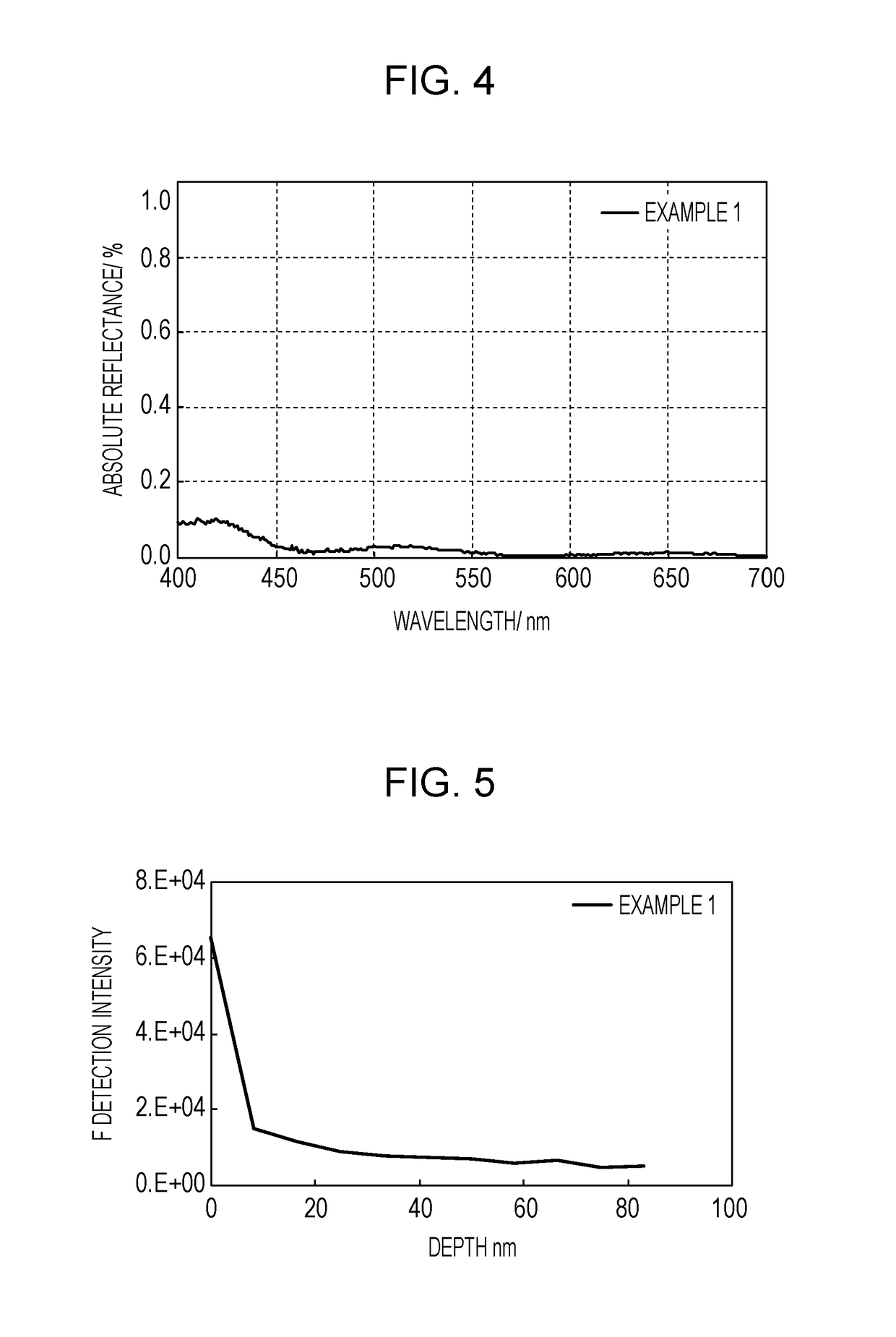

Preparation and application of super-hydrophobic/oleophobic coating layer with excellent performance

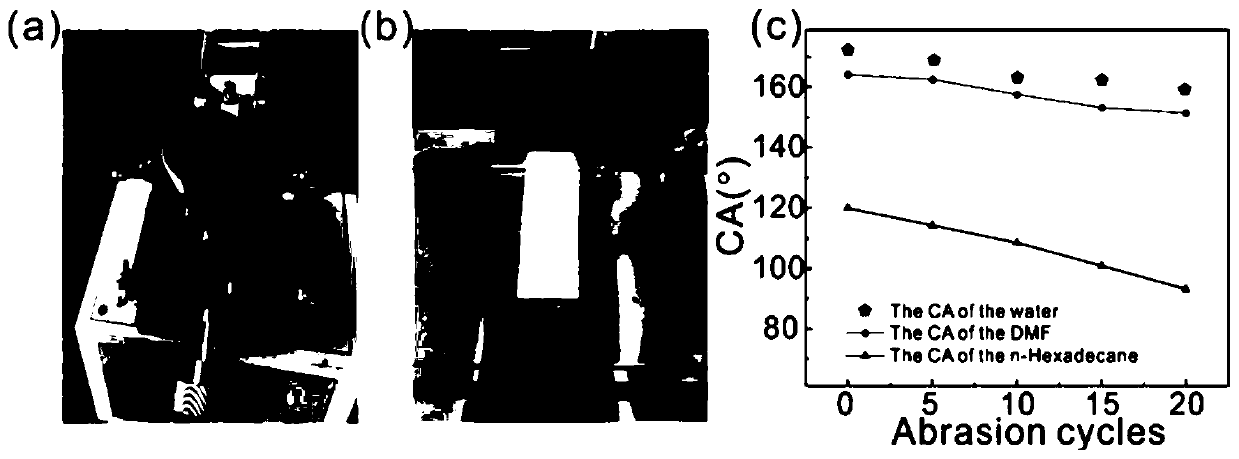

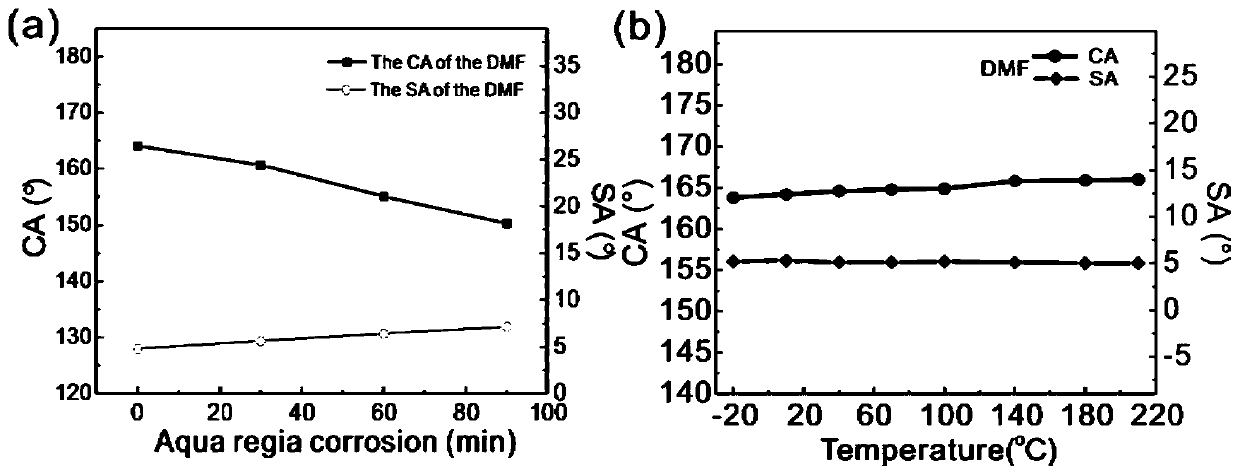

The invention relates to preparation and application of a super-hydrophobic / oleophobic coating layer with excellent performance, wherein the preparation comprises the steps: dispersing nanoparticles and cellulose in an alkaline substance-containing alcoholic solution, and adding tetraethyl orthosilicate and fluorine-containing organosilane for hydrolytic coating to form a solution A; dispersing epoxy resin in an alcoholic solution to form a solution B; uniformly mixing the solution A and the solution B, and then adding tetraethyl orthosilicate and fluorine-containing organosilane to react to generate polysiloxane, to obtain a solution C; dissolving a fluorine-containing amine compound in an alcoholic solution to obtain a solution D; and uniformly mixing the solution C and the solution D, spraying the mixture on a substrate, and curing to obtain the product. A multi-stage micro-nano hierarchical structure is constructed; the super-hydrophobic / oleophobic coating layer has good chemical stability, can achieve a complete repelling effect on N,N-dimethylformamide liquid drops (34.4 mN / m), has a contact angle of 120 degrees on n-hexadecane (27.1 mN / m), is simple in preparation method, can be sprayed on a large scale, and paves a road for industrialization of the super-hydrophobic / oleophobic coating layer.

Owner:QILU UNIV OF TECH

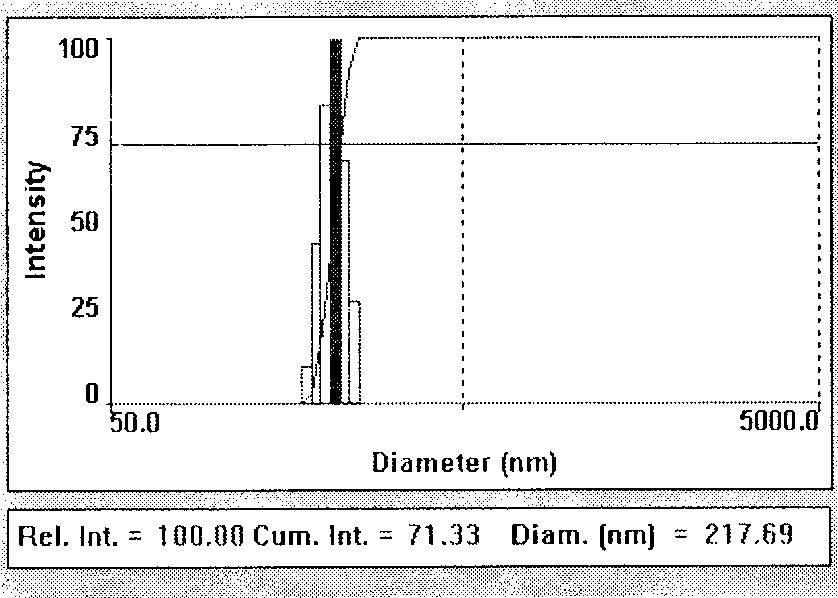

Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

InactiveCN101372527AUniform particle sizeImprove coating efficiency and grafting rateNano zinc oxideNanometre

The invention relates to the manufacturing field of nano composite emulsion materials, in particular to graft nano zinc oxide / polyacrylate composite emulsion and a manufacturing method thereof. Firstly an initiator azobisisovaleric acid is anchored on the surface of nano zinc oxide particles, two portions of hexadecane are added to 100 portions of mixed monomers, and 5 portions of nano ZnO particles anchoring the azo initiator are added and ultrasonically oscillated for 20 minutes to form an oil phase pre-dispersion solution. The pre-dispersion solution is added to an emulsifier aqueous solution and dispersed by a high-shear dispersion homogenizer at high speed for 30 minutes to form a mini-emulsion. The mini-emulsion is transferred to a reactor, heated to the temperature of 75 DEG C, with polyreaction initiated for 3 hours, and then heated to the temperature of 85 DEG C, polymerized for 2 hours, cooled to room temperature and discharged. The invention solves the problems of high cost and poor stability of the nano composite emulsion prepared by coupling agents, and low encapsulation efficiency and graft ratio of nano polymer composite particles. The composite emulsion has the advantages of simple preparation process, low cost, even particle size, good performance, high encapsulation efficiency and graft ratio of the nano-particles, forms nano monodisperse state in the polymer, and is suitable for the fields of coating materials, leather finishing materials, adhesives and functional plastics.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

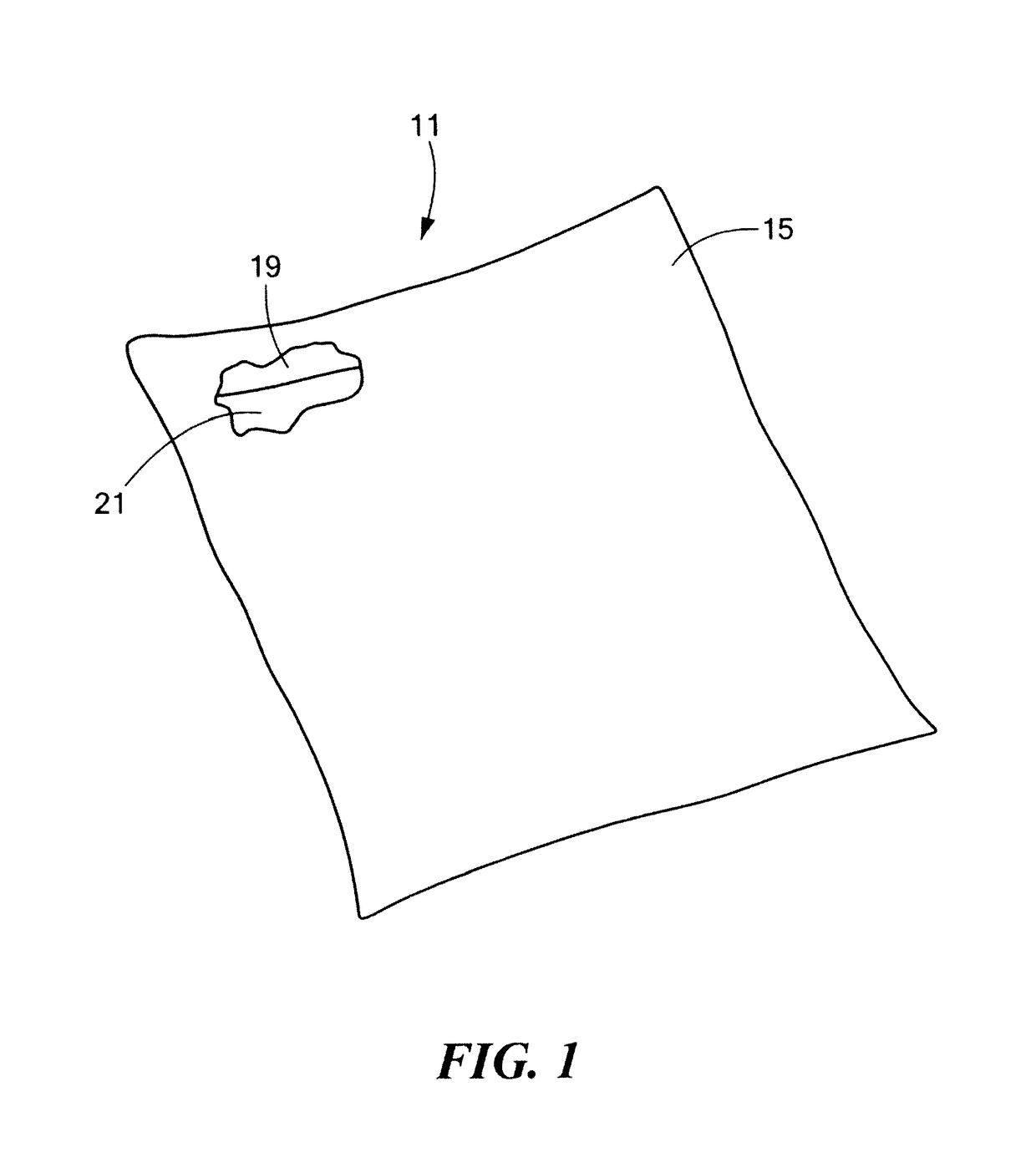

Gel comprising a phase-change material, method of preparing the gel, thermal exchange implement comprising the gel, and method of preparing the thermal exchange implement

Gel including a phase-change material and a gelling agent. In one embodiment, the phase-change material may be n-tetradecane, n-hexadecane or mixtures thereof. The gelling agent may be a high molecular weight styrene-ethylene-butylene-styrene (SEBS) triblock copolymer with a styrene:rubber ratio of about 30:70 to 33:67% by weight. To form the gel, the phase-change material and the gelling agent may be mixed at an elevated temperature relative to room temperature to partially, but not completely, dissolve the gelling agent. The mixture may then be cooled to room temperature. Alternatively, the phase-change material and the gelling agent may be mixed at room temperature, and the mixture may then be heated to form a viscoelastic liquid, which is then cooled to room temperature. The invention is also directed at a method of preparing the gel, a thermal exchange implement including the gel, and a method of preparing the thermal exchange implement.

Owner:COLD CHAIN TECH

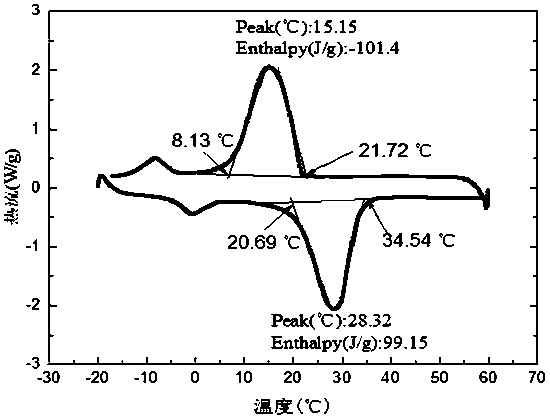

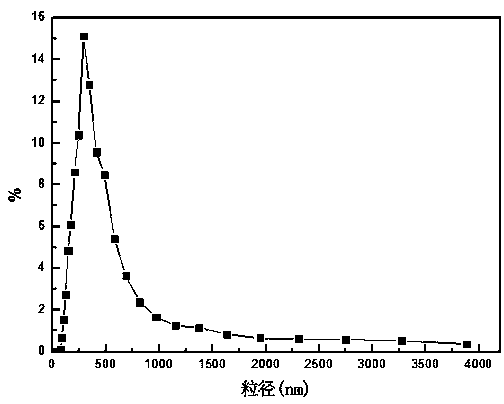

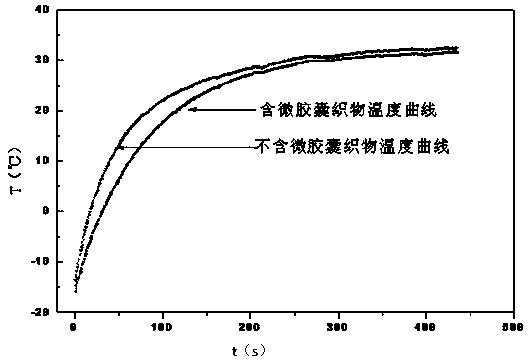

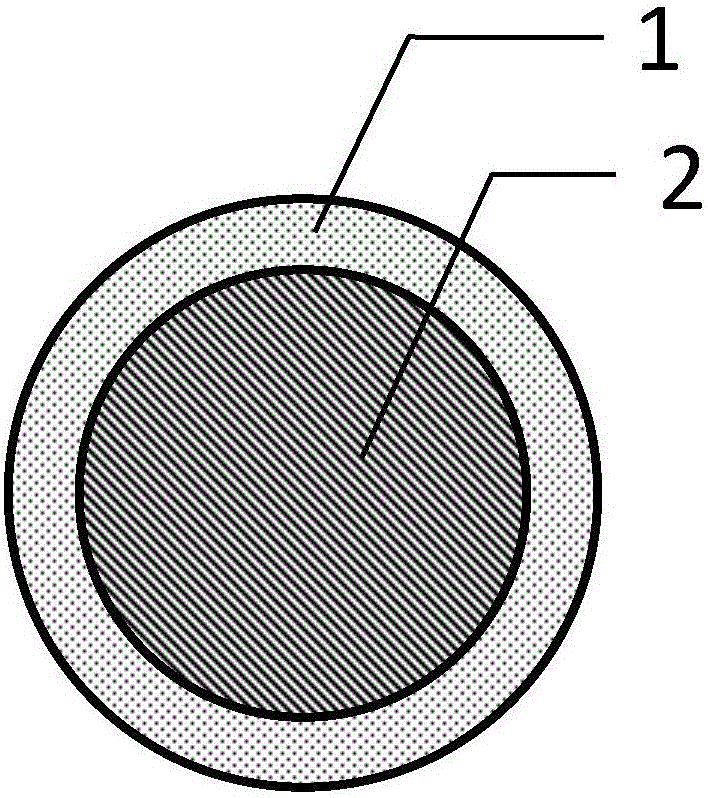

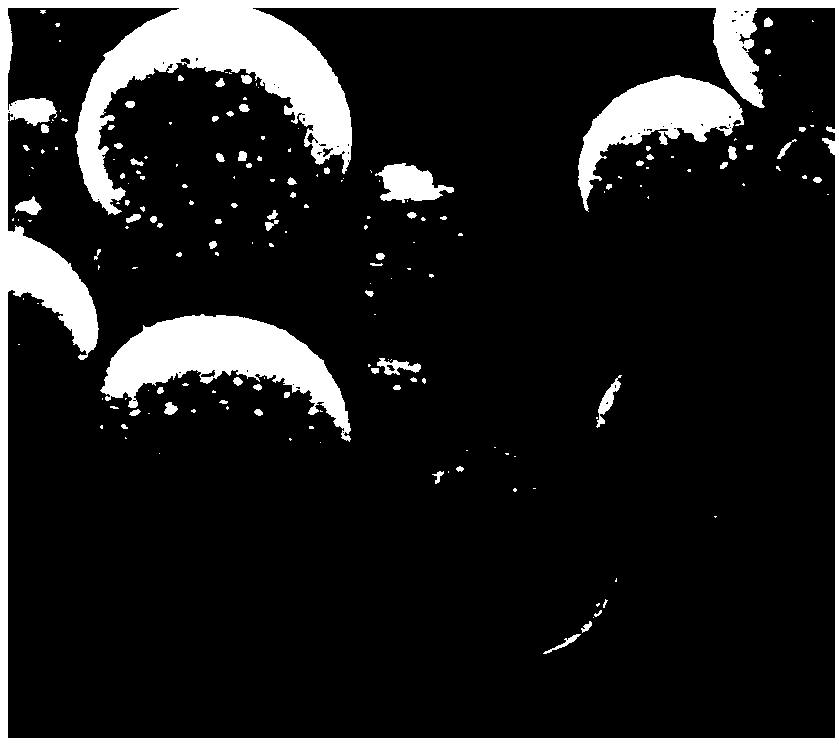

Phase change micro-capsule for clothing thermoregulation as well as preparation method and application thereof

InactiveCN103937461AImprove performanceNo corrosionHeat-exchange elementsVegetal fibresPolymer scienceN-hexadecane

The invention discloses a phase change micro-capsule for clothing thermoregulation as well as a preparation method and application thereof. The phase change micro-capsule for clothing thermoregulation comprises a core material and a wall material, wherein the core material is a mixture of n-octadecane and n-hexadecane, and the molar ratio between n-octadecane and n-hexadecane is (3 : 1)-(24 : 1); the wall material is methyl methacrylate; the phase change micro-capsule is applied to preparation of a clothing thermoregulation material. The phase change micro-capsule is stable in performance, non-toxic, non-corrosive and low in cost, can not cause super-cooling and super-heating phenomenon in use, has a melting and solidification temperature range just in the temperature range in which a human body can feel comfortable, is uniform in particle size distribution and appropriate in melting heat and solidification heat, meets the flexibility of finished fabrics in a later period, has a relatively large heat storage effect, and is suitable for performing thermoregulation on clothing.

Owner:SOUTH CHINA UNIV OF TECH

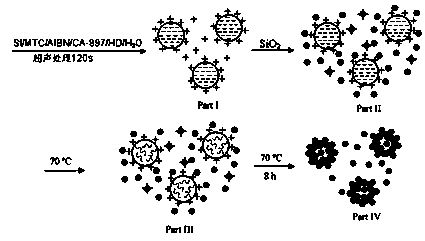

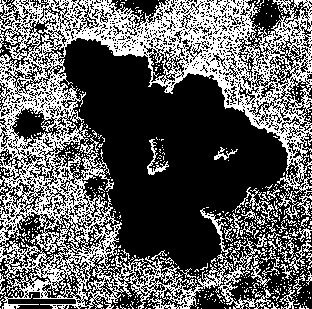

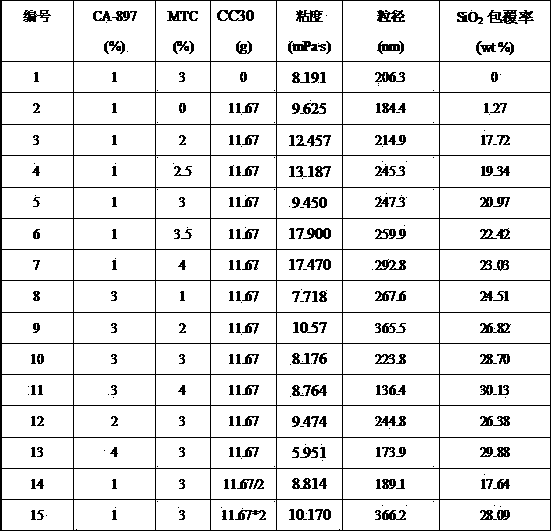

Preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres

The invention relates to a preparation method of strawberry-type polystyrene-silicon dioxide nanocomposite microspheres. The preparation method comprises the following steps: in a nitrogen atmosphere, mixing methacryloyloxyethyl trimethyl ammonium chloride, octaphenyl polyoxyethyiene and deionized water to obtain a water-phase mixture; dissolving azodiisobutyronitrile into styrene and n-hexadecane through ultrasonic wave to obtain an oil-phase mixture; dropping the oil-phase mixture into the water-phase mixture by using a constant-pressure dropping funnel to obtain mixed liquid; performing ultrasonic treatment on the mixed liquid under an ice-water mixed bath condition to obtain miniemulsion; dropwise adding silicon dioxide nanosol into the miniemulsion, and heating to obtain milky dispersion liquid; collecting and cooling the dispersion liquid, and centrifugating and dispersing until no free SiO2 particles exist under a transmission electron microscope, so as to obtain the strawberry-type polystyrene-silicon dioxide nanocomposite microspheres finally. The preparation method is simple and relatively low in cost and the SiO2 cladding rate is relatively high.

Owner:HUBEI UNIV

Processing method of waste plastic

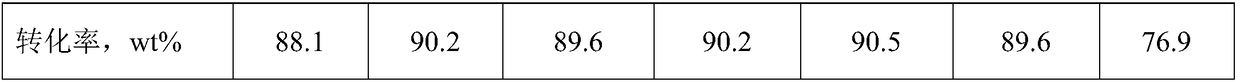

ActiveCN108456328AExpand the scope of recyclingImprove conversion ratePlastic recyclingCatalytic pyrolysisMolecular sieve

The invention discloses a processing method of waste plastic. The method comprises the following steps: adding the waste plastic, a modified catalyst and a reaction solvent into a catalytic pyrolysisreactor, so as to be uniformly mixed, and then performing catalytic pyrolysis reaction. The modified catalyst adopts a modifier oxide modified HZM-5 and HY composite molecular sieve, a modifier is selected from one or more in Sn, Fe, Ti and Zn, and the reaction solvent adopts a mixture of tetrahydronaphthalene and n-hexadecane. The conditions of the catalytic pyrolysis reaction are as follows: thereaction temperature is 150 to 300 DEG C; the reaction time is 120 to 240 minutes; the reaction is performed under stirring; the stirring speed is 600 to 1000 revolutions per minute; hydrogen is fedduring reaction; hydrogen partial pressure is 4 to 7MPa. The method obviously reduces the catalytic pyrolysis temperature of waste plastic on the promise of guaranteeing a high conversion rate, and saves energy.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

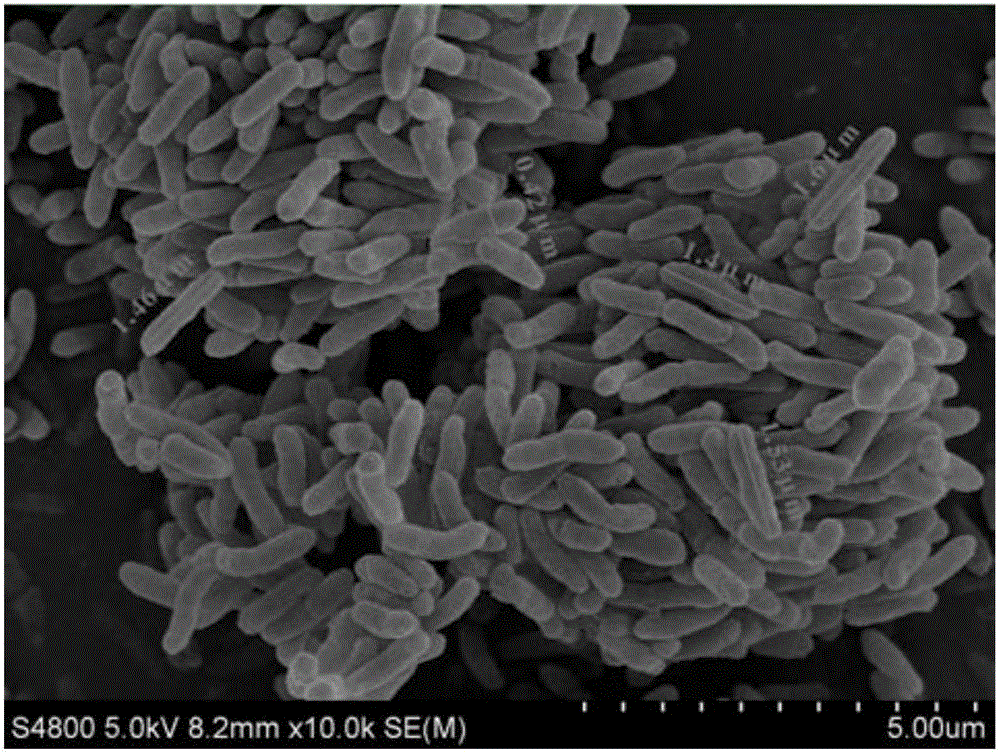

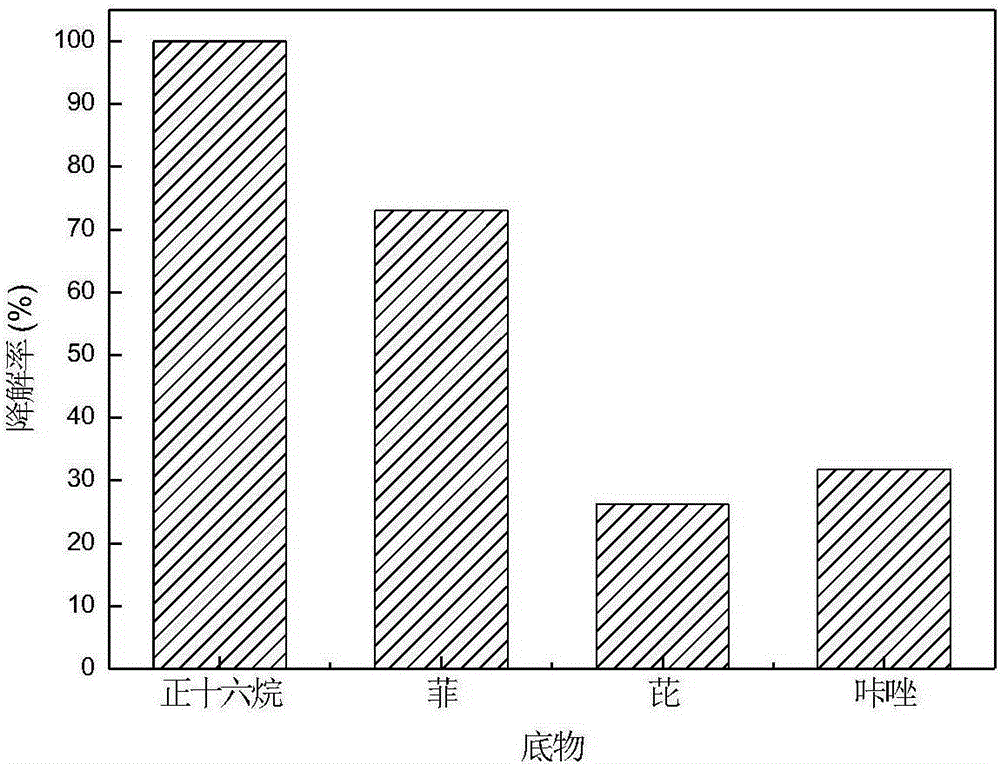

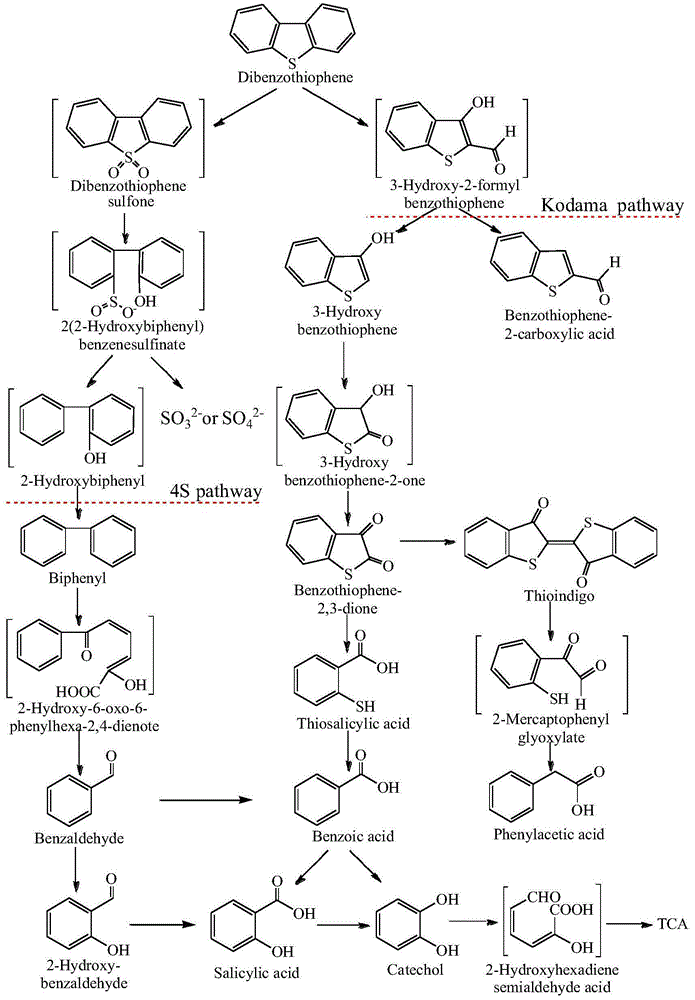

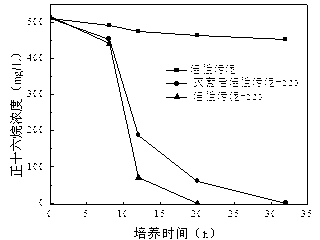

Pseudomonad strain and application thereof in degrading petroleum pollutants

The invention relates to the field of application of microbes in environmental pollutant degradation, particularly a pseudomonad strain and application thereof in degrading petroleum pollutants. The pseudomonad strain (Pseudomonas sp. LKY-5) is screened from petroleum polluted soil in Shengli Oil Field in China, and the collection number is CCTCC NO:M2015448. The screened Pseudomonas sp. LKY-5 can effectively degrade sulfur-containing heterocyclic aromatics, such as dibenzothiophene, benzothiophene, alkyl dibenzothiophene, 4,6-dimethyl dibenzothiophene, 2,4,6-trimethyl dibenzothiophene and the like. Meanwhile, the Pseudomonas sp. LKY-5 can degrade many other pollutants in crude oil, such as n-hexadecane, phenanthrene, pyrene, carbazole and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Microbial composite functional bacterial agent for treating coking wastewater and preparation method thereof

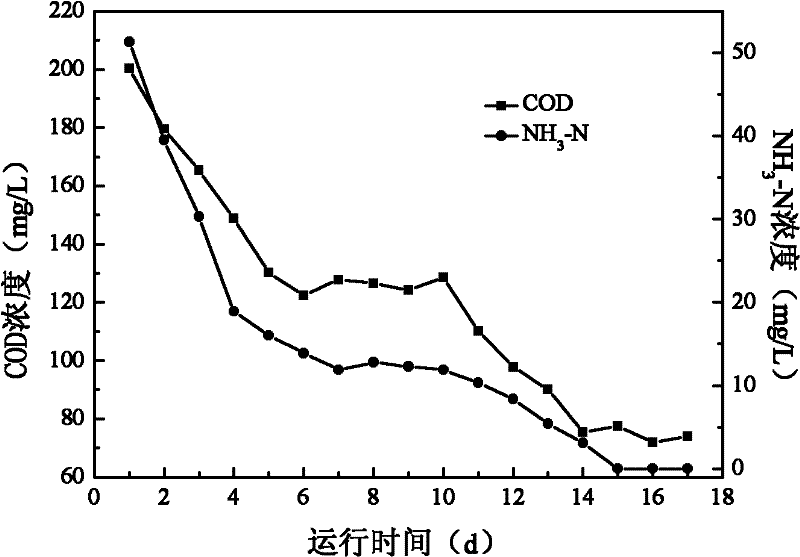

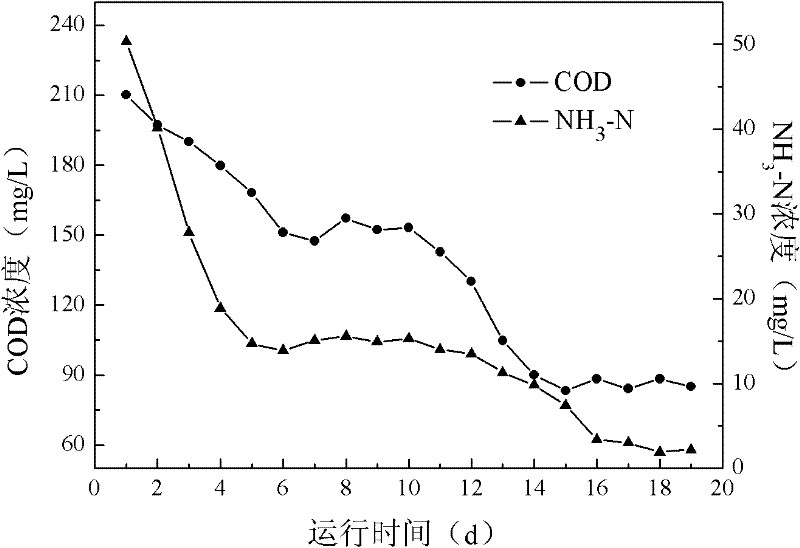

InactiveCN102337214AEfficient degradation abilityRemove inhibitionFungiBacteriaChemical oxygen demandEmission standard

The invention particularly relates to a microbial composite functional bacterial agent for treating coking wastewater and a preparation method thereof. According to the technical scheme, the microbial composite functional bacterial agent comprises the following microbes: 15-20wt% of n-hexadecane degrading bacteria, 20-30wt% of phenol degrading bacteria, 10-15wt% of pyridine degrading bacteria, 8-12wt% of chinoline degrading bacteria, 5-10wt% of carbazole degrading bacteria, 15-20wt% of naphthalene degrading bacteria and 8-12wt% of anthracene degrading bacteria. The microbial composite functional bacterial agent has the characteristics that: the composite functional bacterial agent prepared from artificially bred functional strains is added to an original biochemical treatment device, thus the removing capability of refractory organic matters in the coking wastewater is greatly improved and the contents of COD (chemical oxygen demand) and NH3-N in the coking biochemical effluent can both reach national first-level emission standard. The microbial composite functional bacterial agent has strong environment adaptability, good cooperativity, and broad application prospects in bioaugmentation of coking wastewater.

Owner:武钢集团有限公司 +1

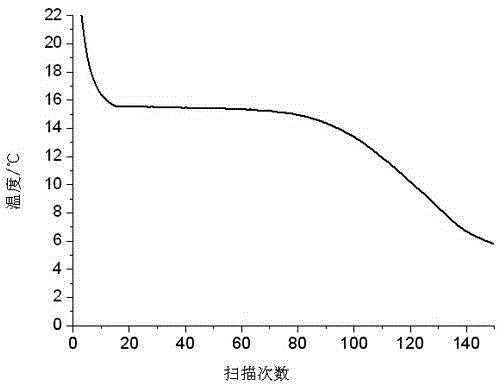

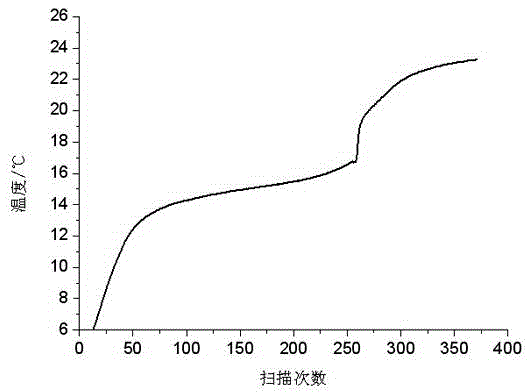

Solid-liquid phase change heat exchange working medium for power generation by oceanic thermal energy and preparation method of working medium

InactiveCN104059616AImprove thermal conductivityImprove heat transfer efficiencyMachines/enginesHeat-exchange elementsDispersion stabilityThermal energy

The invention discloses a solid-liquid phase change heat exchange working medium for power generation by oceanic thermal energy, wherein a ternary solid-liquid phase change heat exchange working medium matrix mixing material is prepared by mixing n-pentadecane (C15H32), n-hexadecane (C16H34) and n-hexadecane (C17H36) at a weight ratio of 6:60:34, and a modifying material with high-thermal conductivity, namely expanded graphite, is added into the mixed material so as to intensify the heat conductive performance. A dispersant, namely organic bentonite, is added into and the dispersion stability of the organic bentonite is improved by ultrasonic oscillation. The solid-liquid phase change temperature range of the solid-liquid phase change heat exchange working medium disclosed by the invention is 14.5-17.5 DEG C, the phase change potential heat value of the working medium is about 212.1kJ / kg and the volume expansion ratio of the working medium is about 8.5%. The material serving as the solid-liquid phase change heat exchange working medium for power generation by oceanic thermal energy can satisfy the basic requirements on solid-liquid phase change heat exchange working medium for power generation by oceanic thermal energy.

Owner:YANSHAN UNIV

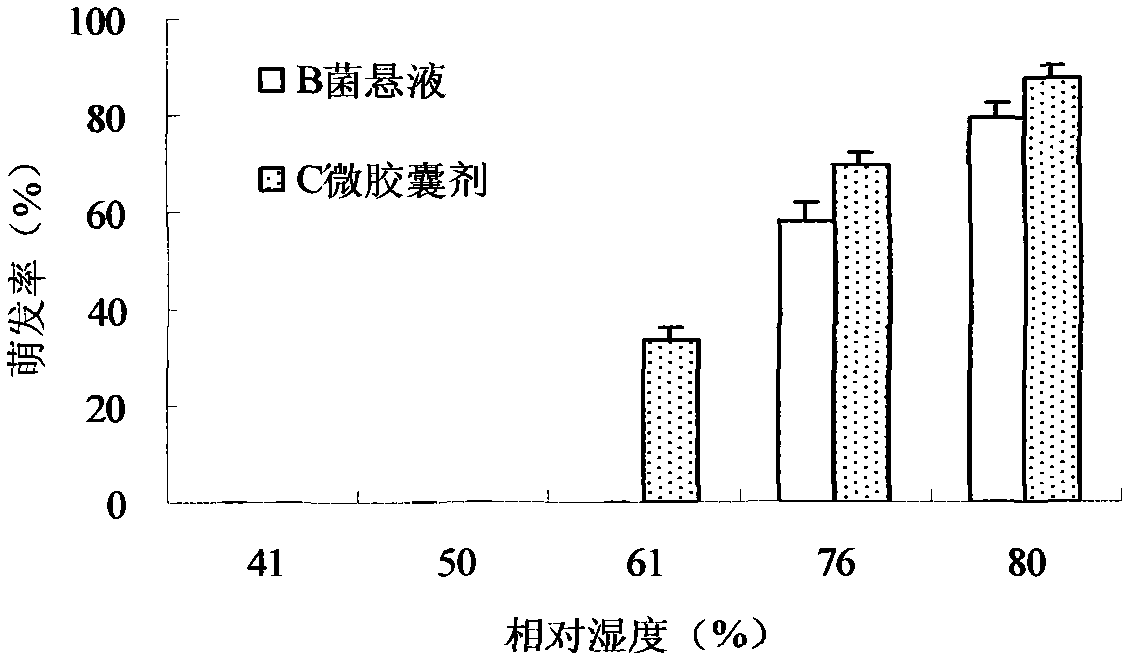

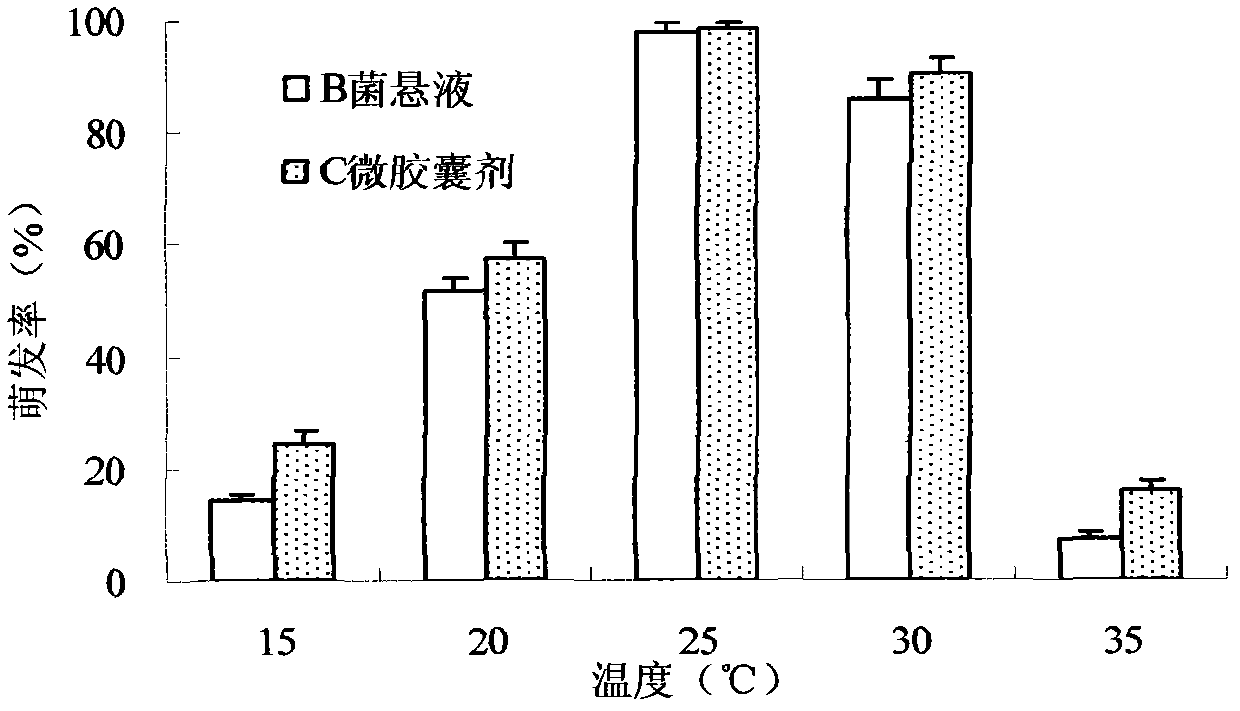

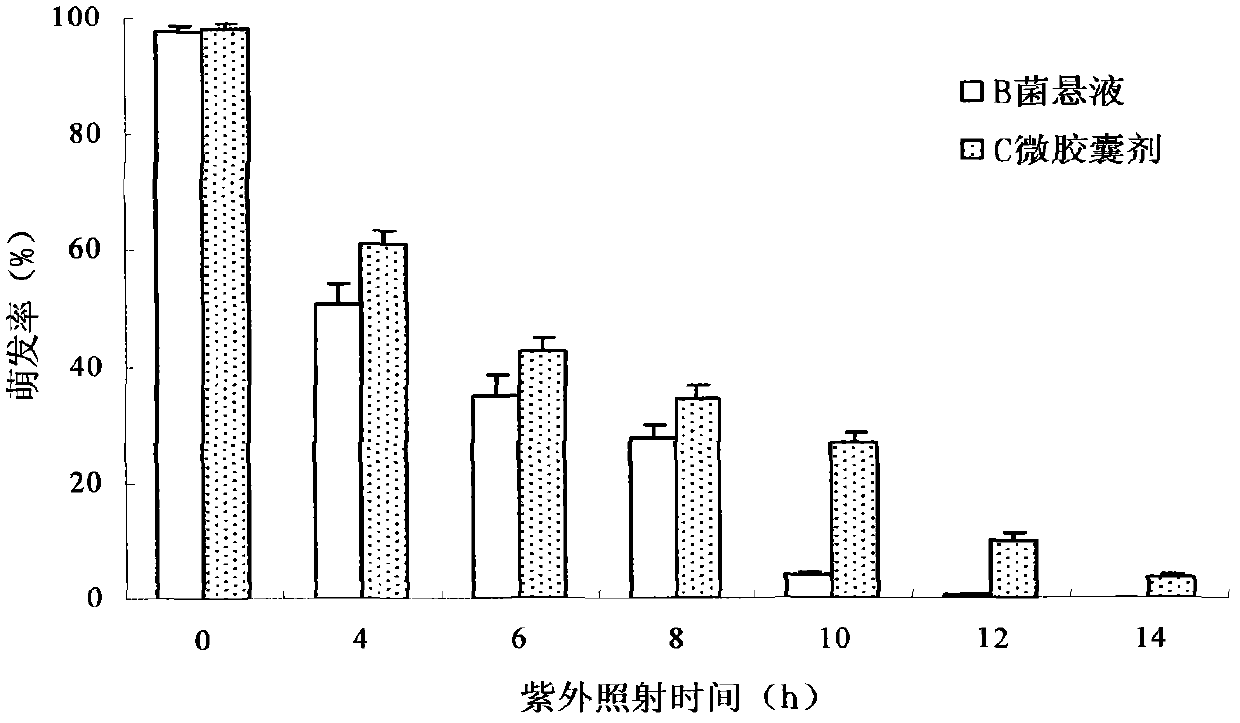

Beauveria bassiana microcapsule formulation

InactiveCN102578154ABarrier effectImprove the immunityBiocideAnimal repellantsSpore germinationBeauveria caledonica

The invention discloses a beauveria bassiana microcapsule formulation which is prepared by taking suspension prepared from beauveria bassiana conidia, kaolin and water as a capsule core, taking sodium alginate as a capsule wall, dispersing in a dispersing agent of n-hexadecane, corn oil and lecithin with different proportions, crosslinking through calcium ions, and solidifying microcapsules to enveloped fine particles with partical diameter being smaller than 100 Mu m. In the germination process of the beauveria bassiana conidia, a germ tube can perforate through the envelop of the capsule wall. The microcapsule formulation is also added with a conidium germination nutrient solution which increases the germination percentage and the germination speed of the conidia. The beauveria bassiana microcapsule formulation can effectively prevent the influences bad environments such as external ultraviolet rays and drying from the conidia, achieves high germination percentage under the influences of the same temperature, humidity and ultraviolet rays, and has good control effect to agriculture and forestry pests; and meanwhile the beauveria bassiana microcapsule formulation has simple production process and is easy for mass production.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

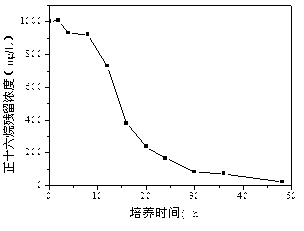

Alkane degrading bacteria and application thereof

InactiveCN102703348APromote degradationImprove solubilityBacteriaContaminated soil reclamationBiotechnologyPositive gram bacteria

The invention discloses an alkane degrading bacterium and an application thereof. The alkane degrading bacterium C20 provided by the invention belongs to Tsukamurellasp. The alkane degrading bacterium is preserved in China Center for Type Culture Collection on 23rd, March, 2012; the preservation number is CCTCC NO: M2012089; the GenBank accession number of the strain 16SrDNA is JQ806393. The alkane degrading bacterium is a gram-positive bacterium; the bacterial colony is chrysanthemum yellow, has regular edge, is round, has drying surface and raised centre; the thallus is in short-rod shape, is arranged in a chain shape and has no capsule under observation of a microscope. The degradation rate of the alkane degrading bacterium for 1000mg / L of n-hexadecane in 48h is more than 98%; medium-long-chain alkane (C12-C24) in the diesel can effectively degraded, and the alkane degrading bacterium metabolizes to produce a bio-emulsifier for accelerating oil to dissolve. The alkane degrading bacterium can be applied in biological strengthening treatment and repairing of refinery waste water, petroleum-polluted water and soil and has good prospect.

Owner:WUHAN UNIV OF SCI & TECH

New method for synthesizing and purifying n-eicosane

InactiveCN101712589ASolve outputReduce investmentHydrocarbon from halogen organic compoundsN-hexadecaneEconomic benefits

The invention relates to a new method for synthesizing and purifying n-eicosane, comprising the following steps: (1) mixing bromo-n-butane and bromo-n-hexadecane; (2) after mixing petroleum ether and mixed liquor, adding sodium to carry out reflux reaction for 1-2h; (3) after dropwise adding absolute ethanol and water, separating organic phase and rinsing organic phase until organic phase is neutral; (4) distilling and collecting distillate at 320-360 DEG C, after washing the distillate until organic phase is colorless or light yellow, rinsing organic phase until organic phase is neutral; and (5) after drying and filtering the organic phase, absorbing, distilling at reduced pressure and collecting the intermediate n-distillate, namely the n-eicosane product. The raw materials adopted in the invention are sufficiently supplied in the market, thus effectively solving the problem that the yield is affected by tension supply of the raw materials; the requirements for process conditions and production equipment are low, thus reducing the investment in equipment and saving the fund; meanwhile, the product quality can be evidently improved while increasing the yield, thus further increasing the economic benefits.

Owner:TIANJIN CHEM REAGENT RES INST

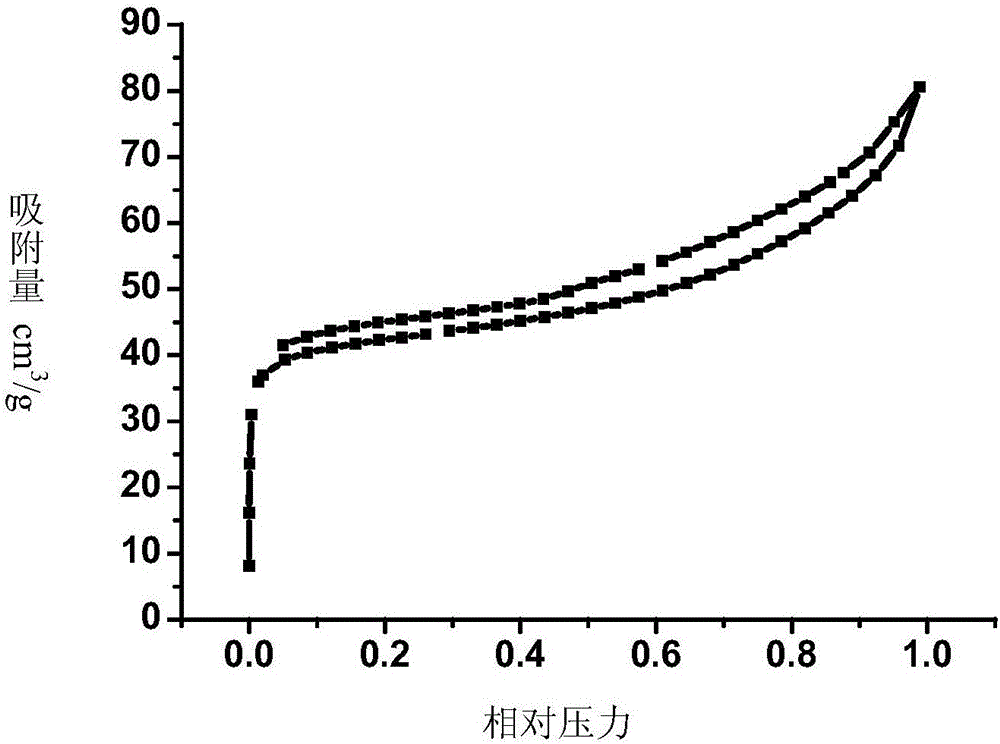

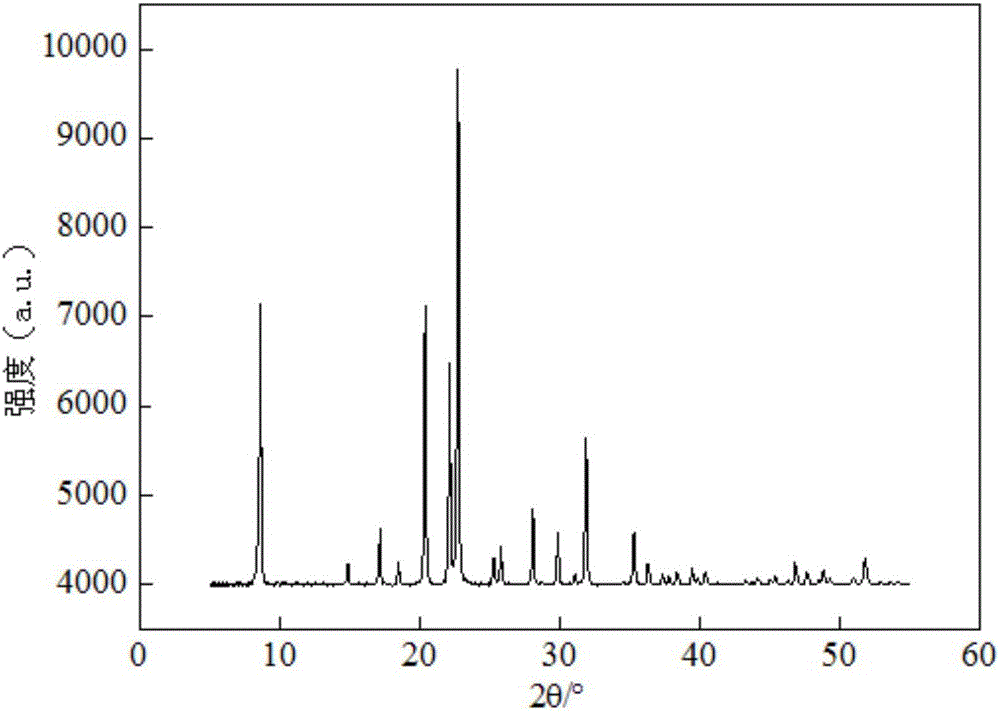

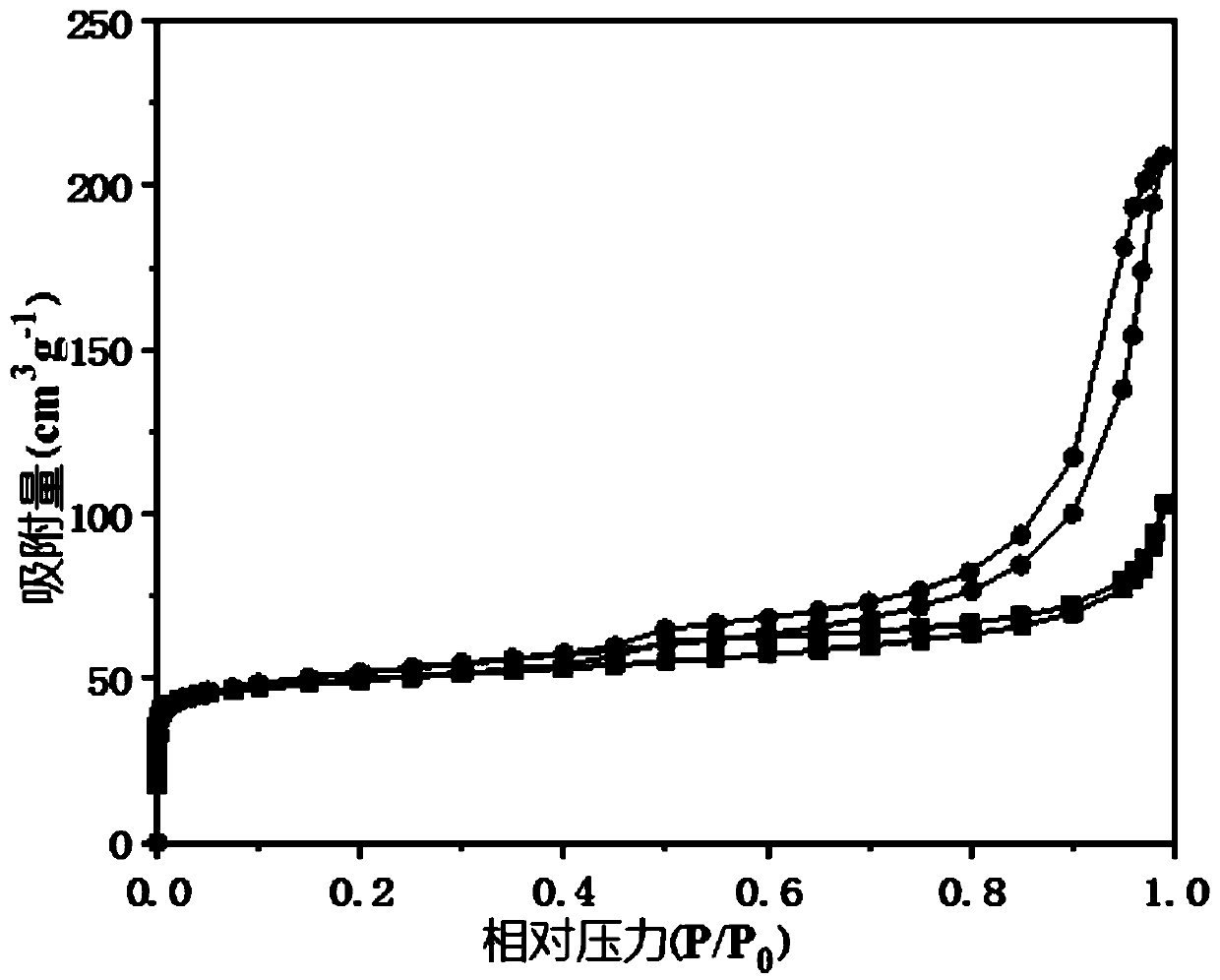

Hierarchically pored SAPO-11 molecular sieve and solid-phase synthesis method

ActiveCN106517230AReduce generationComplete AEL structureHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveN-hexadecane

The invention provides a hierarchically pored SAPO-11 molecular sieve and a solid-phase synthesis method. The solid-phase synthesis method comprises the steps that a solid silicon source, an aluminium source, a mesoporous template and a phosphorus source are mixed, ground and subjected to a crystallization reaction at 140-220 DEG C for 12-72 h, a product is dried centrifugally and roasted, and the hierarchically pored SAPO-11 molecular sieve is obtained after the template is removed. The conversion rate of a hydroisomerization reaction of n-hexadecane by the prepared hierarchically pored SAPO-11 molecular sieve is 83.5%, and the stereoselectivity is 82.1% (under reaction conditions of 290 DEG C, 6MPa, WHSV being 1<-1> and nH2:nC16 being 15. Compared with the prior art, the obtained product not only has a complete AEL structure of the SAPO-11 molecular sieve and higher crystallinity, but also has a mesoporous structure, besides, water is not used in a synthesis process of the molecular sieve, so that produced wastewater is reduced in a production process, and the yield and single-reactor yield are increased to a greater extent.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

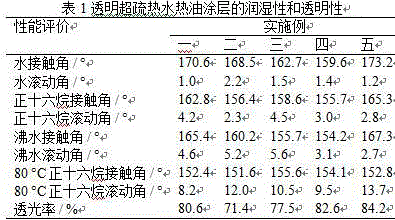

Preparation method of transparent super-amphiphobic hot water and hot oil coating

The invention discloses a preparation method of a transparent super-amphiphobic hot water and hot oil coating. The preparation method comprises the following steps of taking a carbon nanotube as a template, constructing a casing layer on the surface of the carbon nanotube by surface crosslinking modification of organosilicone and crosslinking the carbon nanotube to form a crosslinked network structure; removing the carbon nanotube template and functional groups of the organosilicone by thermal treatment to form a transparent crosslinking micro-nano structure; then uniformly modifying the coating by adopting low-concentration perfluorinated alkyl silane through a liquid phase method, and guaranteeing the transparency of the coating while endowing the coating with super-amphiphobic property. Through detection, a contact angle of the coating prepared by the invention to water and n-hexadecane is greater than 155 degrees, and a rolling angle of the coating to the water and the n-hexadecane is smaller than 5 degrees; a contact angle of the coating to boiling water and 80DEG C n-hexadecane is greater than 150 degrees, and a rolling angle of the coating to the boiling water and the 80DEG C n-hexadecane is smaller than 10DEG C; and the light transmittance of the coating in a visible region is greater than 70 percent. The preparation method is suitable for preparing various super-amphiphobic hot water and hot oil coatings which are prepared from high-temperature-resisting substrate materials and have transparent surfaces.

Owner:上海必定化工有限公司

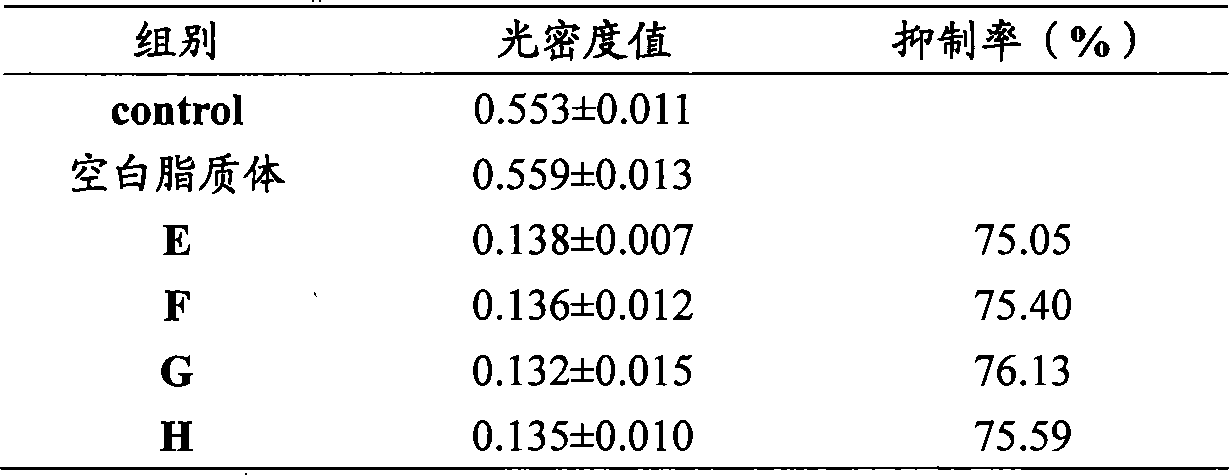

Integrin receptor target lipidosome drug carrier, preparation method and application thereof

The invention discloses an integrin receptor target lipidosome drug carrier and a preparation method thereof, as well as an application of the drug carrier in preparing antitumor lipidosome drug. Hexadecyl fatty chain is conjugated with RGD peptide segment and is hydrophobic-modified so as to synthesize hexadecyl and RGD peptide conjugate with amphipathy, namely, Arg-Gly-Asp-X-NH-C16H33, and X is selected from valine, serine or phenylalanine. The invention introduces fat-soluble antitumor drug into the conjugate with amphipathy to obtain the antitumor target lipidosome drug, the lipidosome system can increase the concentration of the antitumor drug at the target and can reduce toxic and side effects of the antitumor drug to the non-target part, thereby improving the treatment index of the drug. The invention evaluates the antitumor activity of taxol lipidosome by using a Holland sarcoma S180 mouse as a model, the result shows that the taxol lipidosome has more excellent antitumor activity than each control group.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

Phase change latent heat environment-friendly energy-saving type building material and preparation method thereof

The invention discloses a phase change latent heat environment-friendly energy-saving type building material and a preparation method thereof. The phase change latent heat environment-friendly energy-saving type building material comprises 50-80 parts of cement, 30-50 parts of diatomite, 0.5-3.5 parts of acetyl tributyl citrate, 1-5 parts of an aliphatic water reducer, 10-15 parts of poly-2,6-naphthalene acid ethyl ester fiber, 2-7 parts of expanded vermiculite, 30-50 parts of triethylene glycol monomethyl ether, 8-15 parts of sebacic acid, 5-10 parts of tetradecanoic acid and 12-20 parts of n-hexadecane. The method comprises the steps that the sebacic acid, the tetradecanoic acid and the n-hexadecane are mixed and stirred at the temperature of 130-150 DEG C; the expanded vermiculite and the triethylene glycol monomethyl ether are added, the temperature is decreased to be 80-120 DEG C, and stirring continues to be performed; the cement, the diatomite, the acetyl tributyl citrate, the aliphatic water reducer and the poly-2,6-naphthalene acid ethyl ester fiber are added into the mixture after the temperature is decreased to be 50-60 DEG C, the temperature is increased to be 90-130 DEG C, and a vaccumizing reaction is performed for 20-40 min; after cooling is performed, drying and pressing in a drying oven are performed, and then the phase change latent heat environment-friendly energy-saving type building material can be obtained. The building material is high in heat conductivity coefficient, good in fixation and formation and resistant to fire, meanwhile energy consumption is saved, and the comfort is improved.

Owner:刘致浦

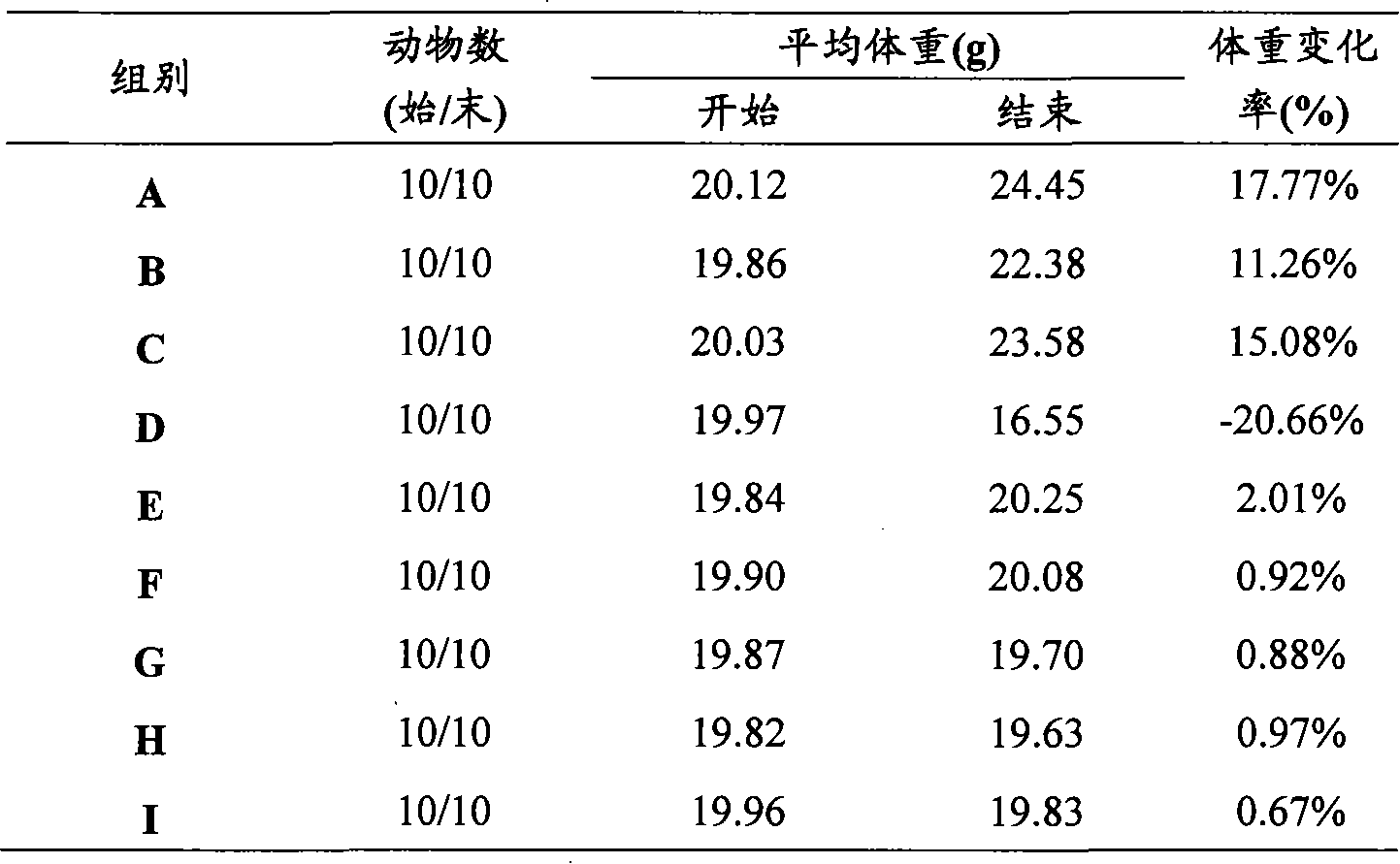

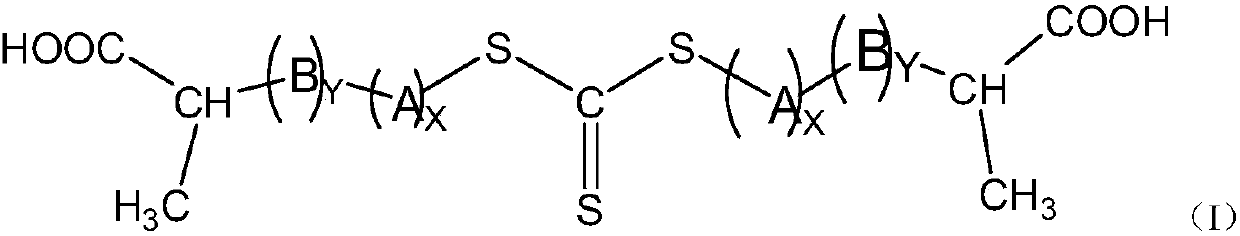

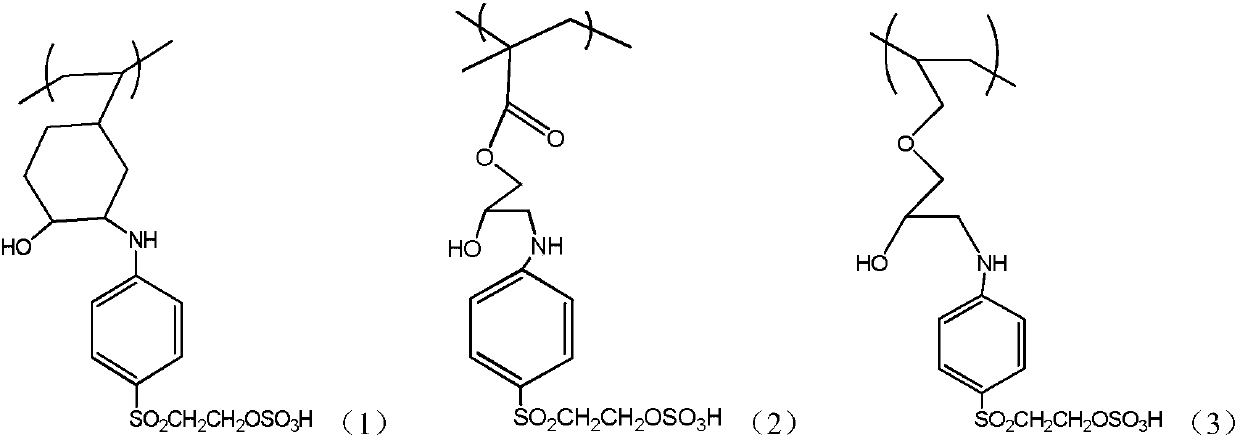

Highly washable and friction-resistant ink for cotton fabrics and preparation method thereof

The invention discloses highly washable and friction-resistant ink for cotton fabrics. The ink is composed of the following components in parts by weight: 3-5 parts of pigments, 2.5-6.5 parts of macromolecular trisulfide carbonate compounds, 0.8-1.0 part of lauryl sodium sulfate, 0.8-1.0 part of n-hexadecane, 15-18 parts of soft monomers, 2-5 parts of hard monomers, 0.03-0.05 part of a water-soluble initiator and 65-80 parts of deionized water. Compared with the traditional non-structured or non-block structure type adhesive film, the block 'core-shell' structure coated ink designed in the invention has excellent mechanical property after film forming, and an RAFT living polymerization technology is adopted when a basic molecular chain structure of the adhesive film is designed, so that each macromolecular chain is directionally and quantitatively grafted with active groups that can carry out characteristic reactions with the cotton fabrics, binding force between the adhesive layer ofthe ink and fibers of the cotton fabrics is greatly enhanced on a molecular level, and macroscopic performances such as washable property and fastness to rubbing of the ink are improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Fluorescence enhancement type encoding beads and preparing method thereof

ActiveCN106226279ASimple codingEasy to decodeFluorescence/phosphorescenceMicroballoon preparationMicrospherePolyvinyl alcohol

Owner:SOUTHEAST UNIV

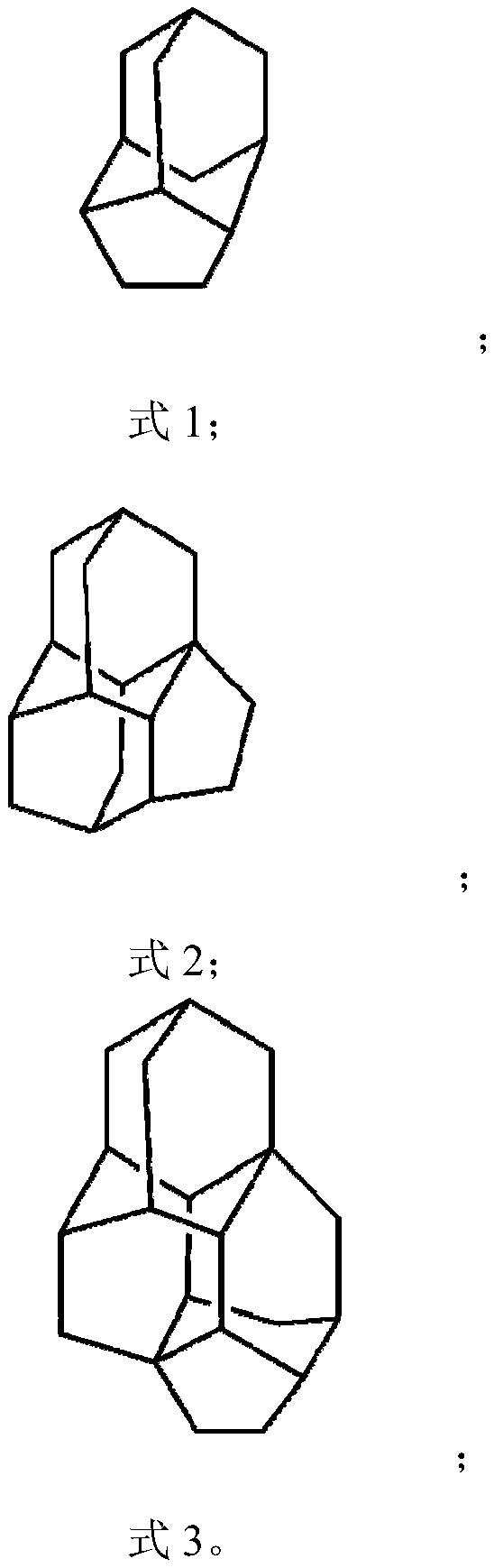

Method for determining biodegradation degree of crude oil

ActiveCN110412143AComponent separationMaterial analysis by electric/magnetic meansN-dodecaneN-hexadecane

The invention provides a method for determining the biodegradation degree of crude oil. The method comprises the following steps: 1, an ethanonoradamantane compound in a crude oil sample is subjectedto identification and quantitative analysis by means of comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometer; 2, according to identification and quantitative analysis results obtained in the step 1, the content ratios of non-substituted single-caged ethanonoradamantane and non-substituted dicaged ethanonoradamantane to n-dodecane and n-hexadecane are calculated; and 3,according to the content ratios obtained in the step 2, the biodegradation degree of the crude oil is determined. By means of the method, the biodegradation degree of the crude oil can be quantitatively determined, and the method is low in degree of dependence on personal experience and accurate in judgment on the biodegradation degree of the crude oil.

Owner:PETROCHINA CO LTD

Internal and external multiple-phase-change thermal insulation building block

InactiveCN103541484AStable outside temperatureComfortable outside temperatureConstruction materialInsulation layerThermal insulation

The invention provides an internal and external multiple-phase-change thermal insulation building block. The internal and external multiple-phase-change thermal insulation building block comprises an intermediate insulating layer, an external phase change layer, an internal phase change layer, intermediate insulating layer ribs, external phase change layer ribs, internal phase change layer ribs and a building block protective layer, wherein the intermediate insulating layer is arranged inside a building block and is separated by one or two intermediate insulating layer ribs; the external phase change layer and the internal phase change layer are respectively arranged on the two sides of the intermediate insulating layer; the external phase change layer and the internal phase change layer are separated by multiple external phase change layer ribs and multiple internal phase change layer ribs respectively; the internal phase change layer adopts paraffin microcapsule, n-hexadecane microcapsule and n-octadecane microcapsule as a phase change thermal insulation material; the external phase change layer adopts the paraffin microcapsule, the n-hexadecane microcapsule, the n-octadecane microcapsule, n-tetracosane microcapsule and stearic acid microcapsule as a phase change thermal insulation material. The internal and external multiple-phase-change thermal insulation building block has the beneficial effects and advantages that a phase change material still can bring the superiority of phase change energy storage to fully play under the condition that an outdoor temperature is greatly changed, energy is saved, thermal insulation is realized, and an indoor temperature is stable and comfortable.

Owner:SHENYANG JIANZHU UNIVERSITY

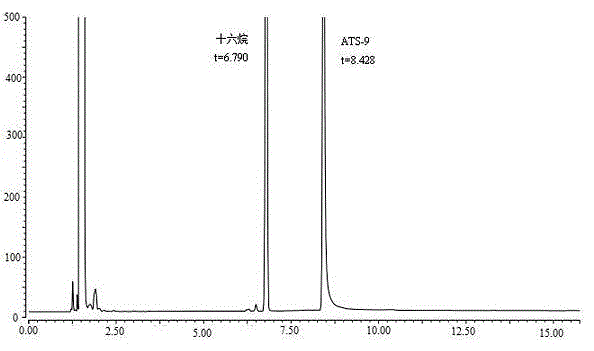

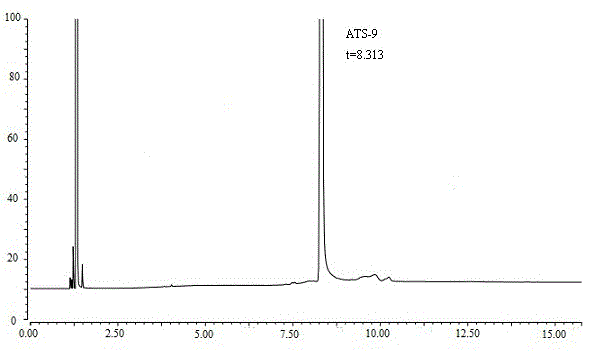

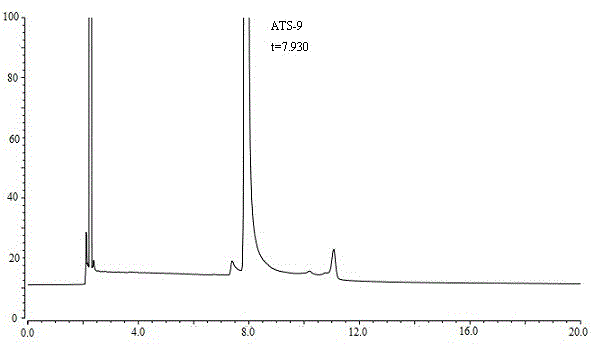

Method for determining (4R, 6R) -6-aminoethyl-2,2-dimethyl-1,3-dioxane-4- tert-butyl acetate content

ActiveCN105136921AAccurate contentAccurate detectionComponent separationCapillary gas chromatographyN-hexadecane

The present invention discloses a method for determining (4R, 6R) -6--aminoethyl-2,2-dimethyl-1,3-dioxane-4- tert-butyl acetate content. The method is as follows: ATS-9 is diluted with 1,2-dichloroethane, an Agilent DB-624 capillary gas chromatography column is used, a hydrogen flame ionization detector is used, appropriate temperature programing, vaporization chamber temperature and detector temperature are set, nitrogen is used as a carrier gas, n-hexadecane is used as an internal standard for detection, and ATS-9 content in a to-be-tested solution can be calculated by internal standard method according to the gas chromatogram. The ATS-9 and related substances and the internal standard can be effectively separated, and the method is rapid, accurate, simple and well reproducible, and lays the foundation for the establishment of ATS-9 quality standards.

Owner:HENAN ZHIWEI BIOMEDICINE CO LTD

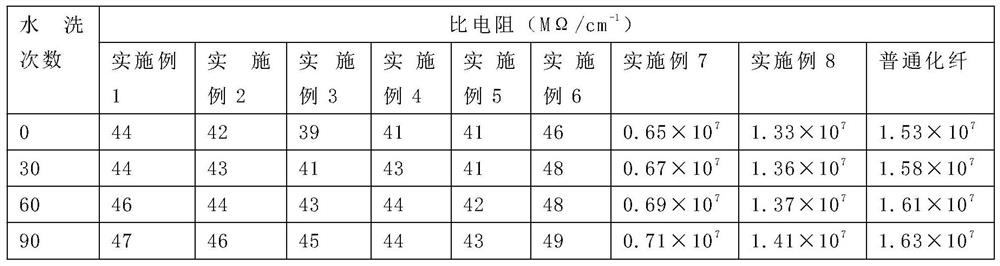

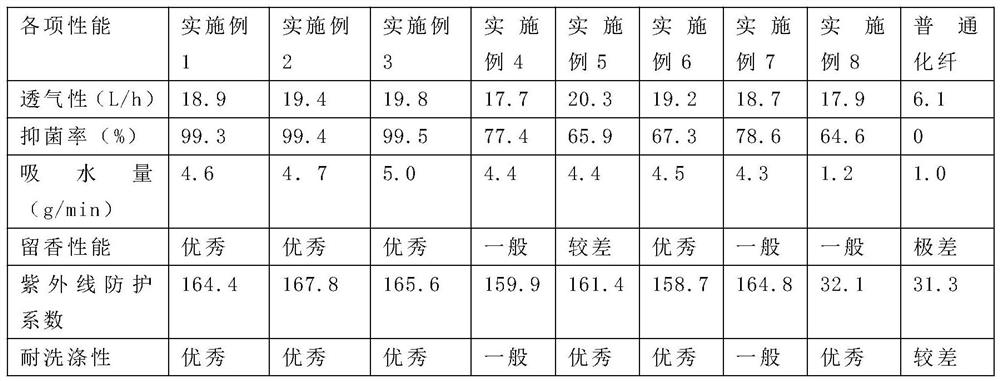

Uvioresistant and anti-static chemical fiber yarn and preparation method thereof

InactiveCN111850764ALarge specific surface areaChange surface topographyBiochemical fibre treatmentLight resistant fibresFiberYarn

The invention discloses a uvioresistant and anti-static chemical fiber yarn and a preparation method thereof. The preparation method comprises the following steps: at first, loading a plurality of silver ions on a modified metal organic framework, blending with spinning solution to obtain chemical fiber, grafting AESO outside the chemical fiber, and carrying out copolymerization on modified microspheres to obtain a chemical fiber inner layer; manufacturing modified microspheres by taking methyl methacrylate as a wall material and taking hexadecane, plant essence and beta-1,4-polyglucosamine ascore materials; and adding an ultraviolet absorbent and dopamine in absorbing film slurry, and soaking the fiber inner layer in the absorbing film slurry for 20-30 hours, and taking the fiber inner layer out. Through synergistic effect of the modified metal organic framework, the modified microspheres, the absorbing film slurry and the like, the problems about hydroscopicity, antibacterial property, fragrance retention property and washability of common chemical fiber fabric are improved to a greater degree, and higher practicality is improved.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

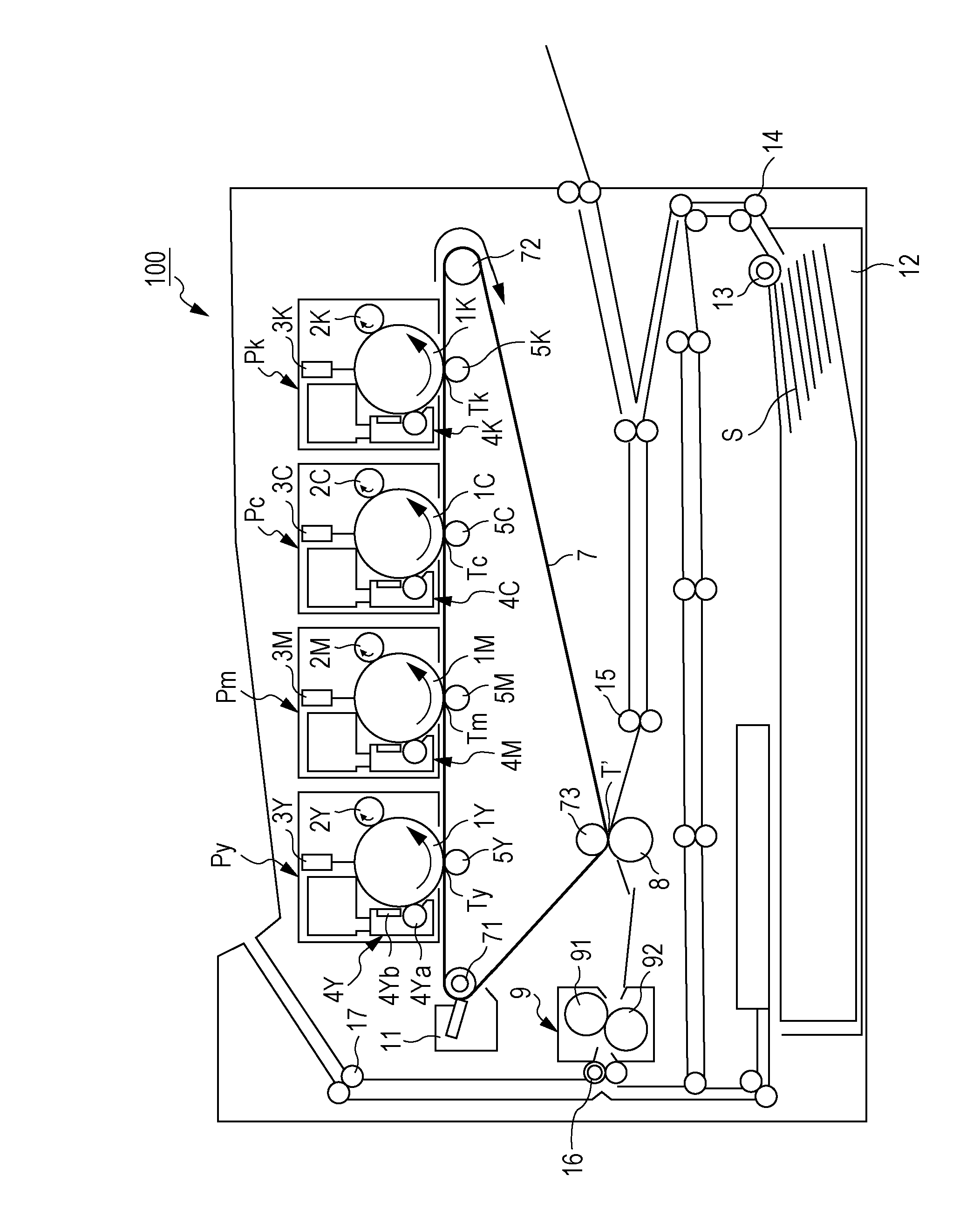

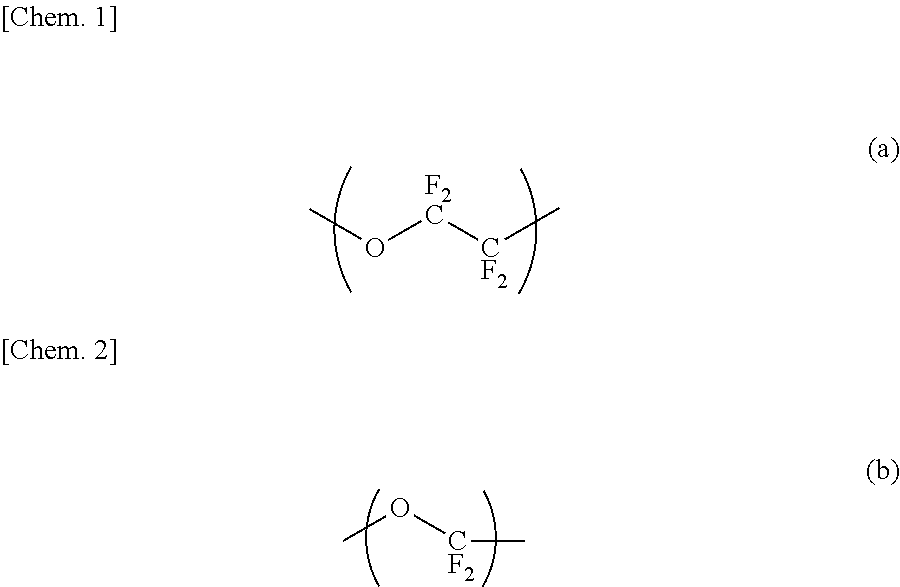

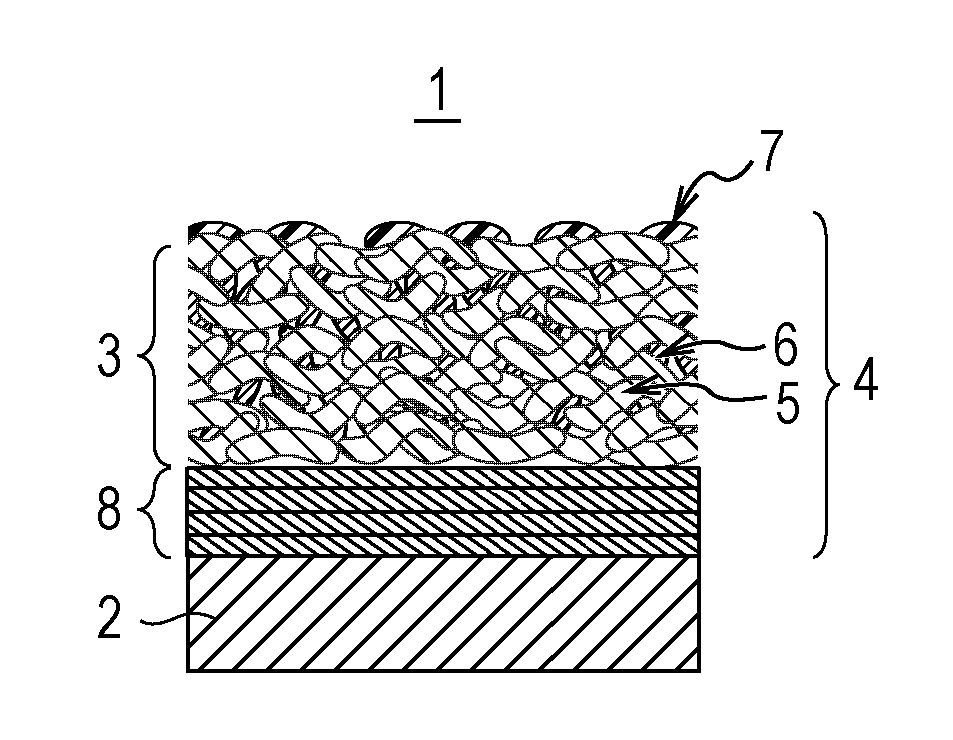

Intermediate transfer member for electrophotography and electrophotographic apparatus

ActiveUS20140377564A1Prevent image defectsHigh quality imagingLayered productsElectrographic process apparatusCelsius DegreeSurface layer

An intermediate transfer member for electrophotography comprising a substrate and a surface layer provided on the substrate. The surface layer comprises a binder resin and a perfluoropolyether. An extraction amount of the perfluoropolyether per 10 mm3 of the surface layer, is 0.10 mg or more and 5.00 mg or less, the extraction amount of the perfluoropolyether obtained by immersing the intermediate transfer member into a solvent that can dissolve the perfluoropolyether at 25 degrees in Celsius for 24 hours. A surface of the intermediate transfer member that is not subjected to first and second treatments, has a n-hexadecane contact angle of 55 degrees or more. A surface of the intermediate transfer member that has been subjected to the first treatment, has a n-hexadecane contact angle of 40 degrees or less. A surface of the intermediate transfer member that has been subjected to the second treatment, has a n-hexadecane contact angle of 50 degrees or more.

Owner:CANON KK

N-hexadecane hydroisomerization reaction method on loaded crystalline state nickel phosphide catalyst

ActiveCN106748613ALow costImprove toleranceMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to an n-hexadecane hydroisomerization reaction method on a loaded crystalline state nickel phosphide catalyst, belongs to the field of heavy alkane isomerization, and particularly relates to the n-hexadecane hydroisomerization reaction method on the loaded crystalline state nickel phosphide catalyst. The invention aims at solving the problems of a precious-metal-containing catalyst used for long-carbon-chain heavy alkane isomerization in the prior art of high cost and poor sulfide poisonousness resistant performance and the problem of a precious-metal-free isomerization catalyst of low selectivity. According to the method, Ni(NO3)2 6H2O and (NH4)2HPO4 are dissolved into water; SAPO-31 molecular sieves are added; drying is performed at the temperature being 100 DEG C; then, the materials are put into a muffle furnace to be roasted; then, temperature-programmed reduction is performed in hydrogen gas atmosphere to obtain the catalyst; the catalyst is filled into a reactor; the n-hexadecane hydroisomerization reaction is performed.

Owner:HEILONGJIANG UNIV

Self-repairing microencapsulated lithium ion battery electrode material and preparation method thereof, lithium ion battery negative electrode and lithium ion battery

ActiveCN109103435AImproves Structural IntegrityWith self-healing functionCell electrodesSecondary cellsArgon atmosphereN-hexadecane

The invention provides a self-repairing microencapsulated lithium ion battery electrode material and a preparation method thereof, a lithium ion battery negative electrode and a lithium ion battery. Liquid alloy particles are mixed with n-hexadecane, liquid alloy particles are used as anode active material, and urea, resorcinol, ammonium chloride and polyvinyl maleic anhydride copolymer are reacted to form resin as shell of capsule. Compared with the prior art, the capsule prepared by the invention encapsulates the liquid alloy particles, has stable chemical properties, and is carbonized at ahigh temperature in an argon atmosphere to finally obtain a carbonized liquid alloy material. The capsule structure can well contain the volume change of liquid alloy particles in the charge and discharge process, greatly improve the structural integrity of liquid alloy particles, and has the function of self-repair. Using this material as the cathode of lithium ion battery, it has the characteristics of high capacity and stable cycling performance. The method provided by the invention is simple, has high yield and good controllability.

Owner:ANHUI NORMAL UNIV

Optical member and method for manufacturing the same

An optical member includes a substrate and an antireflection film on the substrate. The antireflection film includes a porous layer at the surface thereof. The porous layer contains silicon oxide particles and a binder. The porous layer is provided with a fluororesin on at least part of the surface of the porous layer. The contact angle of n-hexadecane on the surface of the antireflection film is in the range of 50° to 80°.

Owner:CANON KK

Method for preparing isohexadecane by using Pd-supported SAPO-31 molecular sieve nanocrystalline bifunctional catalyst

ActiveCN110330402ALow costShorten the diffusion distanceHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention discloses a method for preparing isohexadecane by using a Pd-supported SAPO-31 molecular sieve nanocrystalline bifunctional catalyst, and relates to a method for preparing isoparaffin byadopting the bifunctional catalyst through n-alkane hydroisomerization reaction. The invention aims to solve the problems that the cost of the catalyst is increased due to high loading capacity of noble metals in the catalyst prepared in the prior art, and the selectivity of isomerization reaction is reduced due to large grain size of a micron-sized molecular sieve adopted by the existing catalyst. The method comprises the following steps: with the Pd-supported SAPO-31 molecular sieve nanocrystalline as a bifunctional catalyst, carrying out n-hexadecane hydroisomerization reaction on a fixedbed reactor to prepare isohexadecane. The method has the advantages that the loading capacity of Pd is 0.02 wt%-0.09 wt%; and the proportion of polybranched isomers in the isohexadecane reaches more than 50%. The method is mainly used for preparing isohexadecane.

Owner:HEILONGJIANG UNIV

A pandoraea sp. strain and an application method thereof

The objective of the invention is to develop a microbiological method for treating gasoline type petroleum hydrocarbons, and the invention provides a pandoraea sp. strain and an application method thereof. The strain is pandoraea sp. JWJ-06, and is called pandoraea sp. JWJ-06 for short, and the accession number of the pandoraea sp. is CGMCC No.13558. The application method includes degrading organic compounds or waste water containing organic compounds by adopting the pandoraea sp.. The organic compounds are gasoline type petroleum hydrocarbons, n-hexadecane, toluene, or a mixture of two or three of the gasoline type petroleum hydrocarbons, the n-hexadecane and the toluene. The pandoraea sp. has good degradation effects on the n-hexadecane, single-ring benzene compounds and the gasoline type petroleum hydrocarbons, can rapidly and relatively-completely degrade the n-hexadecane, the single-ring benzene compounds and the gasoline type petroleum hydrocarbons, and provides a novel route for solving a problem that gasoline or other petroleum hydrocarbons pollutes the environment.

Owner:UNIV OF SCI & TECH LIAONING

Electrophotographic member, intermediate transfer member and electrophotographic image forming apparatus

ActiveUS9606478B2Suppressing bleedingMaintaining toner releasabilityLayered productsElectrographic process apparatusSurface layerN-hexadecane

An electrophotographic member which has resistance to discharge degradation and can maintain the toner releasability for a long period is provided. The electrophotographic member includes a substrate and a surface layer. The surface layer includes a binder resin having an acrylic skeleton and a modified silicone compound having a polyether group and a hydroxyl group in a molecule, the surface layer having a surface having a n-hexadecane contact angle of 30° or more.

Owner:CANON KK

Composite non-woven fabric suitable for oil-water separation and preparation method thereof

InactiveCN107630355AOil phase high breakdown pressureHigh breakdown pressureFatty/oily/floating substances removal devicesFibre typesEthylenediamineN-hexadecane

The invention discloses a composite non-woven fabric suitable for oil-water separation and a preparation method thereof. The non-woven fabric comprises: 28-50 parts of polypropylene non-woven fabric,12-26 parts of acetone, 10-25 parts of acrylic acid, 12-25 parts of benzophenone, 13-19 parts of dichloroethane, 8-19 parts of calcium chloride, 8-19 parts of sodium carbonate, 19-32 parts of calciumcarbonate, 15-28 parts of n-hexadecane, 17-27 parts of sodium periodate, 7-20 parts of ethylenediamine, and 23-39 parts of dimethylsulfoxide. According to the method, a co-radiation method is employedfor grafting of acrylic acid to the polypropylene non-woven fabric and then mineralization is carried out, in a solid-water-oil three-phase system, a mineral layer on the non-woven fabric surface plays a role of rigid and stable moisture retention layer, and a mineralized membrane shows the underwater superoleophobic and oil drop adhesion layer effects. The composite non-woven fabric suitable foroil-water separation provided by the invention has the advantages of high oil phase disruptive pressure, small transmembrane resistance, and high retention rate of large-size emulsion droplets.

Owner:苏州市苏真床垫有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com