N-hexadecane hydroisomerization reaction method on loaded crystalline state nickel phosphide catalyst

A technology for hydroisomerization and n-hexadecane, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low selectivity, high cost of noble metal-containing catalysts, and resistance to sulfide poisoning. To achieve the effect of high reactivity, high reactivity and isomerization selectivity, and excellent resistance to carbon deposition and sulfide poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the method for n-hexadecane hydroisomerization reaction on a kind of supported crystalline nickel phosphide catalyst of the present embodiment is carried out according to the following steps:

[0018] Load the 20-40 mesh supported crystalline nickel phosphide catalyst into the constant temperature zone of the fixed-bed isothermal reactor, and activate it for 20min-100min at a temperature of 400-500°C and a hydrogen flow rate of 20mL / min-80mL / min, Then inject n-hexadecane into the fixed-bed isothermal reactor by means of continuous injection, when the reaction temperature is 280-420°C, the reaction pressure is 1MPa-4MPa, and the mass space velocity of n-hexadecane is 1h -1 ~4h -1 Reacting with hydrogen and n-hexadecane at a volume ratio of 300 to 800:1 to obtain isohexadecane;

[0019] The supported crystalline nickel phosphide catalyst is a crystalline nickel phosphide catalyst supported by SAPO-31 molecular sieves.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the SAPO-31 molecular sieve is a SAPO-31 molecular sieve with a circular one-dimensional linear pore structure and mild acidity. Others are the same as in the first embodiment.

specific Embodiment approach 3

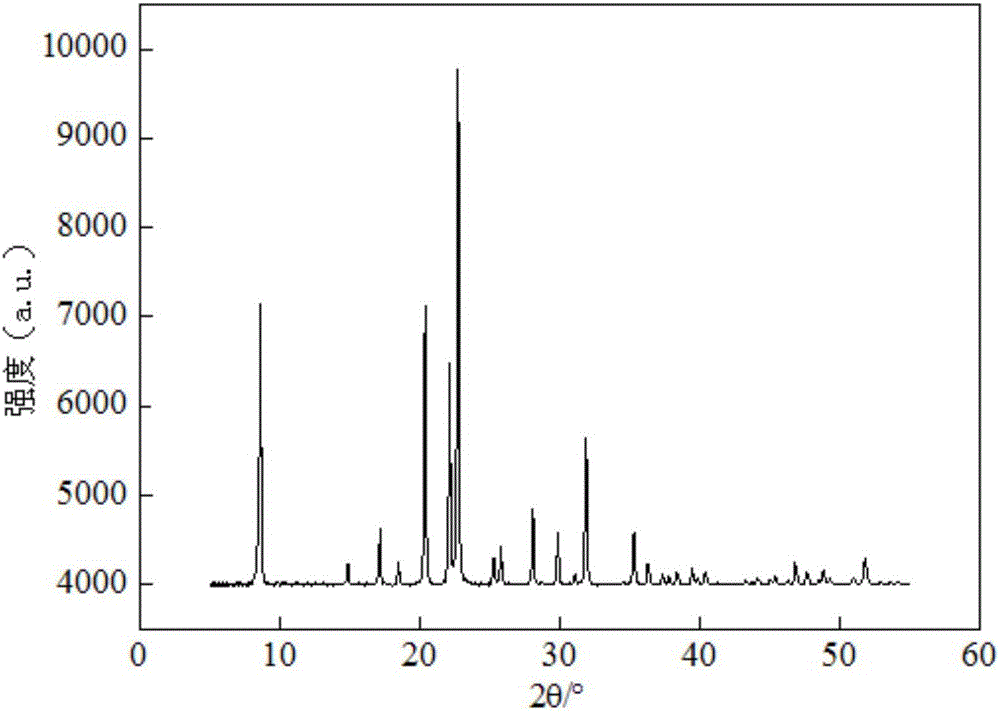

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mass ratio of nickel phosphide to SAPO-31 molecular sieve in the crystalline nickel phosphide catalyst supported by the SAPO-31 molecular sieve is 3 to 8: 100, and the metal active site is located on the 111 crystal plane of nickel phosphide crystal. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com