Preparation method of transparent super-amphiphobic hot water and hot oil coating

A coating and transparent technology, applied in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of poor transparency of super-amphiphobic coatings, poor performance of hydrophobic hot water and oil, etc., and achieve excellent stability. performance, improve stability, and efficiently disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

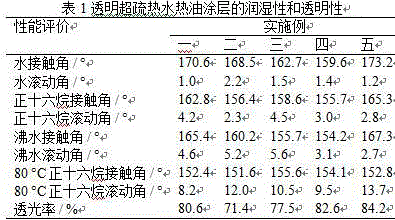

[0019] First, 10 mg of multi-walled carbon nanotubes with a diameter of 10-20 nm were added to 20 mL of ethanol-water (5:1) reaction system. After ultrasonic dispersion for 30 min, 50 μL of tetraethoxysilane and 0.5 mL of ammonia water were added in turn, and stirred under magnetic force. Hydrolysis and condensation reaction at room temperature for 3 hours to form a stable suspension of carbon nanotubes modified by organosilane cross-linking; then control the spraying pressure to 0.2MPa and the spraying distance to 20cm, and spray 4mL of the suspension on the surface of glass (3×8cm) to form a coating; The coating was then treated in a muffle furnace at 500°C for 3 hours to remove the organic groups of carbon nanotubes and organosilanes to obtain a transparent cross-linked nanostructure; Soak in 40mL ethanol solution of oxysilane for 24h to obtain a transparent super-hydrophobic thermal oil coating. The performance indexes of the coating are shown in Table 1.

Embodiment 2

[0021] First, add 50 mg of single-walled carbon nanotubes to 100 mL of methanol-water (10:1) reaction system, ultrasonically disperse for 10 minutes, then add 1 mL of aminopropyltriethoxysilane and 2 mL of acetic acid, and perform hydrolysis and condensation reaction at room temperature under magnetic stirring 6h to form a stable suspension of carbon nanotubes modified by organosilane crosslinking; then control the spraying pressure to 0.1MPa and the spraying distance to 10cm, and spray 10mL of the suspension on the silicon wafer (10×10cm); Treat the coating in a Furnace for 6 hours to remove the organic groups of carbon nanotubes and organosilanes to obtain transparent cross-linked nanostructures; finally, the cross-linked nanostructures were dissolved in 250 mL ethanol solution containing 100 μL perfluorodecyltrichlorosilane Soak in the middle for 2 hours to get a transparent super-hydrophobic thermal oil coating. The performance indexes of the coating are shown in Table 1. ...

Embodiment 3

[0023] First, add 100mg of multi-walled carbon nanotubes with a diameter of 60-80nm into 50mL of methanol-isopropanol-water (methanol-isopropanol-water=5:5:1) reaction system, ultrasonically disperse for 20min, then add 0.5 mL of hexadecyltriethoxysilane, 0.1 mL of ethyl orthosilicate and 2 mL of ethylenediamine were hydrolyzed and condensed at room temperature for 12 h under magnetic stirring to form a stable suspension of carbon nanotubes modified by organosilane crosslinking; then Control the spraying pressure of 0.2MPa and the spraying distance of 15cm, spray 8mL of the suspension on the ceramic surface (10×10cm); then treat the coating in a muffle furnace at 600°C for 2h to remove the carbon nanotubes and organic silanes. group to obtain a transparent cross-linked nanostructure; finally, the cross-linked nanostructure was soaked in 250 mL of toluene solution containing 50 μL perfluorooctyldimethylchlorosilane for 24 hours to obtain a transparent super-hydrophobic thermal o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com