Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Mercuric sulphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mercury sulfide, mercuric sulfide, mercury sulphide, or mercury(II) sulfide is a chemical compound composed of the chemical elements mercury and sulfur. It is represented by the chemical formula HgS. It is virtually insoluble in water.

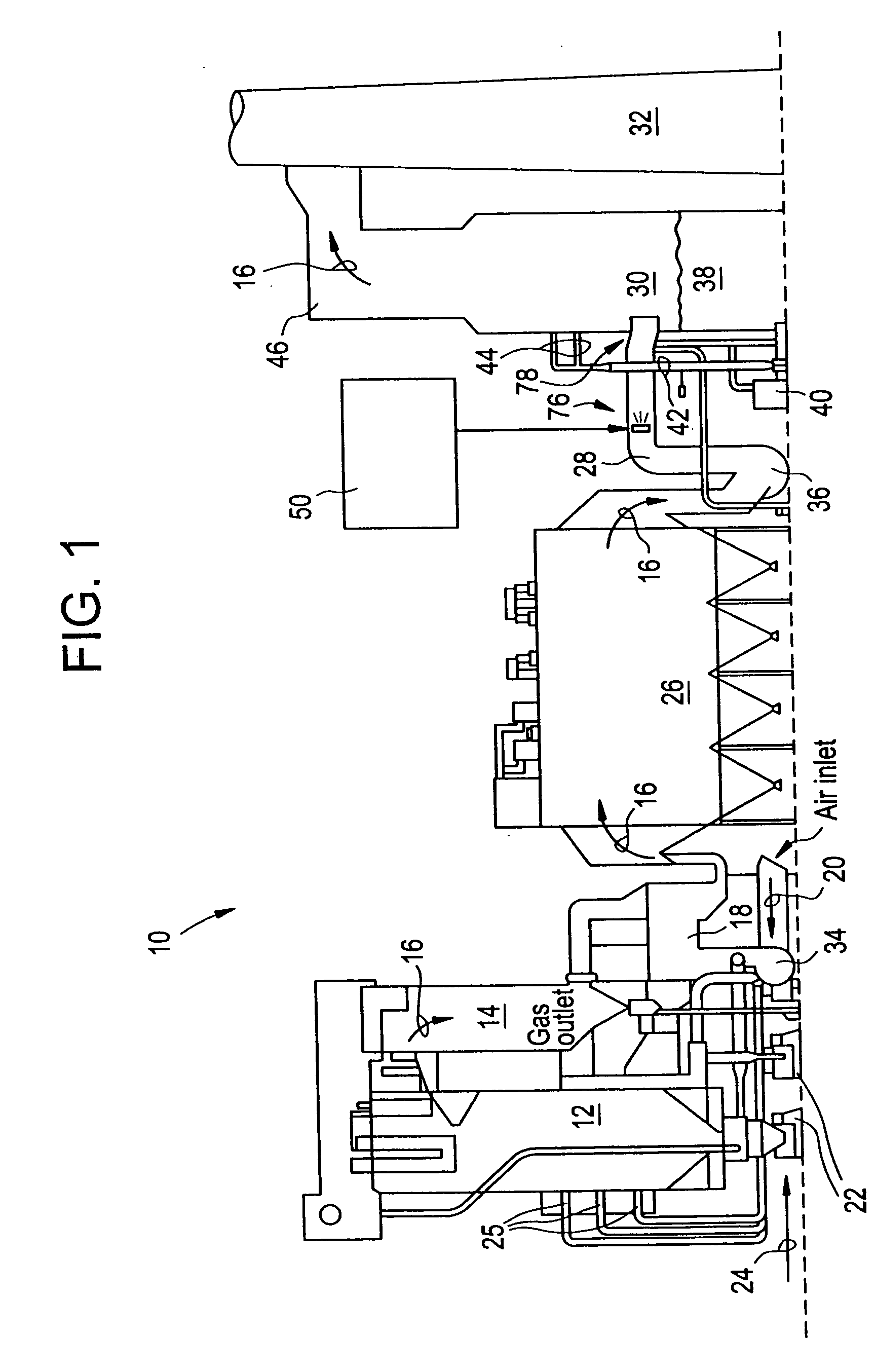

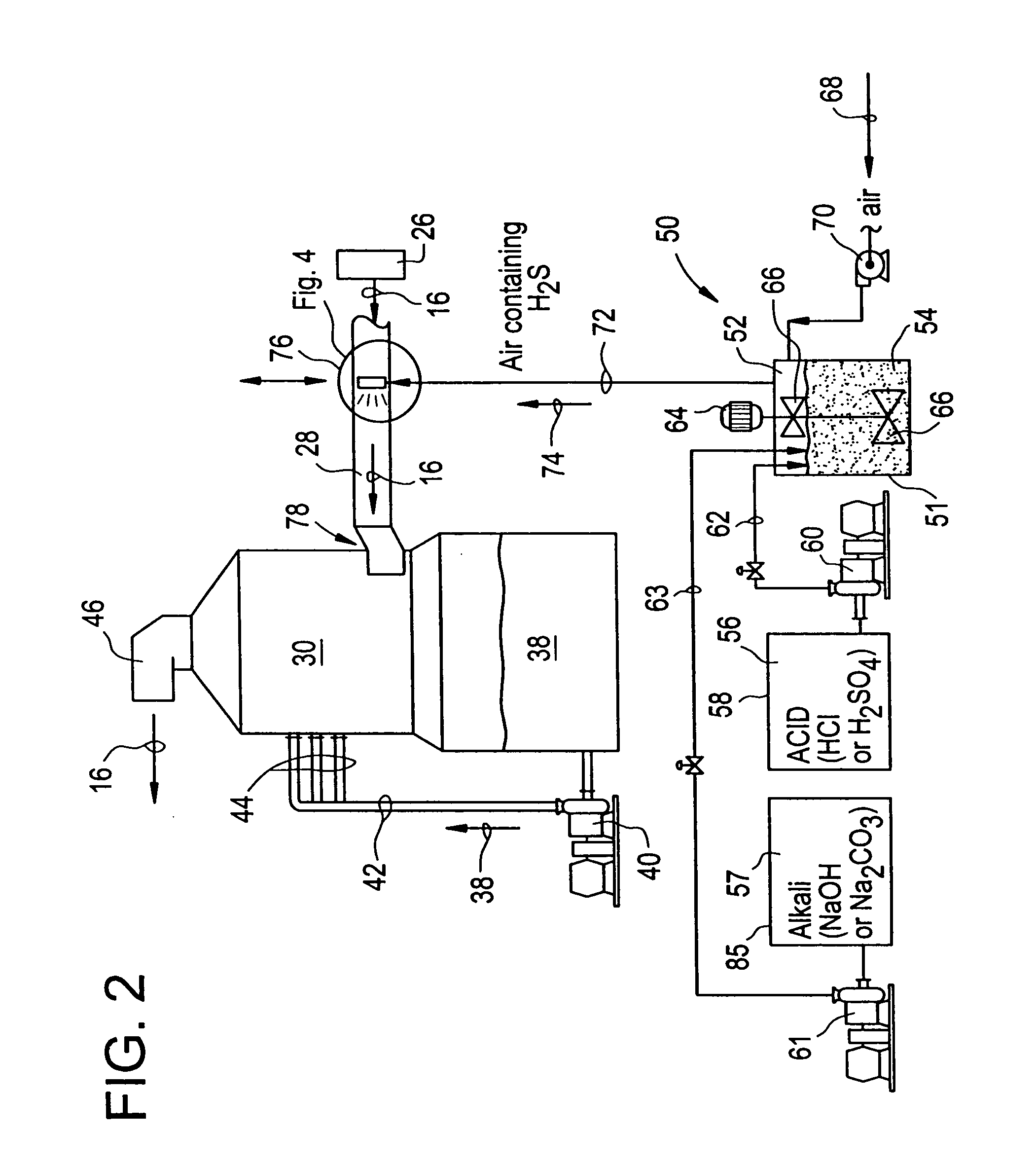

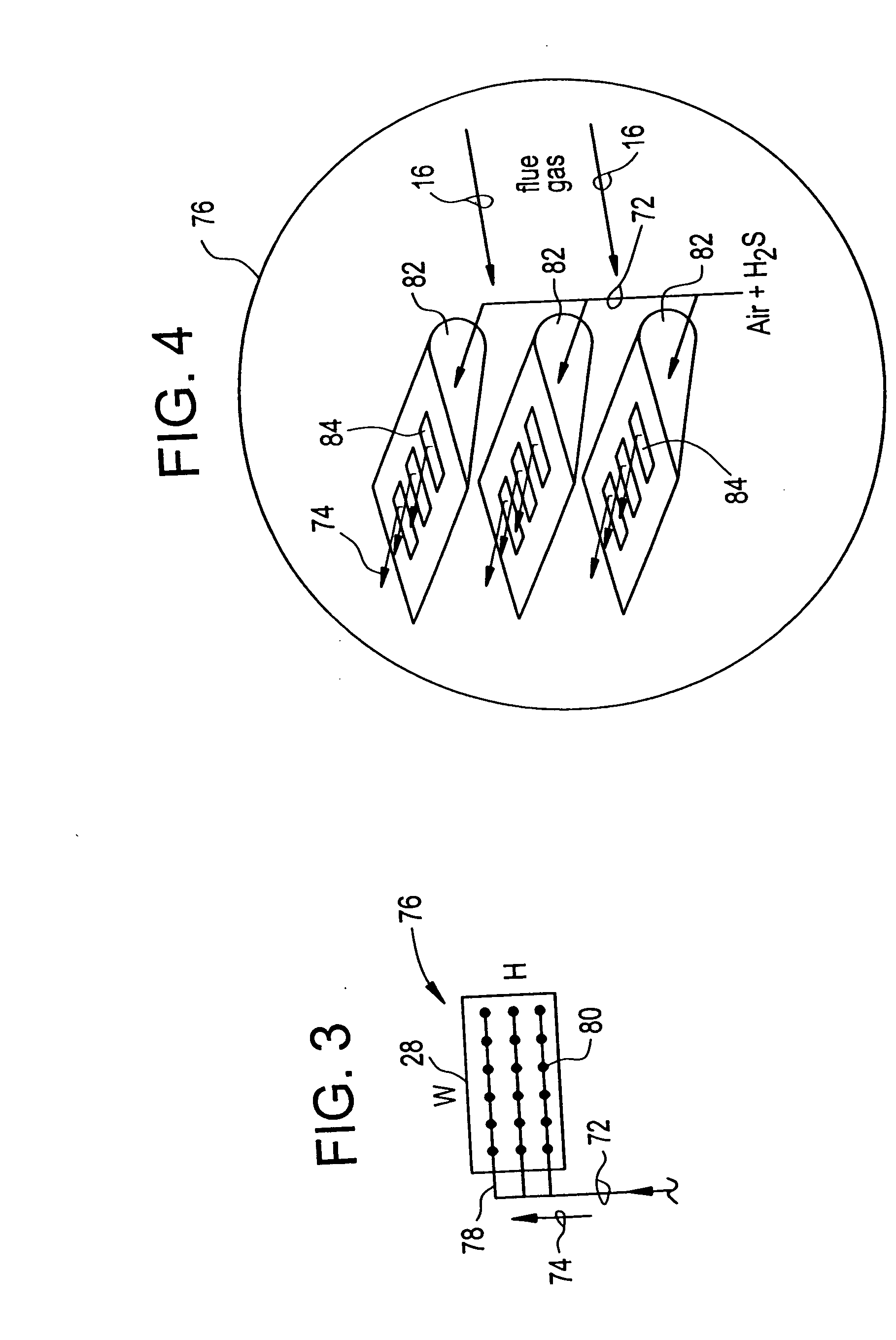

Method for control of mercury

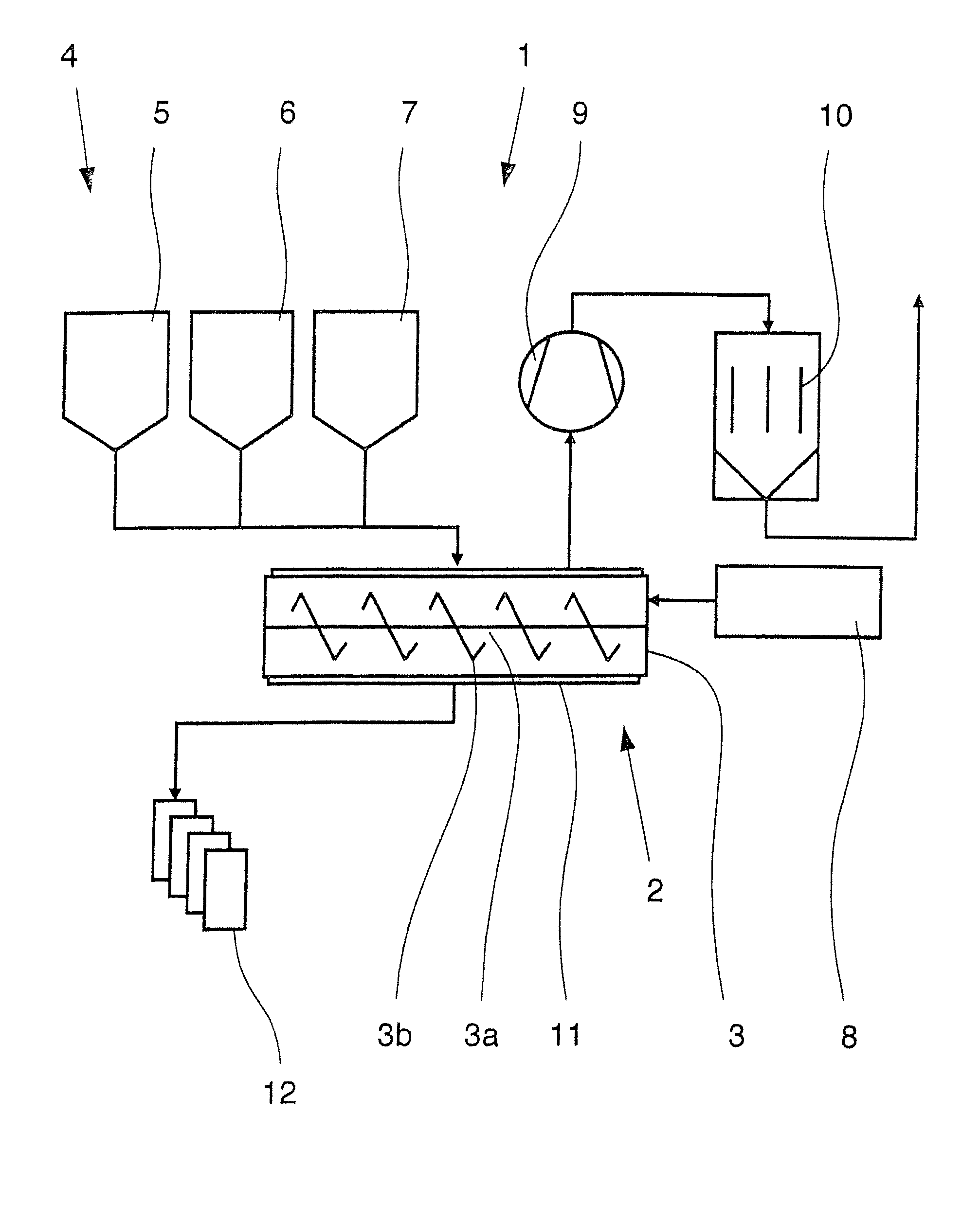

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

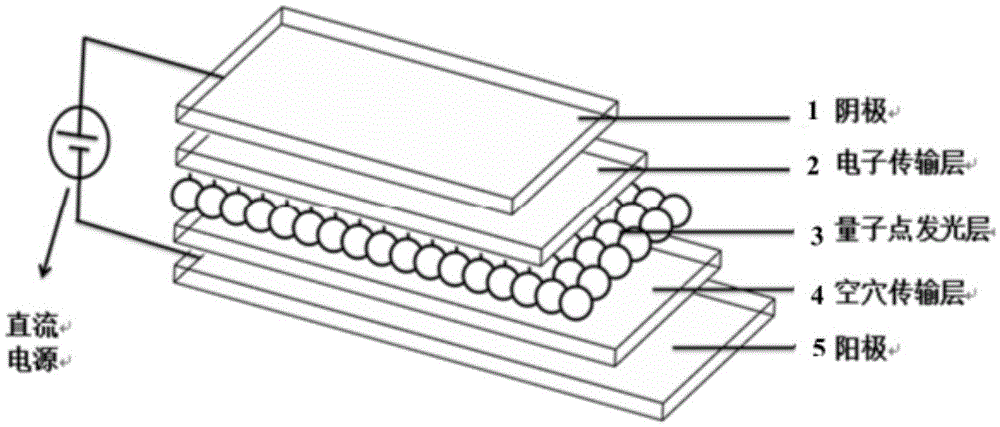

High-efficiency quantum dot light emitting diode with self-assembly polymer hole transmission layer structure

InactiveCN105609651AIncrease transfer rateImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingZinc selenidePolyethylene terephthalate glycol

The invention discloses and proposes a high-efficiency quantum dot light emitting diode with a self-assembly polymer hole transmission layer structure. Except a positive electrode and a negative electrode, the high-efficiency quantum dot light emitting diode comprises a three-layer structure: a hole transmission layer, a quantum dot light emitting layer and an electron transmission layer, wherein one end of the quantum dot light emitting layer is connected with the hole transmission layer, the other end of the quantum dot light emitting layer is connected with the electron transmission layer, the electron transmission layer is organic nanoparticles after doped, the hole transmission layer is formed by doping a monomer, a polymer, small-molecule, inorganic oxidized metal nanoparticles or a two-dimensional nanometer material into poly(3,4- ethylenedioxythiophene monomer), a quantum dot is quantum dots of zinc sulfide, zinc selenide, cadmium sulfide, cadmium selenide, cadmium telluride, mercury sulfide, mercury selenide, mercury telluride or core-shell nanometer structured cadmium selenide-zinc sulfide, cadmium sulfide-zinc sulfide, cadmium sulfide-zinc selenide and graphene thereof and the like, and the negative electrode is glass or polyethylene terephthalate (PET) with a layer of indium tin oxide (ITO) or fluorine-doped tin oxide (FTO) or graphene.

Owner:SOUTHEAST UNIV

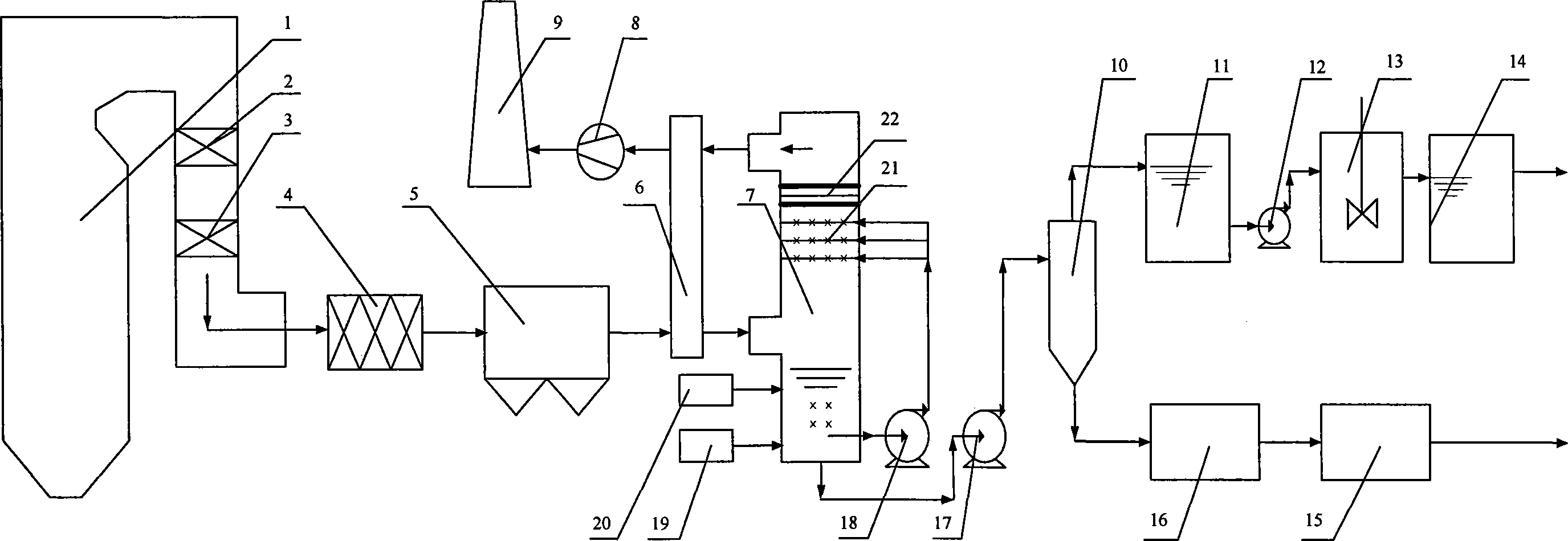

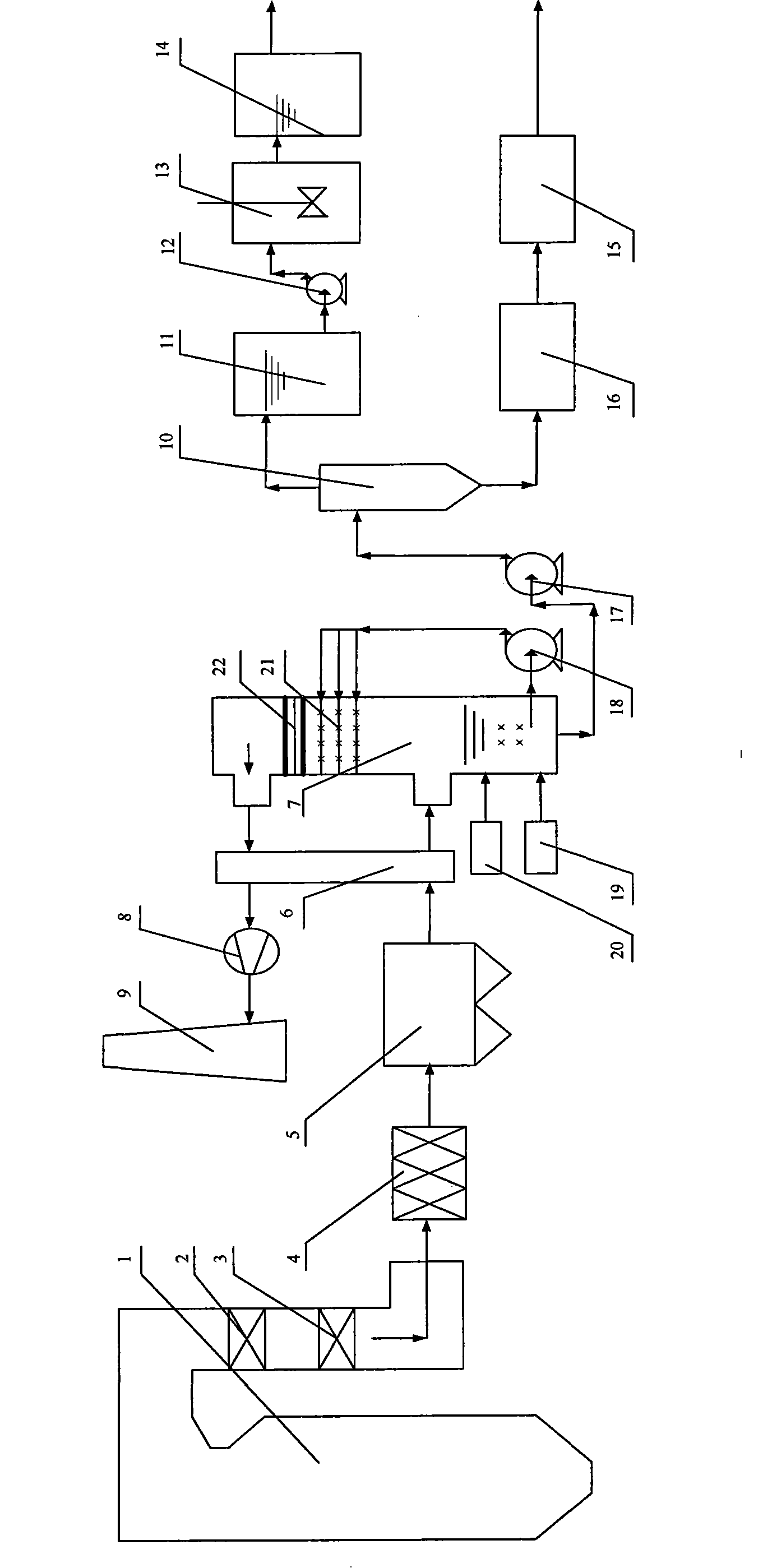

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Chinese medicine external-use preparation medicament for treating surgery wound infection and method for producing the same

InactiveCN101543565ALess medicinal propertiesLess varietyHeavy metal active ingredientsHydroxy compound active ingredientsHalloysiteSide effect

A Chinese medicine external-use preparation medicament for treating surgery wound infection and a method for producing the same. The medicament has the raw materials of pangolin scales, dragon's blood, notoginseng, red halloysite, frank incense, myrrh, artificial mercuric sulphide, black catechu, pearl powder, drgon's bones, calomelas, borneol and gingelly oil. The medicament is mild in temperament, has no toxicity and side effect and is easy for dressing change. The prescription activates blood and resolves stasis, regenerates tissue, tonifies qi, benefits blood, takes temporary solution and effects a permanent cure. The producing method need simple facilities, saves energy and water, has short production period, low cost and no pollution and solves the adverse reaction in the surgery usual wound infection treatment due to frequently externally changing applied medicament and frequently removing necrosis infection tissue.

Owner:卜继武

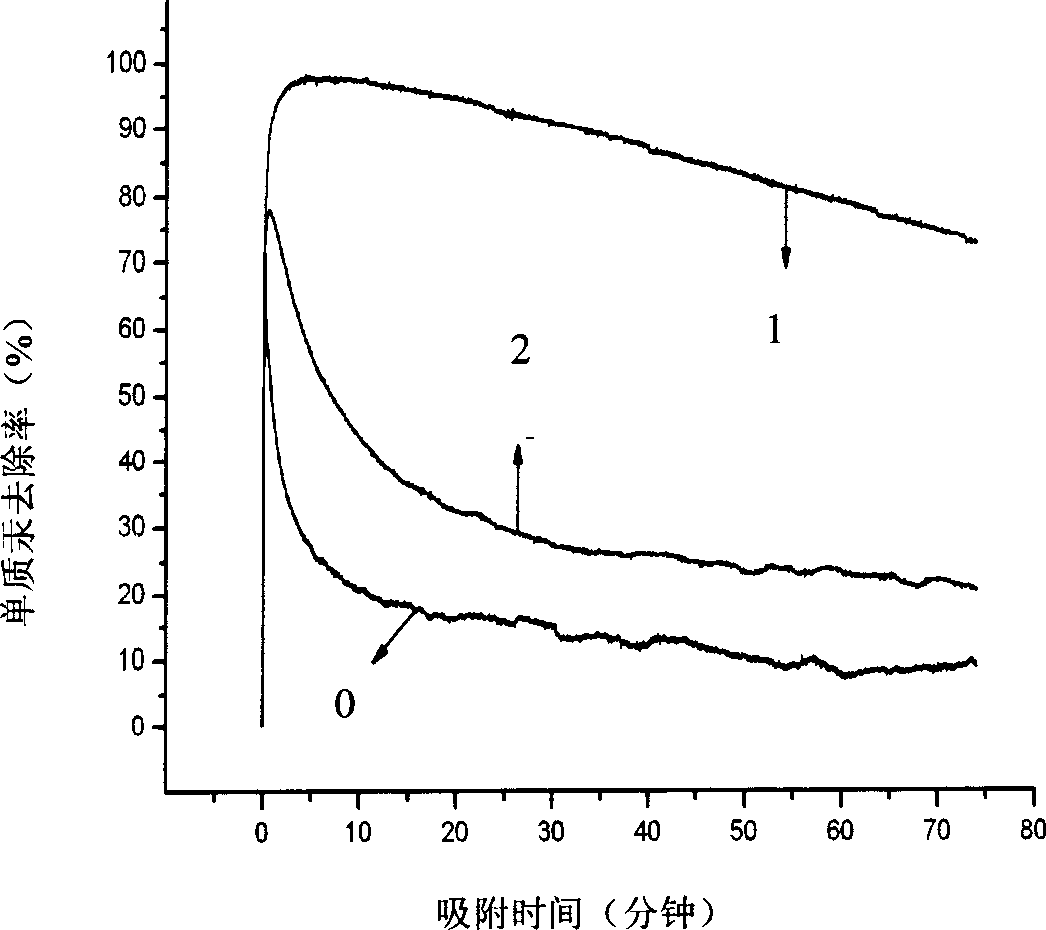

Method for removing mercury for flue gas by using sulfo-halogen compound-supported modified adsorbent

InactiveCN1883760AReduce secondary pollutionReduce dosageOther chemical processesDispersed particle separationHalogenHigh absorption

The invention relates to a method for removing mercury in flue gas by using chalcohalide compound modified absorption. The method is characterized in that: compound containing sulphur and halogen or its precursor is used as modifier for supported modification for adsorbent to make the surface mercury absorption characterization of absorbent change, The weight percentage of supported chalcohalide compound in absorbent is 0.01 to 10%, and the modified absorbent is connected with flue gas in flue gas filling and direct blowing-in manner direct for flue gas mercury removal. The modified absorbent is provided with high absorption capacity for mercury in flue gas, and mercury can be converted to stable mercuric sulphide by using the modified absorbent, as a result, the secondary pollution can be solved.

Owner:SHANGHAI JIAO TONG UNIV

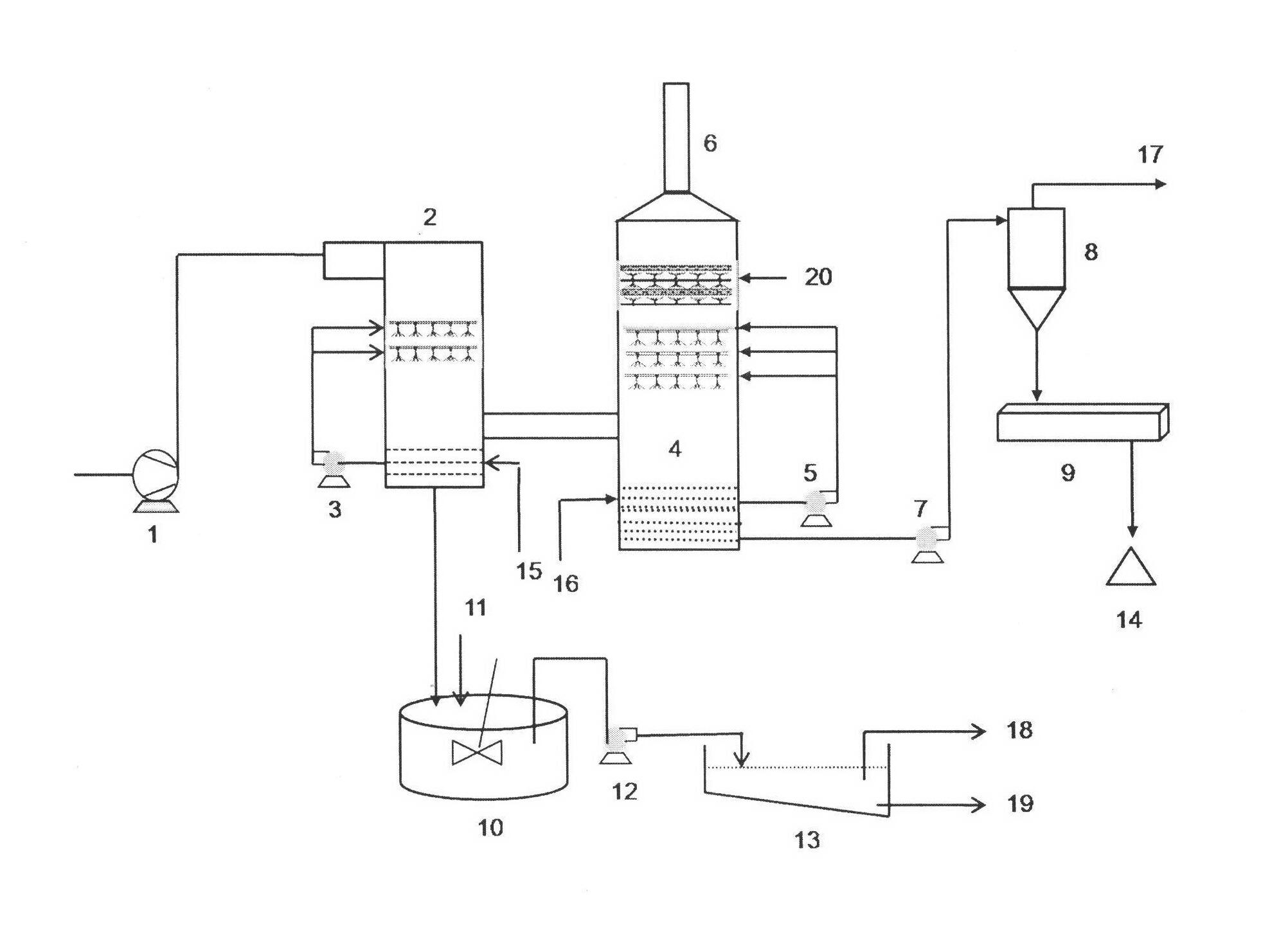

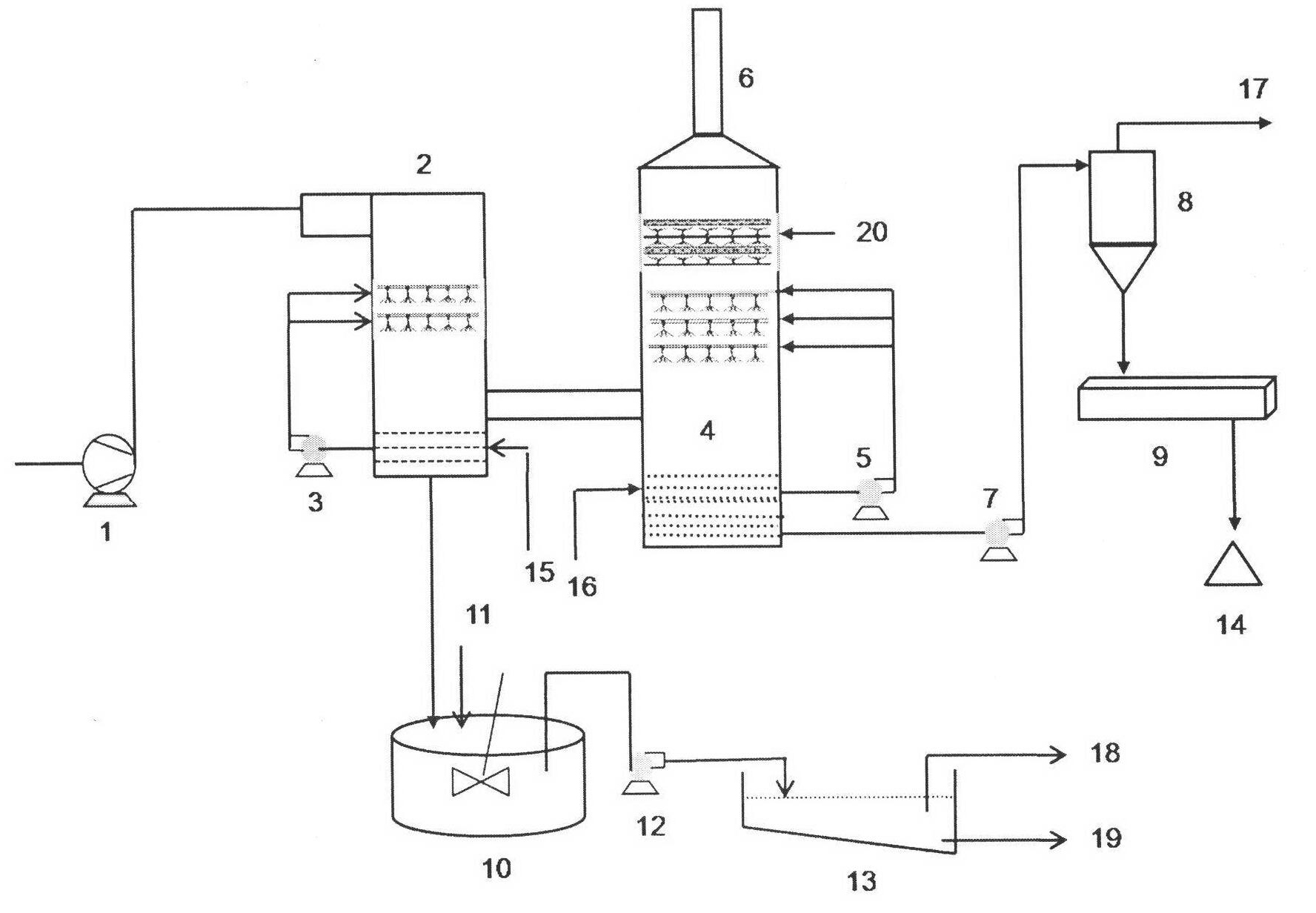

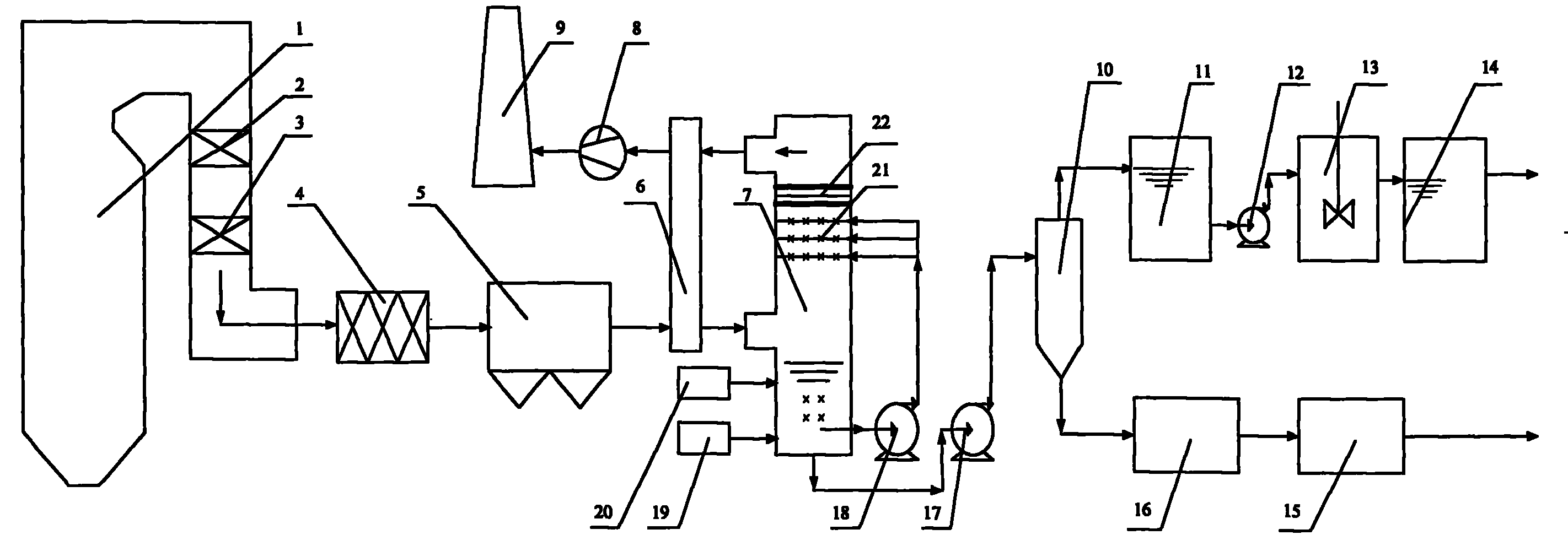

Desulfuration and mercury-removing combined smoke purifying process and system based on magnesium oxide method desulfuration process

InactiveCN102205203AWith resource utilizationRealize resource utilizationDispersed particle separationMagnesium/calcium/strontium/barium sulfides/polysulfidesGas phaseSulfide

The invention discloses a desulfuration and mercury-removing combined smoke purifying process and system based on a magnesium oxide method desulfuration process. The desulfuration and mercury-removing combined smoke purifying process comprises the steps of: improving a pre-washing tower in the magnesium oxide method desulfuration process, circularly spraying original smoke by adopting a halogen oxidant solution to realize full oxidization of elementary substance mercury Hg0 in smoke; transforming oxidized gas-phase bivalent mercury ions into liquid-phase bivalent mercury ions through an improved wet-type magnesium oxide method desulfuration process; and transforming the liquid-phase bivalent mercury ions in a wastewater treatment system into a stable mercuric sulfide precipitate through adding a mercury stabilizing agent. The system mainly comprises the pre-washing tower, a desulfuration tower, a cyclone separator, a vacuum belt fulter, a wastewater basin and a sedimentation basin, wherein the pre-washing tower is used for preparing a mercury oxidant and a magnesium oxide solution and oxidizing mercury; the desulfuration tower is used for carrying out desulfuration and mercury removal on smoke; the cyclone separator and the vacuum belt fulter are used for treating side products; and the wastewater basin and the sedimentation basin are respectively used for treating wastewater and the mercuric sulfide precipitate. The process can be used for effectively removing divalent mercury and elementary substance mercury in the smoke on the premise of ensuring the advantages of the magnesium oxide method desulfuration process, and is suitable for reconstructing the traditional magnesium oxide method desulfuration process.

Owner:CECEP L&T ENVIRONMENTAL TECH

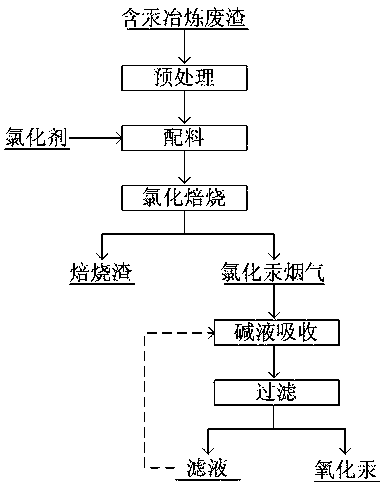

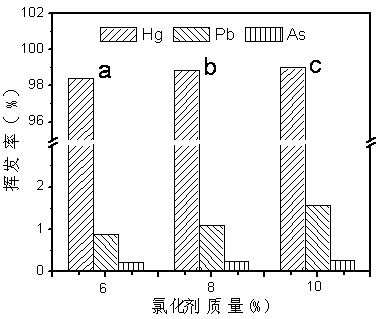

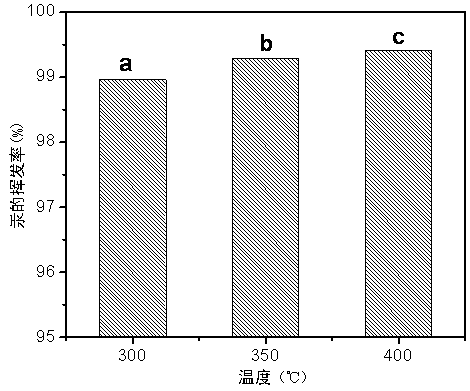

Method for selectively recycling mercury from smelting waste residue

ActiveCN108034808AEfficient evaporationReduce volatilityProcess efficiency improvementSulfateGas phase

Aiming at the problems that the mercury-containing waste residue produced in the smelting industry is complicated in component, difficult to recycle, high in environmental risk and the like, the invention discloses a method for selectively recycling mercury from smelting waste residue. The method has the characteristics of short technological process, simple operation, wide application range, no pollution and the like, can realize efficient and selective recycling of mercury in the complicated smelting waste residue, and is favorable for reducing the pollution of the mercury-containing waste residue to the environment. The method comprises the following specific steps: performing oxygen-enriched chloridizing roasting to convert mercury sulfide, mercury sulfate and the like which are steadyand difficult to volatilize in the mercury-containing waste residue into mercury chloride which is easy to volatilize, thereby realizing selective separation of mercury; and absorbing mercury chloride volatilized into a gas phase by using alkali liquor, and performing hydrolysis to obtain mercury oxide precipitate, thereby realizing recycling of mercury.

Owner:JIANGXI UNIV OF SCI & TECH

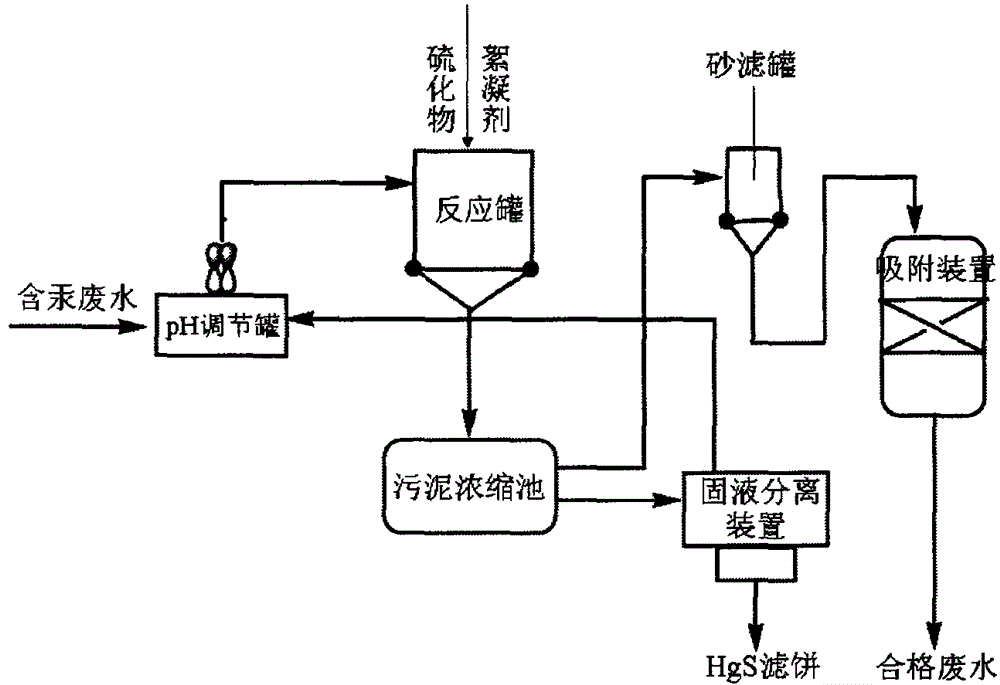

Novel deep mercury removal process

InactiveCN106348484AReduce processing costsEasy to handleSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFlocculationActivated carbon

The invention adopts a sulfide precipitation method and an auxiliary adsorption method to remove mercury from mercury-containing wastewater. A wastewater mercury removal device adopts a mercury sulfide precipitation method which comprises the following steps: mainly adopting intermittent operation; adding sulfide in a certain proportion according to the content of mercury in the water; reacting to generate mercury sulfide precipitates; filtering and separating after flocculation and sedimentation; recycling after performing deep adsorption treatment on obtained crude filtrate through activated carbon. The process can effectively treat the mercury-containing wastewater, reduces environmental pollution, and has better application prospects.

Owner:许中石

Ultrasonic atomization treatment process of electric power plant desulfurization wastewater

InactiveCN104828999ASimple processHigh oxidationMultistage water/sewage treatmentOrganic sulfide compoundIron salts

The present invention relates to an ultrasonic atomization treatment process of electric power plant desulfurization wastewater. According to the process, desulfurization wastewater is conveyed into a pH value adjusting pool; one or a plurality of materials selected from lime, limestone, sodium hydroxide and sodium carbonate are added to the pH value adjusting pool so as to produce partial heavy metal hydroxides and self-flow into a reaction pool; an organic sulfide is added to produce precipitates such as mercury sulfide and copper sulfide, and the precipitates self-flow into a flocculation pool; an iron salt, a polymer flocculant, and a coagulant are added to condense suspended solid particles dispersed in the wastewater and partial COD into the centralized floc; the clear water of the flocculation precipitation pool overflows into a final oxidation neutralization box from the upper portion, an oxidizing agent and a neutralizing agent are poured by using an ultrasonic atomization manner, and the COD in the water is completely oxidized in an atomizing state; and the sludge is subjected to dewatering utilization, and the sewage discharge meets the standard. According to the present invention, the process is simple, and the contaminant removal effect is good.

Owner:WUXI RUNYUAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

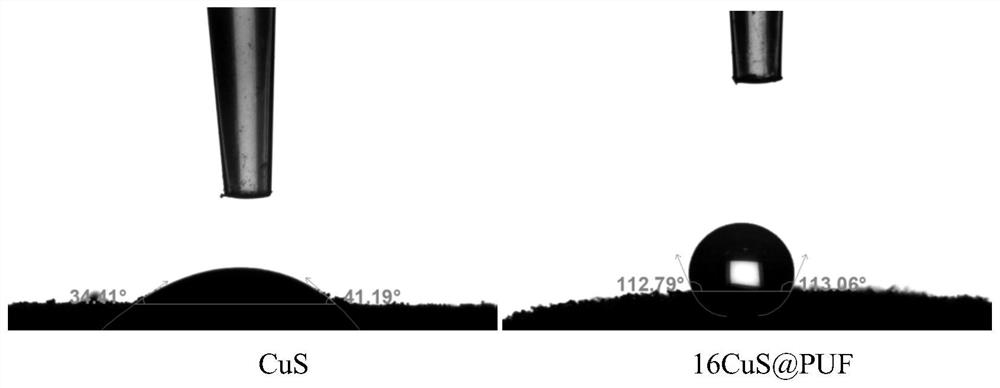

Macroporous skeleton hydrophobic mercury removal material, preparation method and application thereof

ActiveCN112934197ASolve pollutionTurn waste into treasureGas treatmentOther chemical processesSorbentActive agent

The invention discloses a macroporous skeleton hydrophobicmercury removal material, a preparation method and application thereof. A simple one-step precipitation method is adopted, a surfactant is used for regulating and controlling the crystal size of metal sulfide, the metal sulfide is fixed on a macroporous skeleton hydrophobic material, and a novel mercury removal material is obtained. The preparation method of the macroporous skeleton hydrophobic mercury removal material is simple, the contact area of metal sulfide minerals and mercury is increased, and the resistance of an adsorbent to flue gas is reduced. The macroporous framework hydrophobic mercury removal material has extremely high mercury adsorption capacity and adsorption rate, the hydrophobic performance of pure metal sulfide is improved, and the obtained mercury removal material can be used as a mercury removal medium to be applied to a fixed bed or a liquid phase (such as a wet dust removal device) to be in contact with gaseous elemental mercury; and volatile gaseous elemental mercury is converted into stable solid mercuric sulfide, and the material has the advantages of being flexible in application, high in efficiency, environmentally friendly and the like.

Owner:CENT SOUTH UNIV

Method for removing mercury in flue gas by use of waste desulfurizer after being used for recycling elemental sulfur

ActiveCN104338435AReasonably solve the removal problemWell-developed pore structureDispersed particle separationSulfur productFlue gas

The invention provides a method for removing mercury in flue gas by use of a waste desulfurizer after being used for recycling elemental sulfur, and relates to an environment-friendly treatment method in which a heat-treated waste ferric oxide desulfurizer is used as a coal-fired flue gas mercury remover. According to the method comprises, rich elemental sulfur in the waste desulfurizer is recycled by use of carrier gas under a heating condition, wherein based on the total amount of the waste desulfurizer, the content of the total sulfur in the waste ferric oxide desulfurizer in 17wt%-21wt%, and the content of the elemental sulfur in the waste ferric oxide desulfurizer is 6wt%-7wt%; the condition that pores of the desulfurizer are blocked by the elemental sulfur is improved. The content of the elemental sulfur in the heat-treated waste desulfurizer is 1-2wt%; the heat-treated waste ferric oxide desulfurizer has the excellent activity to zero-valence mercury, and is capable of finally converting adsorbed mercury into stabilized mercury sulfide. The method for removing the mercury in the flue gas by use of the waste desulfurizer after being used for recycling the elemental sulfur is used for solving the problem of recycling the waste desulfurizer; as a result, a sulfur product can be obtained, and furthermore, an efficient and cheap waste gas mercury remover is found out, and the environment protection treatment cost can be reduced.

Owner:TAIYUAN UNIV OF TECH

Method for treating mercury-contained tailings by heap leaching-precipitate stabilization

ActiveCN104032138AEasy to operateReduce processing costsProcess efficiency improvementSolubilityDecomposition

The invention belongs to the field of environmental protection; and as mercury-contained tailings produced by the nonferrous metal smelting industry cannot be effectively treated, and bring serious potential pollution hazard to the environment, the invention provides a method for treating the mercury-contained tailings by adopting heap leaching-precipitate stabilization. The method adopts thiosulfate solution as heap leaching liquid to perform the heap leaching for the mercury-contained tailings, and adopts a circular spray heap leaching mode to obtain leaching liquid; the obtained leaching liquid is gathered in a decomposition pool; a thiosulfate complex of mercury is decomposed and precipitated to stable mercury sulfide; and the decomposed leaching liquid is continuously returned to the heap leaching step to be used as the heap leaching liquid. As the mercury, in a transfer state, in the mercury-contained tailings is finally converted to mercury sulfide precipitate with high stability, low solubility and low toxicity, the stability of the mercury in the mercury-contained tailings is realized, and the environmental pollution hazard from the mercury in the mercury-contained tailings can be effectively reduced.

Owner:NORTHEASTERN UNIV

Method for repairing polluted soil through low-temperature thermal desorption with chemical drip washing

ActiveCN107398470AEfficient removalNot volatileContaminated soil reclamationLow-temperature thermal desorptionPollution

The invention discloses a method for repairing polluted soil through low-temperature thermal desorption with chemical drip washing. The method comprises the following steps: firstly, performing low-temperature thermal desorption treatment on mercury polluted soil so as to remove metal mercury, organic combined mercury and a part of inorganic combined mercury with a low melting point in the soil; secondly, performing drip washing with a mixed liquid containing organic acids, iodate and chlorine salts so as to remove mercuric oxide with a high melting point; and finally performing drip washing on mercuric sulfide with a high melting point with a mixed liquid of sodium sulfide and sodium hydroxide. By adopting the method, efficient removal of mercury of multiple valence states in mercury polluted soil can be achieved, a small amount of mercury is retained, the removal rate of mercury is up to 95% or greater, secondary pollution to the environment is avoided, and the cost is low.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

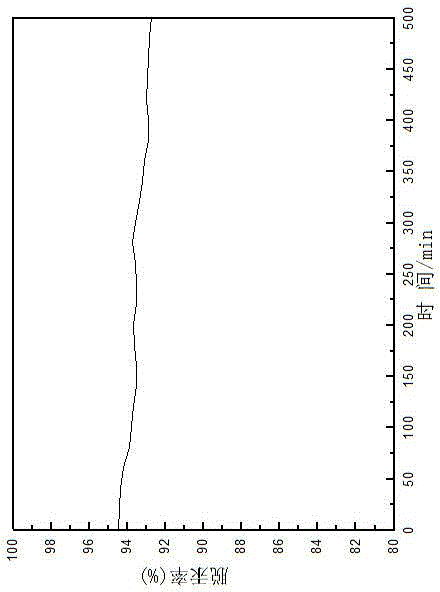

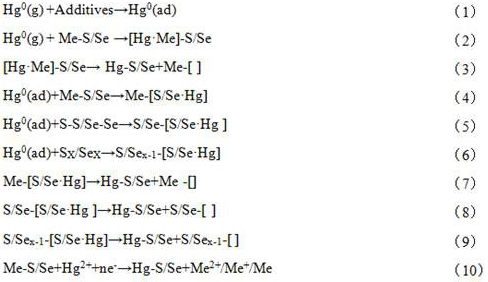

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

ActiveCN112755764AImprove mercury removal efficiencyLarge capacityGas treatmentDispersed particle separationFlue gasControl system

The invention discloses a stable suspension system for removing mercury in flue gas and a recovery method of the suspension system. Metal sulfur, a selenide mercury removal agent and an additive are pretreated to form a stable suspension, the mercury-containing flue gas is in contact with the suspension, gaseous mercury (Hg0) is converted into stable mercuric sulfide or mercury selenide, and efficient removal of gaseous mercury in the flue gas is achieved. According to the method, existing pollutant control systems in various industries can be utilized, and the cost is low; the suspension system is simple to recover and separate and can be recycled; mercury can be recycled as a product; and the market prospect is wide.

Owner:CENT SOUTH UNIV

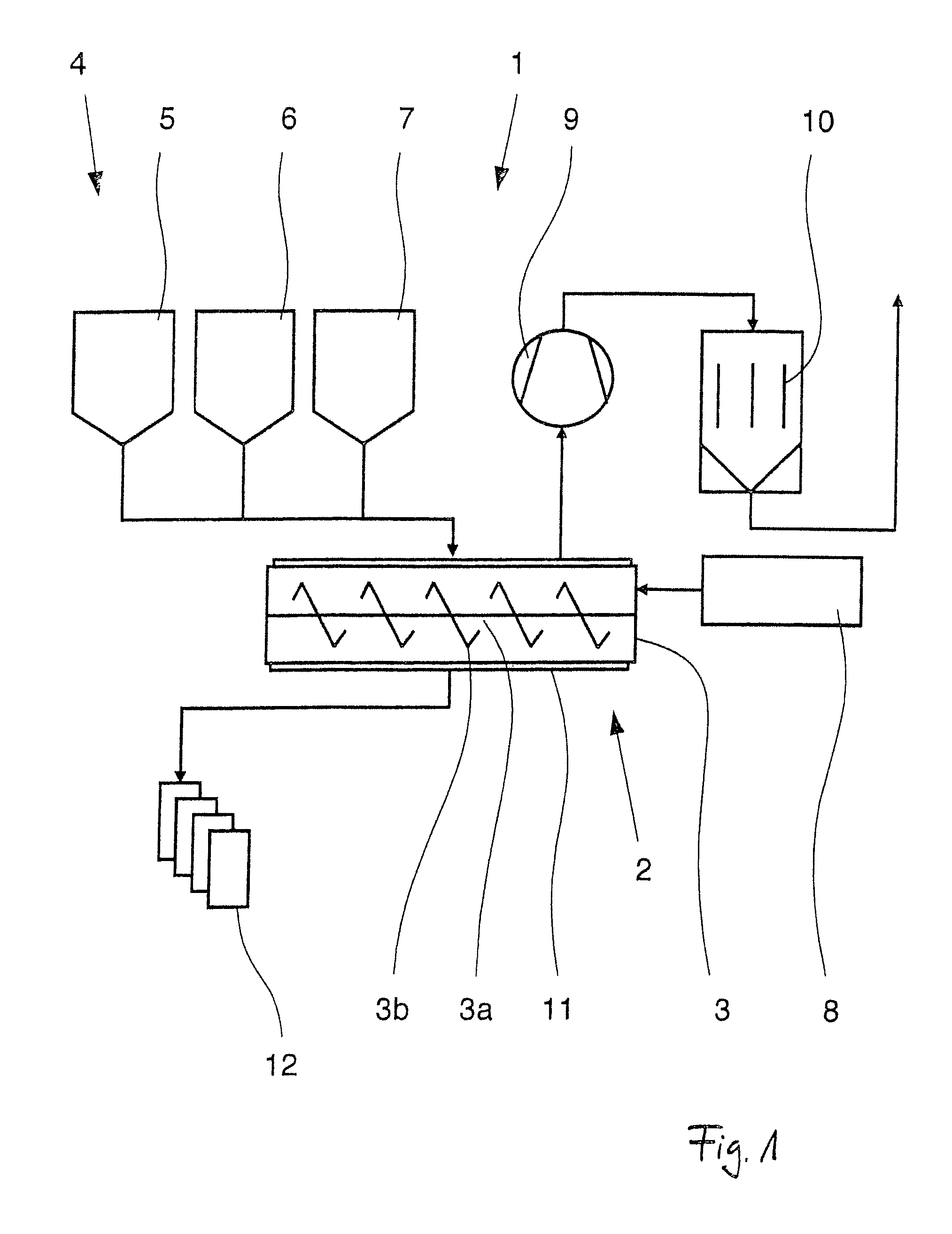

Process and device for immobilizing mercury by producing crystalline mercury sulfide for subsequent disposal of mercury sulfide

InactiveUS7914757B1Promote conversionUsing liquid separation agentCadmium sulfidesSulfurElemental mercury

A process for immobilizing mercury by producing crystalline mercury sulfide for subsequent disposal of the mercury sulfide, the mercury sulfide being formed by the reaction of elemental mercury and an additive material of elemental sulfur or a sulfur compound. The reaction of the mercury and of the additive material takes place at least during one time interval at a temperature above the melting point of the additive material.

Owner:NQR NORDISCHE QUECKSILBER RUCKGEWINNUNG

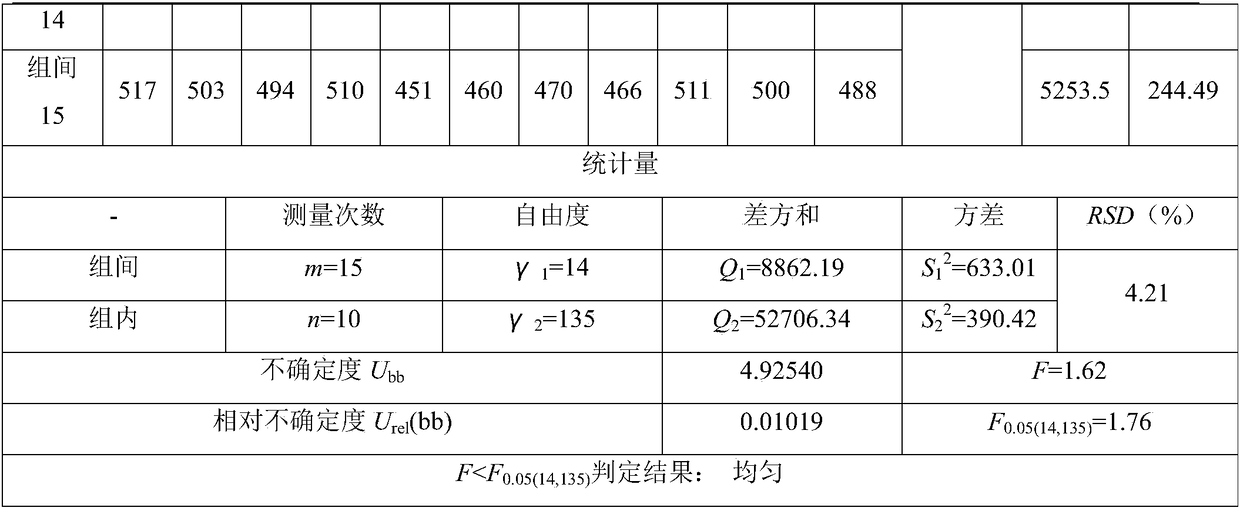

Standard sample for rapid screening and analysis of lead, cadmium, chromium, mercury and bromine in PP for X-ray fluorescence analysis of RoHS detection and preparation method thereof

ActiveCN108084568AReduce wasteReduce pollutionMaterial analysis using wave/particle radiationPreparing sample for investigationAnalysis dataConcentration gradient

The invention discloses a standard sample for rapid screening and analysis of lead, cadmium, chromium, mercury and bromine in PP for X-ray fluorescence analysis of RoHS detection and a preparation method thereof. The standard sample is mainly prepared by the steps of: mixing the following raw materials including polypropylene, a diffusing agent, an antioxidant, toner, an antistatic agent and a target compound, then repeatedly melting, extruding and granulating to prepare round piece-shaped PP plastic. The standard sample prepared by the invention and a sample to be detected have similar chemical composition and physical structure, and a target element is uniformly distributed and has certain-concentration gradient distribution, so that the accuracy and the reliability of analysis data canbe ensured and the production efficiency is high; by adoption of a mode with repeated melting, extrusion and granulation, the former 1 / 3 extruded materials do not need to be discarded, so that the material waste and environmental pollution can be reduced; the formula provided by the invention can meet multiple repeated melting and extrusion without ageing. By adoption of mercury sulfide, the problem that the content of mercury can not be taken on according to an expected design and the mercury pollution can be caused due to loss of mercury element in the process of heating processing can be solved.

Owner:东莞市精析标物计量科技有限公司

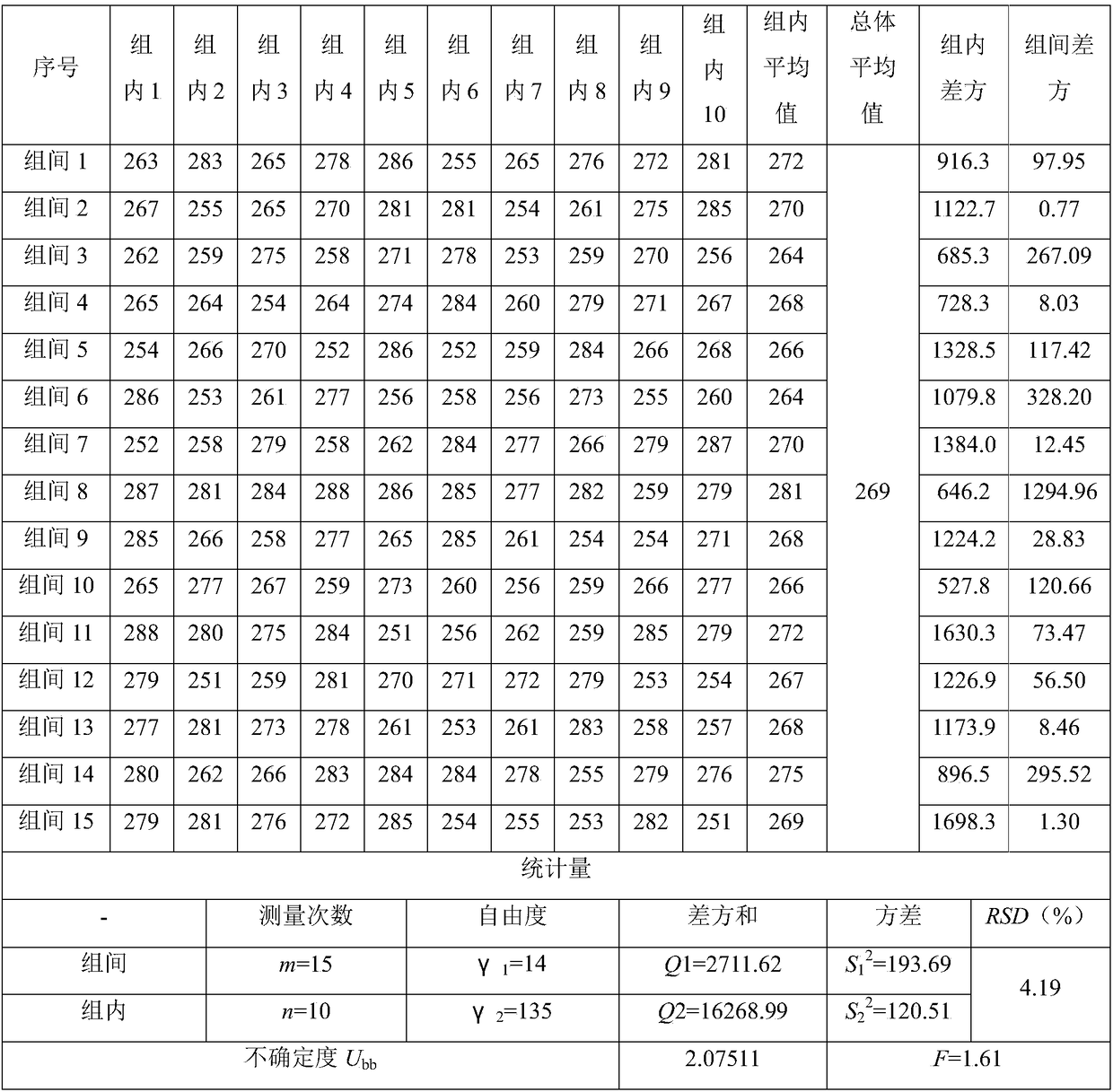

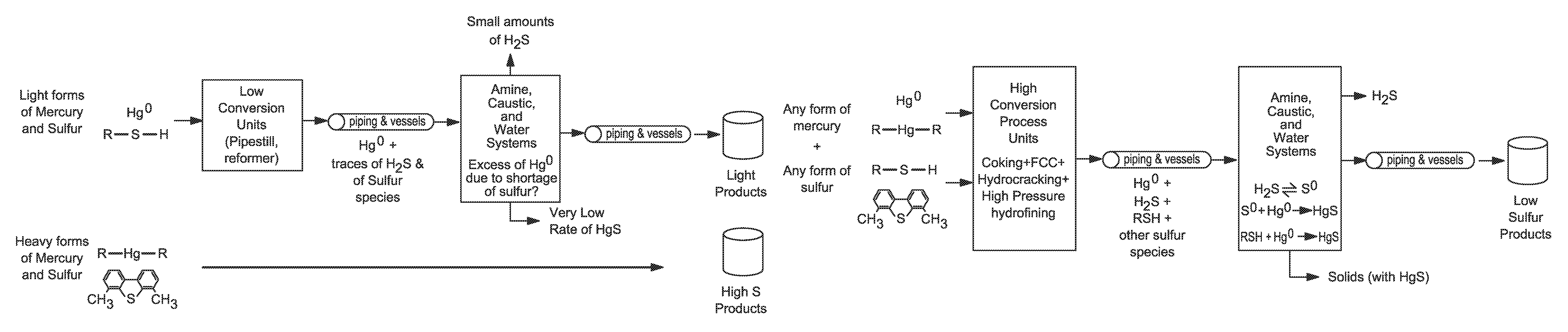

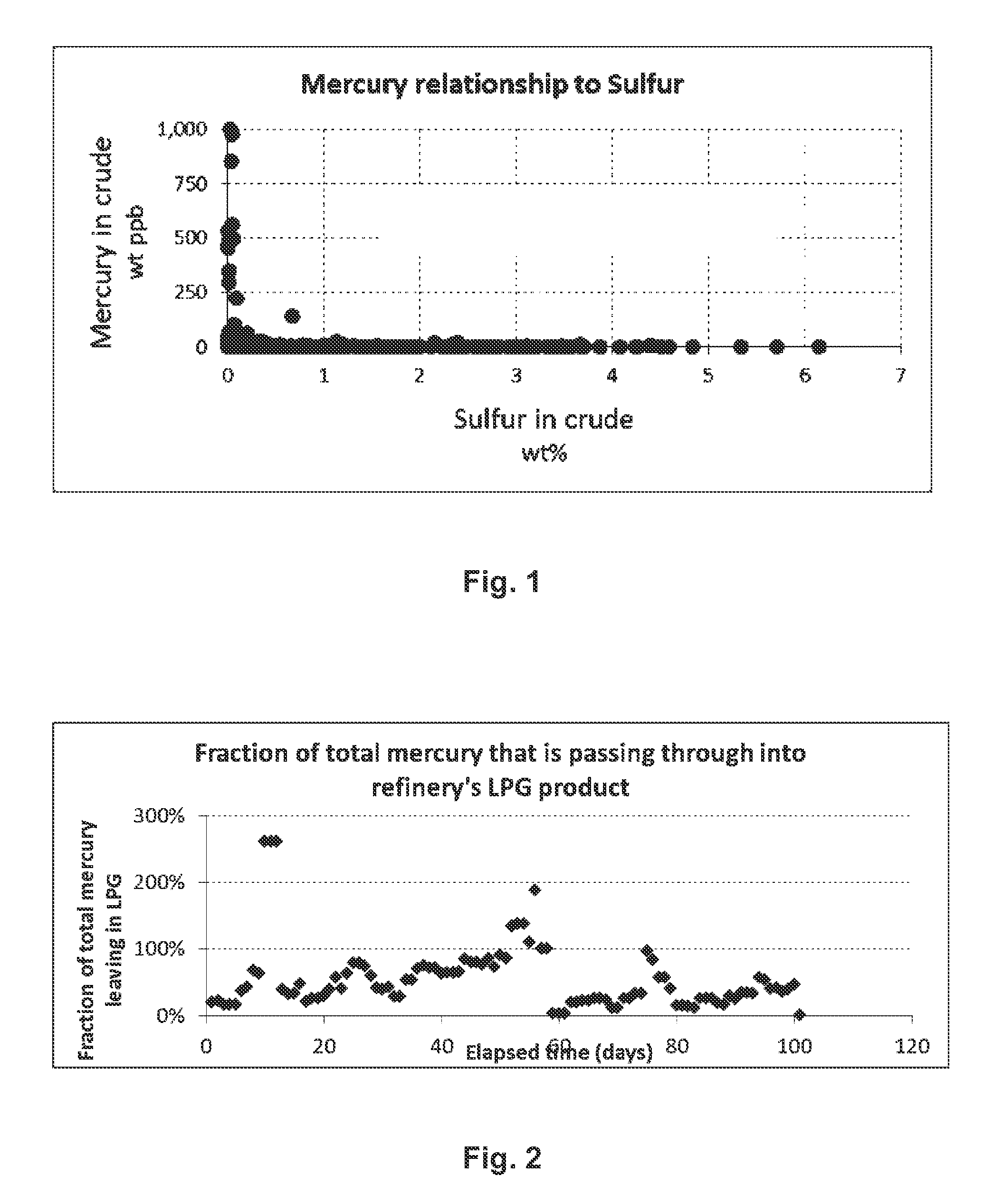

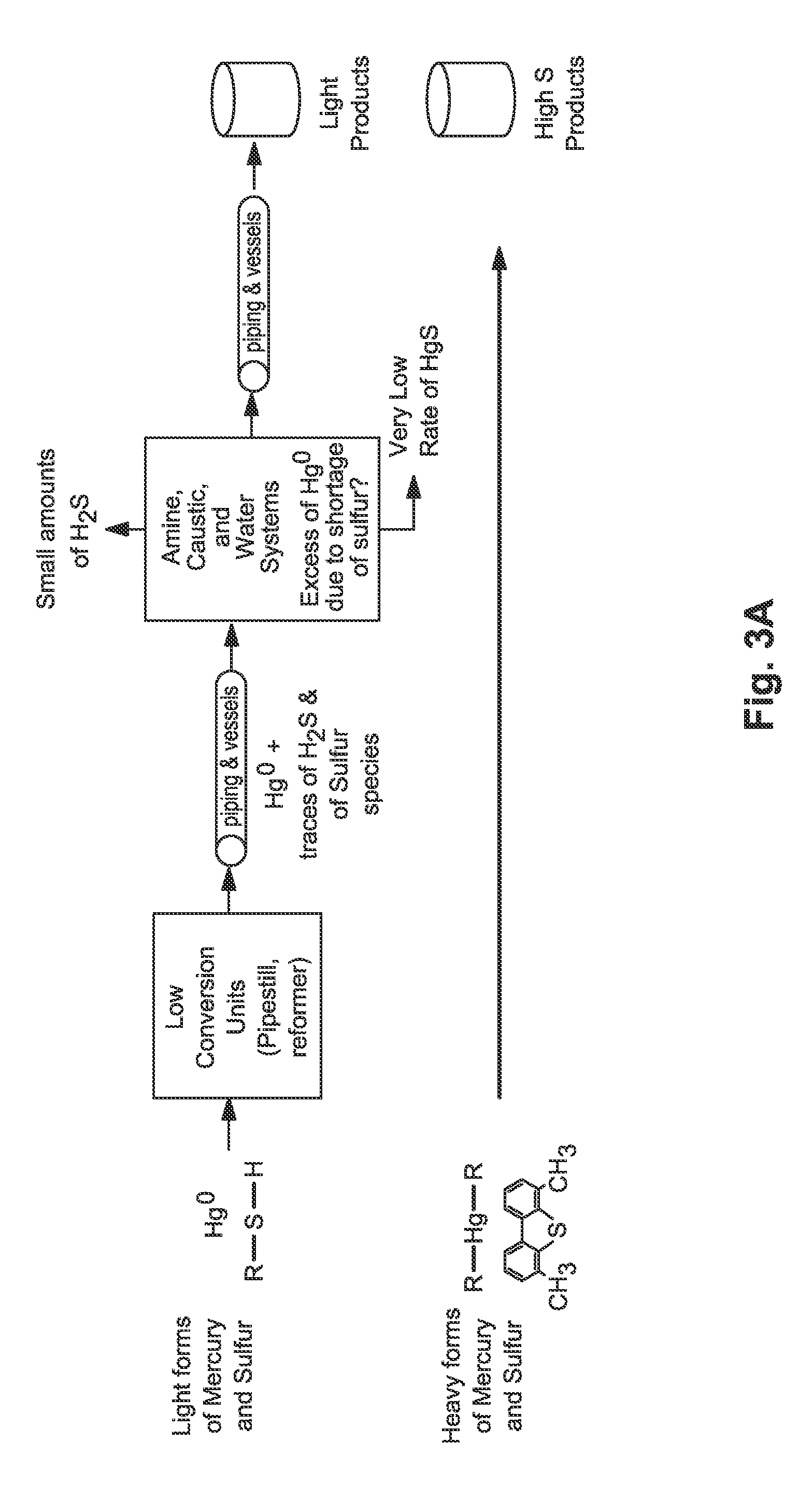

Petroleum refinery mercury control

ActiveUS9441172B2Simple methodLow sulfurRefining with non-metalsRefining to eliminate hetero atomsPetroleum productMethylmercury Compounds

The mercury in crude oils is managed during the refining process to reduce its occurrence in refined petroleum products as well as in refinery emissions and wastes by converting the mercury, which may typically be present in the crude in elemental, ionic or combined organic (organomercury) forms, by operating the refinery on a blend of crudes comprising a mercury-containing crude of low sulfur content and a high sulfur crude. For optimal mercury control, the refinery should be operated in a high conversion regime, preferably with hydroprocessing (severe hydrotreating, hydrocracking) suitable for converting refractory, non-reactive sulfur compounds in the high sulfur crudes to more reactive forms including, for example, hydrogen sulfide, which will combine with the mercury present from the mercury-containing crude to form solid mercury sulfides which may be removed as solid waste by-products and disposed of in an environmentally acceptable manner.

Owner:EXXON RES & ENG CO

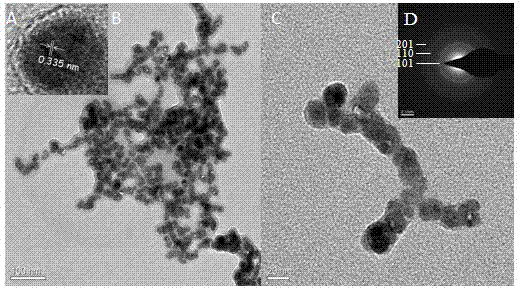

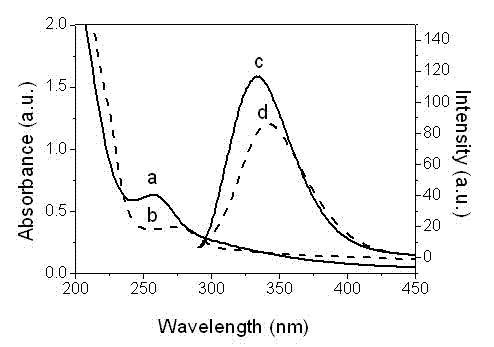

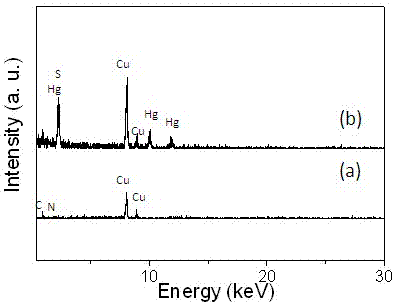

Method for preparing mercuric sulfide (HgS) quantum dots by using mercury-containing wastewater

InactiveCN102633296AEasy to handleHarm reductionNanotechnologyMercury compoundsHigh concentrationActivation method

The invention provides a method for preparing mercuric sulfide (HgS) quantum dots by using mercury-containing wastewater. The method mainly comprises the following steps of: enabling Hg<2+> to react with an organic complexing agent so as to form a mercuric organic complex and transferring the Hg<2+> in a water phase into an oil phase through a phase transfer method; and introducing a sulfur source, and enabling the mercuric organic complex to be combined with the sulfur source so as to produce HgS semiconductor quantum dots respectively through a mixed solvothermal method, a low-temperature stirring method and a high-temperature activation method. According to the method for preparing the HgS quantum dots by using the mercury-containing wastewater, the mercury-containing wastewater can be effectively treated and then can reach the national emission standards (the mercury content is lower than 0.05 mg / L), and the HgS semiconductor quantum dots with a higher application value are synthesized, so that get a double advantage, and the effect of changing waste into valuable is achieved. Moreover, the drugs needed in the method are little in environmental hazard and low in cost, the treatment cost is lowered, and the method for preparing the HgS quantum dots by using the mercury-containing wastewater is especially applicable to the treatment of high-concentration mercury-containing wastewater.

Owner:XINJIANG UNIVERSITY

Application of mercuride in preparing antivenom medicaments

InactiveCN101879186AAvoid damageSave livesHeavy metal active ingredientsAntinoxious agentsBiotechnologyTreatment effect

The invention discloses application of mercuride in preparing antivenom medicaments, aiming at solving the problems of unobvious treatment effect, high death rate and the like in the prior art, wherein the mercuride is one of mercuric sulfide, mercuric oxide, mercuric sulfate, mercuric chloride and the like. Because the main component in the mercuride is heavy metal which has the characteristic of inactivating all proteins, the mercuride has fatal destructive effect on all the proteins; and snake venom is formed by mixing dozens of poisonous proteins, therefore, the mercuride can inactivate the poisonous proteins in the snake venom so as to enable the poisonous proteins to lose activity (toxicity), thereby achieving the purpose of resisting the snake venom.

Owner:丁新侃

Mercury removal agent for treating waste water containing mercury

InactiveCN102476860AHigh selectivityWill not cause secondary pollutionWater contaminantsTreatment with anaerobic digestion processesSodium bicarbonateIron sulfate

The invention discloses mercury removal agent for treating waste water containing mercury, which is formed by compounding engineering bacillus, inorganic matters and organic aldehyde. The engineering bacillus includes one or two of engineering acidithiobacillus, iron-oxidizing bacteria, mercury removal bacillus and pseudomonas cepacia, the inorganic matters include one or two of sodium chloride, sodium bicarbonate, sodium bisulfate and ferrous sulfate, and the organic aldehyde includes one or two of cyclohexyl formaldehyde, trioxymethylene, O-phthalic aldehyde and p-fluoro benzaldehyde. Undera condition with a pH (potential of hydrogen) value ranging from 6.0 to 8.0, the composite mercury removal agent is added into waste water with mercury concentration ranging from 50mg / L to 1000mg / L, the mass ratio of the fed mercury removal agent to the waste water ranges from 1:100 to 1:500, fermentation is carried out for 24 to 48 hours under an anaerobic condition, mercury in the waste water can be converted into mercury steam, the mercury steam is absorbed by hydrogen sulfide gas to generate precipitated mercuric sulfide, and accordingly the purpose of removing the mercury is achieved.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

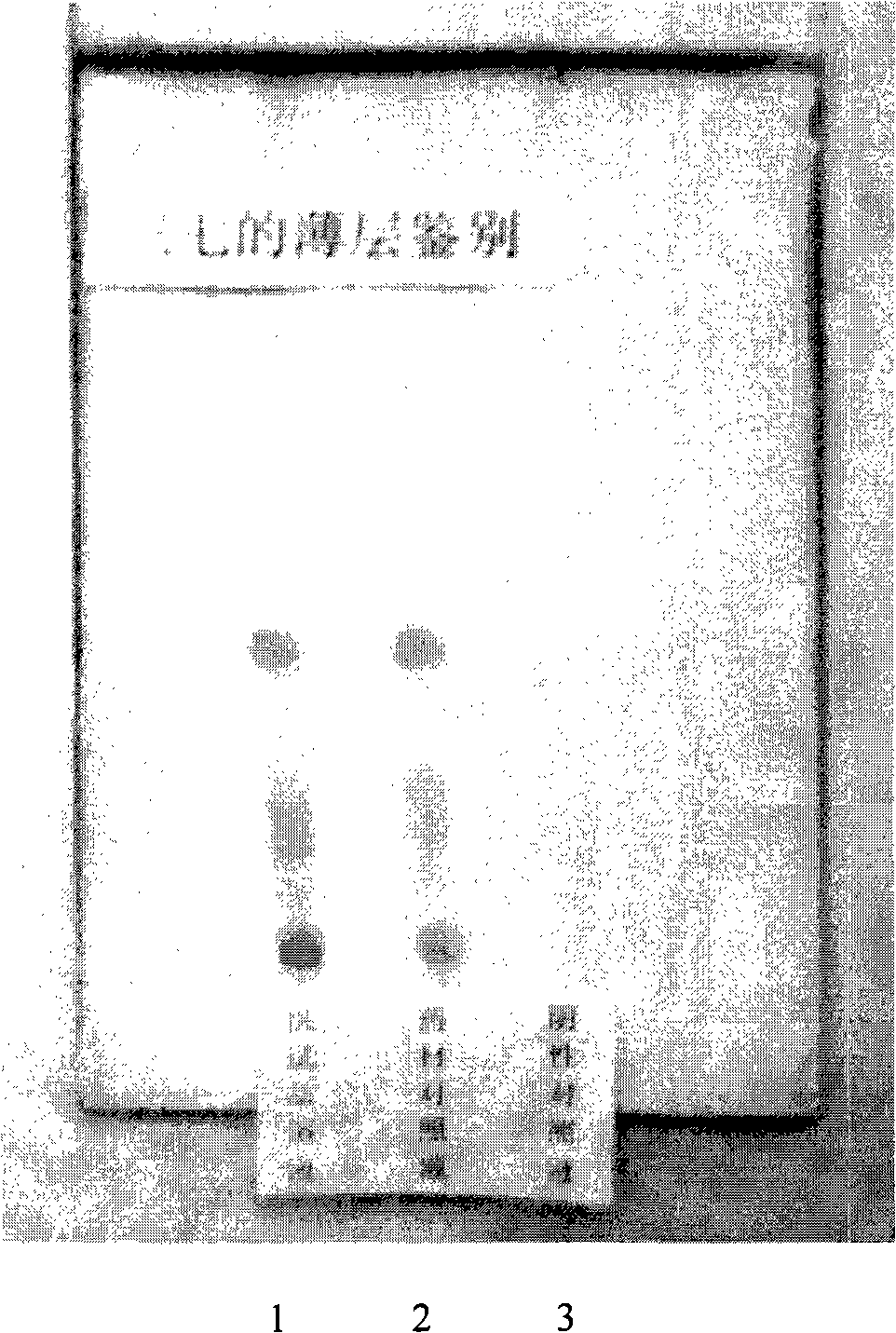

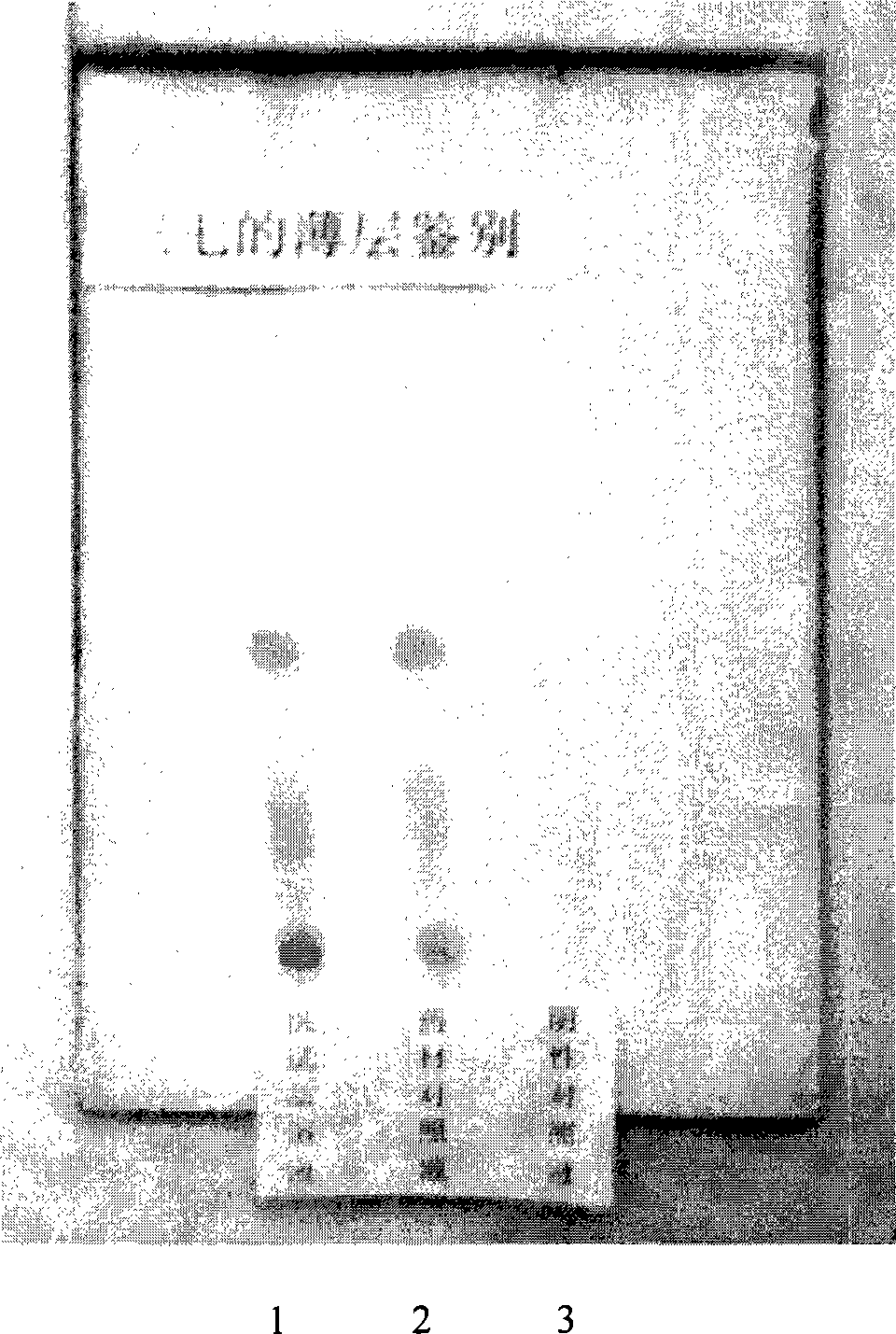

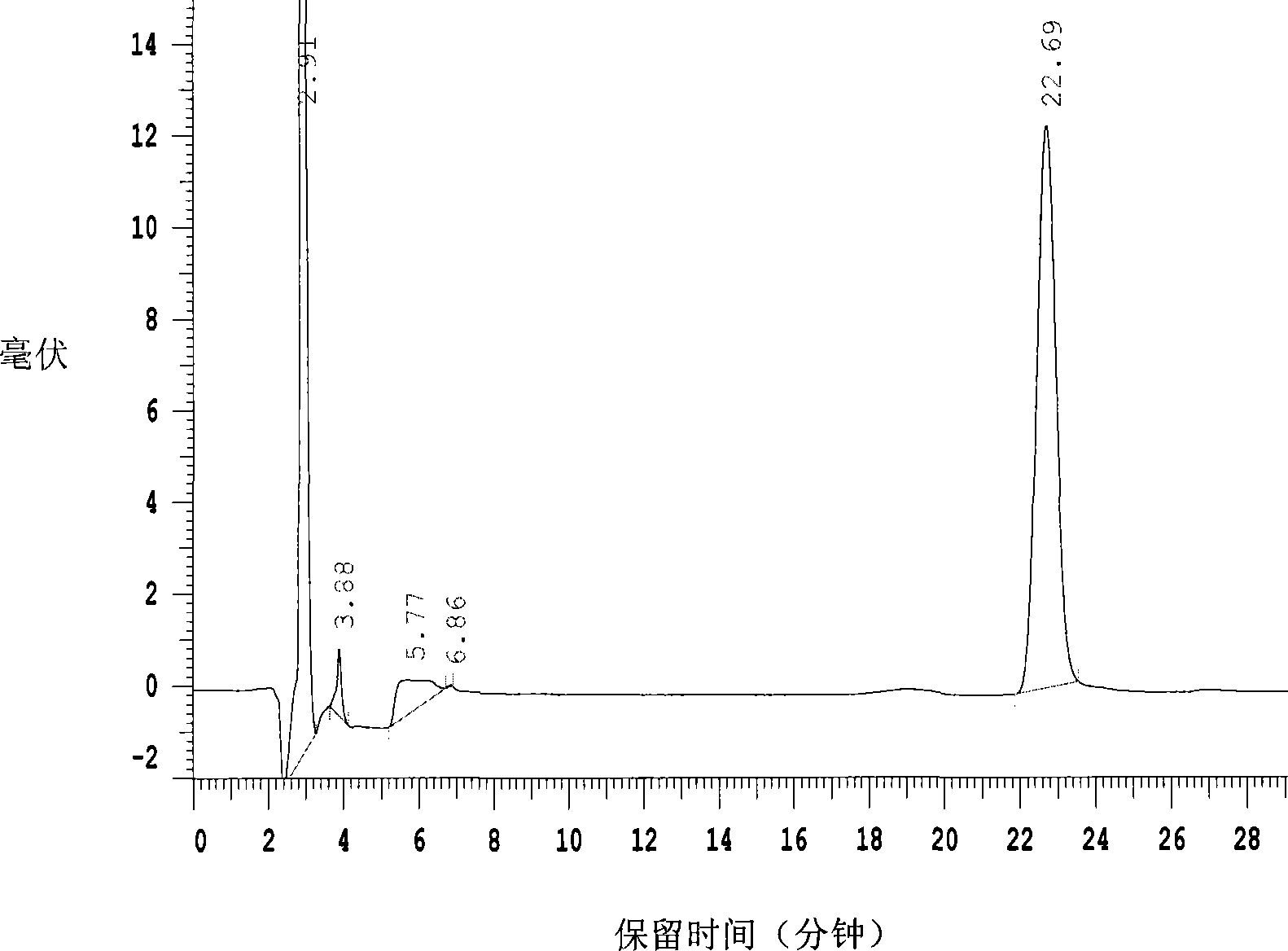

Quality control method of Shangke bone-knitting medicine

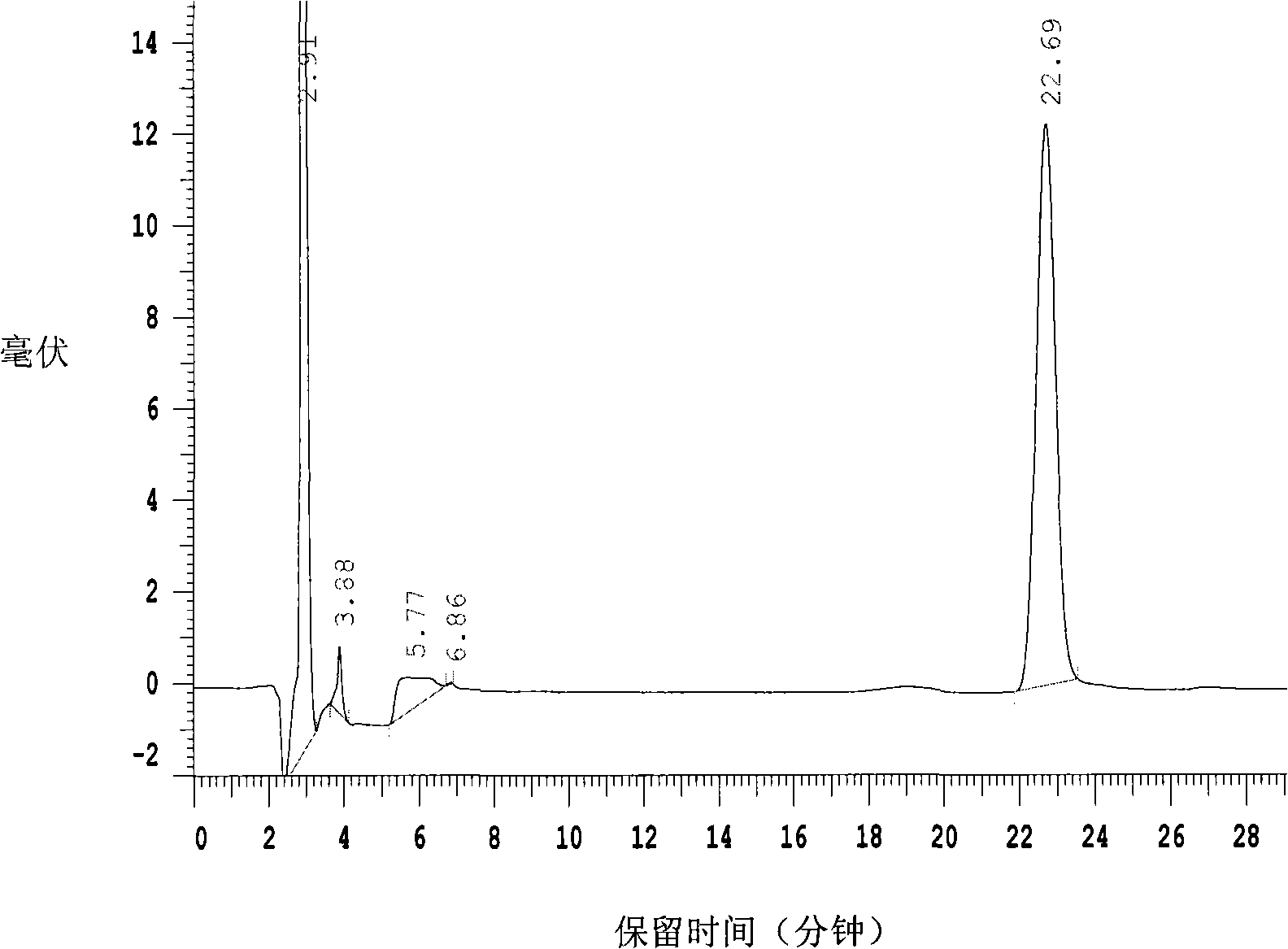

InactiveCN101278976AIncrease assayGuaranteed curative effectHeavy metal active ingredientsAnthropod material medical ingredientsElectrophoresisQuality control

The invention discloses a quality control method for orthopedics-traumatology coaptation. The method adopts TLC to carry out qualitative identification for notoginseng, borneol, safflower and Nux vomica powder and uses electrophoresis for carrying out qualitative identification for starfish. HPLC and GC are respectively adopted to carry out quantitative identification for strychnine and the borneol. Chemical titration is adopted to carry out quantitative identification for mercury sulfide. Therefore, the quality control scope of the orthopedics-traumatology coaptation is enlarged. The quality control method for orthopedics-traumatology coaptation is easy to be practiced and has strong specialization. In addition, the quantitative identification has high precision and good repeatability, thus ensuring that the quality of compound medicine is uniform, stable, effective and controllable.

Owner:大连美罗中药厂有限公司

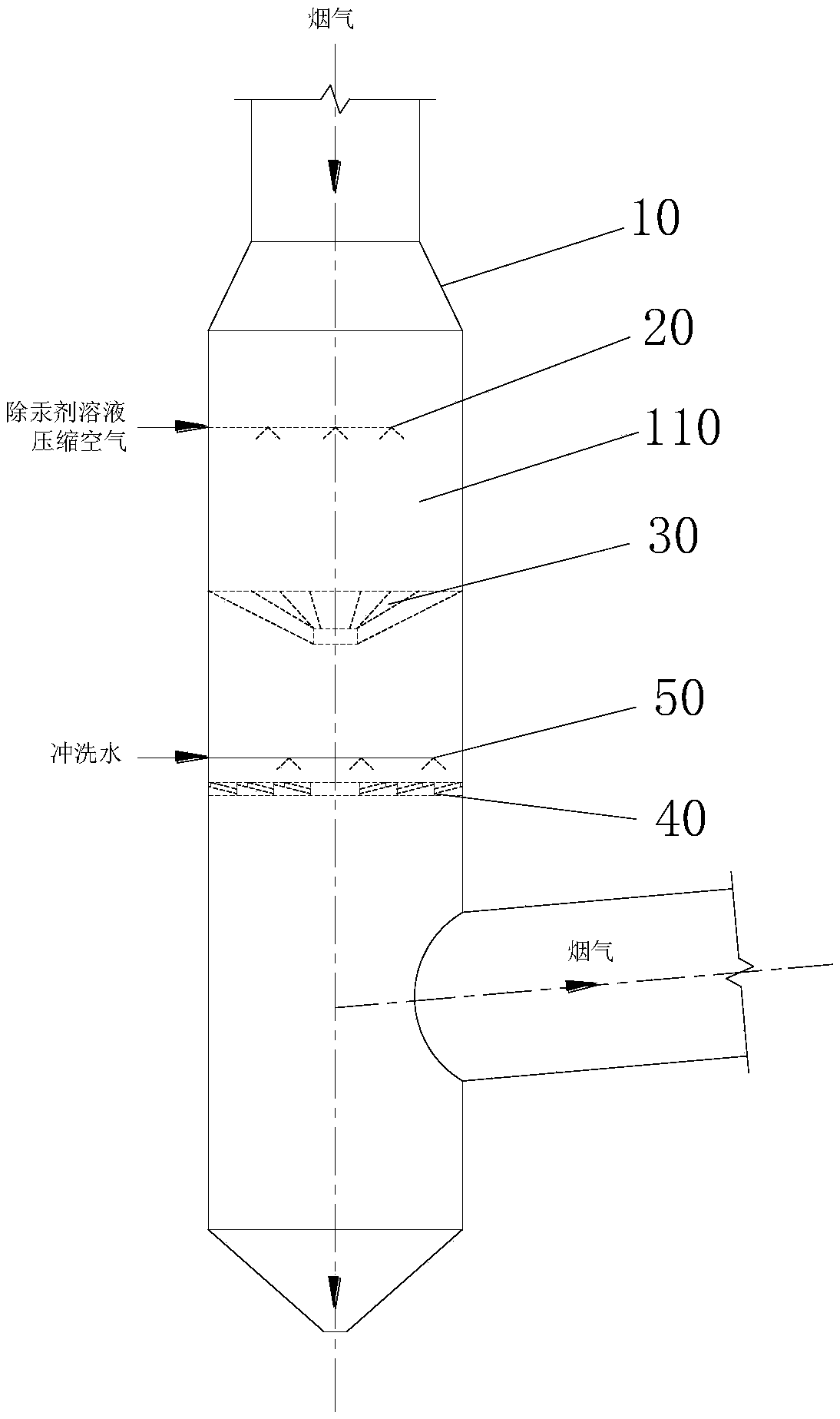

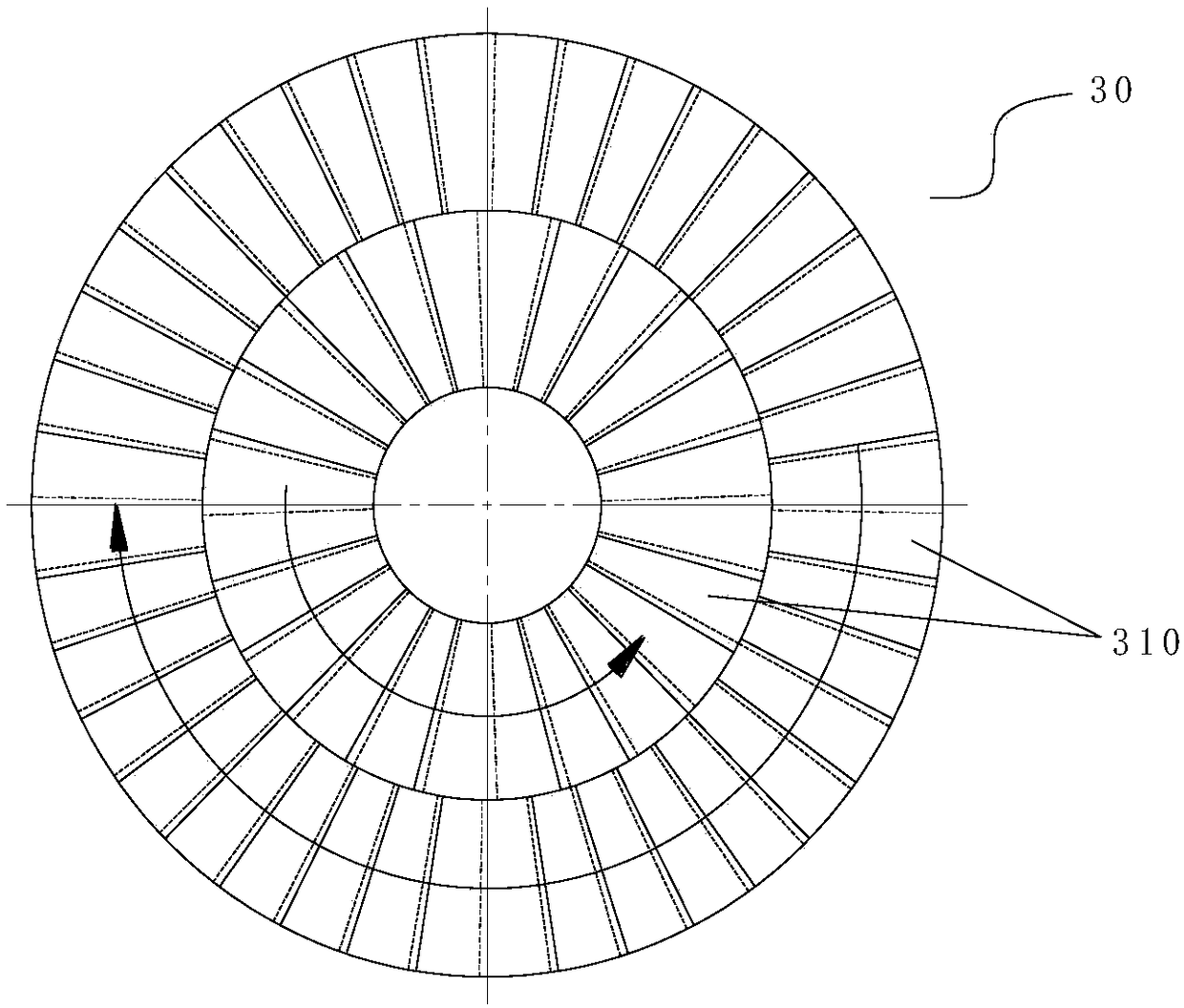

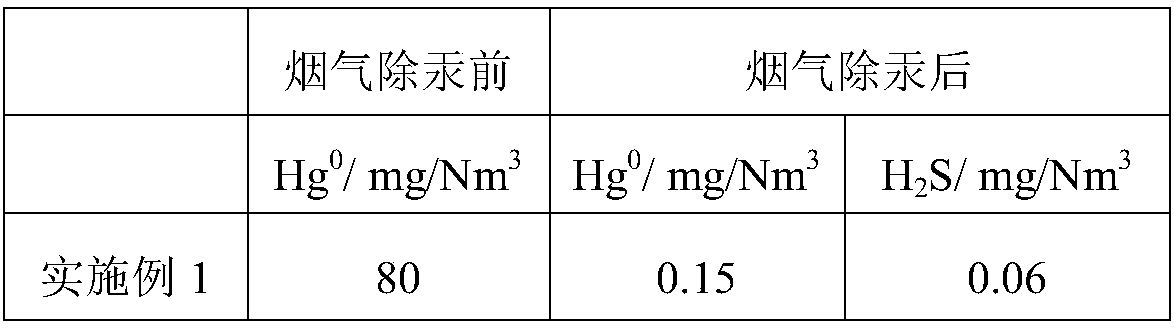

Flue gas mercury removing method

ActiveCN108889110AGood for mercury removalGood dispersionGas treatmentDispersed particle separationFlue gasHigh activity

The invention provides a flue gas mercury removing method. The flue gas mercury removing method comprises the following steps of performing mercury removal, during which mercury remover reacts with sulfur dioxide inside the flue gas into produce elemental sulfur which is applied to processing mercury contained in the flue gas. The mercury remover reacts with the sulfur dioxide inside the flue gasto produce the high-dispersion and high-activity elemental sulfur, which can effectively react with the sulfur dioxide inside the flue gas into mercury sulfide and accordingly remove the mercury out of a system, and also, unreacted superfluous elemental sulfur can be discharged out of the system along with the mercury sulfide. Therefore, the flue gas mercury removing method can achieve mercury removal of the flue gas, and with the superfluous elemental sulfur, can avoid excessive concentration of hydrogen sulfide and further avoid adverse effects of excessive hydrogen sulfide on a subsequent sulfuric acid system.

Owner:CHINA ENFI ENGINEERING CORPORATION

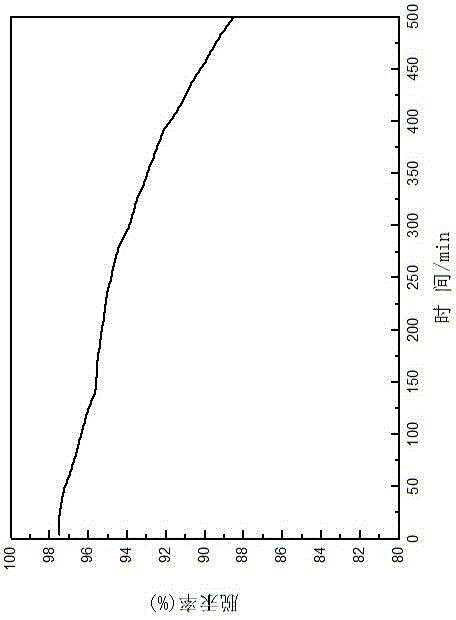

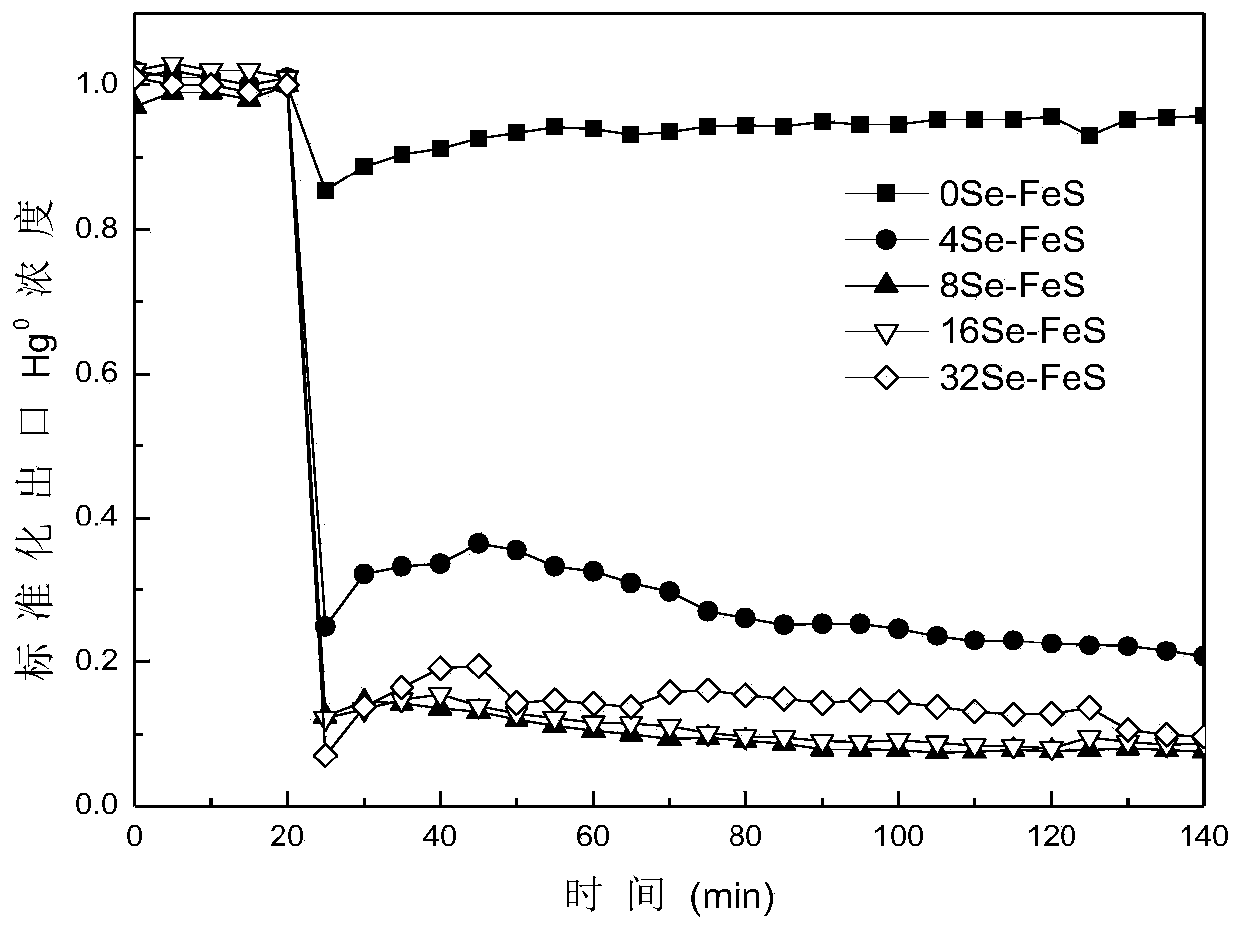

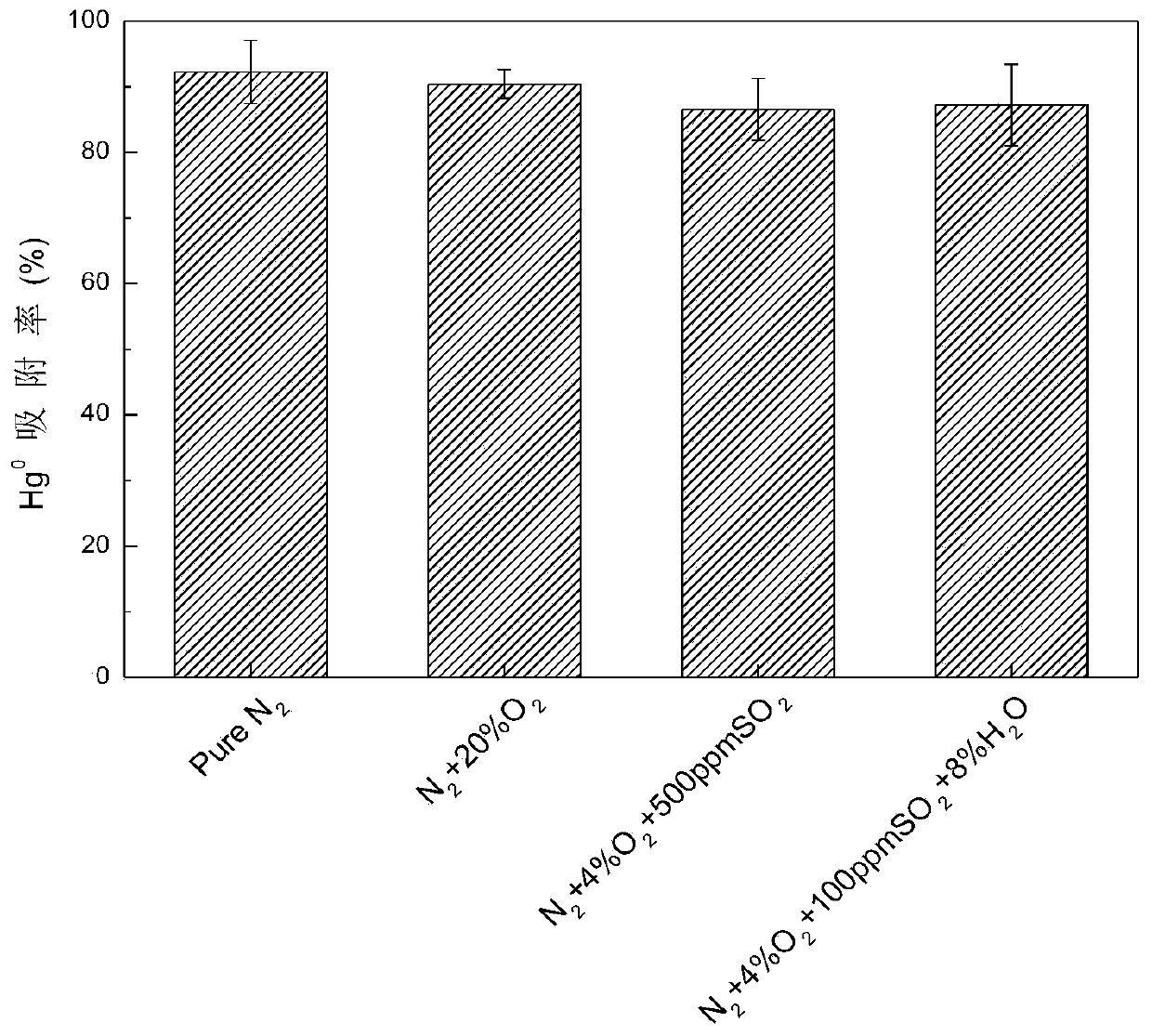

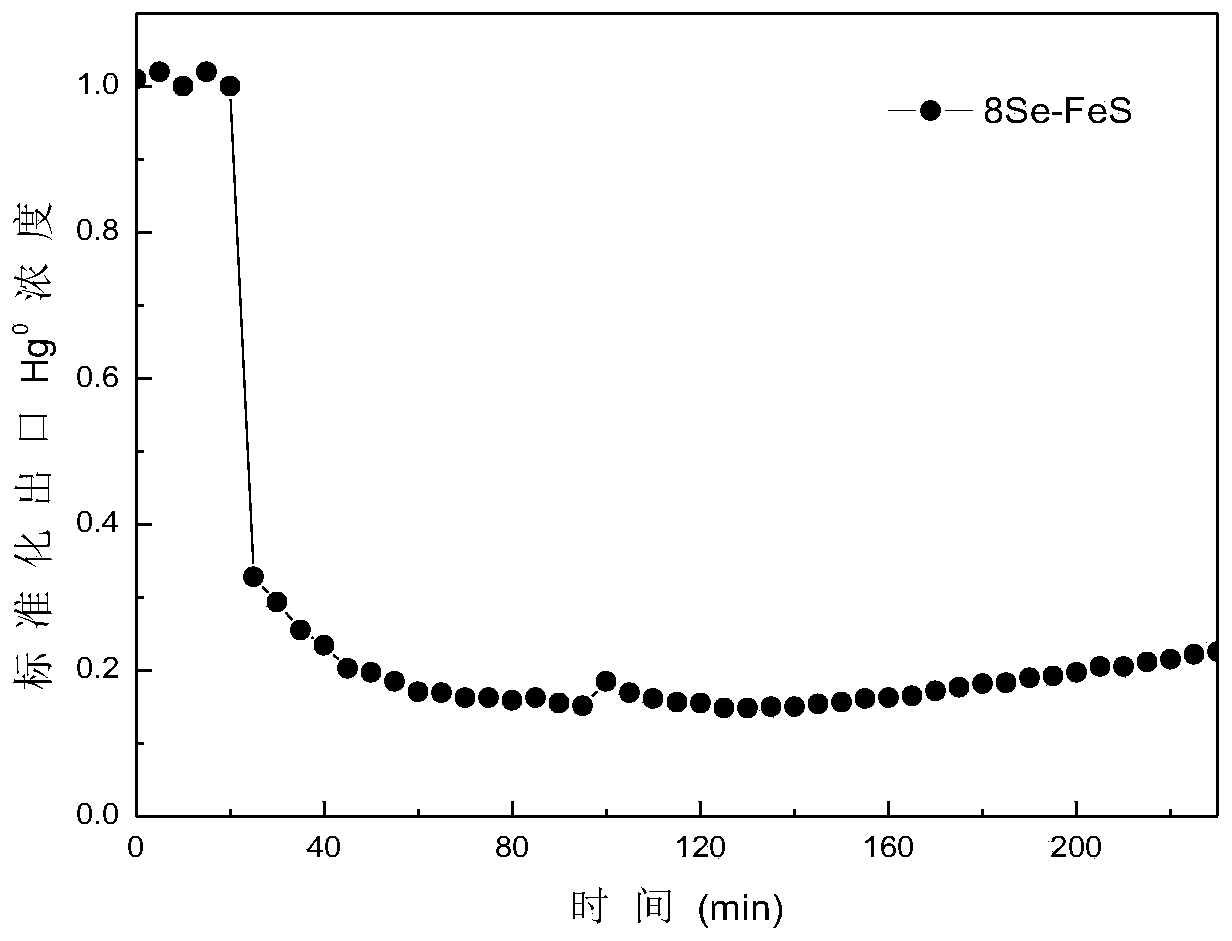

Natural sulfide mineral-based material as well as preparation method and application thereof

The invention discloses a natural sulfide mineral-based material as well as a preparation method and an application thereof. According to the method, a simple one-step anion exchange reaction is employed, and natural metal sulfide minerals are soaked in a Se2-precursor solution to synthesize selenium ion-coated natural sulfide minerals serving as a novel mercury adsorbent; the natural metal sulfide mineral comprises pyrrhotite, pyrite, sphalerite, alabandite, tungstenite and a mixture of the pyrrhotite, pyrite, sphalerite, alabandite and tungstenite. The mercury adsorbent obtained by the invention is used as a mercury removal medium to be in contact with gas-phase elemental mercury in a fixed bed, a fluidized bed or an injection tower, so that the gas-phase elemental mercury is converted into stable mercury sulfide. The preparation method of the natural sulfide mineral-based material is rich in raw material reserve, simple in process and wide in application range; the natural sulfide mineral-based material has extremely high mercury adsorption capacity and adsorption rate, is applied to removal of elemental mercury in a gas phase, and has the advantages of simplicity in operation,high efficiency, environmental friendliness of mercury removal products and the like.

Owner:CENT SOUTH UNIV

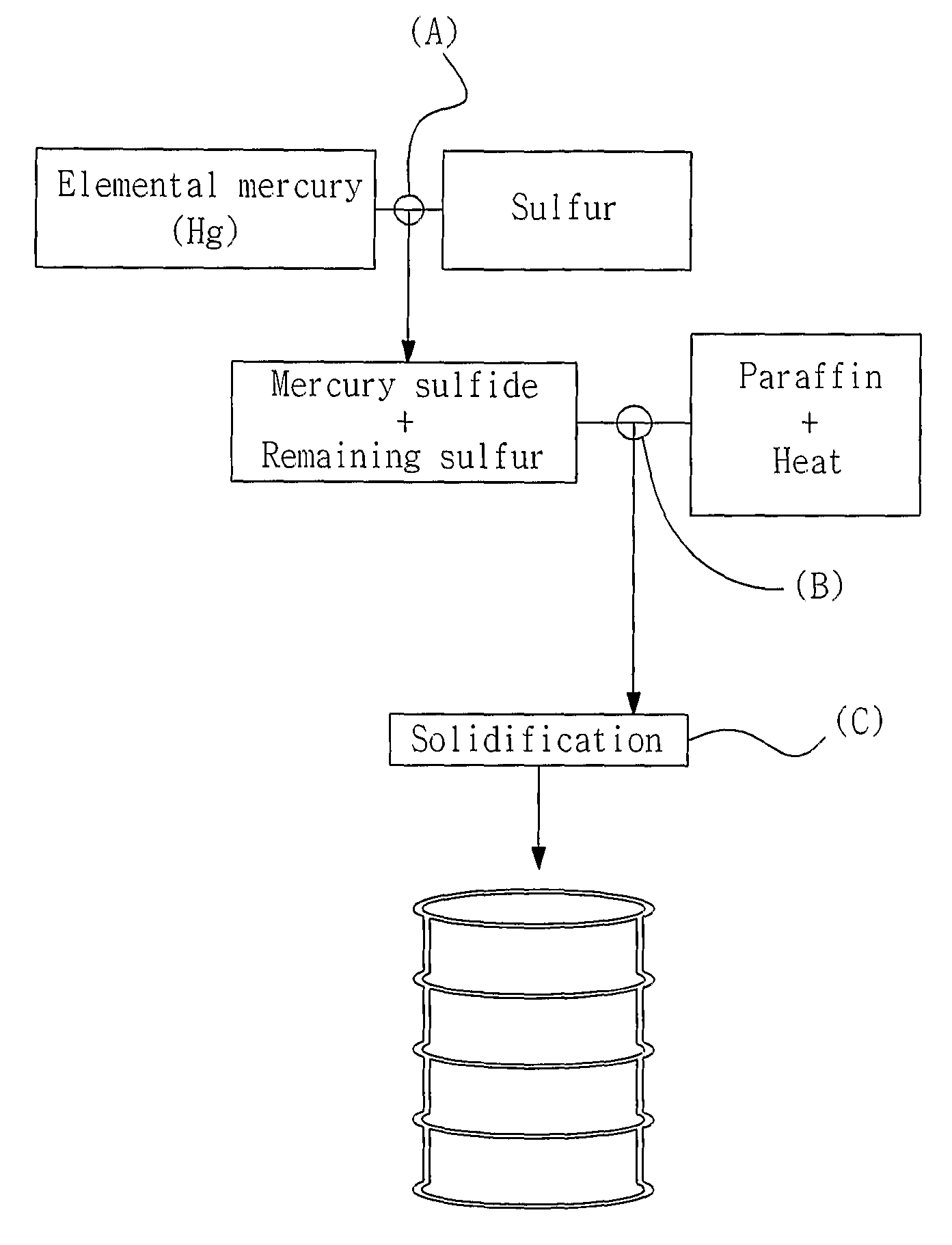

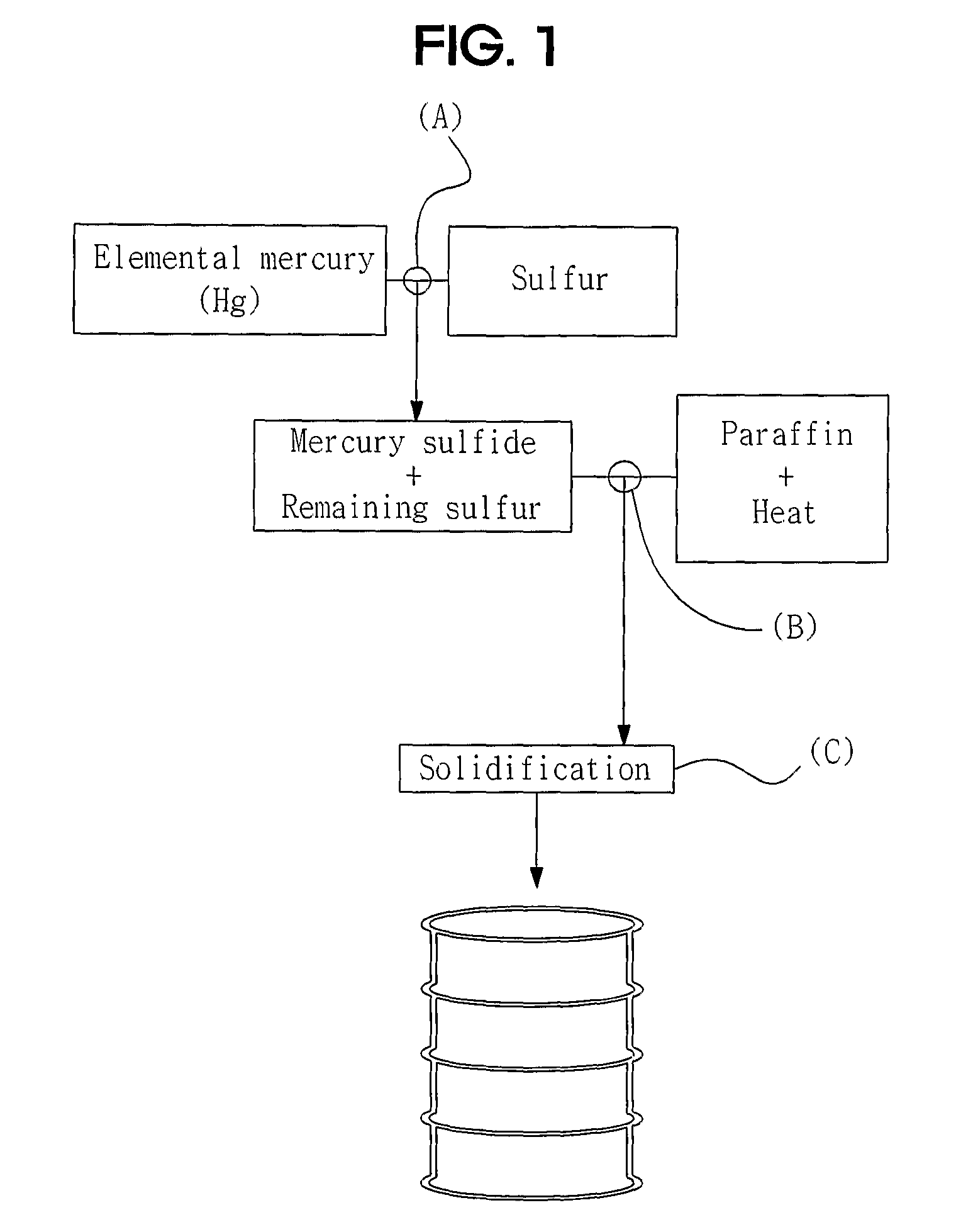

Method of Stablizing and Solidifying Elemental Mercury Using Sulfur and Paraffin

Provided is a method of stabilizing and solidifying elemental mercury using sulfur and paraffin. The method includes reacting elemental mercury with sulfur to prepare a mercury sulfide compound, adding a mixture of the mercury sulfide compound and the remaining sulfur after the reaction to high-temperature liquid paraffin to melt the remaining sulfur, and cooling the sulfur to solidify the mercury sulfide compound. According to the method of stabilizing and solidifying elemental mercury using sulfur and paraffin, a surface of a solidified product is covered with a thin paraffin layer to prevent exposure to the outside.

Owner:PRECISION & PERSONALIZED MEDICINE INC

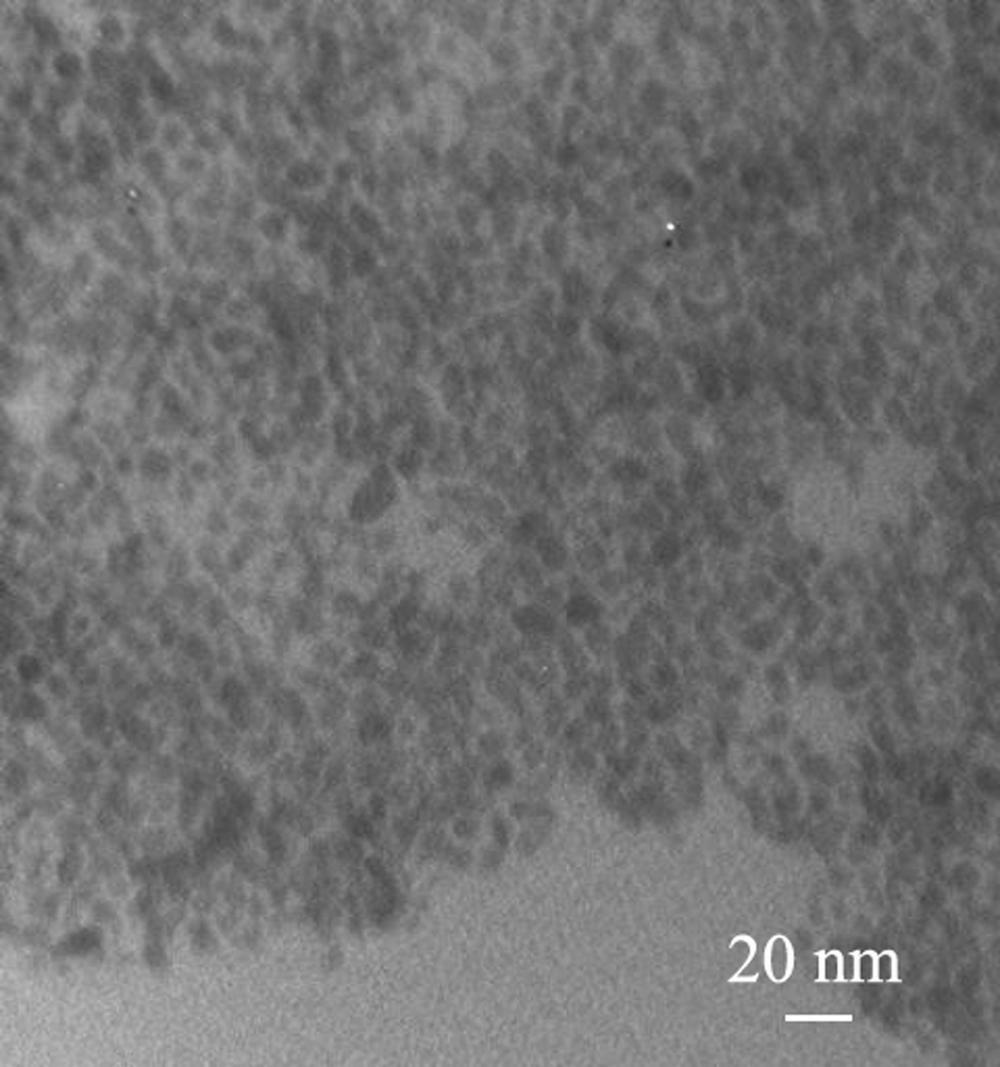

Process for control synthesis of nanometer mercuric sulfide particles based on sheep-anti-human antibody as soft template

InactiveCN102249291AGood dispersionImprove stabilityMaterial nanotechnologyMercury compoundsProtein moleculesSulfide

The invention which provides a process for control synthesis of nanometer mercuric sulfide particles based on a sheep-anti-human antibody as a soft template belongs to technical fields of mercuric sulfide synthesis and nanometer materials. The process has many advantages that: firstly, conditions of reaction generation are mild; secondly, the nanometer particles synthesized through a template control method have the characteristics of uniform particle size and good dispersiveness, and insufficients of traditional methods are overcome; in addition, a material synthesized through treating biomolecules as the template has a good biological compatibility, and protein molecules directly coated on surfaces of the material can interact with other biomolecules, so the material can be used in biological tagging, biological imaging analysis and the like, and has an absolute advantage in the biomineralization aspect; finally, the process has a versatility, and other compounds of zinc sulfide, silver sulfide, cadmium sulfide, lead sulfide, copper sulfide and the like can be obtained through control synthesis with the protein molecules as the template. The process of the present invention is avery effective process for control synthesis of nanometer particles.

Owner:SICHUAN UNIV

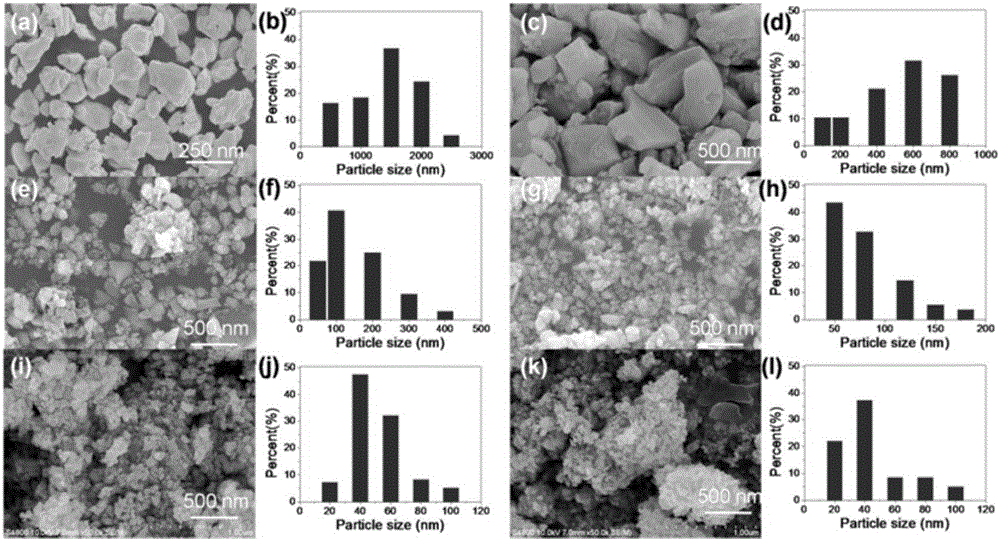

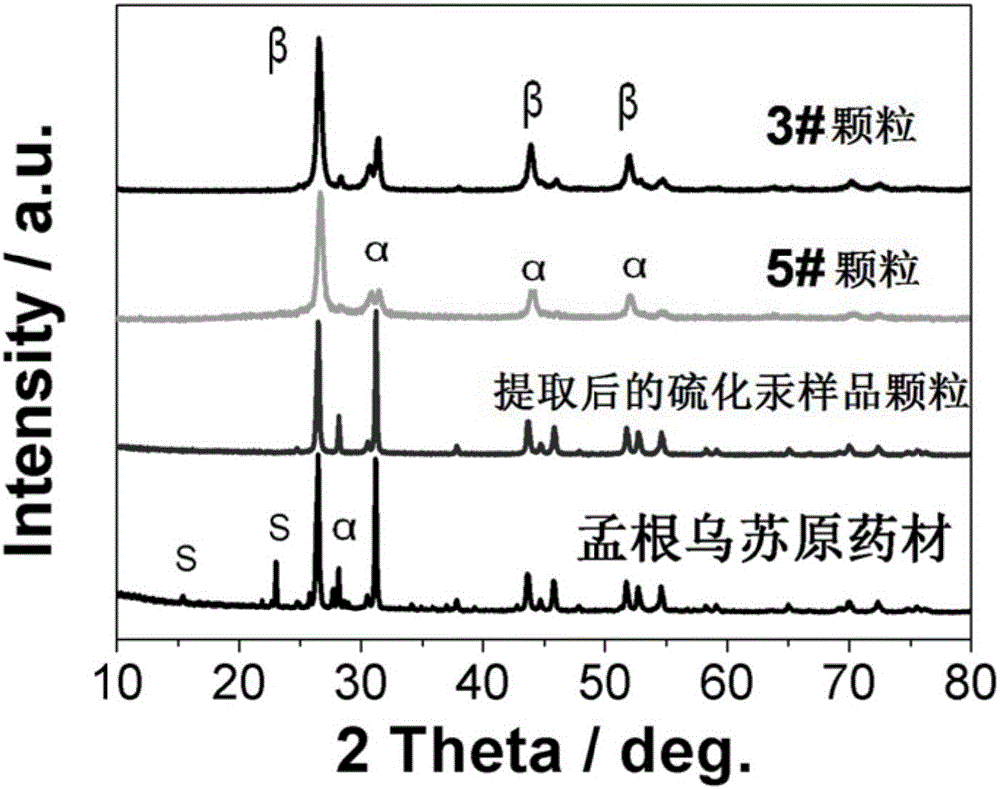

Method for extracting and separating mercury sulfide nanoparticles in Mongolian medicine Menggenwusu

ActiveCN105731524AEfficient separationPlay a key roleNanotechnologyMercury compoundsSulfurCentrifugation

The invention relates to a method for extracting and separating mercury sulfide nanoparticles in a Mongolian medicine Menggenwusu, belonging to the field of active ingredient extraction of a traditional processed product of a Mongolian medicine. The method comprises extraction of mercury sulfide sample particles and differential separation of mercury sulfide micro-nanoparticles, wherein in the extraction, the mercury sulfide sample particles are extracted by xylene, and elemental sulfur in Menggenwusu is removed; and in the differential separation, the mercury sulfide micro-nanoparticles different in particle size can be obtained by controlling the PVP concentration, feed ratio, centrifuge speed and centrifugation time. By adopting the method provided by the invention, the extracted mercury sulfide micro-nanoparticles have high purity, stable composition and exact structure while clinical administration is more scientific; and moreover, with the separated mercury sulfide micro-nanoparticles different in particle size, the efficacy of the nanoparticles different in particle size can be compared.

Owner:INNER MONGOLIA MEDICAL UNIV

Method for treating mercury-containing hazardous waste slag by combining low-temperature thermal desorption with chemical leaching

ActiveCN107413823AVolatile fastEfficient volatilizationSolid waste disposalTransportation and packagingOrganic acidSlag

The invention discloses a method for treating mercury-containing hazardous waste slag by combining low-temperature thermal desorption with chemical leaching. The method comprises the steps that firstly, low-temperature thermal desorption treatment is conducted on the mercury-containing hazardous waste slag to remove organic combined-form mercury and part of low-boiling-point inorganic combined-form mercury in the mercury-containing hazardous waste slag; secondly, leaching is conducted by adopting mixed liquid containing organic acid, iodate and chlorine salt to remove high-boiling-point mercuric oxide-form mercury; and lastly, leaching is conducted by adopting mixed liquid containing sodium sulfide and sodium hydroxide to remove high-boiling-point mercuric sulfide-form mercury. According to the method, multi-form mercury in the mercury-containing hazardous waste slag can be efficiently removed, the mercury residue content is low, the mercury-containing hazardous waste slag can be changed into general waste, the hazardous waste treatment cost is greatly reduced, and the condition that secondary pollution is caused to the environment is avoided.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Quality control method of Shangke bone-knitting medicine

InactiveCN101278976BIncrease assayGuaranteed curative effectHeavy metal active ingredientsAnthropod material medical ingredientsElectrophoresisQuality control

The invention discloses a quality control method for orthopedics-traumatology coaptation. The method adopts TLC to carry out qualitative identification for notoginseng, borneol, safflower and Nux vomica powder and uses electrophoresis for carrying out qualitative identification for starfish. HPLC and GC are respectively adopted to carry out quantitative identification for strychnine and the borneol. Chemical titration is adopted to carry out quantitative identification for mercury sulfide. Therefore, the quality control scope of the orthopedics-traumatology coaptation is enlarged. The qualitycontrol method for orthopedics-traumatology coaptation is easy to be practiced and has strong specialization. In addition, the quantitative identification has high precision and good repeatability, thus ensuring that the quality of compound medicine is uniform, stable, effective and controllable.

Owner:大连美罗中药厂有限公司

Wet-type ammonia flue gas purification technics for associated desulfuration demercuration and system

InactiveCN101157003BSimple processSmall footprintDispersed particle separationMercuric ionFluid phase

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Lime sulfur agent for treating mercury-containing waste residues and preparation method thereof

ActiveCN104263977AImprove performanceImprove conversion abilityProcess efficiency improvementLime sulfurElemental mercury

The invention relates to the technical field of treatment agents for mercury-containing waste residues, and in particular relates to a lime sulfur agent for treating the mercury-containing waste residues and a preparation method thereof. The preparation method comprises the following steps: appropriately proportioning quick lime, sulfur powder, water and sodium salt, combining with a preparation process of the lime sulfur agent, and controlling process parameters in process steps to ensure that a relatively optimal structure morphology can be formed among quick lime, the sulfur powder, the water and the sodium salt, so that the performance of the lime sulfur agent can be improved to a highest extent, a transformation capacity of the lime sulfur agent on elemental mercury or mercury salt can be improved, and the recovery rate of recycling mercury from the mercury-containing waste residues can be promoted; and moreover, combining with the control of addition sequences of quick lime, the water, the sulfur powder and the sodium salt to ensure that the structure performance of the lime sulfur agent is relatively excellent, the lime sulfur agent and elemental mercury or the mercury salt can be converted to the highest extent, mercury sulfide complex ions can be formed, and the development of the comprehensive utilization and mercury recycling industries of the mercury-containing waste residues can be promoted.

Owner:铜仁市万山区盛和矿业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com