Magnesium element-doped NCM622 type high-nickel ternary material and preparation method thereof

A high-nickel ternary material, magnesium technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of backscattering, reduce doping ion activity, complex preparation methods, etc., to improve structural stability properties, improved electronic conductance, improved rate capability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) According to Mg 2+ The doping amount is 0.5mol%, that is, the total metal content M (M=Ni+Co+Mn), 0.5mol%; the stoichiometric ratio of MgC is weighed 2 o 4 2H 2 O, Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, Li 2 CO 3 , so that the three are thoroughly mixed in a blender. Wherein the addition amount of lithium source is that the molar ratio of lithium ion and metal ion is Li + : (Mg+Ni+Co+Mn) 2+ =1.05:1.

[0026] (2) Move the above mixture into a tube furnace, heat it to 400°C at a heating rate of 2°C / min under an oxidizing atmosphere, keep it at this temperature for 5 hours, and then heat it to 750°C at a heating rate of 5°C / min ℃, kept at this temperature for 15 hours, after natural cooling, crushing, grinding and sieving, Mg 2+ Doped high-nickel ternary nickel-cobalt-manganese cathode material Li(Ni 0.6 co 0.2 mn 0.2 ) 0.995 Mg 0.005 o 2 .

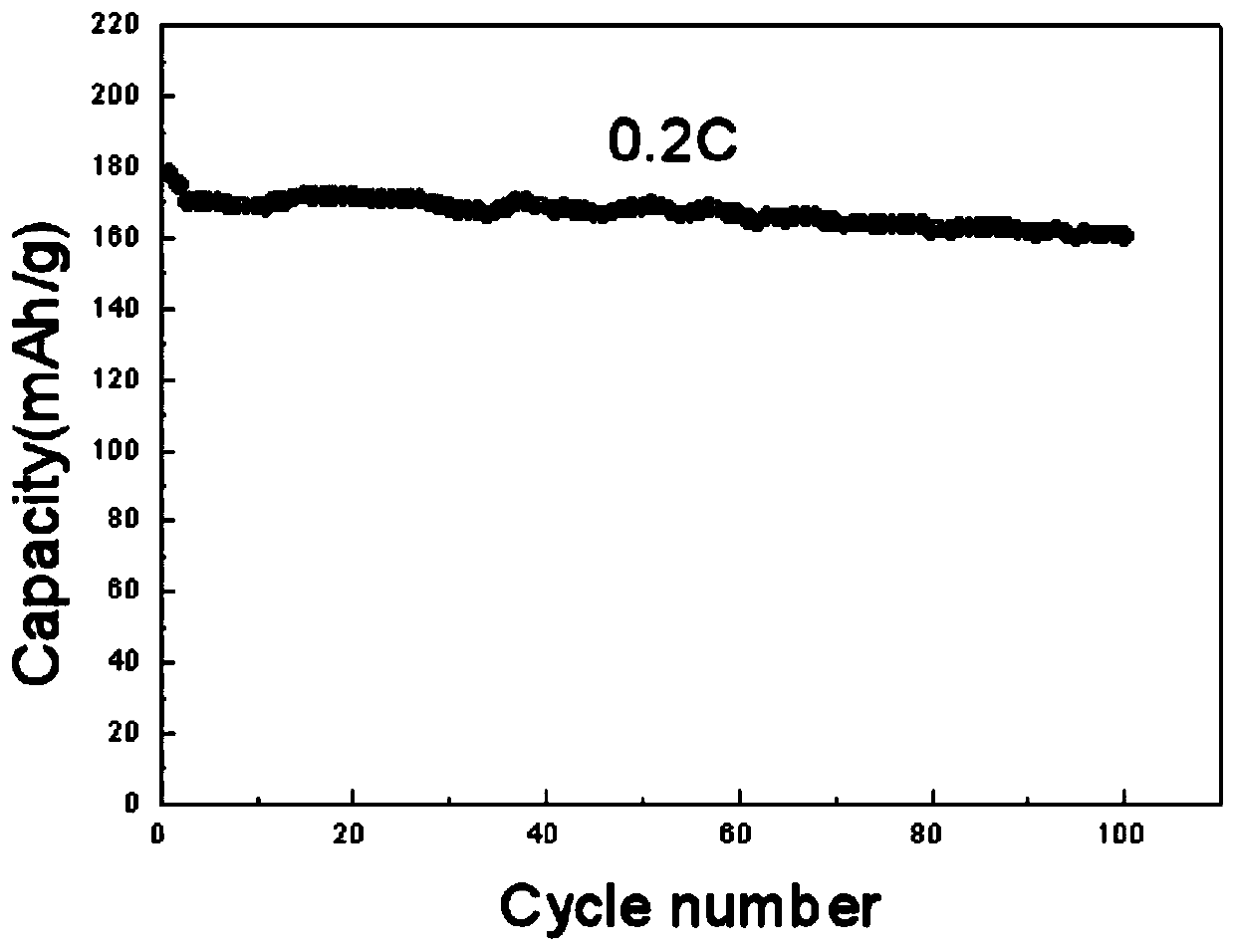

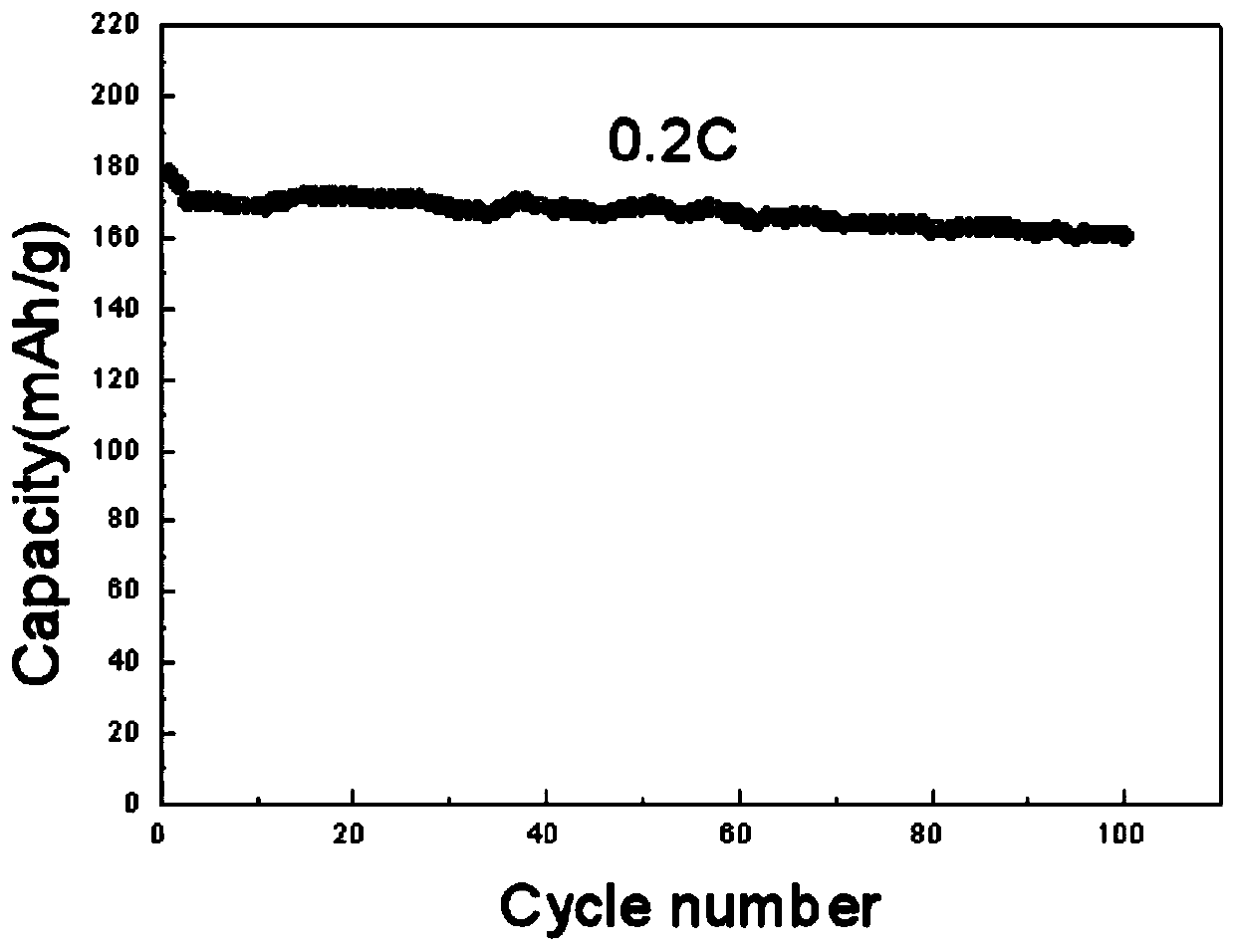

[0027] The material prepared by the above method was scanned by a scanning electron microscope (SEM); the mat...

Embodiment 2

[0031] (1) According to Mg 2+ The doping amount of is 1 mol%, that is, 1 mol% of the total metal content M (M=Ni+Co+Mn). Weigh out the stoichiometric ratio of MgC 2 o 4 2H 2 O, Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, Li 2 CO 3 , mix thoroughly in a blender until smooth. The amount of lithium source added is the molar ratio of lithium ions to all metal ions is Li+: (Mg+Ni+Co+Mn) 2+ =1.05:1.

[0032] (2) Move the above mixture into a tube furnace, heat it to 400°C at a heating rate of 2°C / min under an oxidizing atmosphere, keep it at this temperature for 5 hours, and then heat it to 780°C at a heating rate of 5°C / min ℃, kept at this temperature for 15 hours, after natural cooling, crushing, grinding and sieving, Mg 2+ Doped high-nickel ternary nickel-cobalt-manganese cathode material Li(Ni 0.6 co 0.2 mn 0.2 ) 0.99 Mg 0.01 o 2 .

[0033] The material obtained by the method described above was scanned by a scanning electron microscope (SEM); the material was asse...

Embodiment 3

[0035] (1) According to Mg 2+ The doping amount is 2mol%, that is, 2mol% of the total metal content M (M=Ni+Co+Mn), and the stoichiometric ratio of MgC is weighed 2 o 4 2H 2 O, Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, Li 2 CO 3 Mix well in a mixer until smooth. The amount of lithium source added is based on the molar ratio of lithium ions to metal ions Li+: (Mg+Ni+Co+Mn) 2+ =1.05:1.

[0036] (2) Move the above mixture into a tube furnace, heat it to 400°C at a heating rate of 2°C / min under an oxidizing atmosphere, keep it at this temperature for 5 hours, and then heat it to 800°C at a heating rate of 5°C / min ℃, kept at this temperature for 15 hours, after natural cooling, crushing, grinding and sieving, Mg 2+ Doped high-nickel ternary nickel-cobalt-manganese cathode material Li(Ni 0.6 co 0.2 mn 0.2 ) 0.98 Mg 0.02 o 2 .

[0037] The material obtained by the method described above was scanned by a scanning electron microscope (SEM); the material was assembled int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com