Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Localised corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Localized corrosion refers to the hastened attack of passive metals in corrosive environments. It is characterized by an intense attack at confined areas on surface components, while the remaining area of the surface corrodes at a much slower rate.

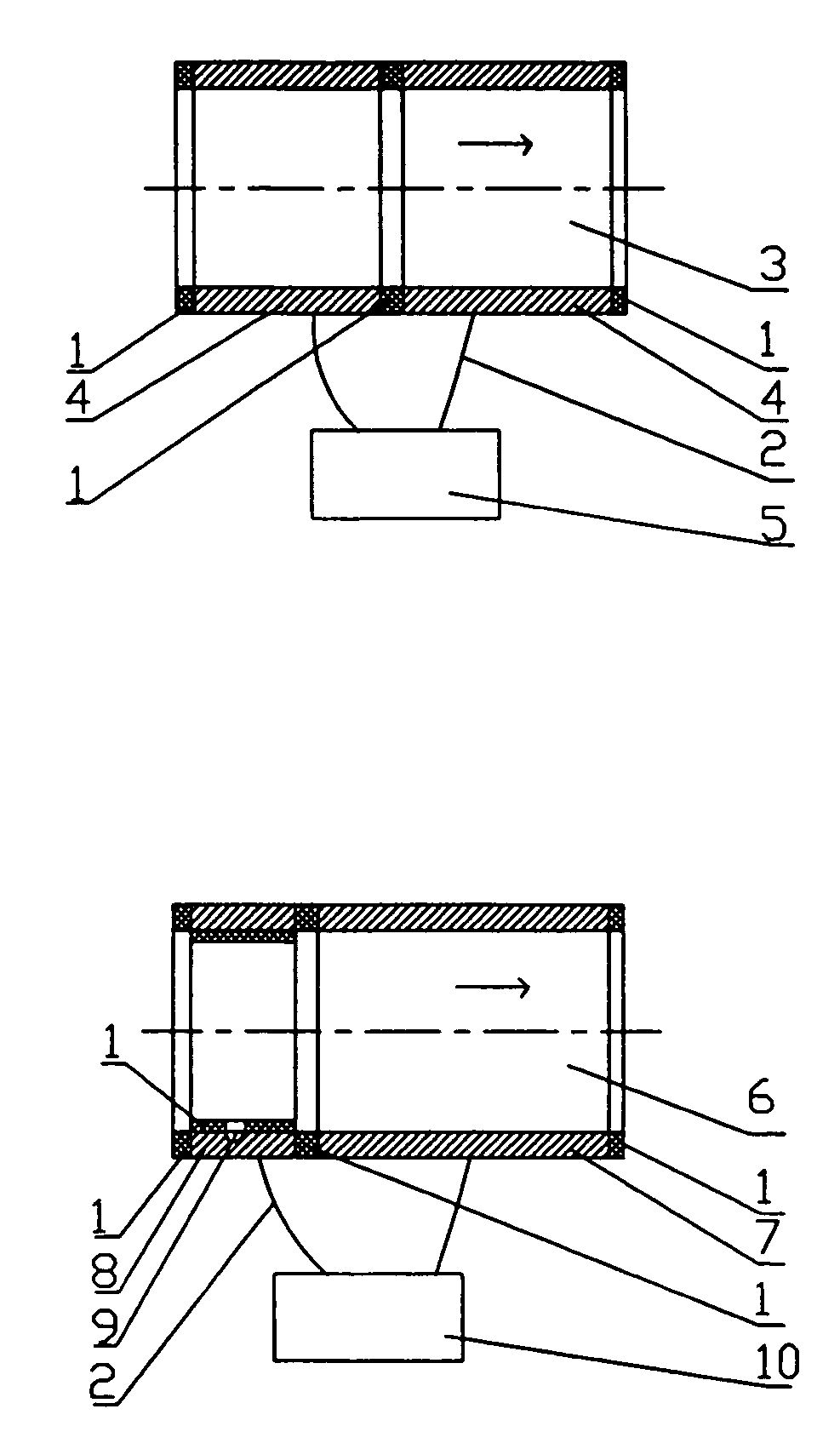

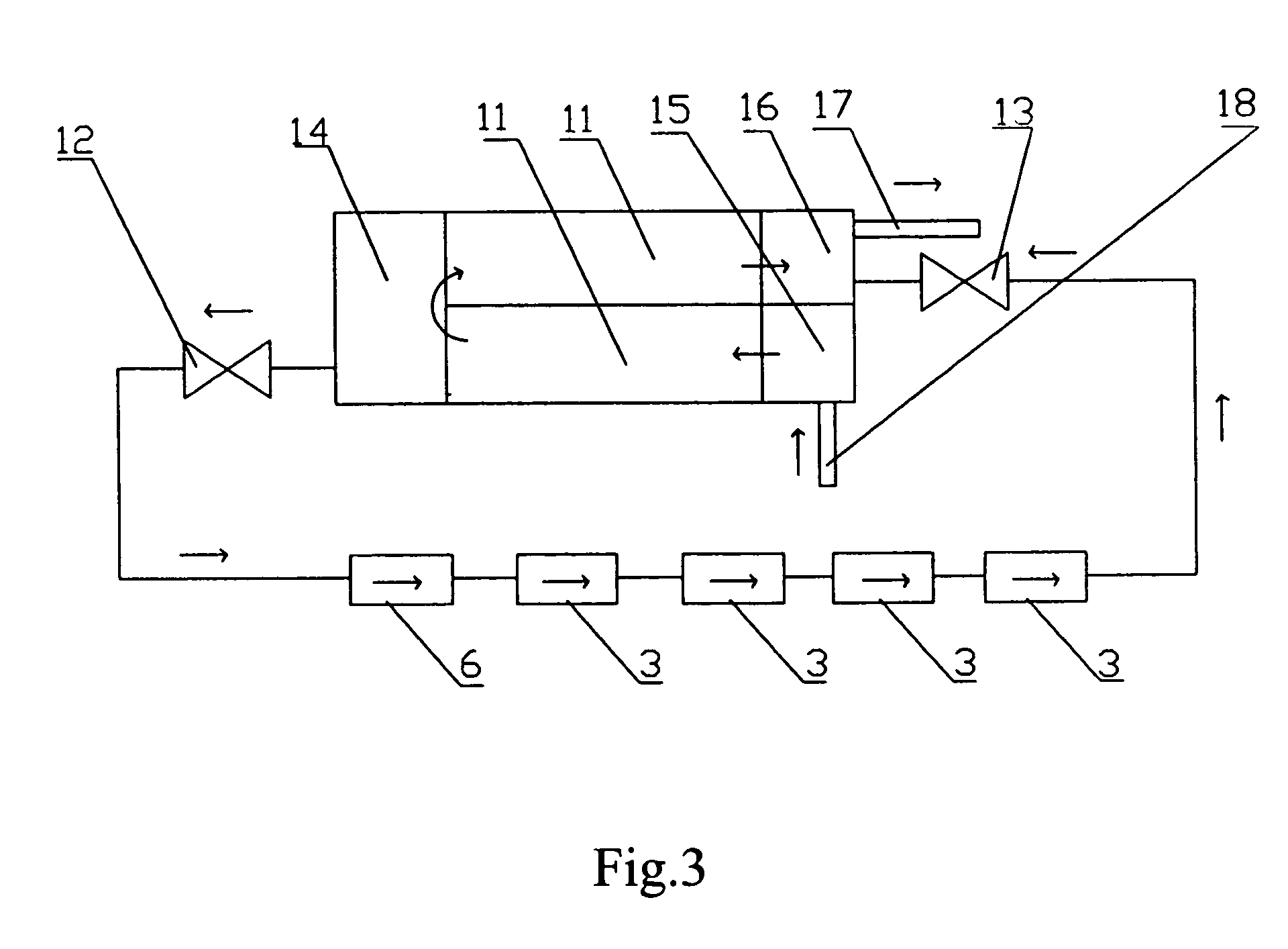

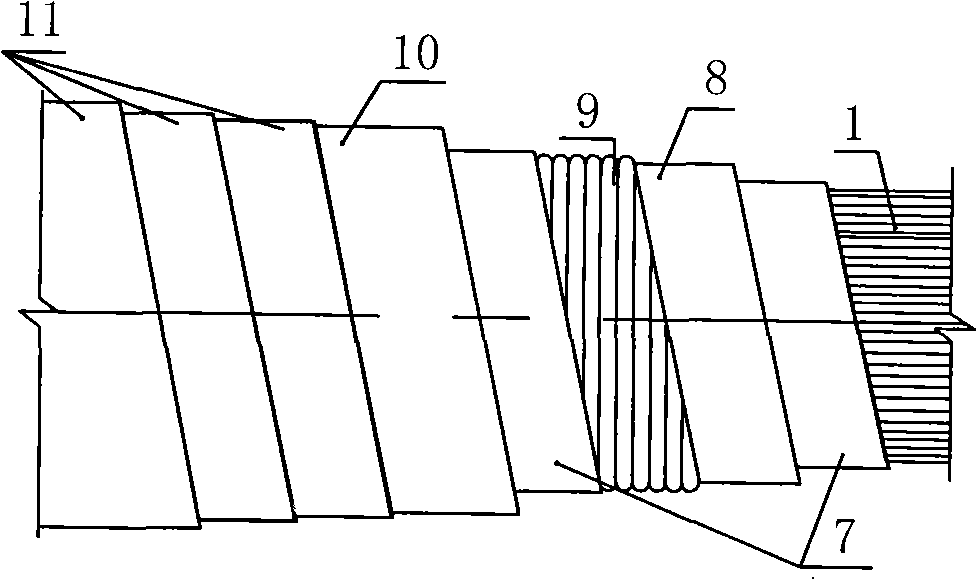

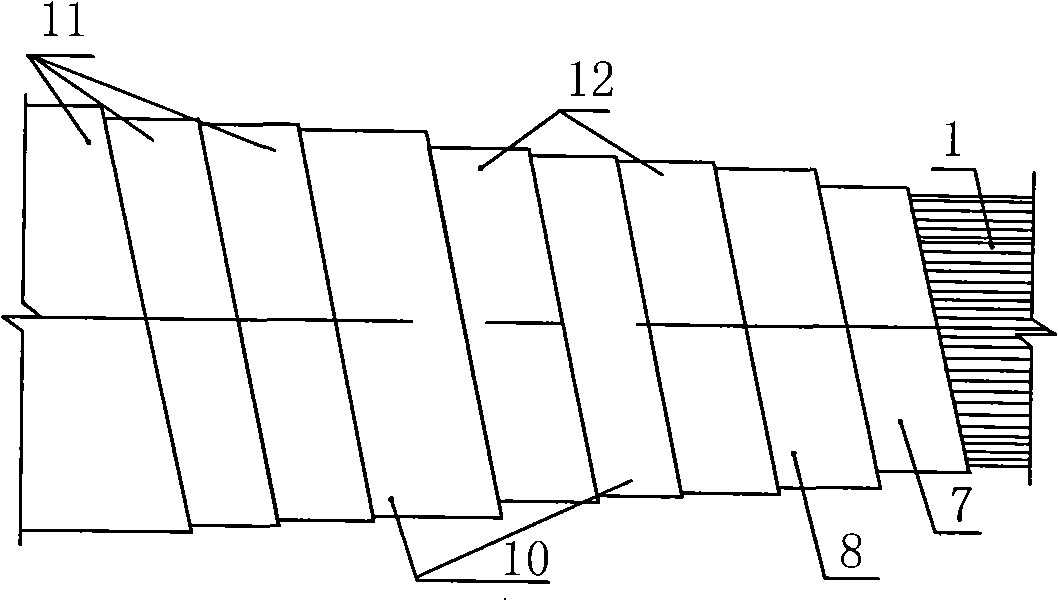

Method of producing sensors for monitoring corrosion of heat-exchanger tubes

InactiveUS7310877B2Sensitively and reliably monitoredAccurate monitoringCellsWeather/light/corrosion resistanceEngineeringCost of treatment

The present invention relates to a method of producing the sensors for monitoring corrosion of heat exchanger tubes in a thermal power plant. The sensor is made of the tubes taken out from actual heat-exchanger. As a result, the sensor not only has the same material as the actual heat-exchanger tubes, but also has the same surface state where it contacts the working medium. Therefore, a serious technical difficulties have been solved that the sensor made by the prior art can't measure different corrosion states of actual heat-exchanger tubes, that the corrosion rate measured is different from the corrosion rate of actual heat-exchanger tubes, and that the cost of anti-corrosive treatments is high . By use of the sensor made by the present invention, the different corrosion states of actual heat-exchanger tubes can be measured, not only the rate of uniform corrosion of actual heat-exchanger tubes can be measured but also the rate of localized corrosion of the heat-exchanger tubes can be measured. Moreover, the cost of treatment of anti-corrosion can be decreased.

Owner:THERMAL POWER RES INST

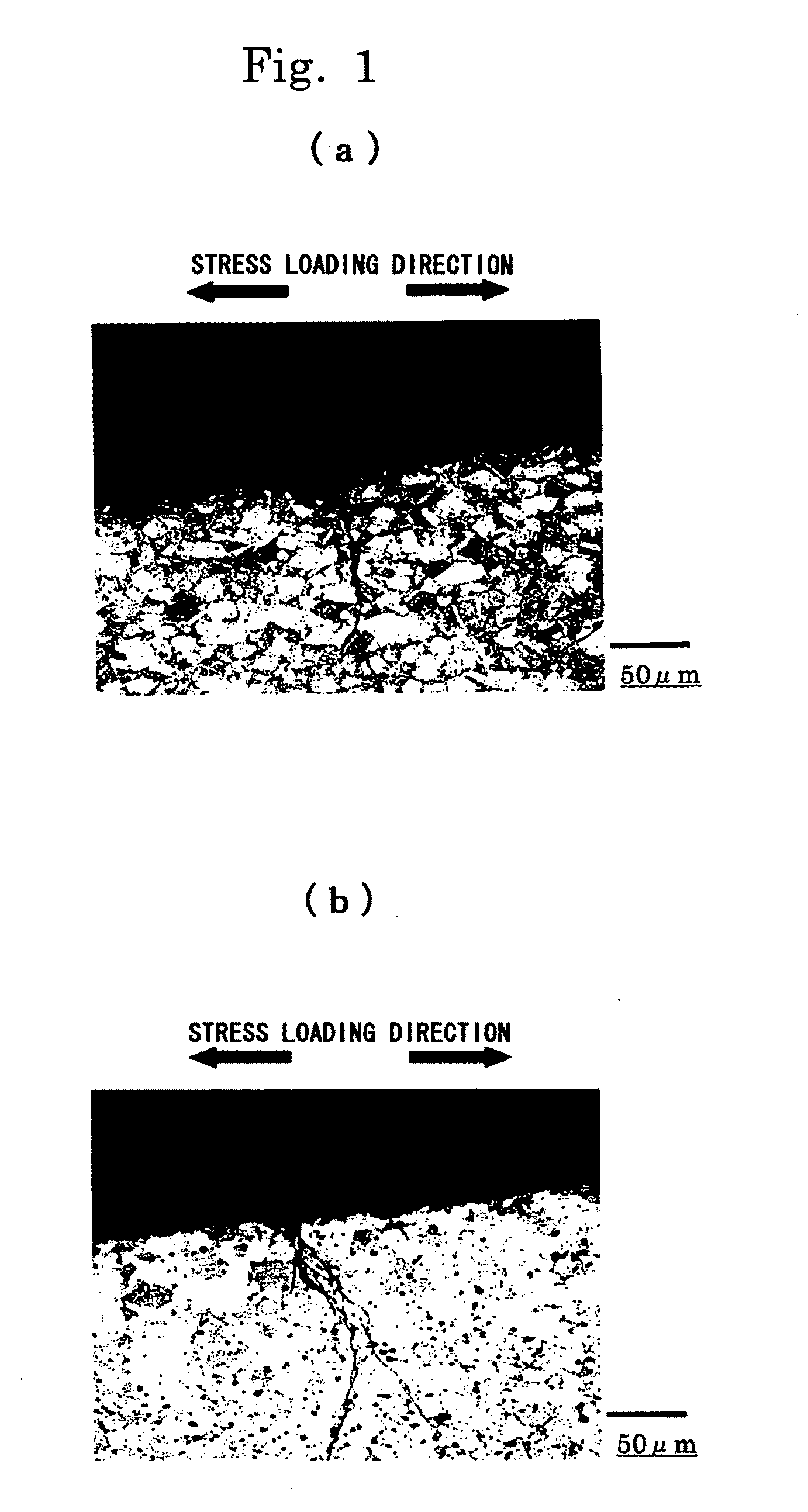

Leadless brass alloy excellent in stress corrosion cracking resistance

ActiveUS20090297390A1Enhanced in stress corrosion cracking resistanceEnhance stress corrosion cracking resistanceCrazingCrack resistance

By enhancing a stress corrosion cracking resistance in a leadless brass alloy, specifically by suppressing a velocity of propagation of corrosion cracks in the brass alloy, a straight line crack peculiar to the leadless brass alloy is suppressed, a probability of cracks coming into contact with γ phases is heightened and local corrosion on the brass surface is prevented to suppress induction of cracks by the local corrosion, thereby providing a leadless brass alloy contributable to enhancement of the stress corrosion cracking resistance. The present invention is directed to an Sn-containing Bi-based, Sn-containing Bi+Sb-based or Sn-containing Bi+Se+Sb-based leadless brass alloy excellent in stress corrosion cracking resistance, having an α+γ structure or α+β+γ structure and having γ phases distributed uniformly therein at a predetermined proportion to suppress local corrosion and induction of stress corrosion cracks.

Owner:KITZ CORP

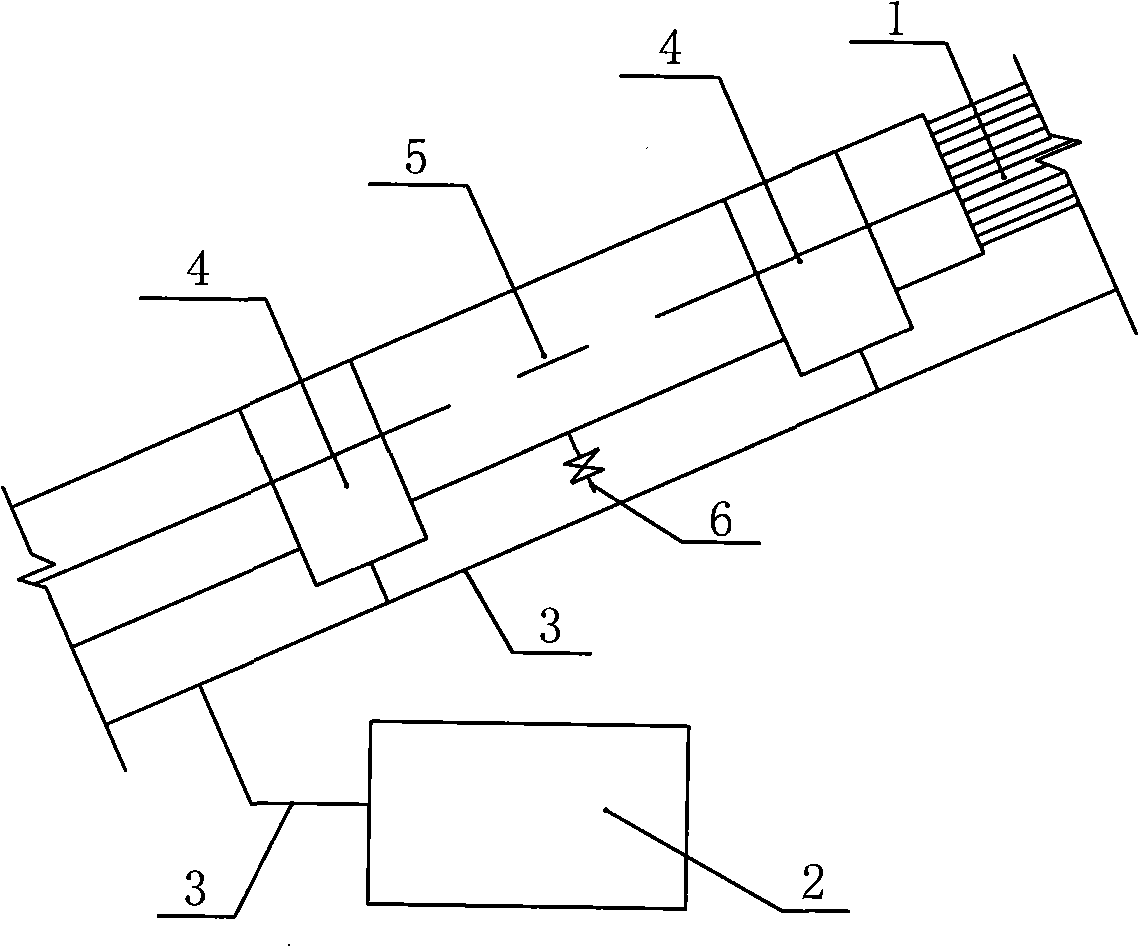

Rope-suspension bridge cable system anti-corrosive protecting method and cable system anti-corrosive protecting structure

InactiveCN101307591AStrong tear resistanceExcellent tear resistance)Bridge structural detailsSuperimposed coating processHigh intensityEngineering

The invention discloses a method for the antiseptic protection of a cable system of a suspension bridge. The cable system comprises a main cable consisting of steel wire bundles formed by multi-strands of high-strength zinc-plated steel wires, a main saddle on the top part of a cable tower, a loosening-cable saddle on the near anchorage end, a plurality of cable clips fixed on the main cable and suspension cables fixed on the cable slips, wherein the main cable comprises a wire wound section main cable section and a non-wire wound section main cable section; the wire wound section main cable orderly undergoes the following treatments: (A) the main cable undergoes the pre-sealing dehumidification treatment; (B) the outer surface of the main cable undergoes the inner-layer antiseptic treatment; (C) a layer of steel wires or a belt material winding layer is wound; (D) the outer surface of the winding layer undergoes the outer layer protective treatment. In the invention, before steel wire bundles of the main cable are coated, the main cable system undergoes the pre-sealing dehumidification treatment, thereby removing water and moistures already existed in the main cable, eliminating the local corrosion phenomenon of the steel wires of the main cable started from the inner part caused by water originally existed in the main cable and ensuring the achievement of expected effects in the protection of the main cable.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

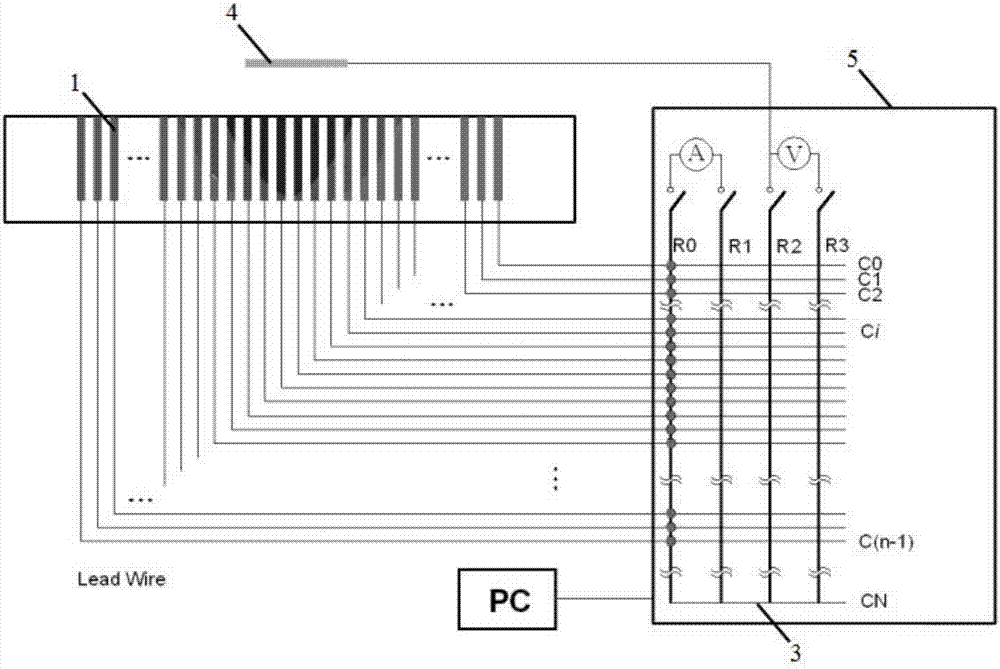

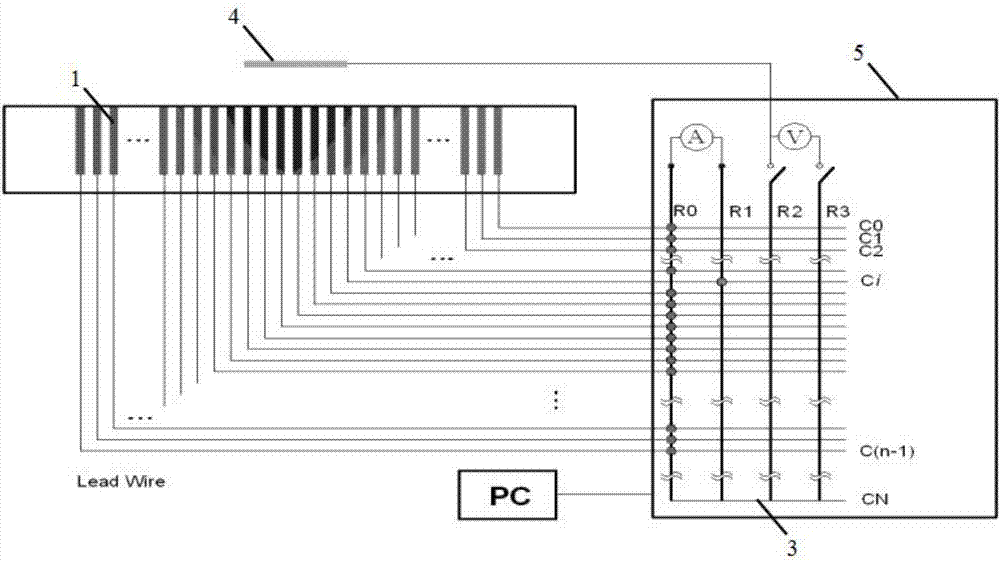

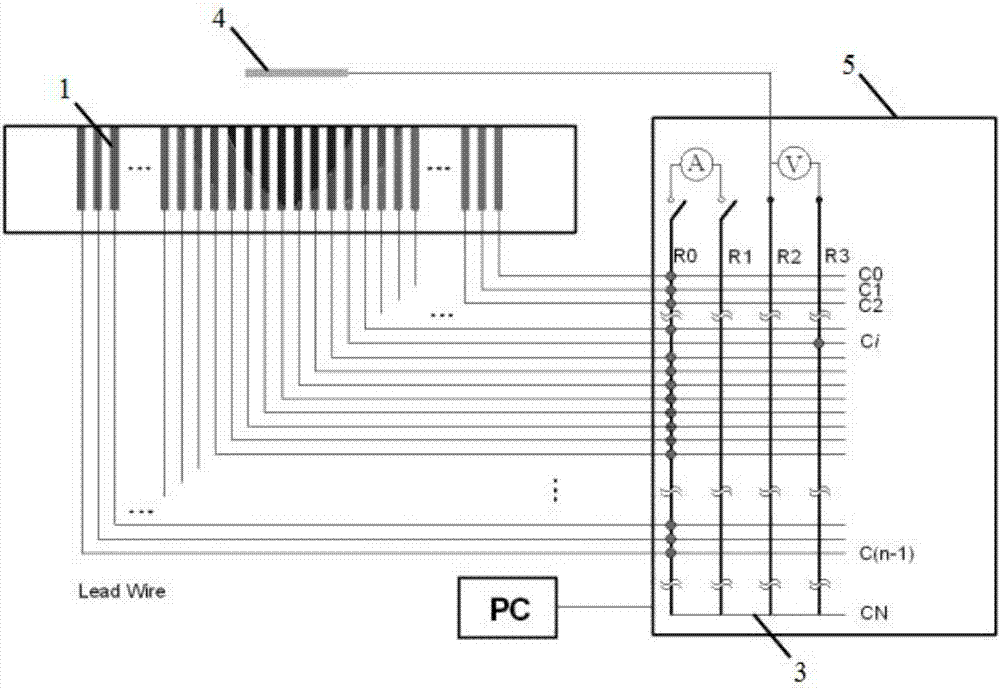

System and method for testing local corrosion of multi-electrode coupled inhomogeneous structure

InactiveCN107192665ANon-uniform stateNon-uniform densityWeather/light/corrosion resistanceSpectroscopyEngineering

The invention relates to a system and a method for testing local corrosion of a multi-electrode coupled inhomogeneous structure. Three testing systems including a classic electrochemical comprehensive testing system, a micro-area electrochemical testing system and a micro-electrode array testing system are arranged in the system; the three testing systems can be used for testing separately and any two testing systems also can be combined together; by using a micro-electrode array as a bridge and a bond, the three testing systems are coupled and combined, three tests of a classic electrochemistry test, a micro-electrode array test and a micro-area electrochemistry test can be carried out, and overall average information such as self-corrosion potential, self-corrosion current density, polarization property and electrochemical impedance spectroscopy, local distribution information such as galvanic potential and galvanic current having certain statistical characteristics, and micro-area distribution information of local cathode and anode areas in a local corrosion process of an inhomogeneous structure can be acquired and effectively associated on aspects of large scale, middle scale and small scale.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

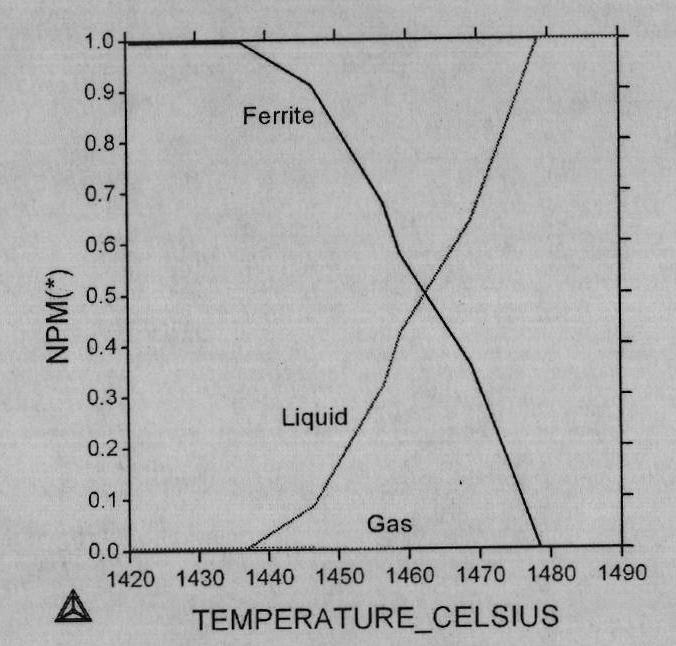

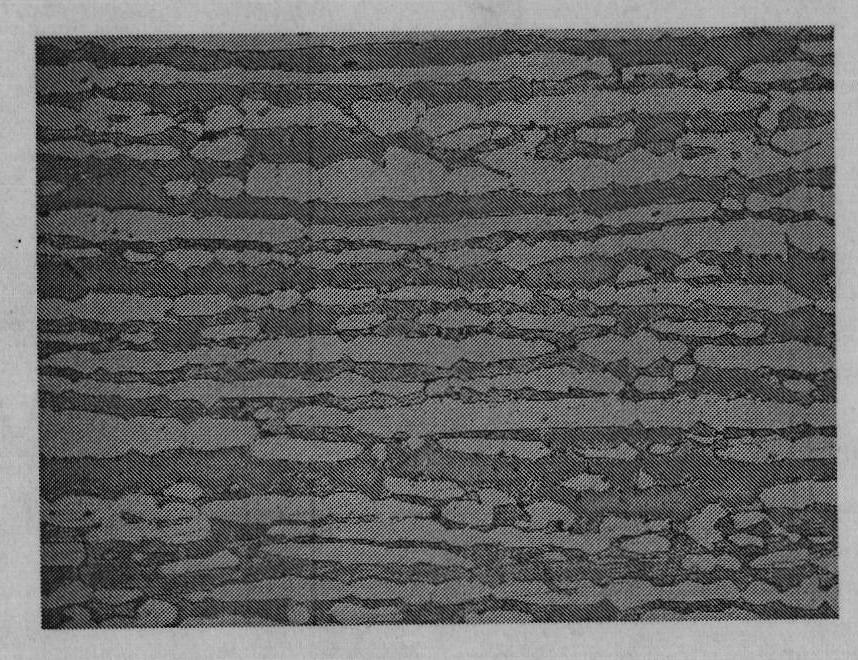

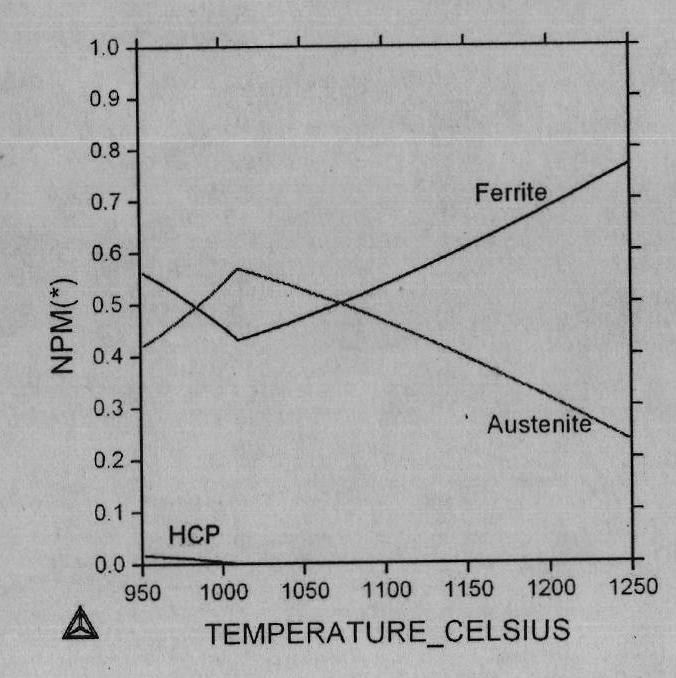

Economic biphase stainless steel with high mechanical property and superior corrosion resistance

The invention provides an economic biphase stainless steel with high mechanical property and superior corrosion resistance, which comprises the following components in percentage by weight: less than or equal to 0.03% of C, 21.5-23.0% of Cr, 1.50-2.50% of Ni, 0.20-0.40% of N, 0.20-0.40% of Mo, 0.20-0.50% of Cu, 0.5-2.0% of Mn, less than 0.005% of S, less than 0.005% of P, and the balance Fe and unavoidable impurities. After the steel product is thermally treated at the temperature range of 980-1080 DEG C, the contents of ferrite and austenite in the obtained biphase structure are approximately same, the local corrosion resistant capacity and the uniform corrosion resistant capacity are superior to those of 304 austenitic stainless steel, the mechanical property is similar to that of 316L austenitic stainless steel, and the steel product can be used as an alternate material for the currently extensively used 304 austenitic stainless steel and 316L austenitic stainless steel.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

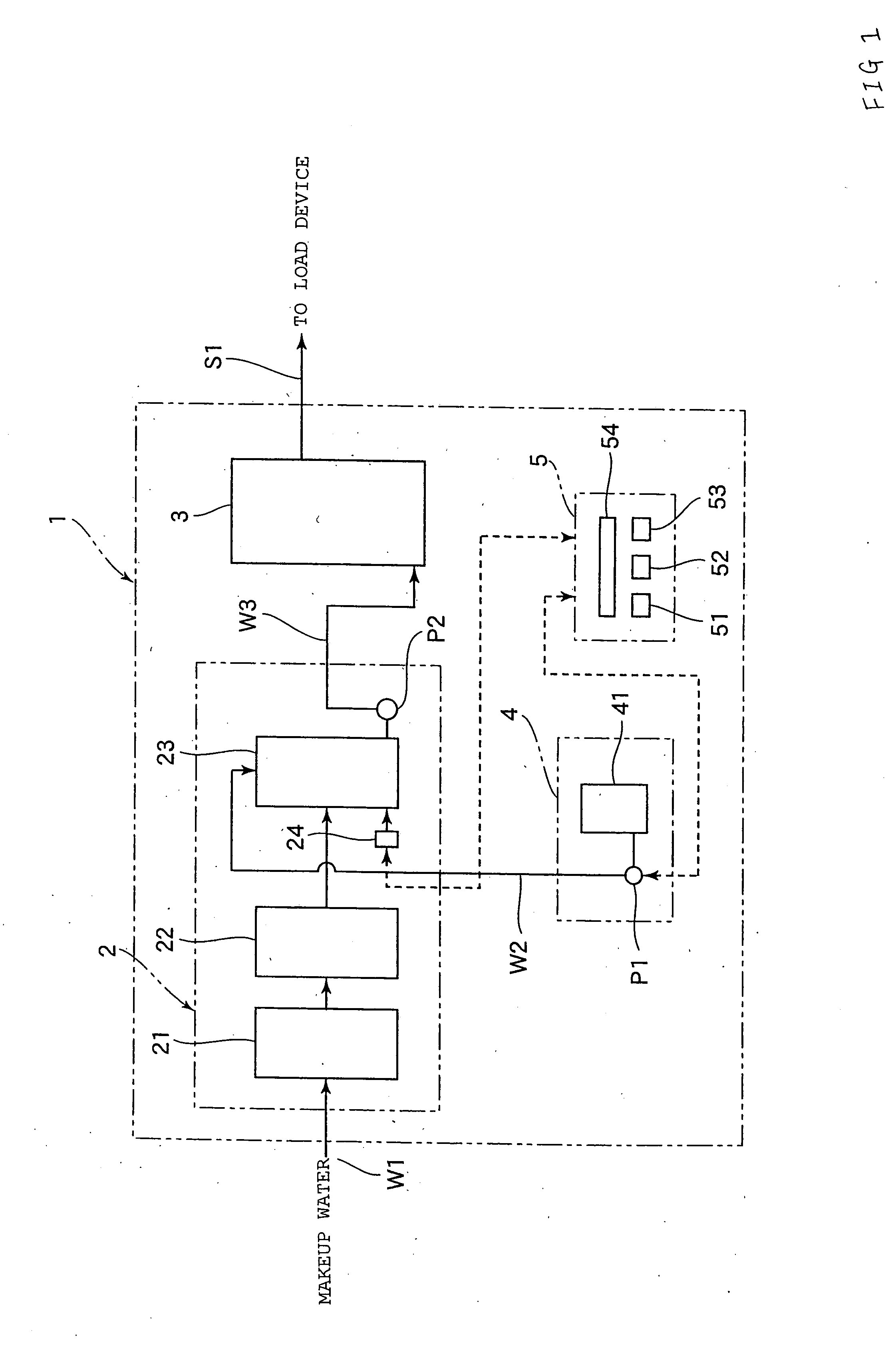

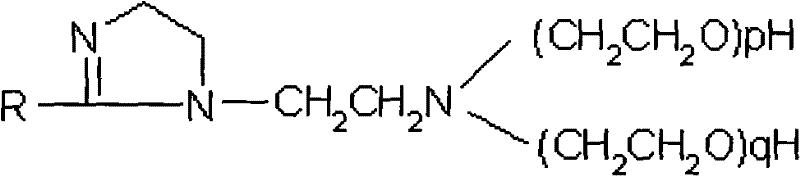

Water Treating Agent and Water Treatment Method

InactiveUS20080257831A1Preventing the general corrosion and local corrosionImprove heat transfer performanceWater treatment parameter controlSpecific water treatment objectivesEngineeringFilm-forming agent

A water treating agent is constituted by blending water as a main component with a coating film forming agent of which a coating film is formed on the heat transfer surface of a boiler tube, a oxygen scavenger, a scale inhibitor, and a pH adjustor in such a manner that the general corrosion and local corrosion of the heat transfer surface of the boiler tube can be prevented and excellent heat transfer property can be obtained. The water treating agent is injected into boiler feed water to perform the prevention of the corrosion of the heat transfer surface of the boiler tube and the suppression of the scaling of the heat transfer surface in a balanced manner. Thus, a coating film capable of suppressing corrosion is formed of the coating film forming agent on the heat transfer surface of the boiler tube. Dissolved oxygen in boiler feed water is removed by the oxygen scavenger. Furthermore, the scaling of the heat transfer surface of the boiler tube is prevented by the scale inhibitor, and the pH of the boiler feed water is adjusted. Therefore, the general corrosion and local corrosion of the heat transfer surface of the boiler tube can be prevented, and excellent heat transfer property can be obtained.

Owner:MIURA COMPANY LIMITED

Pickling solution capable of removing hot-rolled corrosion-resisting alloy oxide skin and pickling method thereof

The invention relates to a pickling solution capable of removing hot-rolled corrosion-resisting alloy oxide skin and a pickling method thereof. The pickling solution comprises 10 g / L-60 g / L of sulfuric acid, 90 g / L-120 g / L of hydrochloric acid, 25 g / L-75 g / L of nitric acid and the balance of water by proportioning. The pickling method comprises the following steps of: I. soaking corrosion-resisting alloy which is annealed and is subjected to shot blasting in the pickling solution capable of removing the hot-rolled corrosion-resisting alloy oxide skin and comprising 10 g / L-60 g / L of sulfuric acid, 90 g / L-120 g / L of hydrochloric acid, 25 g / L-75 g / L of nitric acid and the balance of water by proportioning, wherein the soaking temperature is 20-90 DEG C, and the soaking time is 120-1 minute; and II. cleaning the pickled corrosion-resisting alloy by using a nylon brush or a roll brush, and then washing and airing. The pickling solution reduces environmental pollution caused by hydrofluoric acid; and due to application of the pickling method, local corrosion is not easy to generate on the surface of a pickled surface.

Owner:TAIYUAN IRON & STEEL GROUP

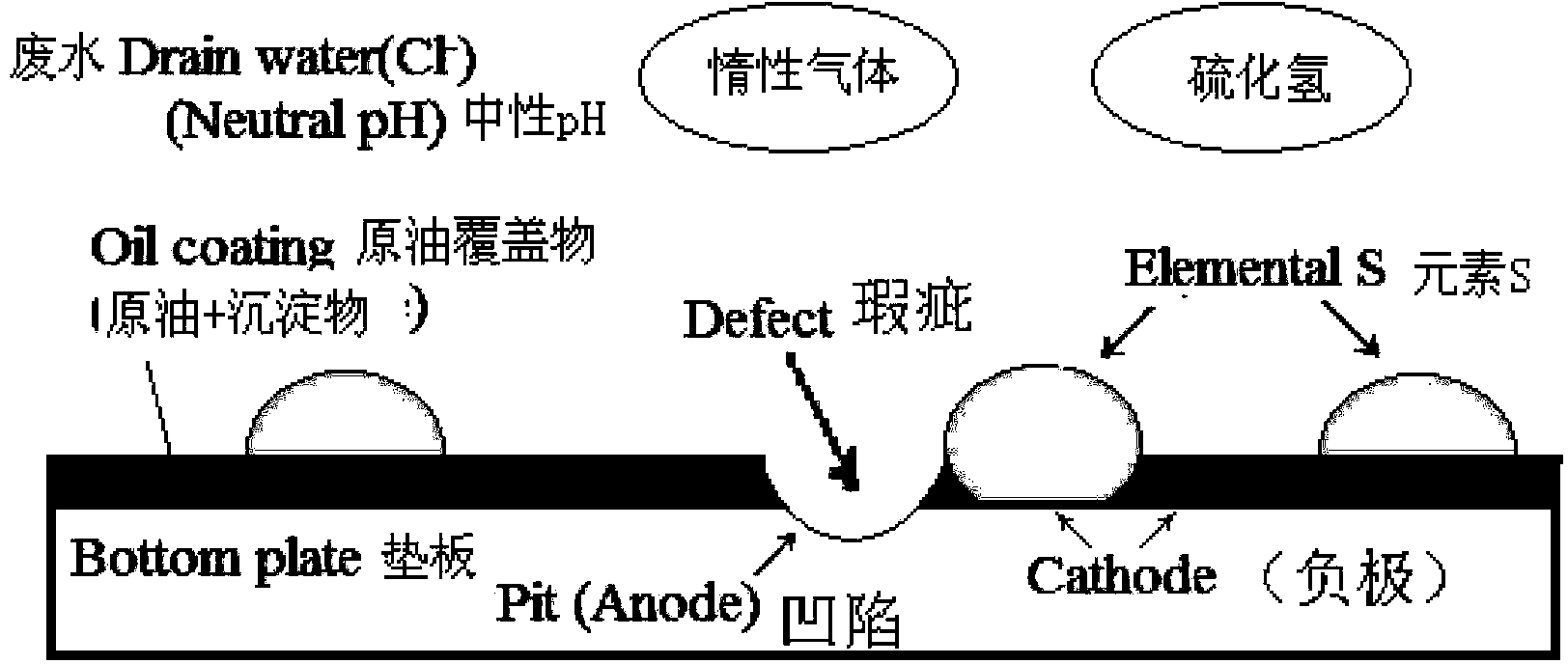

Manufacturing method of corrosion-proof steel plate used for crude oil tanker cargo oil hold inner bottom plate and steel plate

ActiveCN103290186AExcellent resistance to localized corrosionPrevent intrusionProcess efficiency improvementSteel platesControl parameters

The invention discloses a manufacturing method of a corrosion-proof steel plate used for a crude oil tanker cargo oil hold inner bottom plate and the steel plate, and belongs to the technical field of steels used for hot rolling flat-plate boat body structures. The method of manufacturing the corrosion-proof steel plate comprises the following steps of: heating a slab; descaling the slab; rolling; cooling by ACC (activated calcium carbonate) water; cooling by air; controlling parameters. The steel plate disclosed by the invention comprises the following chemical compositions in percentage by mass: 0.02-0.25% of C, 0.05-0.5% of Si, 0.1-2.0% of Mn, at most 0.025% of P, at most 0.01% of S, 0.05-2% of Cu, 0.05-2% of Ni, 0.001-1% of W, 0.001-0.1% of Zr, 0.005-0.1% of Ti, 0.020-0.1% of Als and the balance of Fe and inevitable impurities. The corrosion-proof steel plate disclosed by the invention has the advantages that the steel plate can be directly used for construction of the tanker cargo oil hold lower bottom plate in a bare state, has an excellent local corrosion resistance capability under the service conditions of a high concentration of Cl<-> and a low pH value, coating protection is not needed, the maintenance cost is reduced, and the service life of a hold body is effectively prolonged.

Owner:SHOUGANG CORPORATION

Thermal treatment method for improving corrosion resistance of steel plate for marine-atmospheric-corrosion-resistant structure

InactiveCN103421941AGood mechanical propertiesImprove corrosion resistanceHeat conservationThermal treatment

The invention discloses a thermal treatment method for improving the corrosion resistance of a steel plate for a marine-atmospheric-corrosion-resistant structure. The thermal treatment method is characterized in that a TMCP (thermo-mechanical control process) for rolling the steel plate under the control and then quickly cooling the steel plate is adopted, and the cooling speed is higher than or equal to 15 DEG C / s . The thermal treatment method includes directly feeding the TMCP-state steel plate in a room-temperature state into a non-oxidation roller-hearth type thermal treatment furnace at a furnace temperature, computing a heating period according to a uniform temperature period per unit thickness of 1.0-2.5min / mm, and heating the steel plate so that the temperature of the steel plate reaches a subordinate normalizing temperature which is lower than Ac3 by 20-100 DEG C; computing a heat preservation period for preserving the heat of the steel plate according to a uniform temperature period per unit thickness of 0.5-2.2min / mm after the temperature of the heated steel plate reaches the subordinate normalizing temperature; cooling the steel plate in air until the temperature of the steel plate reaches the room temperature. The thermal treatment method has the advantages that the steel plate for the marine-atmospheric-corrosion-resistant structure is excellent in shape, mechanical property and corrosion resistance, and is excellent in comprehensive corrosion resistance and local corrosion resistance in a marine atmospheric environment.

Owner:NANJING IRON & STEEL CO LTD

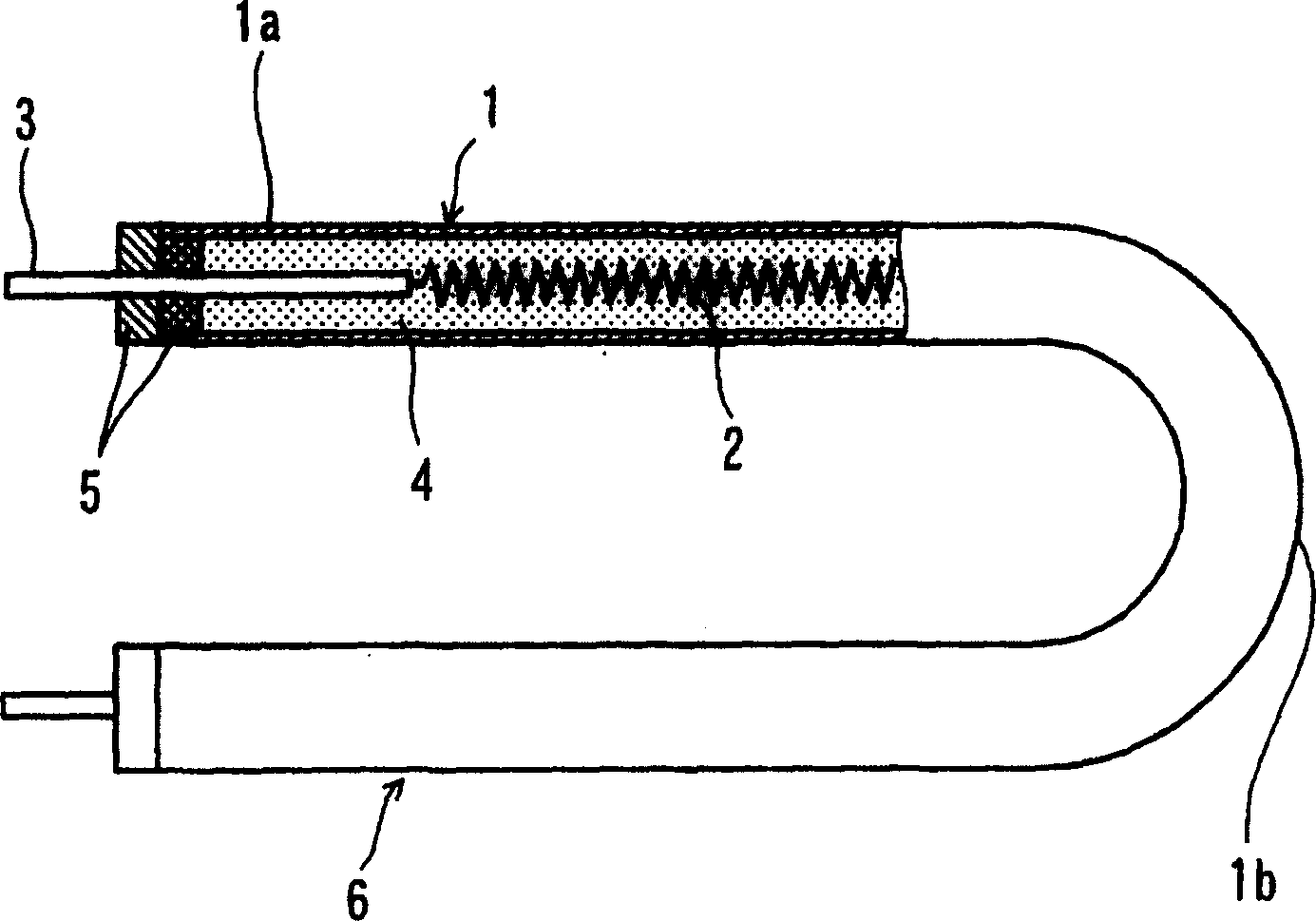

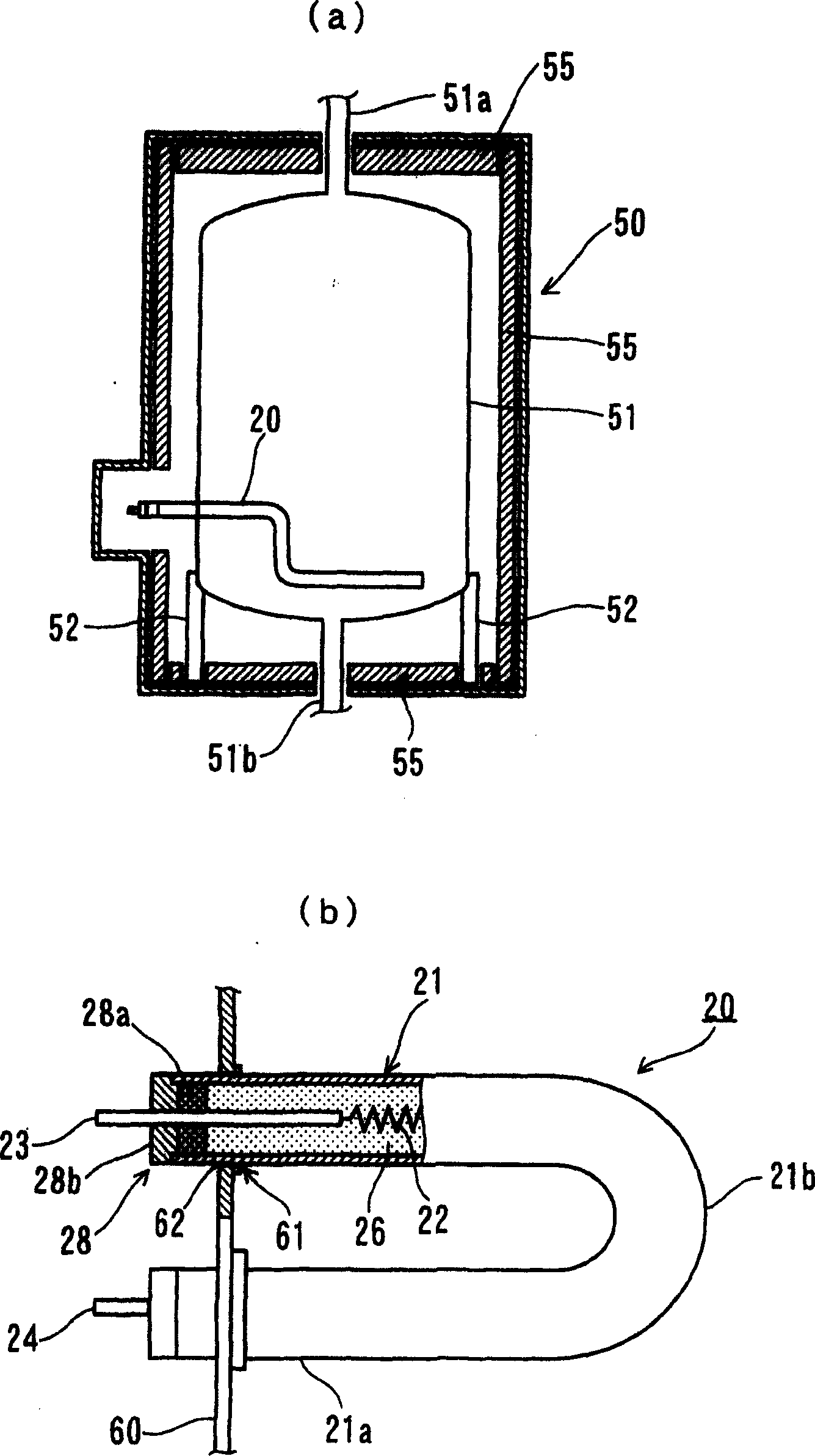

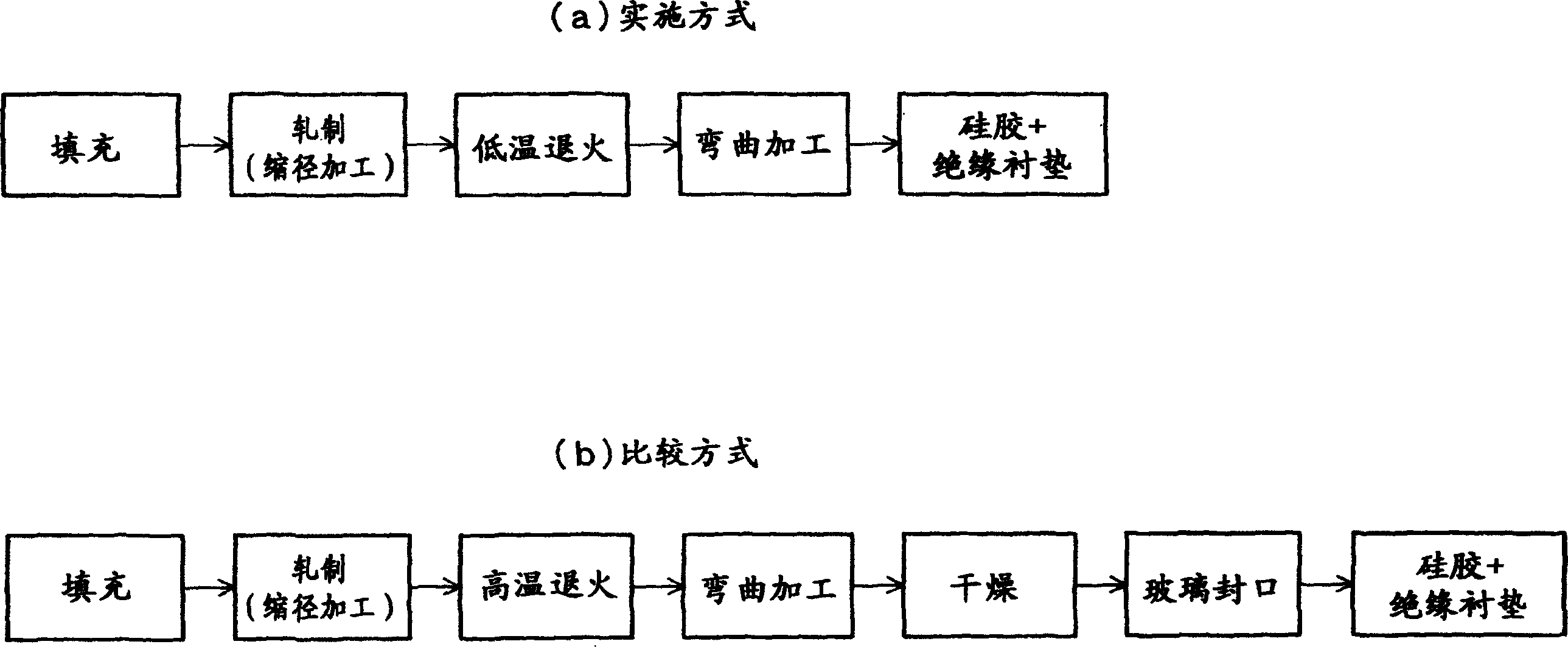

Sheathing heater,its mfg. method and heater

InactiveCN1697574ASimplify the manufacturing processEasy to useImmersion heating arrangementsHeating element shapesMaterials scienceCorrosion

Owner:SAKAE CO LTD +1

Green corrosion inhibitor for hot-dip zinc-aluminium alloy steel, and application thereof

The invention discloses a green corrosion inhibitor for hot-dip zinc-aluminum alloy steel and an application thereof, wherein a main component of the green corrosion inhibitor is vitamin B1. The application is that: a pickle of dilute hydrochloric acid or dilute sulfuric acid having a concentration of 0.1M to 2M is added with the corrosion inhibitor within a concentration range of 0.01kg / m3 to 0.2kg / m3, the temperature being controlled to be maintained at a room temperature of about 25 DEG C, and zinc, zinc-aluminum alloy or hot-dip zinc, zinc-aluminum alloy coating steel for pickling are added and submerged for 0.5h to 3h. Products of the invention are applied to industrial pickling of zinc, zinc-aluminum alloy or hot-dip zinc, zinc-aluminum alloy coating steel and products thereof, allowing an avoidance of general corrosions and local corrosions of metal or coatings during a pickling process. As few researches on similar pickling corrosion inhibitors are taken at present, the product has significant advantages of low price, low dosage, high corrosion inhibition efficiency and good ability of continuous reaction. The product of the invention is a natural plant extract, which is nontoxic and harmless to environment and creatures, fitting the developing trend of pickling corrosion inhibitors and providing a promising application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Flame-retardance-type multi-layer wrapping anticorrosion system and construction method thereof

ActiveCN107955531AGood construction toleranceImprove adaptabilityAntifouling/underwater paintsHeat resistant fibresWeather resistanceAdhesive

The invention discloses a flame-retardance-type multi-layer wrapping anticorrosion system. The system comprises anticorrosion paste, a flame-retardance-type anticorrosion band, an oil separation basecoating, a flame-retardance-type nonmetal protection cover and a dirt-adhesive-resistance surface coating along the metal structure surface towards outside in sequence. The flame-retardance-type multi-layer wrapping anticorrosion system has excellent construction tolerance and adaptability, a long-acting and lasting anticorrosion effect, flame retardance, excellent dirt-adhesive-resistance and weather resistance and is attractive in appearance, wide in application field and particularly suitable for steel structure connection parts, local severe-corrosion parts, facilities of splash areas in ocean and the like, the anticorrosion effect can last for above 20 years, maintenance is not needed within the anticorrosion validity period, and the system has remarkable economic benefits and wide popularization prospects.

Owner:青岛海弗莱安全科技有限公司

Formula of green corrosion inhibition cleaning agent for hot-dip coated steel and application thereof

The invention discloses a green corrosion inhibitor for hot-dip galvanized aluminum alloy steel and an application thereof. Main components of the green corrosion inhibitor comprise vitamin B4 and vitamin C, and the compounding ratio is (1:1)-(5:1). The application is as follows: an acid cleaning solution is of dilute hydrochloric acid or dilute sulfuric acid, the concentration is 0.1M-2M, 0.01kg / m<3>-0.20kg / m<3> of the corrosion inhibitor is added, the temperature is controlled at room temperature which is about 25 DEG C, and zinc, zinc-aluminum alloy or hot-dip galvanized and zinc-aluminum alloy-coated steel to be cleaned is added for immersing for 0.5h-3h. The product disclosed by the invention is used for industrial acid cleaning of zinc, zinc-aluminum alloy or hot-dip galvanized and zinc-aluminum alloy-coated steel and the products thereof, and can prevent total corrosion and local corrosion of metal or plated layers during the cleaning process; and the studies of the similar acid cleaning corrosion inhibitors are fewer at present, and the product has the prominent advantages of cheap price, low using quantity, high corrosion inhibition efficiency and strong continuous acting ability. The product disclosed by the invention is a natural plant extract which is non-toxic and harmless to the environment and organisms, is in line with the trend of development of acid cleaning corrosion inhibitors, and has great application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Super-martensitic stainless steel and preparation method thereof

InactiveCN102534419AHigh strengthImprove pitting resistanceSolution treatmentMartensitic stainless steel

The invention relates to super-martensitic stainless steel and a preparation method thereof, and belongs to the field of steel materials. The super-martensitic stainless steel comprises the following chemical components in percentage by mass: 0 to 0.03 percent of C, 0 to 0.03 percent of N, less than 0.015 percent of S, less than 0.020 percent of P, less than 1 percent of Si, less than 1 percent of Mn, 13 to 16 percent of Cr, 4 to 6 percent of Ni, 1 to 2 percent of Mo, 0.05 to 0.15 percent of Nb, 0.001 to 0.01 percent of Ti and the balance of Fe. The preparation method comprises the following steps of: smelting by using a vacuum induction furnace to obtain a casting blank which meets the requirements of chemical component ranges, performing hot forging at the temperature of 1,200 DEG C, performing hot rolling at the temperature of between 1,100 and 1,200 DEG C, performing solid solution treatment at the temperature of between 1,050 and 1,100 DEG C for 0.5 to 1 hour, performing air cooling and normalizing treatment, tempering at the temperature of between 550 and 700 DEG C for 2 to 4 hours, and performing oil cooling to room temperature. The super-martensitic stainless steel has high strength and toughness and high local corrosion resistance.

Owner:NORTHEASTERN UNIV

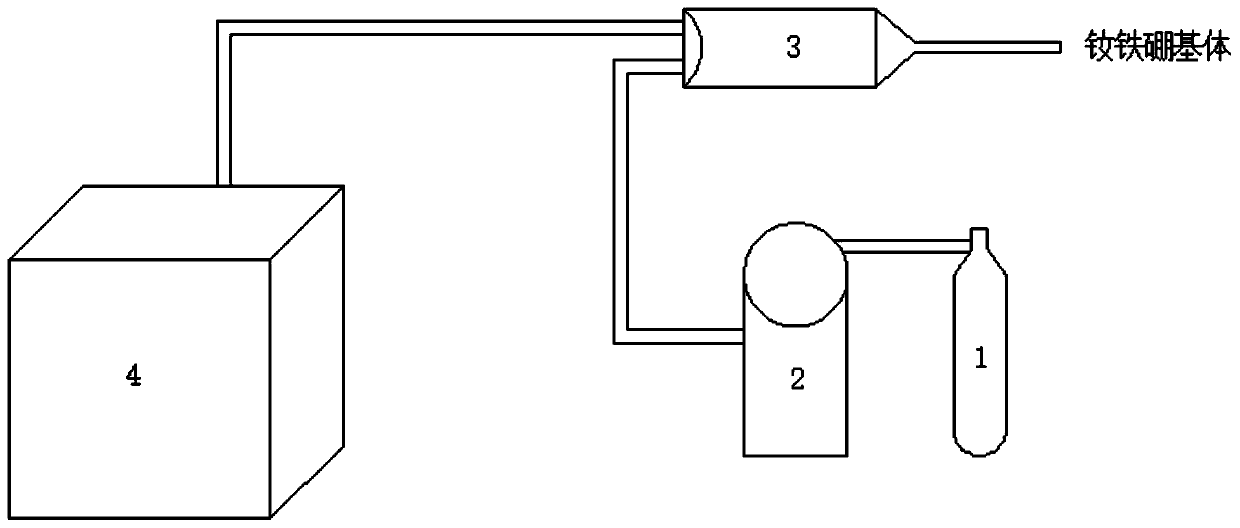

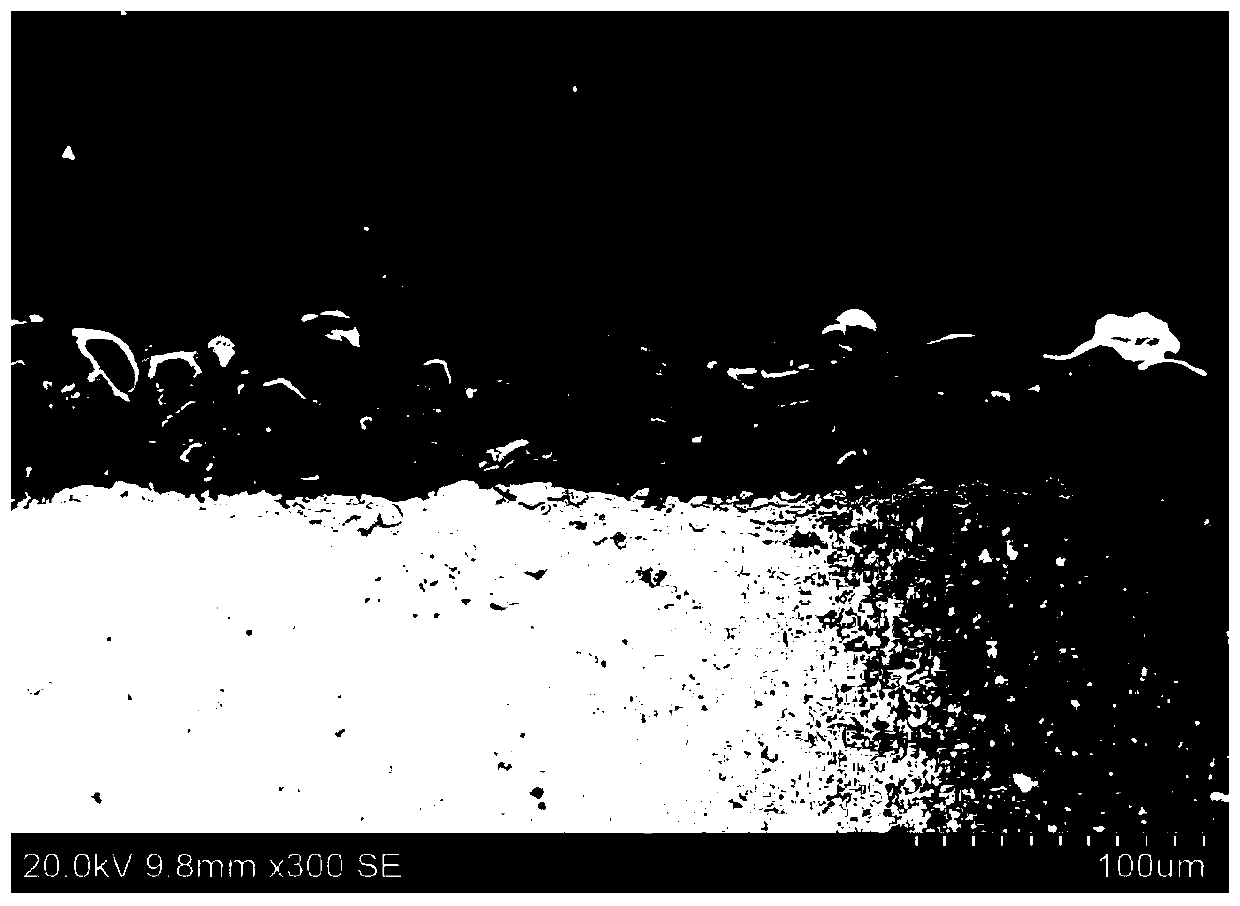

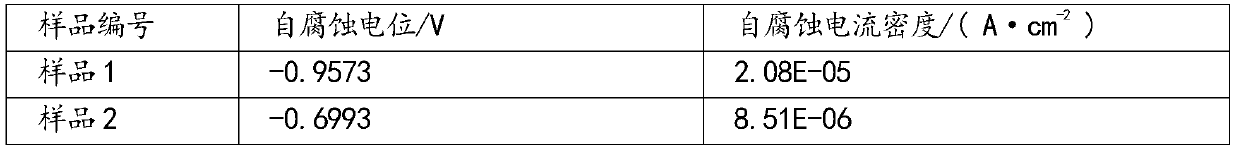

Neodymium-iron-boron magnet surface composite corrosion-resistant coating and preparation method thereof

InactiveCN110828099AExtended service lifeSimple preparation processPermanent magnetsTransformers/inductances corrosion protectionCoated surfaceAluminium powder

The invention discloses a neodymium-iron-boron magnet surface composite corrosion-resistant coating and a preparation method thereof. The composite corrosion-resistant coating sequentially comprises acold spraying aluminum coating, an aluminum oxide passivation layer obtained through surface passivation treatment and a hole sealing ceramic paint layer from the surface of a neodymium-iron-boron magnet to the outside. The preparation method comprises the following steps of: (1) surface treatment of a neodymium-iron-boron substrate; (2) treatment of aluminum powder; (3) cold spraying of an aluminum coating; (4) passivation treatment to obtain an aluminum oxide passivation layer; and (5) hole sealing treatment to obtain a hole sealing ceramic paint layer. The prepared neodymium-iron-boron magnet surface composite corrosion-resistant coating has excellent local corrosion resistance, the corrosion-resistant coating is formed by well combining with the neodymium-iron-boron magnet, the defects that a pure aluminum coating is low in strength and hardness and micropores exist in the surface are overcome, and the service life of the corrosion-resistant coating is prolonged when the corrosion-resistant coating is used as a sintered neodymium-iron-boron magnetic material surface corrosion-resistant process.

Owner:INNER MONGOLIA UNIV OF TECH

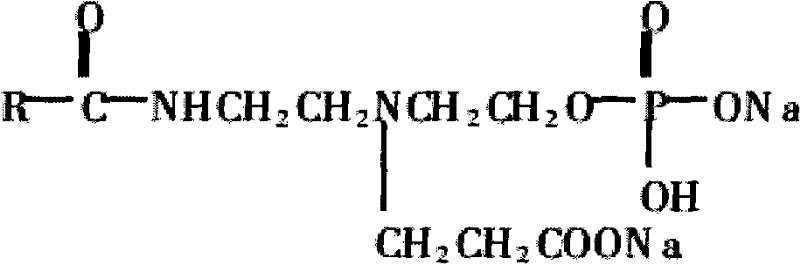

Rapid judgment for corrosion of sodium bicarbonate water type oil well and corrosion inhibitor

ActiveCN101699268BRapid qualitative judgment of corrosionShorten the determination timeWeather/light/corrosion resistanceTesting waterSodium bicarbonatePhosphoric Acid Esters

The invention relates to rapid judgment for the corrosion of a sodium bicarbonate water type oil well, which is applied to the corrosion treatment of a pit shaft of the oil well. A production liquid is of a sodium bicarbonate water type. When the mole ratio of Ca to HCO3- is between 0 and 1 and less than 0.6, the corrosion which is local corrosion and scale formation coexist; along with the increase of the mole ratio of the Ca to the HCO3-, the scale formation of the pit shaft is relieved, but the corrosion becomes serious; and when the mole ratio of the Ca to the HCO3- is greater than 0.6, the pit shaft of the oil well is mainly corroded. The corrosion condition of a sodium bicarbonate water type medium is fast known through the mole ratio of the Ca to the HCO3-. A corrosion inhibitor for the sodium bicarbonate water type medium is made from the following components in percentage by weight: 20 to 35 percent of carboxylate sodium imida, 20 to 35 percent of water-soluble rosinyl imidazoline, 5 to 10 percent of dodecyldimethylbenzylammonium chloride, 0 to 5 percent of aminotri-methylene phosphonic acid, 0 to 5 percent of hydroxyl ethidene diphosphonic acid, 5 to 10 percent of methanol, 2 to 5 percent of dispersant and the balanced of water. The rapid judgment and the corrosion inhibitor can improve the efficiency of corrosion inhibition.

Owner:PETROCHINA CO LTD

Acidic cleaner for carbon steel and applications

This invention discloses an acidic detergent for carbon steel and its application. The acidic detergent is composed of xacin-series antibacterial drug and 0.1-2 M acid solution at a ratio of 0.010-5.0 kg / L. The acidic detergent can be applied by soaking carbon steel in the acidc detergent at room temperature for 15 min-3 h. The acidic detergent can prevent carbon steel from local or whole corrosion, and has such advantages as low usage amount, high corrosion-inhibiting efficiency, long effective time, no harm to the environment or creatures, etc., thus having good application potential.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

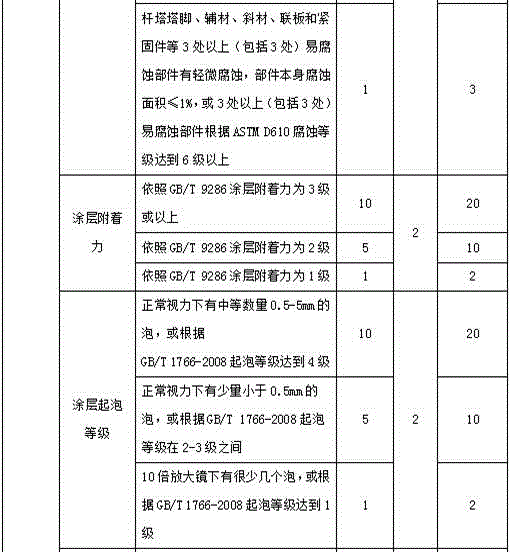

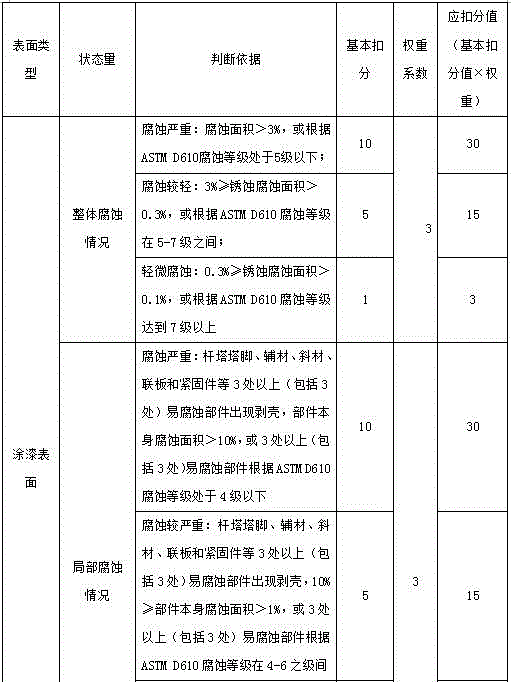

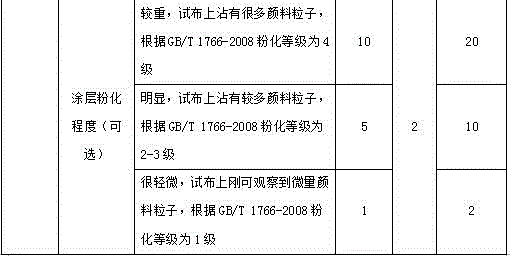

Tower paint surface corrosion safe state evaluation method

InactiveCN105548467AObjective evaluationAccurate evaluationMaterial analysisWeight coefficientState parameter

The invention relates to a tower paint surface corrosion safe state evaluation method and belongs to the technical field of in-service tower safety evaluation and maintenance. The method comprises carrying out basic score deduction according to detection results of four state parameters such as a paint surface whole corrosion degree, a paint surface local corrosion degree, coating adhesion and a coating foaming degree, calculating products of the basic deducted scores of the state parameters and corresponding weight coefficients (3, 3, 2, 2) to obtain scores to be deducted and determining a safe state of the tower paint surface according to the sum of the score to be deducted of each one of the state parameters and the scores to be deducted of the state parameters. Compared with the existing tower corrosion state subjective judgment method, the method provided by the invention can give objective and accurate tower corrosion state evaluation according to the tower corrosion safety evaluation standard. The state parameters are reasonable, a state parameter detection related standard or apparatus exists and the method can be executed easily.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY

Copper-plated layer washing degreaser applied in electroplating industry

InactiveCN103805369AQuick removalSolve problems such as localized corrosionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium metasilicateActive agent

The invention discloses a copper-plated layer washing degreaser applied in the electroplating industry. The copper-plated layer washing degreaser comprises the following ingredients in percentage by weight: 10-15 percent of sodium carbonate, 20-25 percent of sodium metasilicate, 20-25 percent of trisodium phosphate, 10-12 percent of anhydrous sodium sulfate, 5-8 percent of an anionic surfactant, 3-5 percent of a nonionic surfactant and 10-30 percent of a grinding material. A preparation method comprises the following steps: sieving the raw materials through a 20-mesh vibration sieve; respectively weighing the raw materials according to the percentage, and pouring the raw materials into a horizontal mixer for mixing; adding the anionic surfactant and the nonionic surfactant according to the percentage and mixing; adding the grinding material and mixing. The copper-plated layer washing degreaser disclosed by the invention can be used for rapidly removing the dirt such as grease, residual polishing paste, dust, fingerprints and the like from the surface of a copper layer before chroming and also has the function of roughening a copper-plated layer; an oxide layer on the surface of the copper layer is removed and the Ra value of the roughness of a copper polished layer is reduced to 0.10-0.12 micrometer from 0.06-0.08 micrometer, thus the binding force between the copper layer and a subsequent chromed layer is increased, the problems of partial corrosion of the chromed layer and the like are solved, reworking is reduced, the roller printing quality is improved and the service life is prolonged.

Owner:张贵明

Heat exchanger electrochemically-induced film formation method in circulating cooling water micro-alkalifying transition period

The invention relates to a heat exchanger electrochemically-induced film formation method in a circulating cooling water micro-alkalifying transition period. The method comprises the following steps: connecting a circulating cooling water system heat exchanger with an active metal zinc block to constitute a primary cell, regulating the pH value of circulating water to 2-4, monitoring the metal ion content of the circulating water in the operation process, and after 2-3 days, finishing cleaning when the rise trend slows down; as for a brass heat exchanger, regulating the system to alkality, adding an oxidizer, and forming a Cu2O passivating film on the surface after some time, wherein after the cathode protection is removed, the Cu2O passivating film is gradually converted into a stable CuO passivating film, and afterwards, the brass corrosion rate is less than 0.005 mm / a; and as for the a carbon steel heat exchanger, adding Fe<2+> at one time, circulating for some time, regulating the solution to alkality, adding an oxidizer, removing cathode protection after some time, and forming a compact ferric oxide passivating film on the surface, wherein the corrosion rate is less than 0.01mm / a. The method prevents local corrosion and completes the circulating cooling water micro-alkalifying transition period.

Owner:浙江常山利盛新材料有限公司 +1

Antirust method for 20A steel tube for aviation

ActiveCN103924054AQuality improvementHigh yieldFurnace typesHeat treatment furnacesAviationSteel tube

The invention discloses an antirust method for a 20A steel tube for aviation. The method comprises steps of (1) thermal treating under argon shield; (2) straightening, flaw detecting, and cutting off unqualified parts; (3) polishing, then soda boiling and acid prickling; (4) neutralizing, washing and draining off; (5) steeping in lubricating oil, acid pickling, alkali washing, and draining off; (6) steeping in antirust oil, draining the oil, bagging and packaging. Being treated by the method, the steel tube avoids pitted surface due to local corrosion, and the yield and quality of the product are improved.

Owner:宝武特冶航研科技有限公司

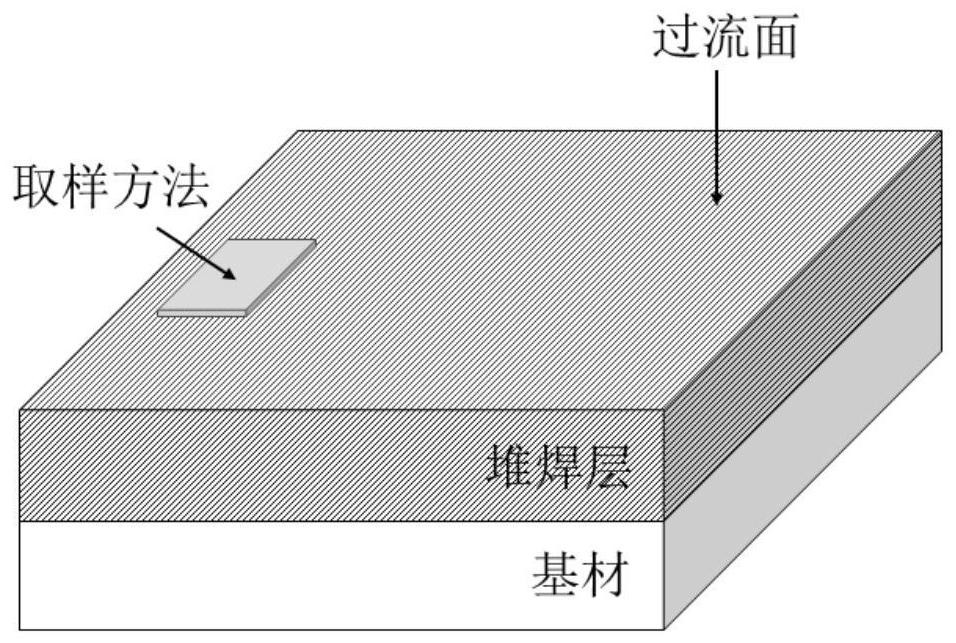

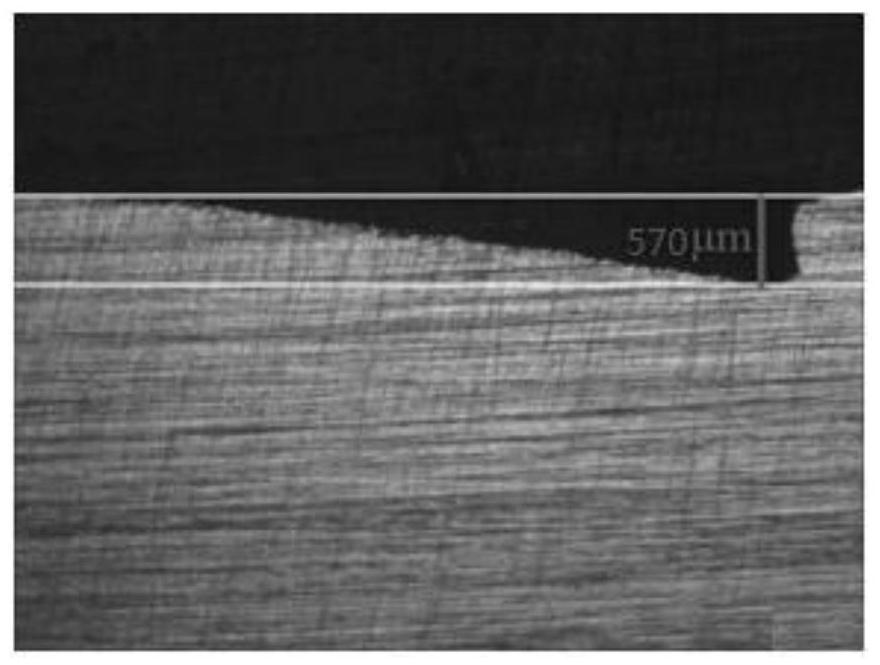

Corrosion evaluation method for corrosion-resistant alloy surfacing welding layer of underwater oil and gas facility

ActiveCN111721619AEffective guide selectionReduced risk of corrosion failureWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMechanical propertyMaterial selection

The invention provides a corrosion evaluation method for a corrosion-resistant alloy surfacing welding layer of an underwater oil and gas facility. The method is used for quantitatively evaluating thecorrosion resistance of a surfacing welding layer by comprehensively characterizing the structure state, the mechanical property, the comprehensive corrosion rate and the local corrosion risk of thesurfacing welding layer. According to the invention, quantitative indexes are provided mainly for the corrosion resistance of the corrosion-resistant alloy surfacing welding layer of the underwater oil and gas facility, corrosion resistance evaluation can be conducted on surfacing welding materials applied under corresponding working conditions, and material selection, welding process evaluation and corrosion control are guided.

Owner:CHINA NAT OFFSHORE OIL CORP +2

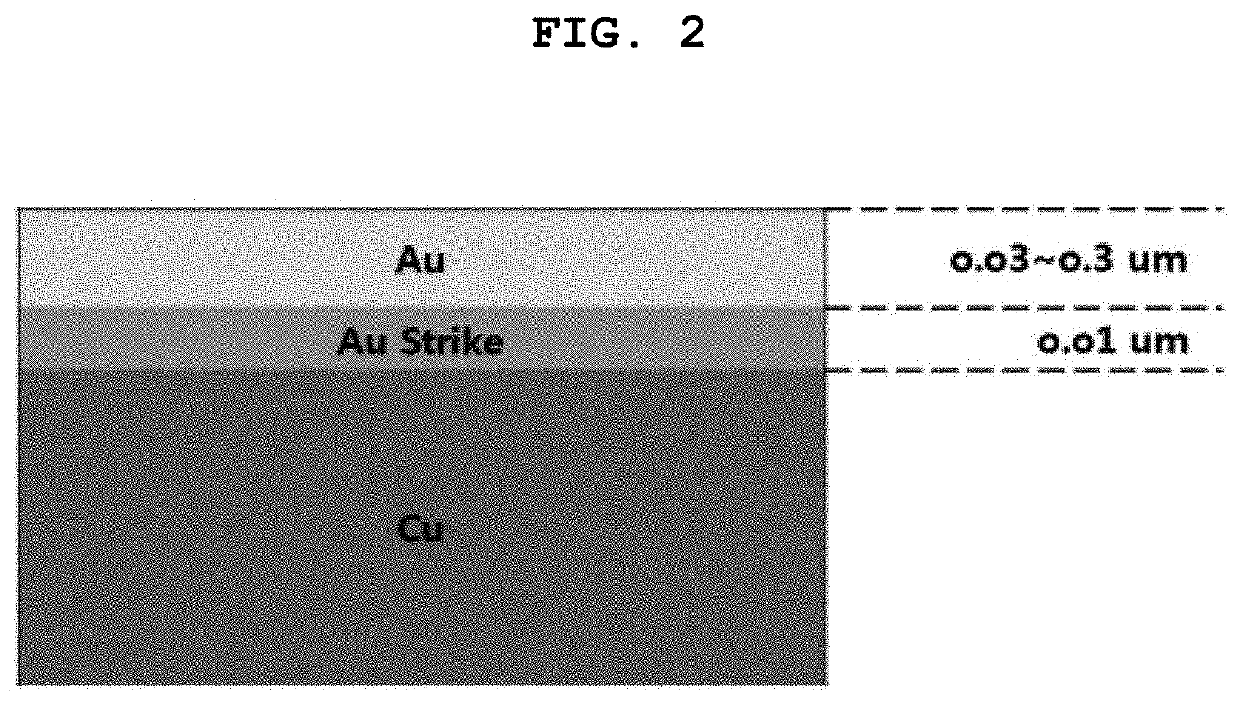

Substitution-type electroless gold plating solution containing purine or pyrimidine-based compound having carbonyl oxygen and substitution-type electroless gold plating method using the same

ActiveUS20200095685A1Avoid erosionMaintain long-term stabilityLiquid/solution decomposition chemical coatingConductive pattern reinforcementActive agentPurine

A substitution gold plating solution for performing uniform gold plating directly on copper wiring of a printed circuit board is provided and a gold plating method using the same is provided, the solution comprising a purine-based compound or a pyrimidine-based compound having a carbonyl oxygen used as a localized corrosion inhibitor, a water-soluble gold compound, an aminocarboxylic acid as a complexing agent, a dicarboxylic acid as a conductivity improving agent, an α-hydroxycarboxylic acid and heteroaryl carboxylic acid as a base metal elution and re-precipitation preventing agent, a sulfite compound as a gold ion stabilizer, an axole compound as a surface corrosion inhibitor, other surfactants, crystal regulators, pH adjuster, and buffers.The substitution-type electroless gold plating solution according to the present invention prevents the localized corrosion of the copper surface, which is the base metal, and thus the gold plating film produced is excellent in solder mounting reliability.

Owner:M K CHEM & TECH

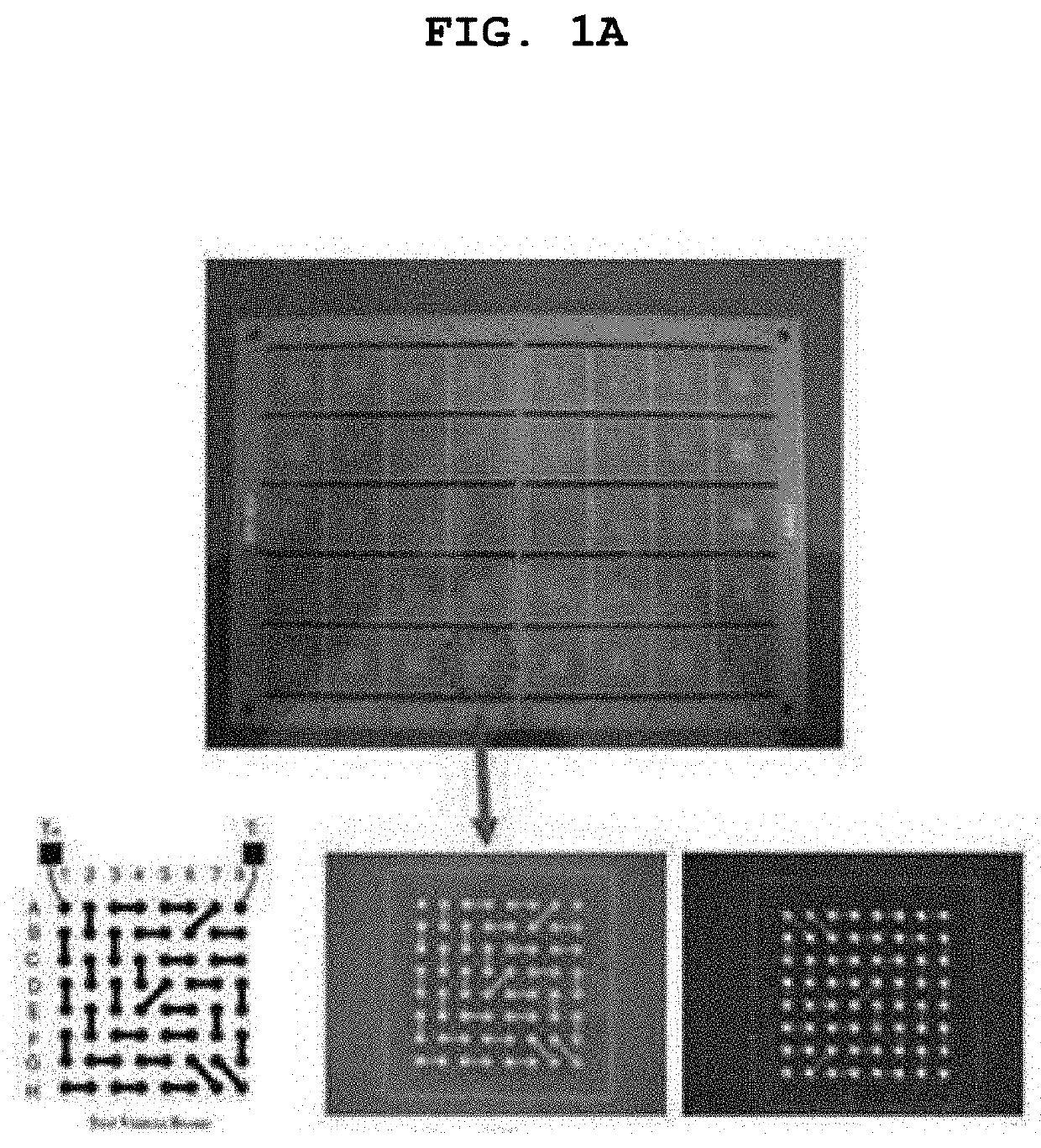

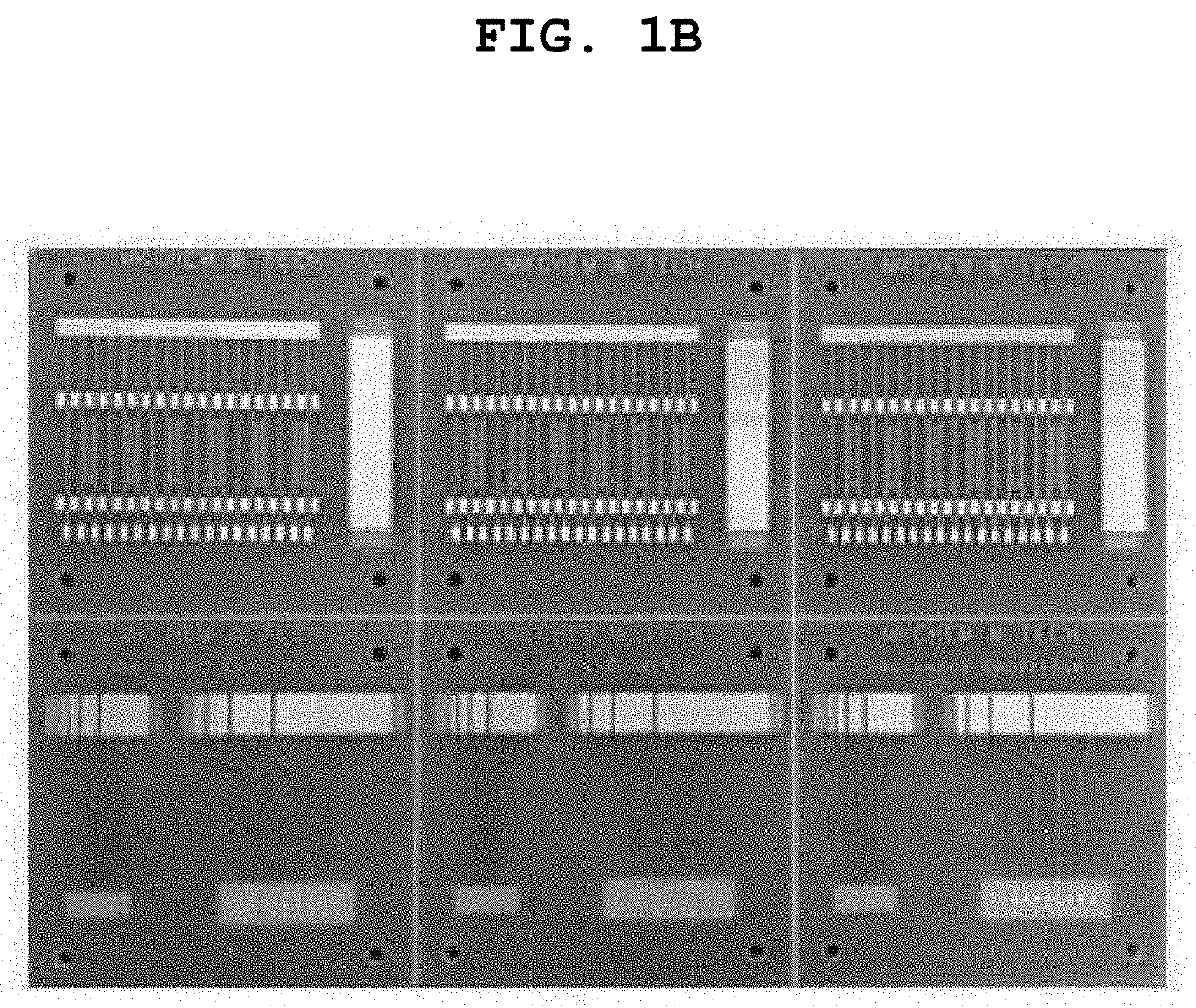

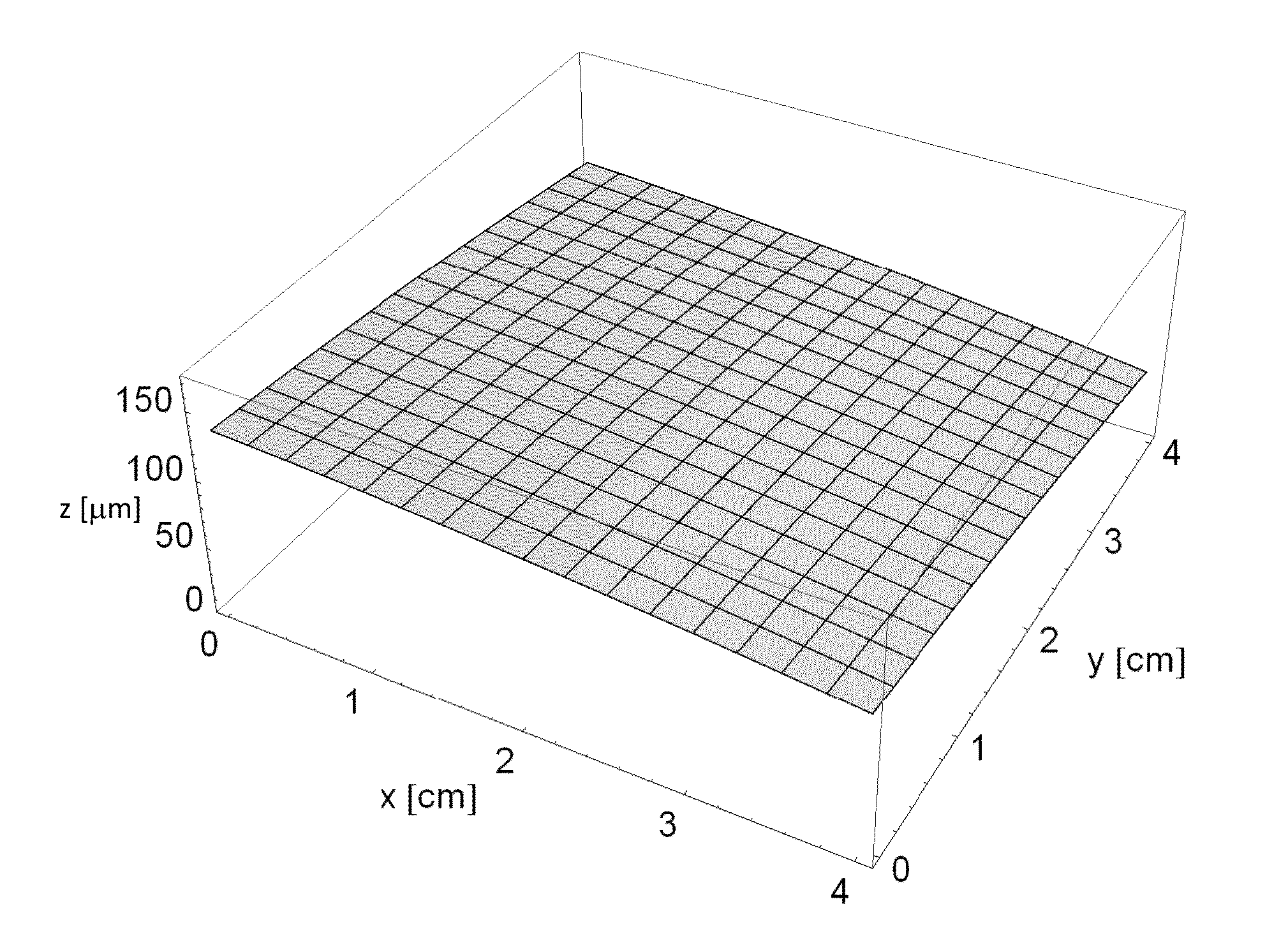

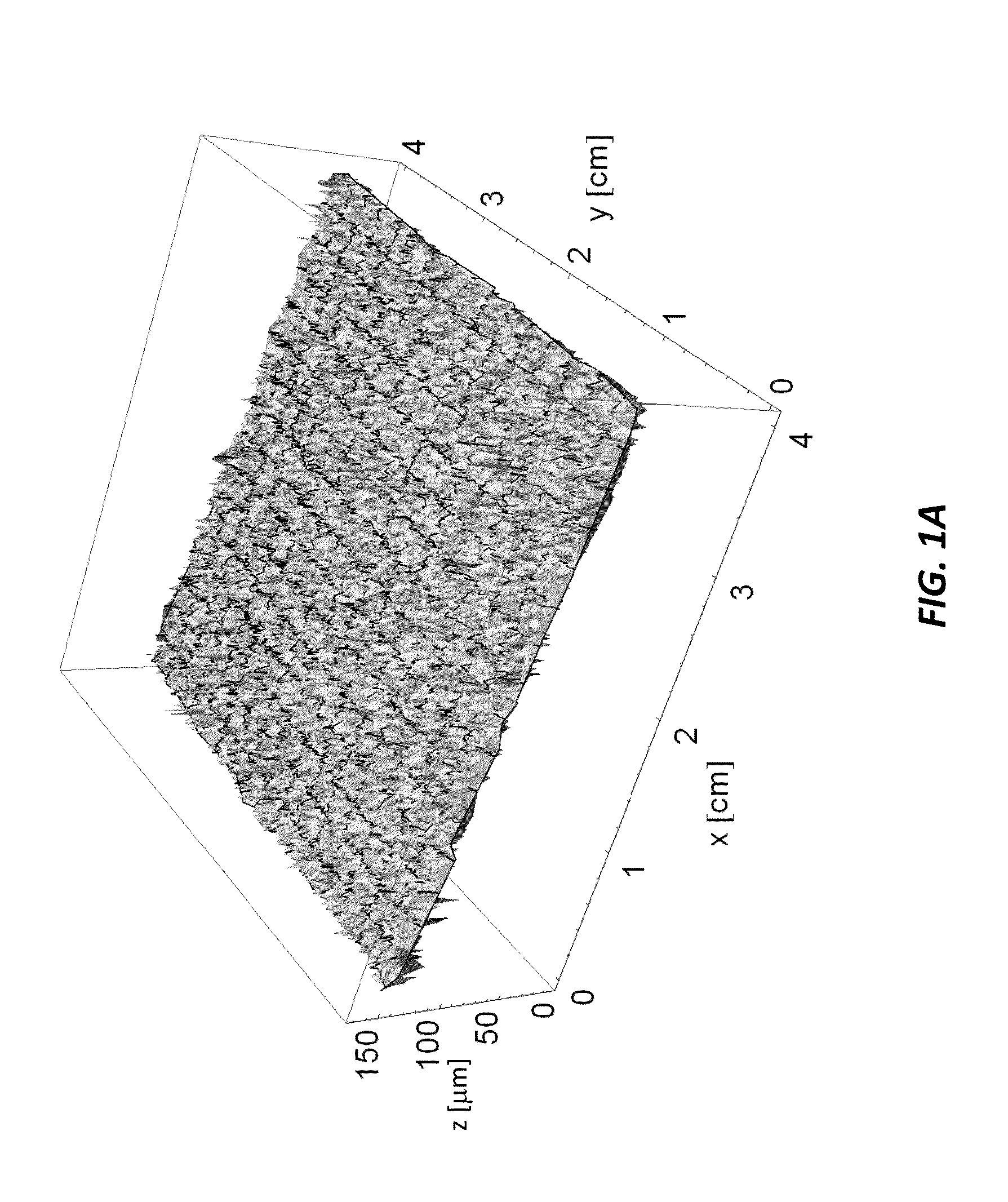

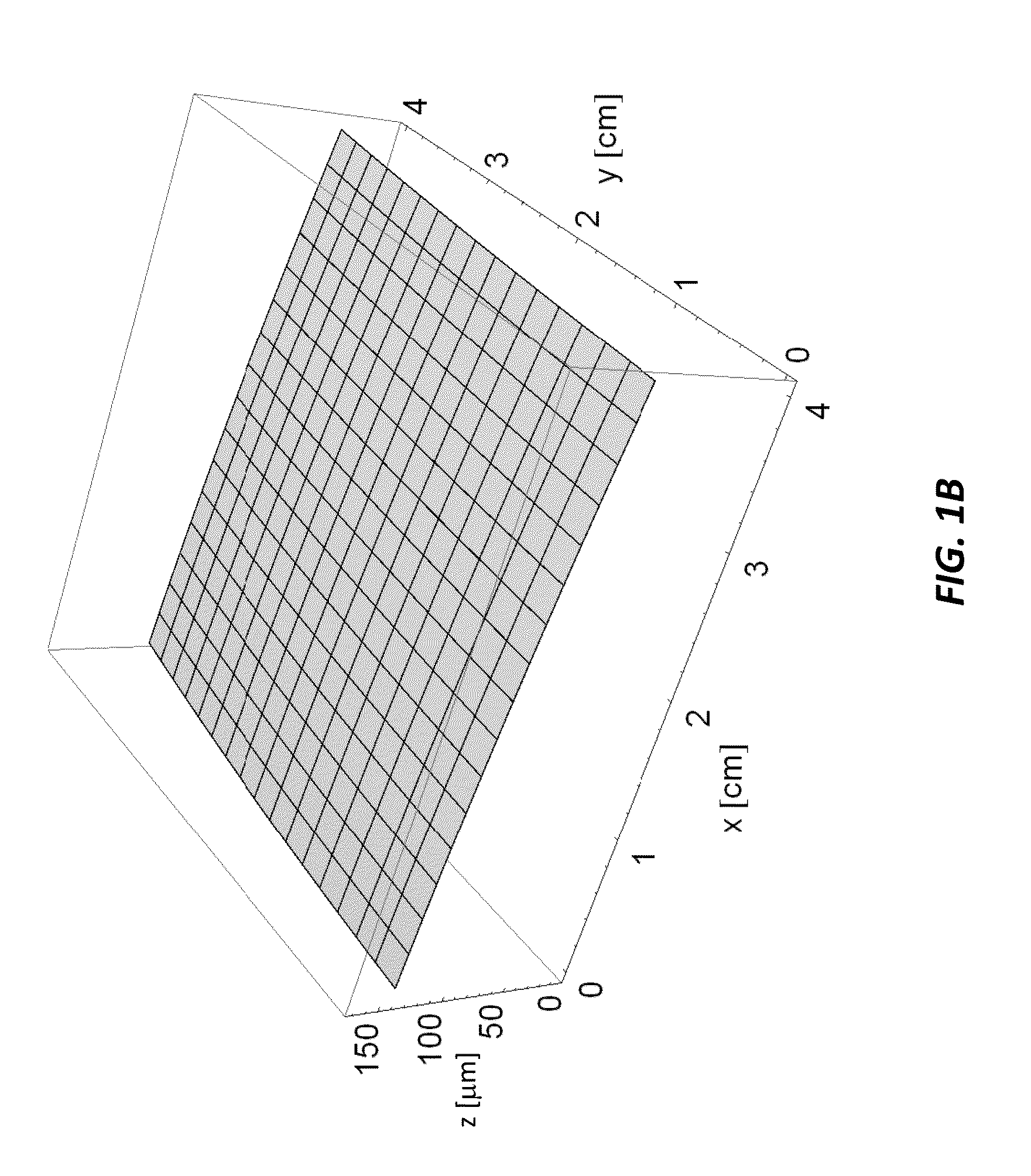

System, Apparatus Or Method For Characterizing Pitting Corrosion

ActiveUS20160069789A1Weather/light/corrosion resistanceOptically investigating flaws/contaminationMaterials scienceMetal

The present invention relates to a system, apparatus or and method to quantify features of relatively small defects or anomalies on a selected surface. Such defects may be associated with localized corrosion, such as pitting, that takes place on the surface of a metal exposed to a metallic environment.

Owner:SOUTHWEST RES INST

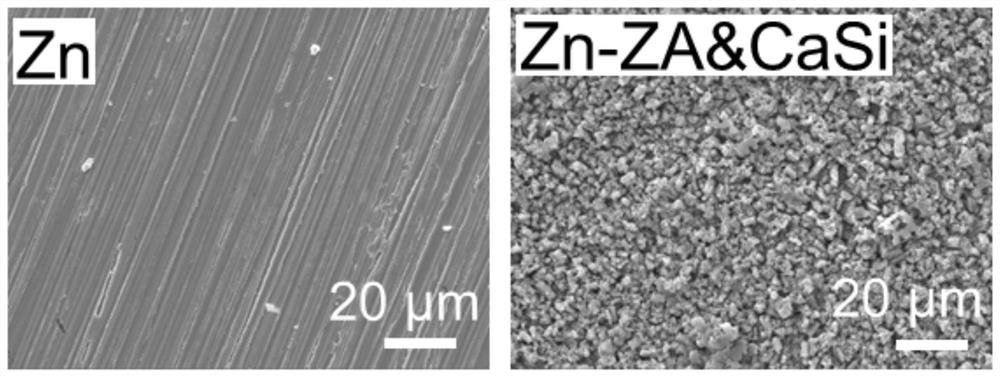

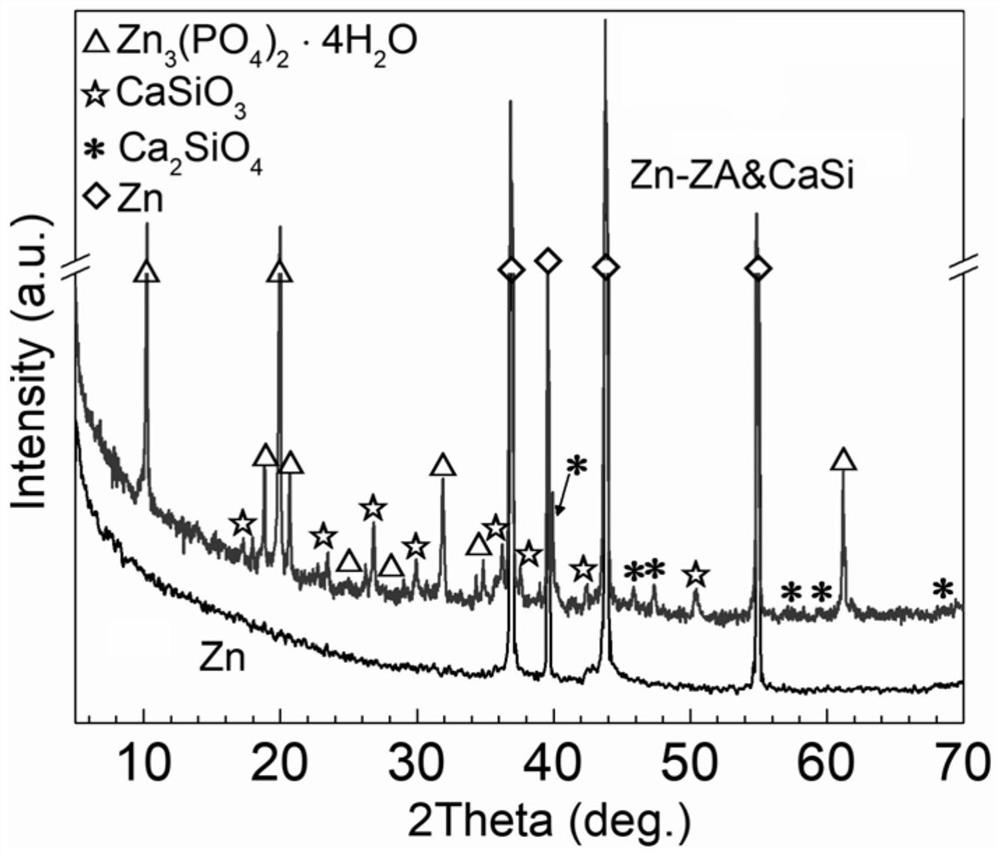

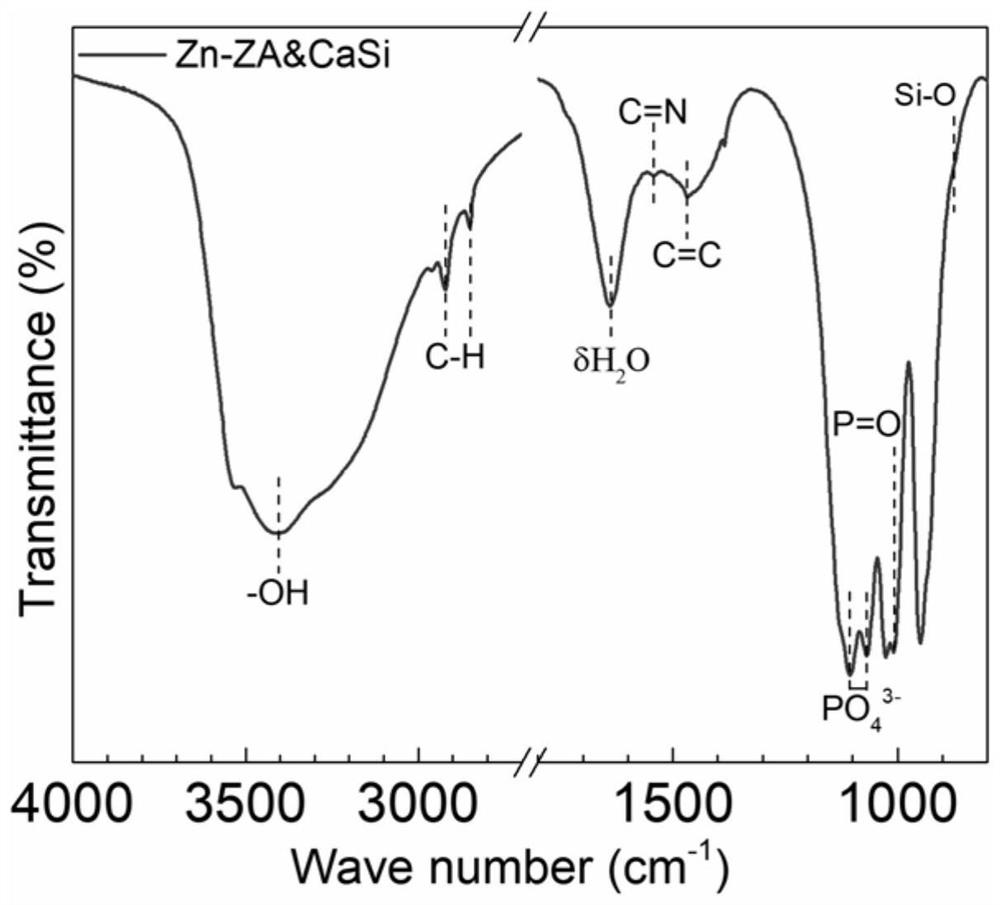

Metal-organic/inorganic hybrid coating for promoting bone regeneration and regulating and controlling corrosion on degradable metal surface and preparation method thereof

ActiveCN113577383AEfficient integrationTightly boundPharmaceutical delivery mechanismMetallic material coating processesOsseointegrationFluid phase

The invention discloses a metal-organic / inorganic hybrid coating capable of promoting bone regeneration and regulating and controlling corrosion on a degradable metal surface and a preparation method thereof, and the metal-organic / inorganic hybrid coating capable of promoting bone regeneration and regulating and controlling corrosion and degradation is prepared in an alternate liquid phase deposition mode in combination with a chemical coordination chelation principle. According to the coating, the problem that degradable metal, especially zinc-based metal, is insufficient in bone integration and regeneration promoting activity is solved in a targeted mode, and the purpose of promoting bone healing and regeneration is achieved from three aspects of promoting bone generation, promoting angiogenesis and inhibiting osteoclast differentiation at the same time. And the problem of non-uniform corrosion of the zinc-based metal is solved, the corrosion degradation mode of the zinc metal is changed, local corrosion and small hole corrosion are avoided, and the zinc metal can be effectively prevented from being broken and losing efficacy in advance.

Owner:SOUTHWEST JIAOTONG UNIV

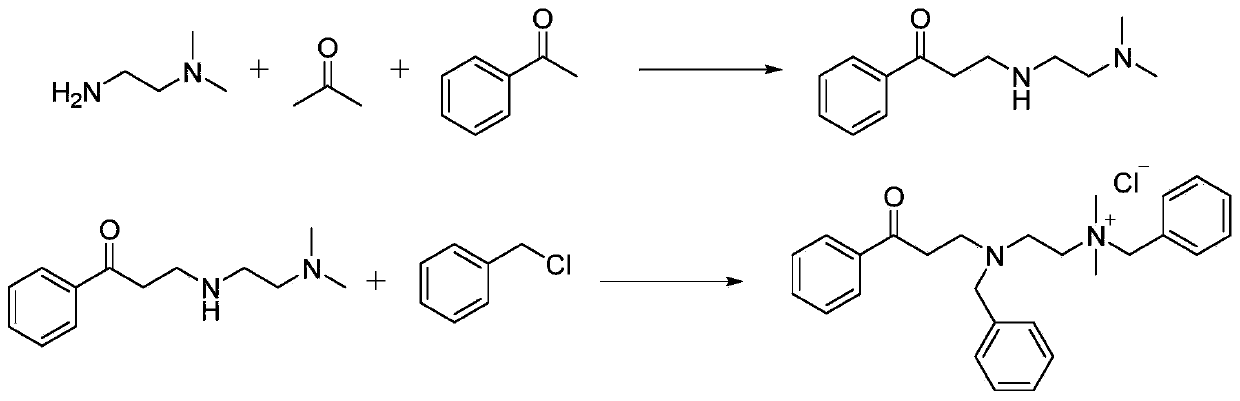

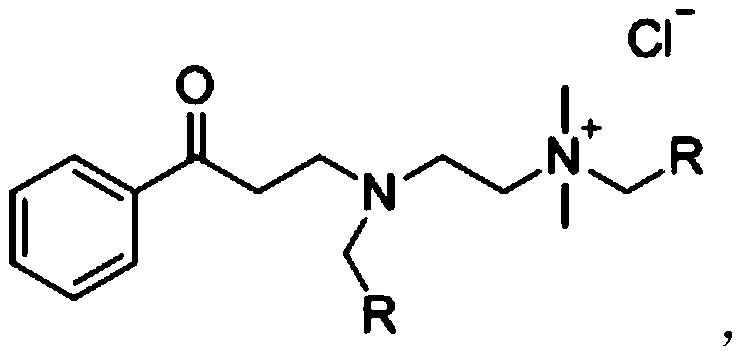

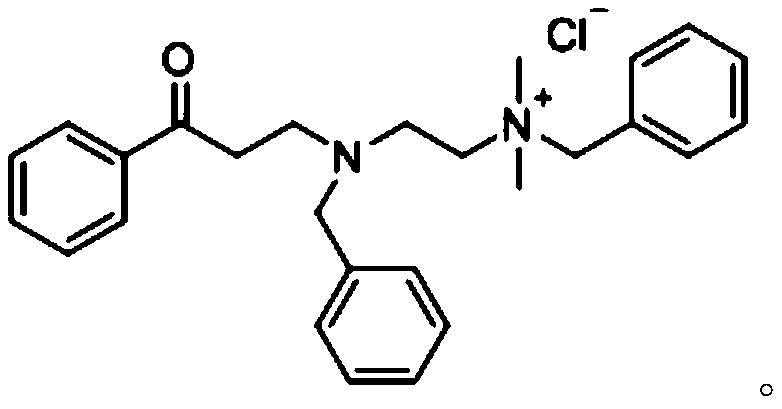

Mannich base acidizing corrosion inhibitor and preparation method thereof

ActiveCN110982508AImprove adsorption capacityReasonable distanceOrganic chemistryOrganic compound preparationBenzyl chlorideAcetophenone

The invention discloses a Mannich base acidizing corrosion inhibitor and a preparation method thereof, and belongs to the technical field of corrosion inhibitor preparation. A two-step synthesis process is adopted. Firstly, paraformaldehyde, N,N-dimethyl ethylenediamine and acetophenone are subjected to a Mannich base reaction, and then benzyl chloride, 2-(chloromethyl)naphthalene or 9-chloromethyl anthracene are added to perform a quaternization reaction. Problems of excessive by-products and incomplete reaction are avoided and the yield of corrosion inhibitor products is improved. The prepared corrosion inhibitor has good solubility in an acid solution system, and can reach the first-class industry standard under the conditions of medium temperature and high temperature. A tested hangingpiece is flat in surface and free of obvious pitting corrosion, and the corrosion inhibitor has a good inhibitory effect on uniform corrosion and local corrosion.

Owner:SOUTHWEST PETROLEUM UNIV

Corrosion-resistant steel for high-Nb crude oil cargo ship cabin base plate

ActiveCN103469101ASimple preparation processImprove corrosion resistanceCargo vesselComponents of crude oil

The invention discloses corrosion-resistant steel for a high-Nb crude oil cargo ship cabin base plate. The corrosion-resistant steel is used in a crude oil cargo ship cabin base corrosion environment and can reduce local corrosion on a base plate. The corrosion-resistant steel comprises one or two of 0.04-0.2% of Nb, 0.01-0.2% of C, 0.05-2% of Mn, 0.05-1% of Si, less than 0.01% of P, less than 0.01% of S, 0.01-0.6% of Ni, 0.05-0.8% of Cu, 0.01-0.5% of W, less than 0.2% of Cr, 0.002-0.4% of Mo and 0.01-0.5% of W, and the balance Fe and unavoidable impurities. The corrosion-resistant steel can be prepared by simple processes, and can form an oxide protection film on the steel surface thereby improving local corrosion resistance and corrosion resistance in a seawater spittle environment and a seawater dipping environment.

Owner:UNIV OF SCI & TECH BEIJING

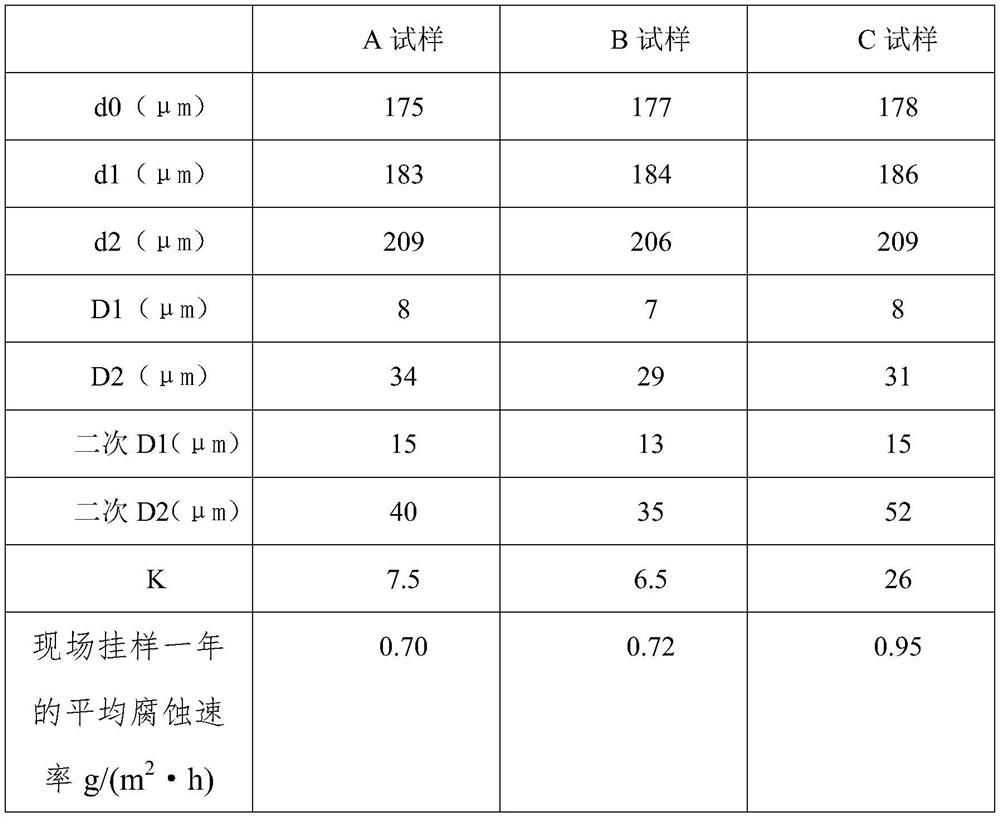

Method for rapidly evaluating performance of weather-resistant steel rust layer for transmission tower in coastal atmospheric environment

ActiveCN112394024AShorten calculation and evaluation timeShorten the evaluation periodWeather/light/corrosion resistancePreparing sample for investigationTransmission towerEnvironmental engineering

The invention discloses a method for quickly evaluating the performance of a weather-resistant steel rust layer for a power transmission tower in a coastal atmospheric environment and belongs to the technical field of performance evaluation of the weather-resistant steel rust layer. According to the method, a corrosion simulation test is performed according to the service characteristics of a simulated coastal atmospheric corrosion environment; with the local corrosion of weather-resistant steel under the coastal atmospheric corrosion environment mainly applied, local corrosion general situation D2 and comprehensive corrosion general situation D1 are compared with each other, so that an evaluation basis index K value can be obtained; the corrosion tendency of a material is judged through local corrosion tendency observation; and therefore the measurement and evaluation time can be greatly shortened. Compared with an original weightlessness method which reflects comprehensive corrosion,the method of the invention enables a user to observe corrosion depth and the reflects the problem of local corrosion; the comprehensive corrosion measurement of the weightlessness method needs at least more than 10 days, while the method of the invention can be used for effectively shortening the evaluation period to be 2 or 4 days, and has the advantages of cheap equipment, simple operation andpopularization significance.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

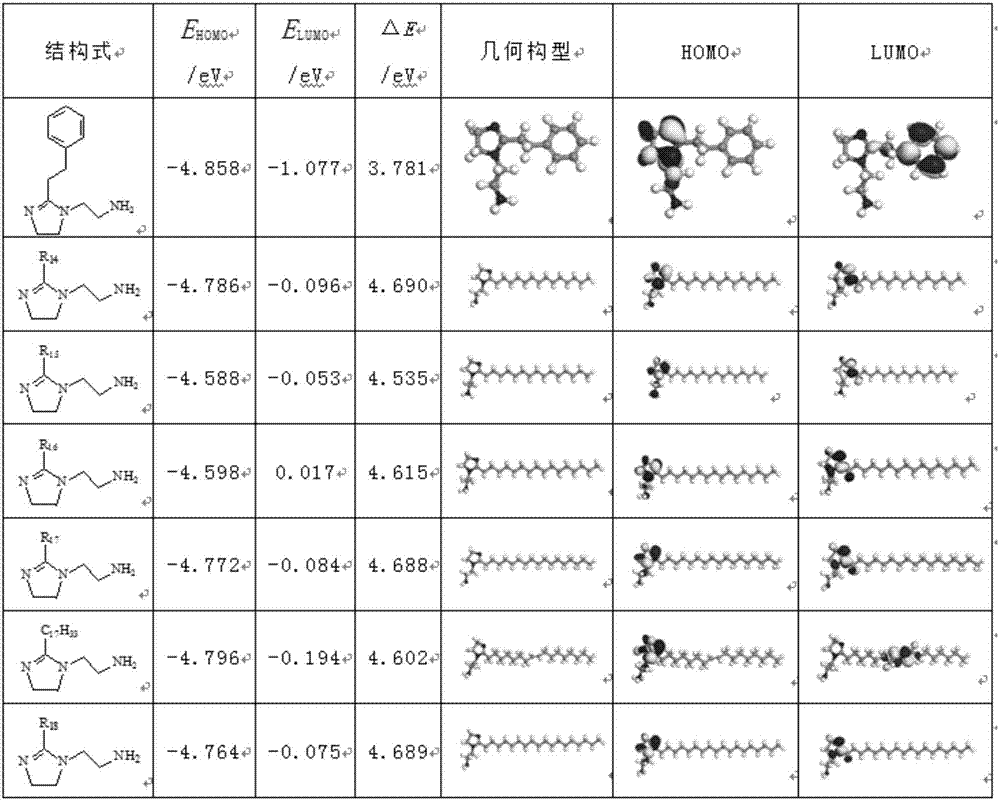

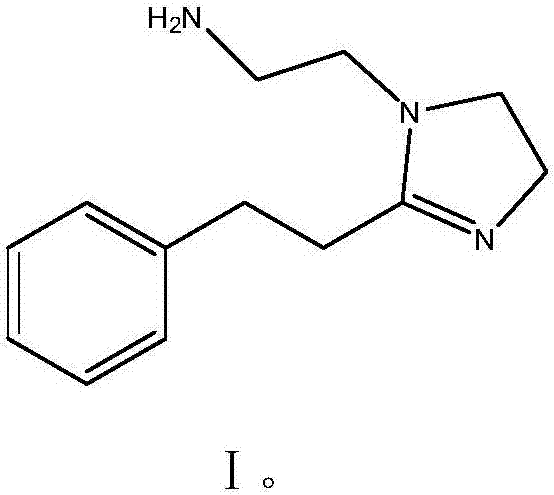

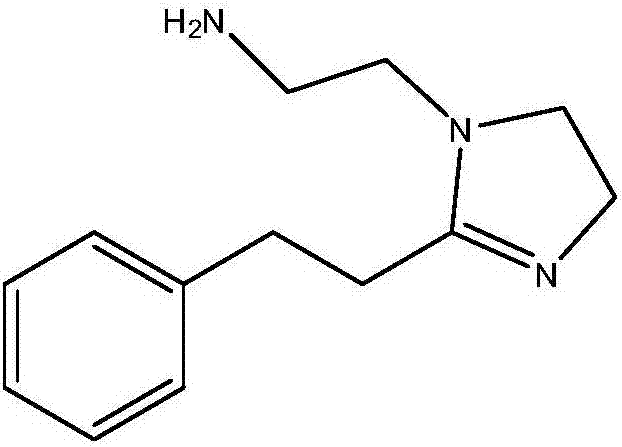

Preparing method and application of corrosion inhibitor restraining carbon steel acid corrosion

InactiveCN107385449AEasy to produceEasy to synthesizeOrganic chemistryDiethylenetriamineAcid corrosion

The invention provides corrosion inhibitor for carbon steel in the oil field acid environment, and particularly relates to preparation and application of low-toxicity and efficient corrosion inhibitor for restraining corrosion of carbon steel and products of the carbon steel in oil field acid pickling liquid or a saturated CO2 medium. According to the preparing method of the corrosion inhibitor, 3-phenylpropionic acid and diethylenetriamine are subjected to the dehydration reaction, and the phenylpropionic acid imidazoline ramification is obtained. According to the product, comprehensive corrosion and local corrosion is prevented from being generated in the process that the carbon steel makes contact with the acid pickling liquid or the CO2 medium. The compound does not serve as metal corrosion inhibitor at current. By adoption of the corrosion inhibitor, production is simple and convenient, toxicity is small, the inhibition rate is high, corrosion damage to the carbon steel from the acid pickling liquid or CO2 can be effectively restrained, and wide application prospects are achieved. The steps are simple, operation is convenient, and practicability is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

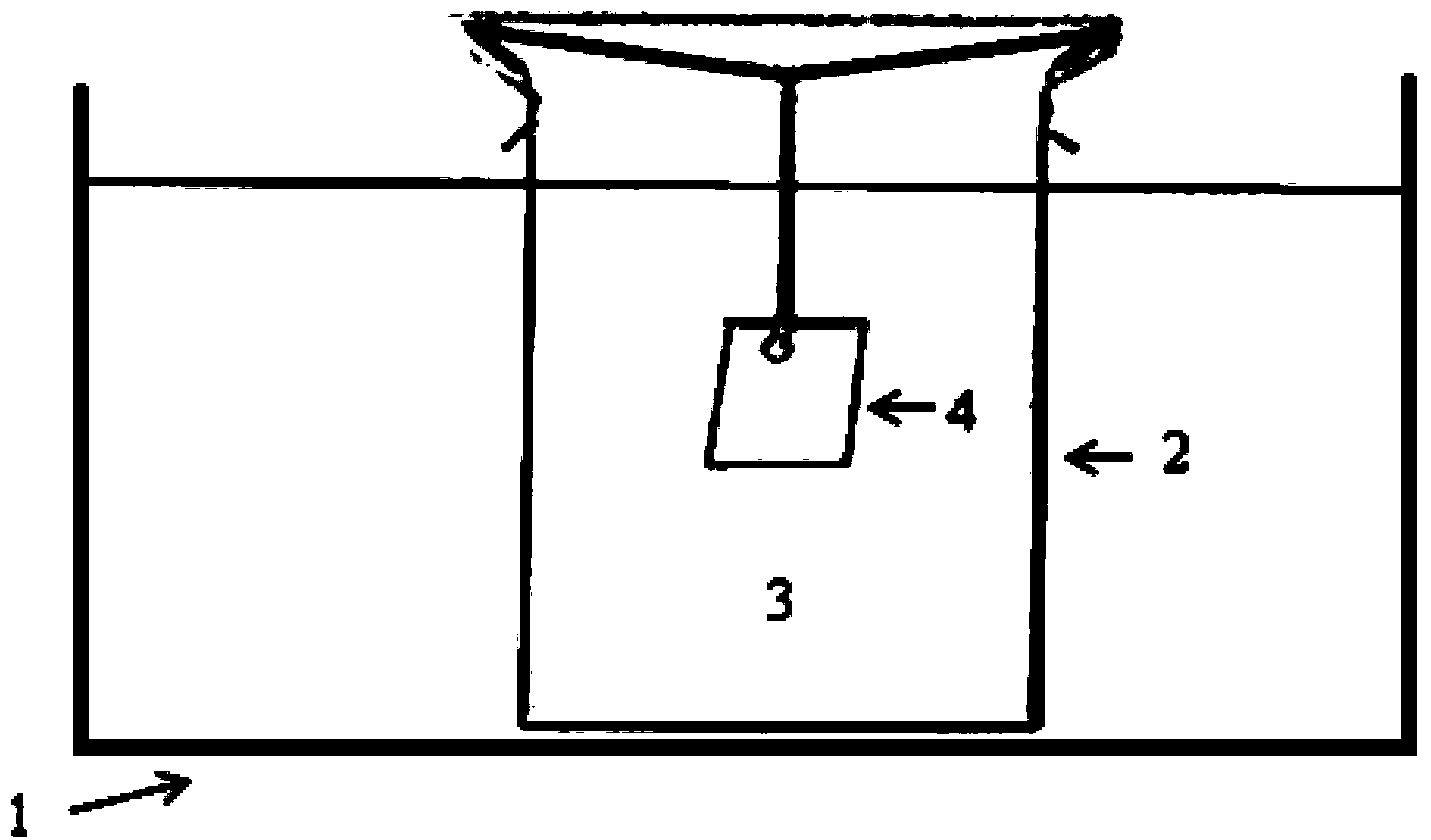

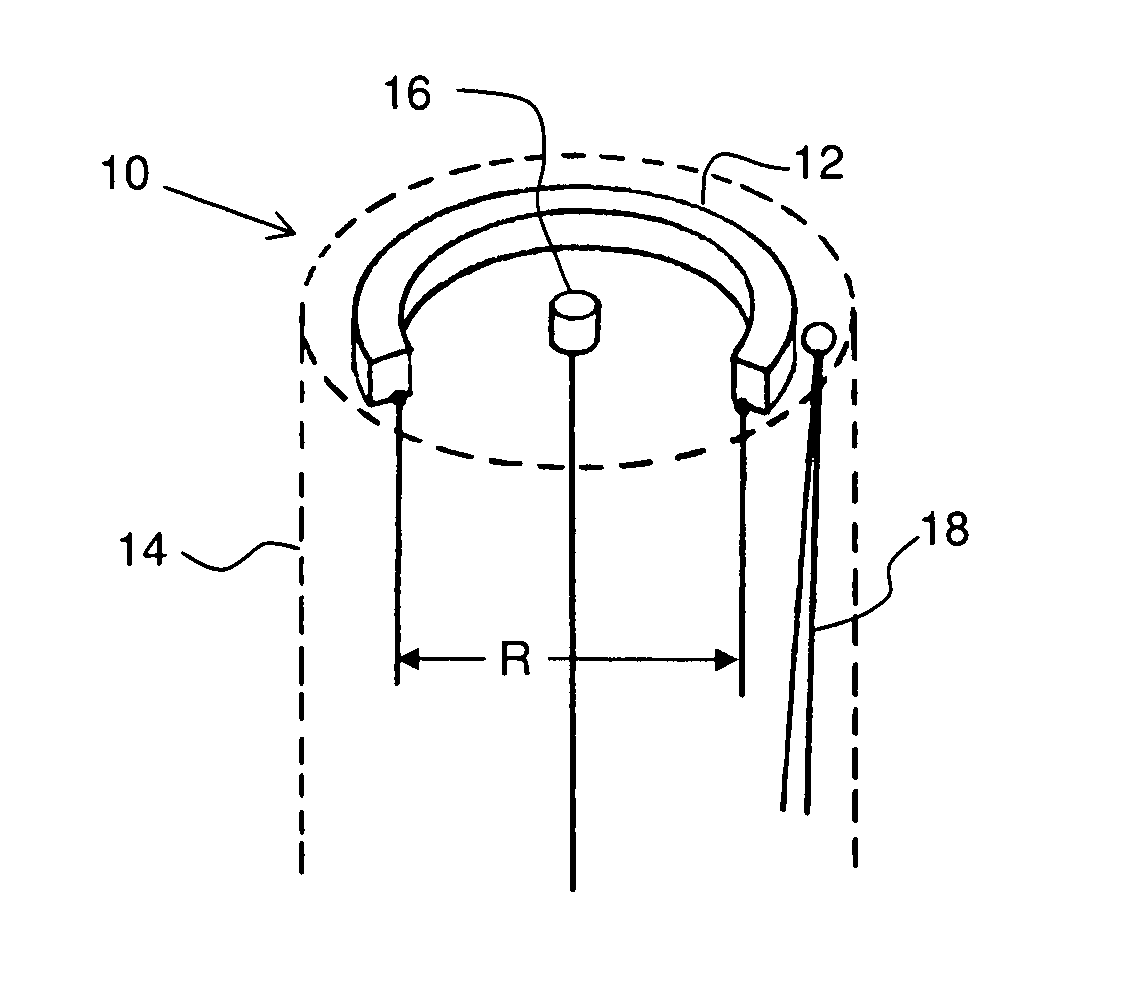

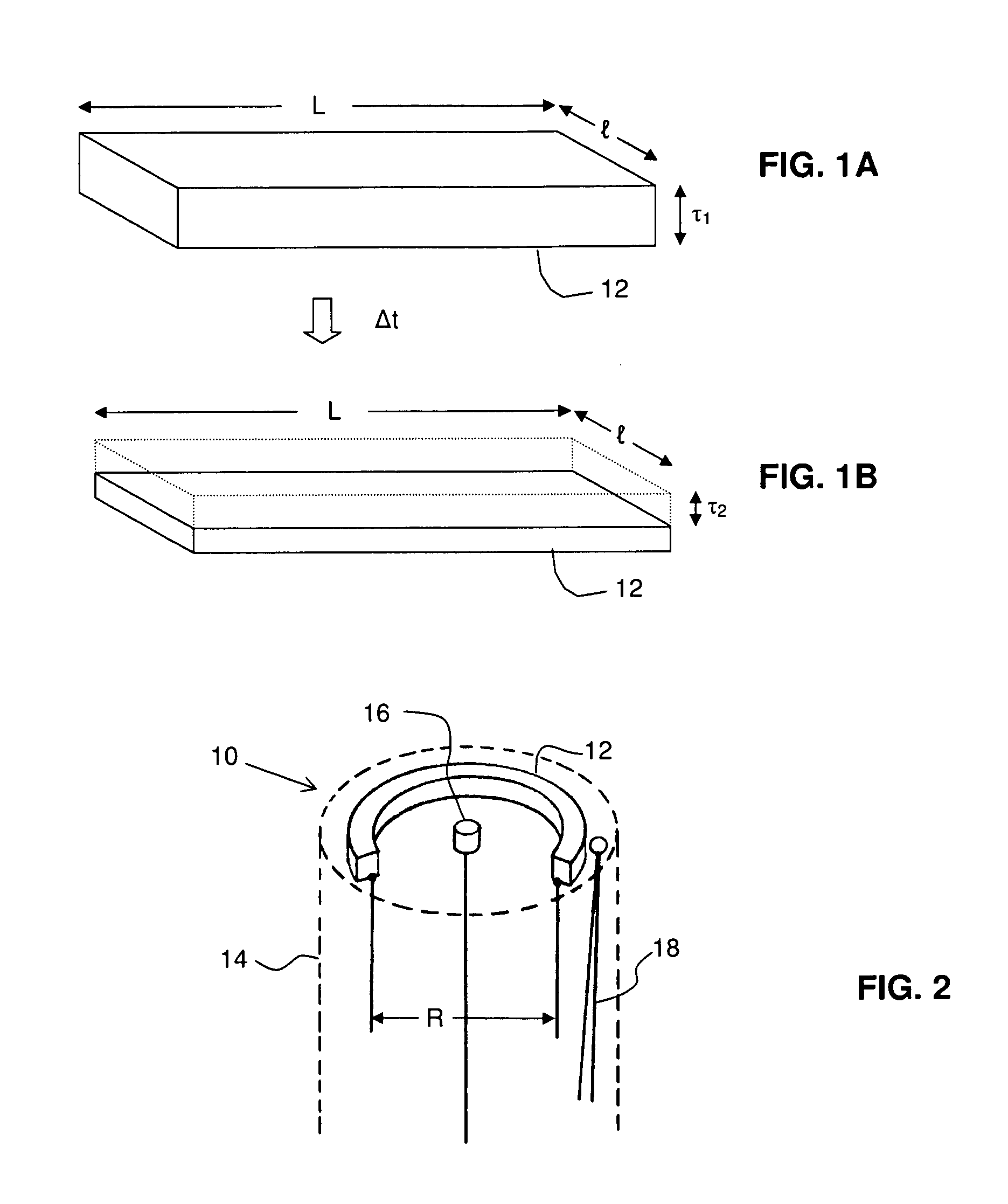

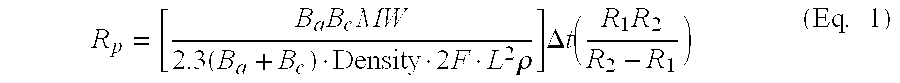

Localized corrosion monitoring device for limited conductivity fluids

ActiveUS8133383B2Weather/light/corrosion resistanceVolume/mass flow measurementEngineeringMaterials science

A localized corrosion monitoring (LCM) device is modified to obtain polarization resistance (Rp) from electrical resistance of a probe having a strip of metal under investigation (test electrode), a reference electrode and a temperature sensor (e.g. thermocouple). This configuration allows the probe to be used in areas where only a thin film of conductive fluid is available or required to provide potential monitoring. Thus, the applicability of the LCM technique is broadened. All the above devices are expected to be configured in one item of equipment, except for the probe which may be remotely located from the rest of the equipment.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com