Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Magnesium oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium oxalate is an inorganic compound comprising a magnesium cation with a 2+ charge bonded to an oxalate anion. It has the chemical formula MgC₂O₄. Magnesium oxalate is a white solid that comes in two forms: an anhydrous form and a dihydrate form where two water molecules are complexed with the structure. Both forms are practically insoluble in water and are insoluble in organic solutions.

Non-woven cloth suspension filler

InactiveCN102838203AChange propertiesImprove adhesionSustainable biological treatmentBiological water/sewage treatmentFerric oxalateAntioxidant

The invention discloses a non-woven cloth suspension filler which is prepared by the following constituents in parts by weight with the conventional method: 40-50 parts of polyethylene, 25-35 parts of polypropylene, 6-10 parts of carbon black, 3-7 parts of ferric oxalate, 4-6 parts of magnesium oxalate and 1-2 parts of antioxidant. The specific gravity of the non-woven cloth suspension filler is closed to that of water. No fixing support is required. The filler can suspend in the water in a pool with aeration stirring and is uniformly fluidized in the whole pool. The energy consumption is low, and the non-woven cloth suspension filler has a good prospect.

Owner:金宝玲

Method for preparing high-purity magnesium oxalate, lithium carbonate and high-purity nanometer magnesia from salt lake brine of high magnesium-lithium ratio

ActiveCN104803399ANo pollution in the processReduce energy consumptionMaterial nanotechnologyCarboxylic acid salt preparationHigh magnesiumLithium carbonate

The invention discloses a method for preparing high-purity magnesium oxalate and lithium carbonate from salt lake brine of high magnesium-lithium ratio. The method comprises the following steps: 1) filtering the salt lake brine to remove suspended matters and solid impurities; 2) adding oxalic acid into the filtered salt lake brine; carrying out reaction for 30 to 180 min under the conditions that the temperature is 20 to 60 DEG C, the pH is 3 to 5, and the stirring speed is 150 to 500 rpm, so as to obtain brine of low magnesium-lithium ratio and magnesium oxalate precipitate; washing the magnesium oxalate precipitate with 40 to 60 DEG C hot water for 3 to 5 times; drying the washed magnesium oxalate precipitate at 80 to 102 DEG C for 60 to 120 min to obtain the high-purity magnesium oxalate of which the purity is larger than or equal to 98%; 3) adding an impurity removing agent into the brine of low magnesium-lithium ratio, so as to obtain refined brine; adding sodium carbonate into the refined brine to obtain lithium carbonate crystal; filtering the lithium carbonate crystal; carrying out washing and drying to obtain lithium carbonate. The magnesium oxalate prepared according to the method is high in purity.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for recycling electrolytic manganese metal anode waste liquor

InactiveCN103466830ASolve the problems existing in the long-term recycling processImprove crystallizationWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteSlag

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

Method for recovering manganese and magnesium from complex salt crystals generated in manganese electrolysis process

The invention discloses a method for recovering manganese and magnesium from complex salt crystals generated in the manganese electrolysis process, which is characterized by recovering manganese and magnesium from complex salt crystals in the mode of preparing manganese dioxide and magnesium oxalate. The method comprises the following steps: totally dissolving the complex salt crystals by hot water to obtain a solution containing manganese sulfate and magnesium sulfate; filtering the solution, and adding an oxidant ammonium persulfate in the obtained filtrate to prepare manganese dioxide; continuously filtering the solution, adding a precipitator oxalate dehydrate into the obtained filtrate to prepare magnesium oxalate; and then, filtering again to obtain a filtrate containing ammonium sulfate and the like, wherein the filtrate can be reused when electrolytic manganese is produced. The manganese dioxide and the magnesium oxalate obtained with the method are pure and can be directly used as other raw materials for industrial production. The method has the characteristics of small investment, low cost and simple technology and is easy to operate, and the recovery rates of manganese and magnesium are respectively 97.9% and 98.7%.

Owner:CHONGQING ACADEMY OF SCI & TECH

Chemical carbon dioxide gas generator

A chemical carbon dioxide gas generator comprising: - a charge housing; - a carbon dioxide gas penetrable charge, contained in the said housing, the charge comprising a) 40-60 wt. % of a substance which upon decomposition generates carbon dioxide, which substance is selected from the group of magnesium carbonate, other carbonates, magnesium oxalate and other oxalates, b) 20-50 wt. % of an oxidiser selected from the group of sodium chlorate, potassium chlorate, lithium chlorate, other metal chlorates, sodium perchlorate, potassium perchlorate, lithium perchlorate, and other metal perchlorates, c) 1-20 wt. % of carbon or another fuel, d) 1-10 wt. % binder, said components a), b), c) and d) together forming 90-100 wt. % of the total weight of the charge; - an ignition device for igniting the charge; - a carbon dioxide gas treatment unit for reducing the content of one or more side-products - which may have been formed by the charge - in the generated carbon dioxide, and / or for cooling carbon dioxide gas generated by the charge; and - an outlet for carbon dioxide gas generated by the charge.

Owner:荷兰应用自然科技研究组织TNO

Process for preparing high-viscosity polyester chip

InactiveCN101508767AOvercome the disadvantage of slow solid-state polycondensation rateImprove quality and efficiencyPolyesterMagnesium acetate

The invention relates to a method for producing high-viscosity polyester slice. The production method comprises esterification reaction, polycondensation reaction and solid phase polycondensation reaction. The method is characterized in that titanium catalyst is added during the esterification reaction or the polycondensation reaction; cocatalyst is also added at the same time; the cocatalyst is magnesium acetate, magnesium oxalate, zinc acetate or zinc oxalate; and the addition of the cocatalyst is based on that the content of magnesian ion or zinc ion in the total weight of polyester is 50-250ppm. The invention has the advantages that the polyester has high solid phase polycondensation speed; the method can satisfy the requirement of industrial production; and the produced high-viscosity polyester slice does not contain heavy metal.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

Preparation method of composite cathode material of rechargeable magnesium battery

InactiveCN105390684AIncrease energy densityImprove cycle stabilityCell electrodesSecondary cellsHigh energyPorous carbon

The invention discloses a composite cathode material of a rechargeable magnesium battery and a preparation method thereof. The preparation method comprises the following steps of mixing and crushing silicon dioxide, vanadium hydroxide, magnesium oxalate and dysprosium oxide to obtain a mixture, and adding a sodium hexametaphosphate dispersing agent and water to obtain a nanometer precursor; immersing a template into a solution including starch, and carbonizing by the entrance of the mixed gas of acetonitrile and nitrogen; adding a carbonized compound into a hydrofluoric acid solution to obtain an N-doped porous carbon material after removal of the template; and carrying out ball milling and sintering on the precursor and the porous carbon material to obtain a carbon-coated rare-earth doped vanadium magnesium silicate composite material. According to the prepared composite material, the vanadium magnesium silicate is taken as a base material, Dy is added to modify the vanadium magnesium silicate, and nitrogen-doped porous carbon is adopted to coat the vanadium magnesium silicate, so that when the composite material is used for the rechargeable magnesium battery, the composite material has higher energy density and good cycling stability, and the battery has high specific capacity and a longer service life.

Owner:宁波高新区锦众信息科技有限公司

Method for preparing magnesia with high specific surface

InactiveCN1872689AExcellent high temperature sintering resistanceImprove performanceMagnesiaMagnesium acetateOxalic acid

This invention provides a method for preparing MgO with ultra-large specific surface area. The method comprises: (1) reacting between magnesium acetate and oxalic acid solution to obtain magnesium oxalate; (2) torrefying at a high temperature to obtain MgO with a specific surface area larger than 400 sq m / g. The method has such advantages as inexpensive raw materials, easy operation and high product quality.

Owner:PEKING UNIV

Method for preparing ferrodolomite under high temperature and high pressure

InactiveCN107512741ANot easy to absorb waterGood chemical stabilityUltra-high pressure processesIron compoundsPlatinumHigh pressure

The invention discloses a method for preparing ferrodolomite under high temperature and high pressure, which comprises the steps of grinding and uniformly mixing analytically pure calcium carbonate, magnesium oxalate dihydrate, ferrous oxalate dehydrate powder and anhydrous oxalic acid according to stoichiometric molar ratio; pressing an obtained mixture into a cylindrical shape by a tablet press; putting a cylindrical sample into a platinum tube, sealing the two ends with a welding gun; taking h-BN as a pressure transmitting medium, putting the platinum sealed sample into an h-BN tube; assembling the sample loaded in the h-BN tube in a high-pressure synthesis assembly block, putting the sample in a six-faced top large press for high temperature and high pressure reaction; taking out the reacted sample, opening the platinum tube by a diamond cutter, naturally airing to obtain the ferrodolomite. The method provided by the invention solves the defects that the present ferrodolomit e preparation method is complex in operation process and long in reaction time, and the obtained sample is low in purity, poor in chemical stability and easy to absorb water.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Magnesium binding agent for cement-free castable and preparation method thereof

ActiveCN110668828AImprove corrosion resistanceImprove thermal shock resistanceCarbide siliconCitrate magnesium

The invention discloses a magnesium binding agent for cement-free castable and a preparation method thereof. The preparation method comprises the following steps: baking a magnesium raw material containing crystal water at a high temperature to remove the crystal water, and then grinding and sieving to obtain the magnesium binding agent, wherein the magnesium raw material can be any one of magnesium citrate, magnesium oxalate, magnesium gluconate and the like, the high temperature is 100-400 DEG C, and the baking time is 1-200 hours. The magnesium binding agent can form a net-shaped structureand has coagulation performance when being added with water and stirred, a refractory castable prepared from the magnesium binding agent has excellent normal-temperature mechanical performance, and spinel generated in situ at high temperature can improve the erosion resistance and thermal shock resistance of the castable; the binding agent has the advantages of no environmental pollution, simple production process, low production energy consumption and the like, is wide in application range, and is suitable for high-alumina, corundum, silicon carbide and other cement-free castables.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Production technique for high-purity nanoscale metal magnesium powder

InactiveCN102728853ASmall particle sizeSmall and uniform particle size distributionUltrasonic assistedSeparation technology

The invention belongs to the field of metal powder production, and in particular relates to a production technique for high-purity nanoscale metal magnesium powder. The production process comprises the following steps of: reacting magnesium hydroxide with oxalic acid to generate magnesium oxalate, controlling crystallization by adopting an ultrasonic-assistant crystallization technology with frequency of 21-140KHz under stirring condition after reaction is finished, filtering, conducting high-temperature vaporization to magnesium oxalate to generate nanoscale metal magnesium powder and carbon dioxide gas, and separating by a gas-solid separation technology to obtain nanoscale metal magnesium powder. The prepared magnesium powder has the advantages of small grain size, small grain size distribution range, good crystal form, complete crystal face, high surface activity, large specific surface area and the like.

Owner:仇晓丰

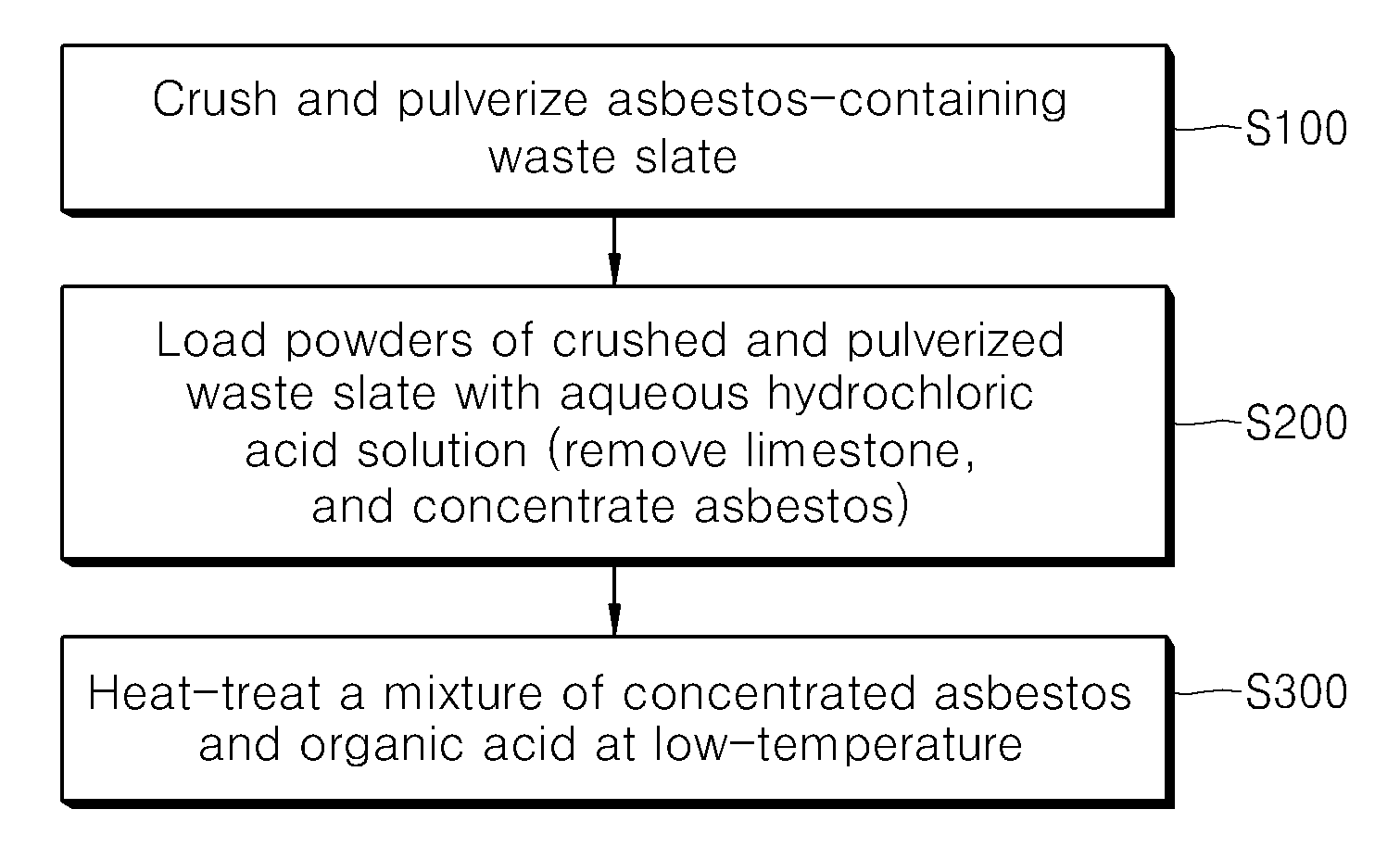

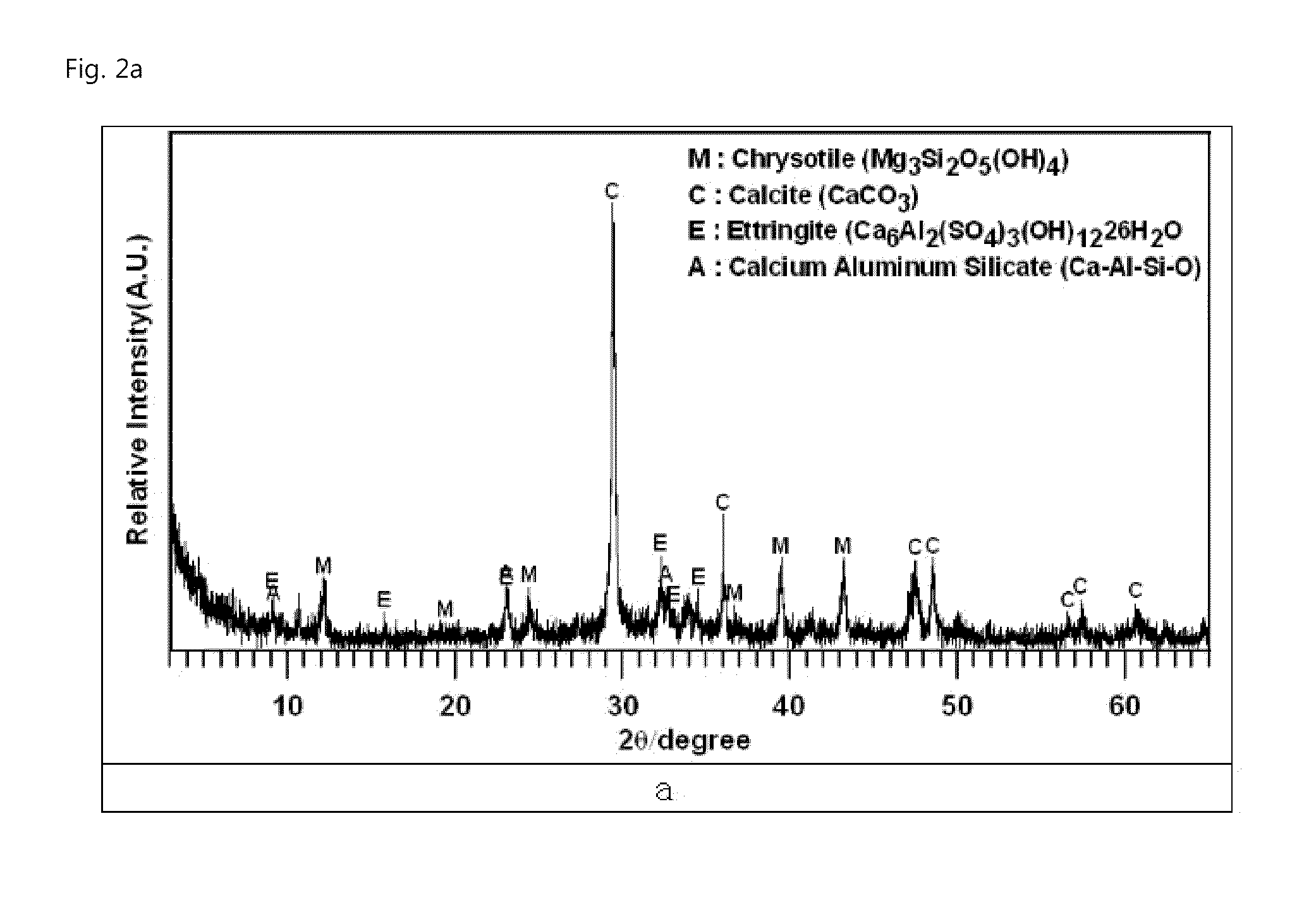

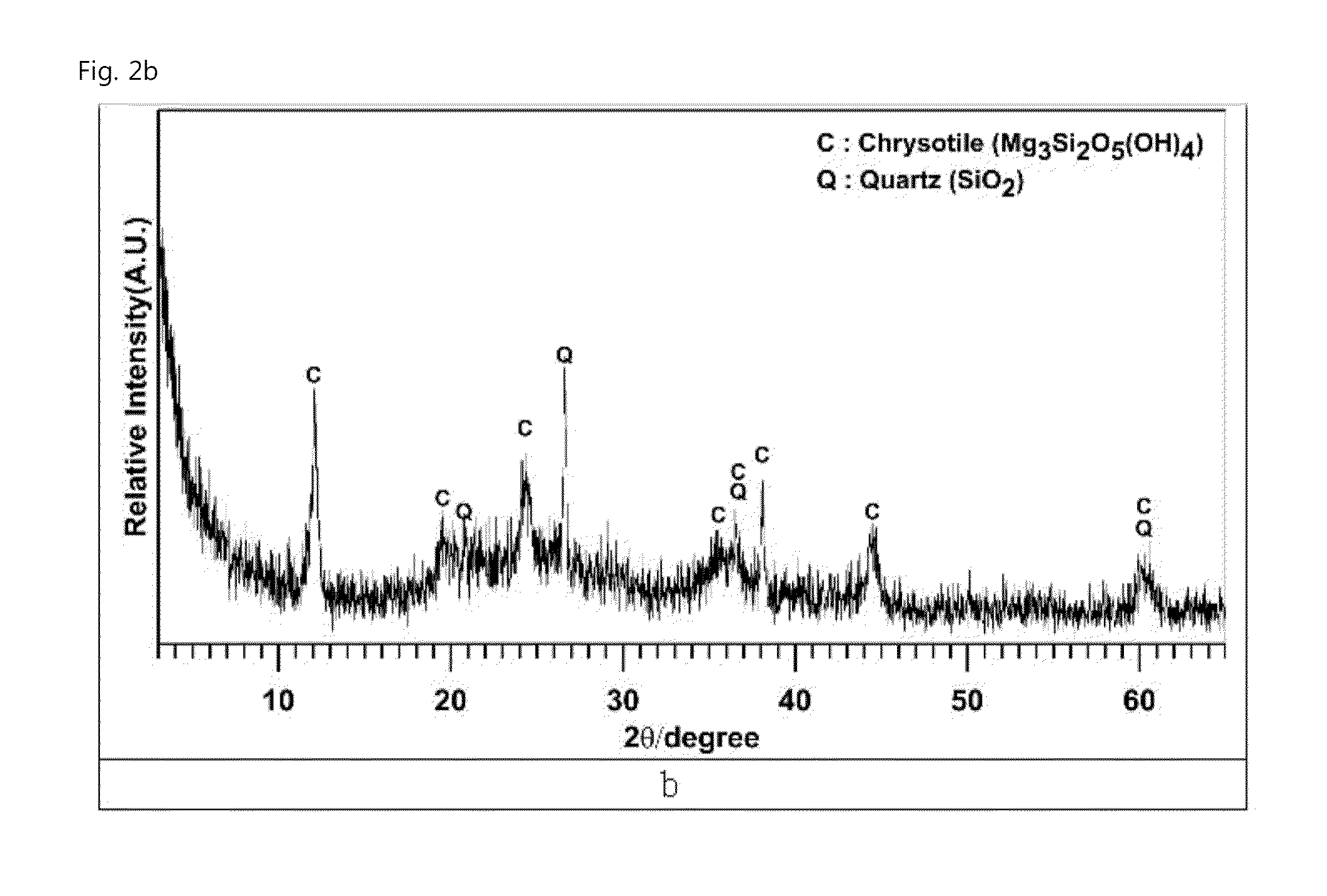

Method of detoxifying asbestos contained in waste slate and detoxified asbestos obtained through the same

ActiveUS20140378735A1Avoid damageLow costOrganic chemistrySolid waste disposalAqueous solutionOxalic acid

Disclosed is a method of detoxifying asbestos of waste slate. The method includes concentrating the asbestos by introducing hydrochloric acid aqueous solution into waste slate powder to dissolve and remove a limestone component contained in the waste slate; and mixing the concentrated asbestos with oxalic acid and performing a low-temperature heat treatment. The waste slate is crushed and pulverized and powder of the crushed and pulverized waste slate is formed in a size in a range of 100 meshes to 300 meshes. The detoxified asbestos includes re-crystallized magnesium oxalate having a rhombohedral or amorphous shape.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Method for preparing spectrally pure magnesium oxide

The invention relates to a method for preparing spectrally pure magnesium oxide. The preparation method comprises the following steps of: reacting metal magnesium powder with nitric acid, namely putting the magnesium powder into a small white porcelain pot, dripping high-purity diluted nitric acid into the pot, then adding H2O2 into the pot, and filtering the mixture to obtain filtrate A so as toobtain magnesium nitrate; and preparing saturated solution from high-purity oxalic acid, slowly adding the oxalic acid solution into the filtrate A to generate a large amount of white sediment, and heating and cooling the sediment to separate out the spectrally pure magnesium oxide. According to the preparation method, the metal magnesium powder is reacted with the nitric acid to prepare the magnesium nitrate, the prepared magnesium nitrate is reacted with the high-strength oxalic acid to generate magnesium oxalate, and the magnesium oxalate is dried at a high temperature to form the spectrally pure magnesium oxide. The preparation method has the advantages of simple processes, easy control of operation steps, advanced technology and high production efficiency; and the prepared spectrallypure magnesium oxide product has high purity and low impurity content, and the prepared magnesium oxide meets the requirement of high-end technology of the electronic industry.

Owner:TIANJIN CHEM REAGENT RES INST

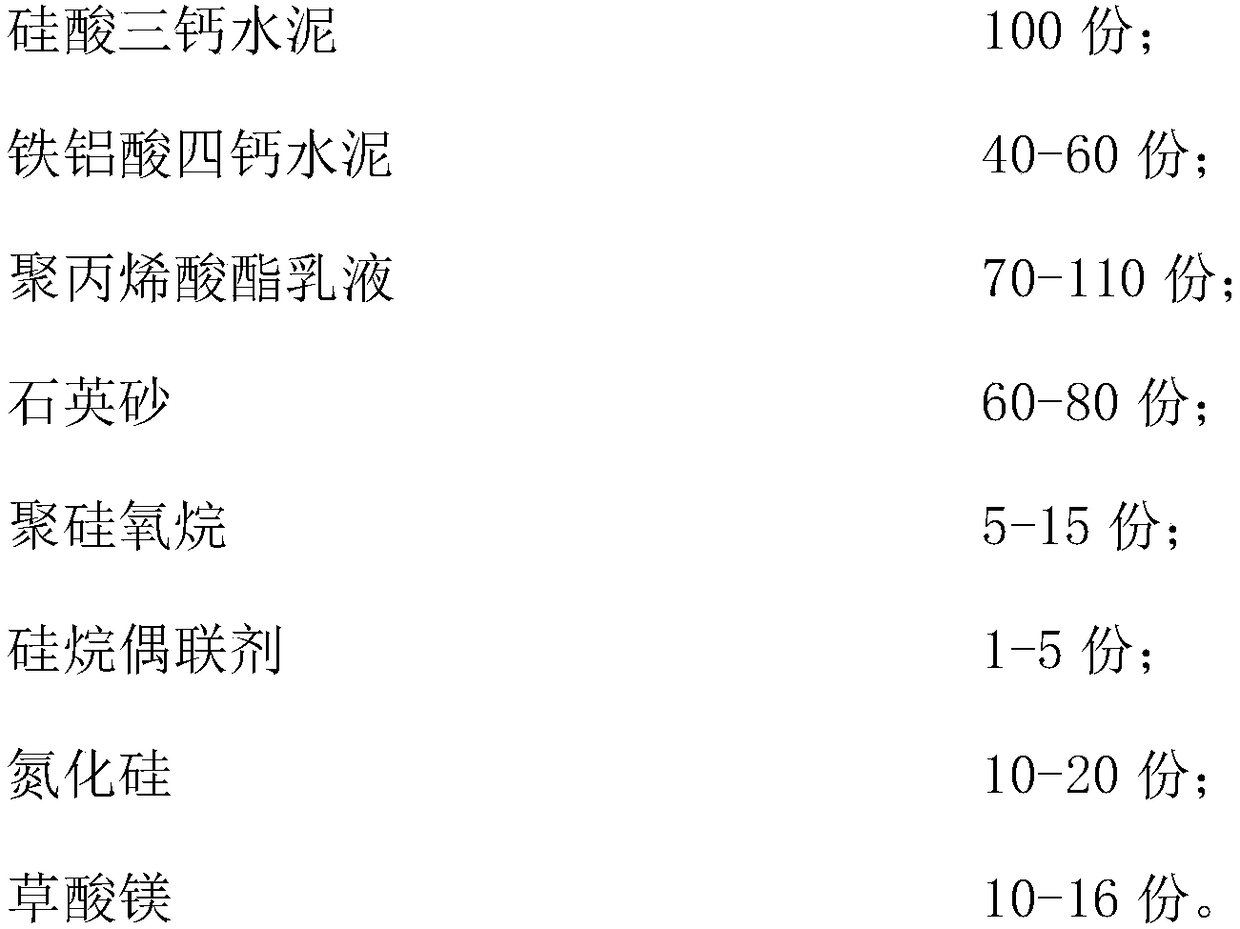

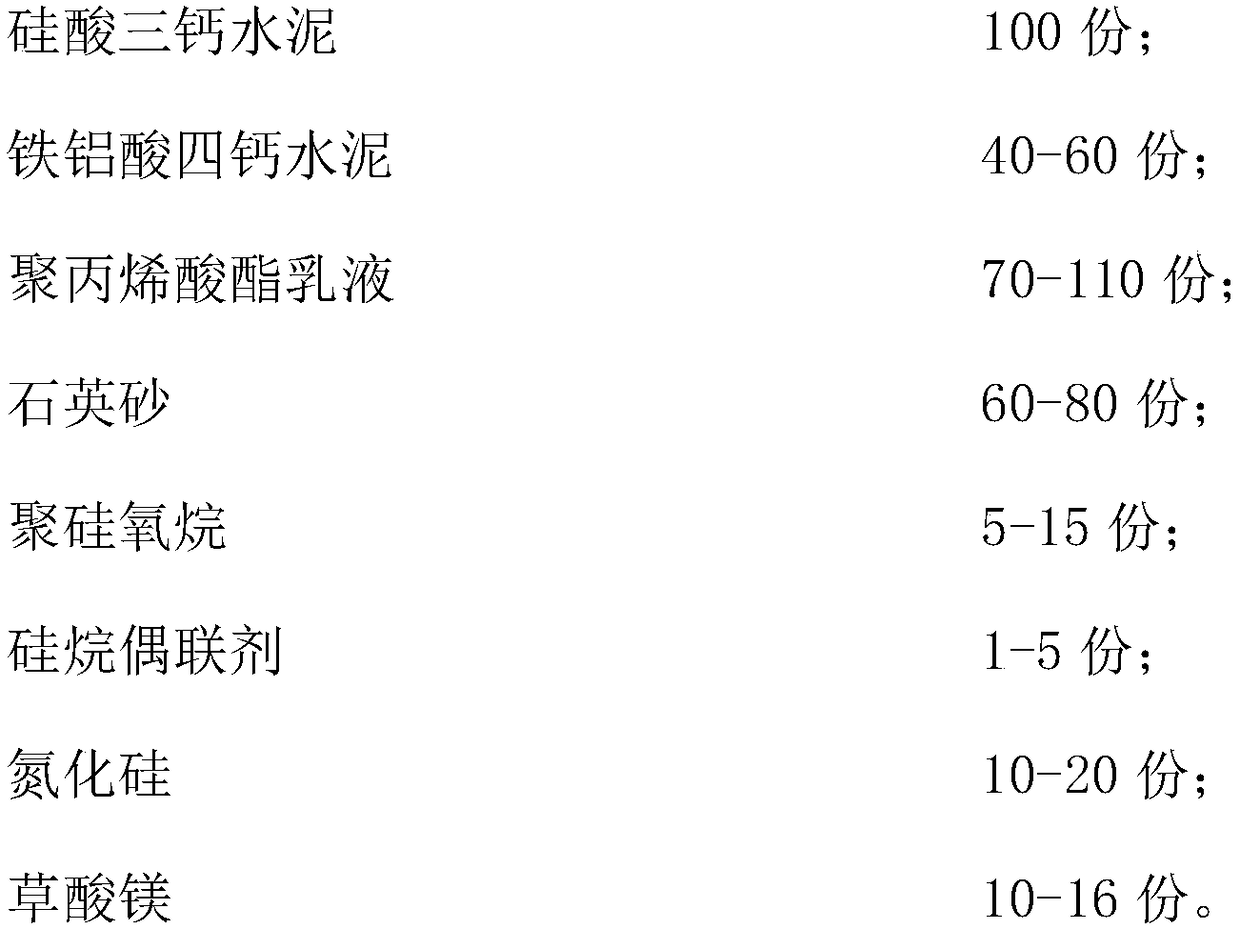

Polyacrylic ester polymer cement-based waterproof paint and preparation method thereof

The invention discloses polyacrylic ester polymer cement-based waterproof paint and a preparation method thereof. The paint is prepared from the following ingredients in parts by weight: 100 parts oftricalcium silicate cement, 40 to 60 parts of tetra-calcium aluminoferrite cement, 70 to 110 parts of polyacrylic ester emulsion, 60 to 80 parts of quartz sand, 5 to 15 parts of polysiloxane, 1 to 5 parts of silane coupling agents, 10 to 20 parts of silicon nitride and 10 to 16 parts of magnesium oxalate. The preparation method comprises the following steps of mixing the tricalcium silicate cement, the tetra-calcium aluminoferrite cement, the quartz sand, the silicon nitride and the silicon carbide; dispersing the mixture into the polyacrylic ester emulsion; heating the materials to 85 DEG C;then, adding the polysiloxane and silane coupling agents; performing stirring reaction; when the quantity of Si-C, Si-O-C, Si-C-N and Si-O-Si in the reaction system is unchanged, and after the cooling, adding the magnesium oxalate; performing homogeneous treatment. The produced polyacrylic ester polymer cement-based waterproof paint can be fast cured and coagulated; the space structure is compact;excellent mechanical property and waterproof and acid-alkali resistant performance are realized.

Owner:安徽朗凯奇科技股份有限公司

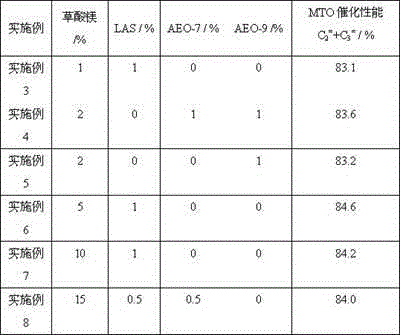

Preparation method of MgO-modified silicoaluminophosphate fluidized bed catalyst

ActiveCN104549482AIncrease the effective response ratioAvoid cloggingMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveLiquid medium

The invention relates to a preparation method of an MgO-modified silicoaluminophosphate fluidized bed catalyst. According to the preparation method, the problem that ethylene and propylene are low in selectivity in the process for preparing low carbon olefin from methanol by virtue of the catalyst in the prior art is solved. The preparation method comprises the following steps: (a) uniformly mixing a molecular sieve, a binding agent, a matrix material, magnesium oxalate, a surfactant and a liquid medium to form suspension liquid; (b) shearing the suspension liquid at high speed until the sizes of 90% of particles in the suspension liquid are smaller than 8 microns; (c) drying the suspension liquid to form a microsphere catalyst; and (d) roasting the microsphere catalyst at high temperature to form a finished catalyst, wherein a magnesium oxalate precursor with the specific surface larger than 200 m<2> / gMgO can be obtained by virtue of roasting at 50 DEG C in the step (a). According to the technical scheme, the problem is well solved. The preparation method can be applied to the industrial production for preparing a low carbon olefin catalyst from a methanol or dimethyl ether raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon/magnesium aluminum spinel composite powder

The invention discloses carbon / magnesium aluminum spinel composite powder. The composite powder comprises the following raw materials in percentage by mass: 28.6%-40.8% of magnesium oxalate, 20.6%-28.6% of magnesium peroxide, 19.0%-22.2% of alumina and 19.8%-23.8% of aluminum powder, and the sum of the mass percentages of the raw materials is 100%. Preferably, the composite powder comprises the following raw materials in percentage by mass: 33.4% of magnesium oxalate, 22.2% of magnesium peroxide, 22.2% of alumina and 22.2% of aluminum powder. The composite powder solves the problem that carbon in carbon-containing refractory materials is difficult to disperse uniformly and easy to agglomerate, and the prepared composite powder has fine grains and can be better applied in the field of refractory materials.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Water culture nutrient solution for tea trees

InactiveCN105732173ABright leavesRobust leavesMagnesium fertilisersAlkali orthophosphate fertiliserHydrogen NitrateIron salts

The invention discloses a water culture nutrient solution for tea trees and relates to the technical field of water culture of tea trees. The water culture nutrient solution is characterized by comprising the following components: 500-800mg of calcium hydrogen nitrate, 400-500mg of potassium nitrate, 75-82mg of ammonium sulfate, 100-150mg of potassium dihydrogen phosphate, 200-300mg of magnesium oxalate, 2.2ml of iron salt solution, 4-4.5 ml of trace element liquid and 1L of distilled water. The water culture nutrient solution disclosed by the invention has the advantages of bright and robust branches and leaves, healthy plants, good culture effect and strong stress resistance of plants.

Owner:郎溪县姚村乡盛茂贵茶叶种植家庭农场

Method for preparing vanadyl oxalate from vanadium slag through short process

ActiveCN110358926AInhibit entryReduce manufacturing costOrganic compound preparationCarboxylic acid salt preparationSolubilitySlag

The invention discloses a method for preparing vanadyl oxalate from vanadium slag through a short process, and belongs to the technical field of preparation for vanadyl oxalate. The method for preparing vanadyl oxalate from the vanadium slag through the short process comprises the following steps: roasting the vanadium slag to obtain roasted clinker; adding water and oxalic acid into the roasted clinker, and leaching and filtering; and concentrating and crystallizing a filtrate, and then carrying out solid-liquid separation to obtain vanadyl oxalate solid. According to the method for preparingvanadyl oxalate from the vanadium slag through the short process, oxalic acid is taken as a leaching agent, and on one hand, an acidic environment is provided for dissolving out vanadium from the clinker; and on the other hand, ferrous oxalate, calcium oxalate, manganese oxalate, magnesium oxalate and aluminum oxalate which have extremely low solubility are formed with iron, calcium, manganese, magnesium and aluminum in the clinker, and then the impurity elements are prevented from entering a leaching solution, so that one-step completion of leaching for vanadium and separation for the impurities is realized, and short process and low production cost are achieved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Composite mineral salf of potassium-magnesium hydrogen citrate and its prepn process

InactiveCN1486969ARaise the pHReduce concentrationUrinary disorderCarboxylic acid salt preparationPotassiumMagnesium ion

The present invention relates to composite mineral salt of potassium-magnesium hydrogen citrate and its preparation process. The potassium-magnesium hydrogen citrate is prepared through mixing citric acid and water, and reaction with potassium compound and magnesium compound at the temperature below 100 deg.c with the molar ratio between Mg, K, H and citric acid being 1 to 3 to 1 to 2. The composite salt of potassium-magnesium hydrogen citrate has obvious curative effect on urinary calculus, owing to the citrate radical ion and magnesium ion to suppress calcium-containing calculus crystallization, magenesium ion to lower the concentration of calculus forming matter in urine and capable of combining with oxalic acid to form magnesium oxalate to exhaust together with urine. The composite salt can raise pH value of urine and dissolve uric acid calculus and cystine calculus directly without causing adverse reaction.

Owner:NANJING DRUM TOWER HOSPITAL

Vanadium cell electrolyte

The invention relates to the technical field of cell electrolyte, and in particular relates to a vanadium cell electrolyte. The vanadium cell electrolyte is characterized in that at least one of inorganic molybdate, phosphate and oxalate is selected as an ionic liquid additive, wherein the inorganic molybdate is selected from at least one of sodium molybdate, ammonium molybdate, potassium molybdate, magnesium molybdate, zinc molybdate, iron molybdate, manganese molybdate and calcium molybdate; oxalate is selected from at least one of sodium oxalate, ammonium oxalate, potassium oxalate, lithiumoxalate, magnesium oxalate, zinc oxalate, iron oxalate, manganese oxalate and calcium oxalate. According to the vanadium cell electrolyte, the additive is capable of increasing the dissolvability ofthe electrolyte, inhibiting the hydrolyzing of pentavalent vanadium ions, and greatly improving the stability of cathode electrolyzing; inorganic molybdate is treated as the cathode electrolyte additive through which the stability of the cathode electrolyte is improved, and the running temperature range of a vanadium cell is expanded. The vanadium cell electrolyte is simple in preparation processand operation, and low in cost; the vanadium cell can easily stably run under high temperature.

Owner:杨昌恩

Microporous magnesium-chromium spinel raw material and preparation method thereof

The invention relates to a microporous magnesium-chromium spinel raw material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: adding magnesium oxalate and chromium carbide into a ball mill in a mass ratio of (1.1-1.15) to 1, and carrying out ball milling until the particle sizes are less than or equal to 100 microns, so as to obtain ball-milled powder; putting the ball-milled powder into a drying oven, and maintaining the temperature at 200-250 DEG C for 30-40 minutes, so as to obtain thermally processed powder; adding water which accounts for 15wt%-20wt% of the thermally processed powder into the thermally processed powder, carrying out wet milling in the ball mill until the particle size is less than or equal to 60 microns, so as to obtain a wet-milled material; and adding the wet-milled material into a mud refining machine, carrying out vacuum mud extrusion molding, and standing for 24-36 hours; putting the processed material into a muffle furnace, maintaining the temperature at 1550-1600 DEG C in an air atmosphere for 3-4 hours, carrying out furnace cooling, and crushing, so as to obtain the microporous magnesium-chromium spinel raw material. The preparation method is simple and low in production cost; the prepared microporous magnesium-chromium spinel raw material is good in sintering performance, high in spinel conversion rate and low in heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

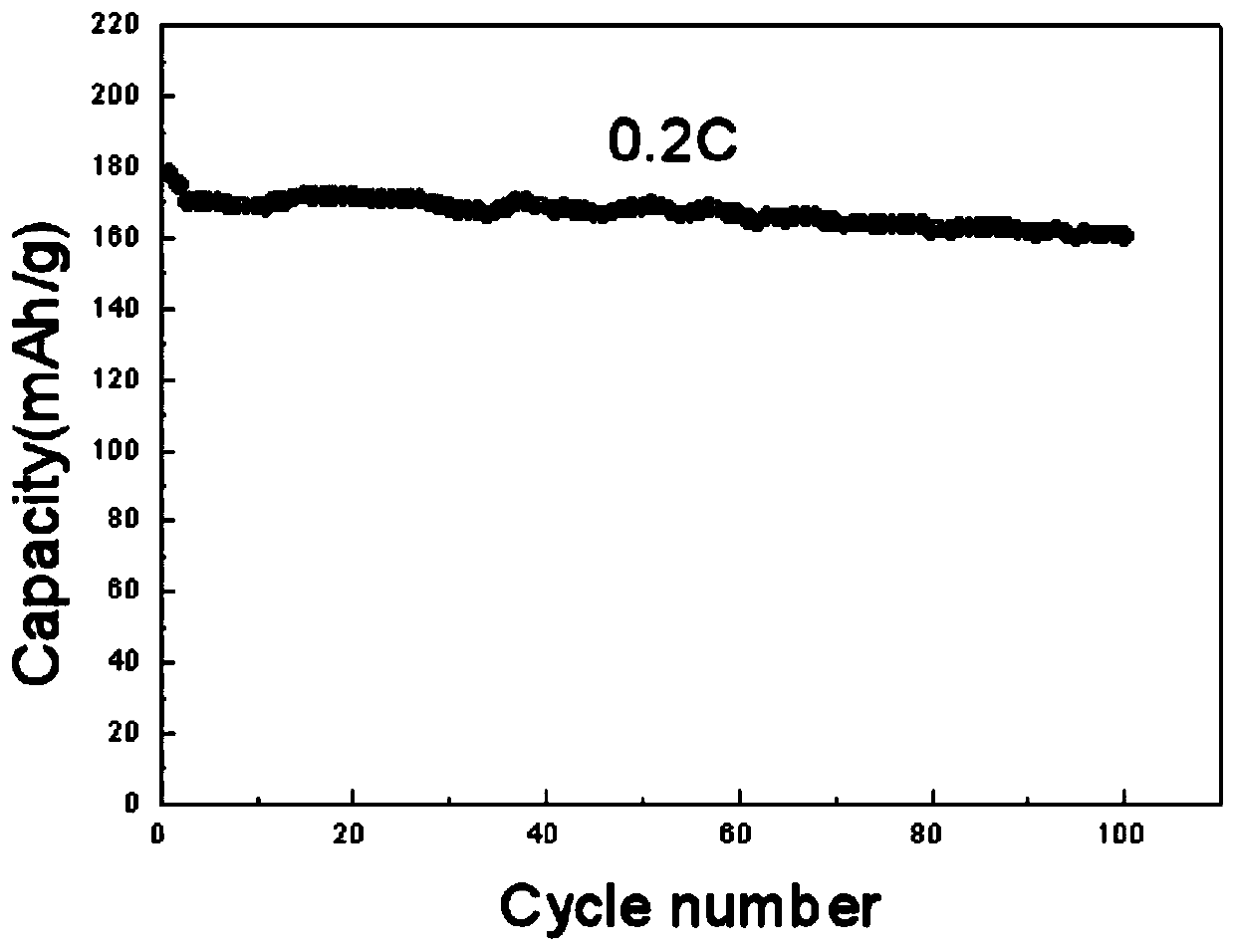

Magnesium element-doped NCM622 type high-nickel ternary material and preparation method thereof

InactiveCN109921010AImprove structural stabilityImproved magnification performanceCell electrodesSecondary cellsTube furnaceLithium-ion battery

The invention discloses a magnesium element-doped NCM622 type high-nickel ternary material and a preparation method thereof. The preparation method comprises the following steps of (1) according to apreset Mg2+ doping amount, weighing magnesium oxalate, LiNi0.6Co0.2Mn0.2O2 precursor and a lithium source based on stoichiometric ratio to be fully and uniformly mixed; and (2) putting the mixture into a tubular furnace, carrying out calcining at an air or oxygen atmosphere and a certain temperature for several hours, and performing grinding and sieving on the prepared product to obtain the high-nickel ternary material. According to the preparation method of the magnesium element-doped NCM622 type high-nickel ternary material, the Mg element is adopted to realize interval doping on LiNi0.6Co0.2Mn0.2O2 (NCM622), so that the process flow is simple; and the prepared lithium ion battery ternary positive electrode material is uniform in particle size distribution, clear in the particle boundary, relatively high in secondary particle spherical structure, and high in rate performance and cycling stability.

Owner:四川纳创时代新能源科技有限公司

Nano-composite foam rope and preparation method thereof

InactiveCN107604469AImprove toughnessQuite toughConjugated cellulose/protein artificial filamentsMelt spinning methodsAlkali freeAntioxidant

The invention discloses a nano-composite foam rope and a preparation method thereof. The nano-composite foam rope comprises the following raw materials by weight: 65% to 80% of nano-modified polypropylene, 5% to 11% of natural fiber, 2.5% to 6% of methyl propyl naphthyl phosphate, 4% to 10% of trimethyl oxalate acetate, 2% to 6% of a compound stabilizer, 0.2% to 0.7% of magnesium oxalate, 1% to 3%of a defoaming agent and 0.8% to 1.6% of an antioxidant. A surfactant is used for surface treatment of alkali-free glass powder to obtain modified alkali-free glass superfine powder, the modified alkali-free glass superfine powder is used for nano-modified filling of polypropylene to obtain nano-modified polypropylene, the rigidity is improved, toughness and dimensional stability are high, thermal expansion rate is low, melt strength of the nano-modified polypropylene is increased by 5-7 times, the nano-modified polypropylene has good low temperature toughness, and can withstand impact of lowtemperature of-30 DEG C; the preparation method is simple, the work efficiency is improved, the filled nano-filler is comparable with 5-time-filled ordinary packing in rigidity, cost is greatly reduced, and the prepared nano-composite foam rope has high strength, good toughness and long service life.

Owner:界首市宏利塑料股份有限公司

Method for recycling magnesium oxalate in case of treating sewage containing benzene-based pollutants

InactiveCN103588328AEfficient degradationSimple methodWater contaminantsMultistage water/sewage treatmentBenzeneEngineering

The invention discloses a method for recycling magnesium oxalate in the case of treating sewage containing benzene-based pollutants, and belongs to the field of the treatment of sewage containing the benzene-based pollutants. The method mainly comprises the following steps: A), filtering sewage to be treated to remove suspended matters in the sewage; B), introducing the sewage treated through the step A) to an ozone aeration tank, adding brucite into the sewage, and then performing ozone aeration; C), introducing the sewage treated through the step B) to a settling pond to be subjected to precipitation separation; D), dehydrating and drying sediments at the bottom of the settling pond, so as to obtain magnesium oxalate crystals. According to the invention, the pollutants can be effectively degraded while the magnesium oxalate which can be used as a resource can be obtained; the method has the advantages of simplicity, convenience for operation, low cost and environment protection.

Owner:NANJING UNIV

Method of detoxifying asbestos contained in waste slate and detoxified asbestos obtained through the same

ActiveUS9446273B2Avoid damageLow costTransportation and packagingSolid waste disposalAqueous solutionOxalic acid

Disclosed is a method of detoxifying asbestos of waste slate. The method includes concentrating the asbestos by introducing hydrochloric acid aqueous solution into waste slate powder to dissolve and remove a limestone component contained in the waste slate; and mixing the concentrated asbestos with oxalic acid and performing a low-temperature heat treatment. The waste slate is crushed and pulverized and powder of the crushed and pulverized waste slate is formed in a size in a range of 100 meshes to 300 meshes. The detoxified asbestos includes re-crystallized magnesium oxalate having a rhombohedral or amorphous shape.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

Hydroponic method of tea trees

InactiveCN107162778AReasonable formulaGrow fastMagnesium fertilisersAlkali orthophosphate fertiliserManganeseNutrient solution

The invention discloses a hydroponic method of tea trees. The method comprises the following steps: 1, preparing a nutrient solution: respectively weighing 200-300 mg of manganese sulfate, 300-350 mg of potassium nitrate, 150-200 mg of zinc sulfate, 400-450 mg of calcium nitrate, 250-350 mg of magnesium sulfate, 450-550 mg of copper sulfate, 100-150 mg of magnesium oxalate, 200-300 mg of potassium chloride and 2-3 L of distilled water, and preparing the nutrient solution; 2, adding the nutrient solution into an incubator, placing a mesh plate in the incubator, inserting a sapling to every mesh of the mesh plate, and allowing the root of every sapling to stretch into the nutrient solution; and 3, carrying out culture management: placing the nutrient solution in a greenhouse, and timely adding the nutrient solution in the culture process. The nutrient solution prepared through adopting method has a reasonable formula, is rich in various nutrients needed by tea trees, fully supplies nutrients needed by samplings, and provides reliable preconditions for the culture of the saplings; and the temperature, the humidity and the illumination conditions are reasonably controlled in the culture process to make the tea trees fast grow, so the yield is increase, and the economic benefit is increased.

Owner:镇江西古山生态农业养殖发展有限公司

A method for preparing calcium magnesium carbonate mineral ca1-xmgxco3 under high temperature and high pressure

InactiveCN107640781BNot easy to absorb waterGood chemical stabilityCalcium/strontium/barium carbonatesUltra-high pressure processesHigh pressureCalcium magnesium carbonate

The invention discloses a method for preparing calcium-magnesium carbonate mineral Cal-xMgxCO3 at a high temperature under high pressure. The method includes evenly grinding and mixing analytically-pure calcium carbonate, magnesium oxalate powder and anhydrous oxalic acid to obtain a mixture serving as an initial raw material, pressing the mixture into a cylinder by a tablet machine, inserting a cylindrical sample into a platinum tube, sealing two ends of the platinum tube by a welding gun, putting the sample sealed by platinum in an h-BN tube by taking h-BN as a pressure transfer medium, assembling the sample in the h-BN tube in a high-pressure combined assembly block, putting the high-pressure combined assembly block in a cubic press for high-temperature high-pressure reaction, taking out the reacted sample, opening the platinum tube by a diamond cutter, and naturally air-drying the sample to obtain calcium-magnesium carbonate minerals. By the method, the technical problems such as operation process complexity, long reaction time, and low purity, low chemical stability and proneness to water absorption of obtained samples in existing calcium-magnesium carbonate mineral preparation methods are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

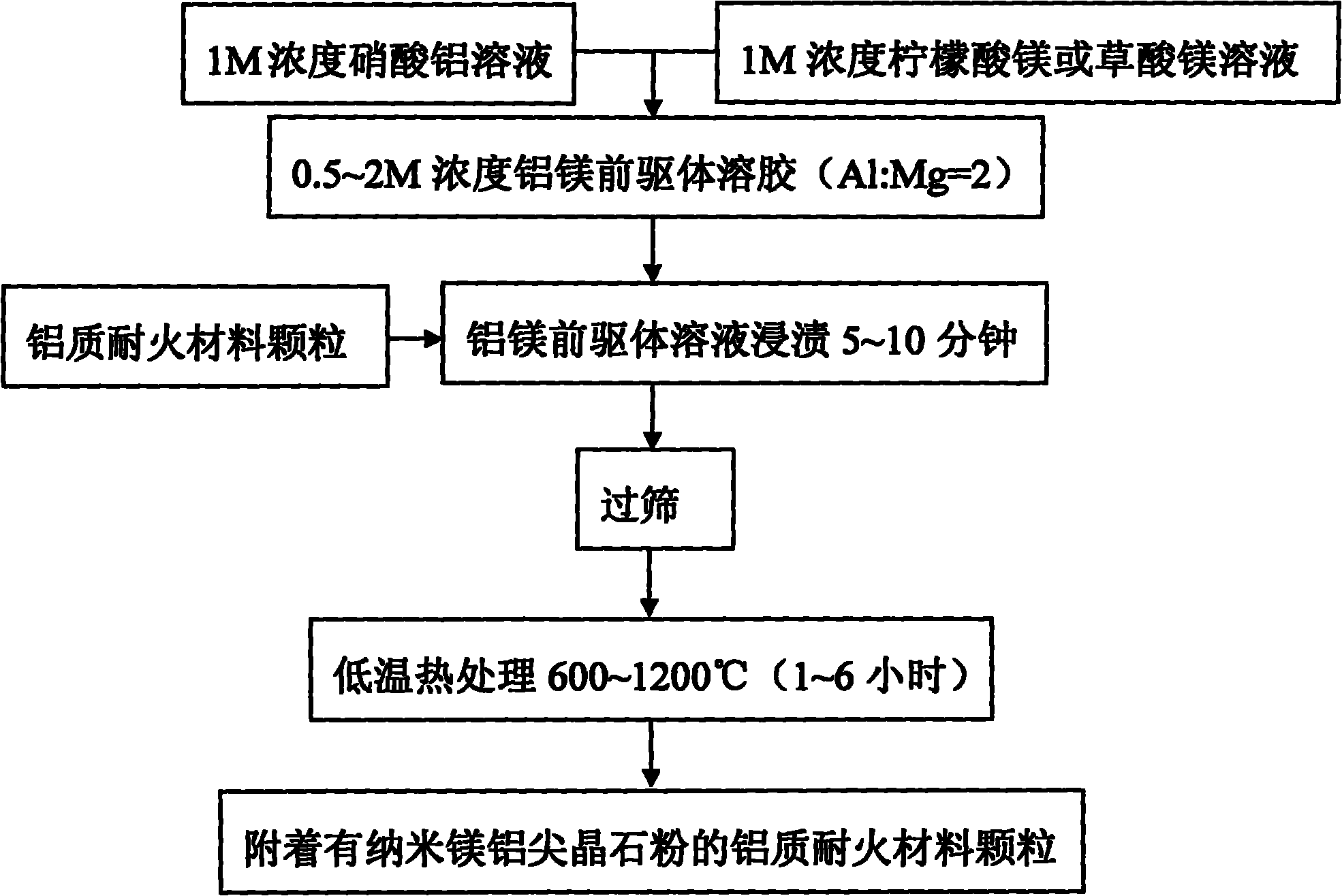

Method for processing sols of alumina refractory particles

The invention discloses a method for processing sols of alumina refractory particles, which mainly aims to solve the problem of agglomeration of nano-powder during use in the prior art. The method comprises the following steps of: preparing magnalium precursor sols with a molar concentration of 0.5 to 2M from aluminium nitrate serving as an aluminum source, and magnesium oxalate or gnesium citrate serving as a magnesium source according to a mole ratio of Al to Mg of 2; putting the particles of aggregate particles of the alumina refractory material into an anti-acid container, and then pouring the magnalium precursor sols with a molar concentration of 0.5 to 2M into the container to soak for 5 to 10 minutes; after filtering the obtained objects by using a screen, putting the obtained particles into a sagger, and then carrying out thermal treatment on the obtained particles at the temperature of between 600 and 1,200 DEG C for 1 to 6 hours, and reacting the aluminosilicate refractory particles to synthesize nano magnesia-alumina spinel powder, and then obtain the aluminosilicate refractory particles attached with the nano magnesia-alumina spinel powder. The method of the invention has the advantage of uniformly-distributed nano-particles in the alumina refractory material can be used for processing refractory raw materials and improves the sintering process of the refractory raw materials.

Owner:XIDIAN UNIV

Preparation method of supported ruthenium-based catalyst

PendingCN112387274AReduce contentLow costCatalyst activation/preparationHydrogen productionPtru catalystPhysical chemistry

The invention discloses a preparation method of a supported ruthenium-based catalyst, and belongs to the field of catalyst preparation. The method comprises the following steps of: taking magnesium oxalate as a carrier precursor, and preparing the supported ruthenium-based catalyst by adopting a precipitation deposition method. The supported ruthenium-based catalyst comprises a carrier and an active component, wherein the carrier comprises magnesium oxide, and the active component comprises Ru. The catalyst can be used as an ammonia decomposition hydrogen production catalyst. The supported ruthenium-based catalyst obtained according to the method has a low content of precious metal ruthenium, and has high catalytic activity and catalytic stability at a relatively low temperature. In addition, the method is simple in preparation process, low in cost and easy to realize large-scale production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Magnesium olivine-texture lightweight refractory and preparation method thereof

The invention relates to a magnesium olivine-texture lightweight refractory and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: blending a DDBAC foaming agent, polyacrylamide, ammonium hydrogen carbonate and water in a mass ratio of 1 to (1-4) to (2-5) to (50-60), and carrying out ultrasonic dispersion in a container under a water bath condition, so as to prepare foaming liquid; blending nature magnesium olivine ore and silicon carbide in a mass ratio of 100 to (4-7), carrying out ball-milling, mixing in a planetary ball mill, and carrying out compression molding; carrying out thermal treating at 900-1000 DEG C in a muffle furnace, carrying out furnace cooling, crushing, and grinding, so as to obtain a thermally treated material; and blending the foaming liquid, the thermally treated material and magnesium oxalate in a mass ratio of (30-40) to 100 to (6-8), mixing, forming, carrying out vacuum freeze drying, and sintering at 1400-1500 DEG C in the muffle furnace, so as to obtain the magnesium olivine-texture lightweight refractory. The preparation method has the characteristics of low cost and high yield; and the prepared magnesium olivine-texture lightweight refractory has low volume density, large compression strength and small heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com