Thermal treatment method for improving corrosion resistance of steel plate for marine-atmospheric-corrosion-resistant structure

A heat treatment method, marine and atmospheric technology, applied in the field of metal heat treatment, to achieve the effect of excellent plate shape and excellent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

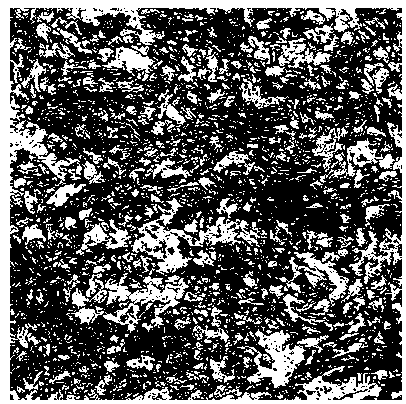

Image

Examples

Embodiment 1

[0016] The production process of the steel plate for marine atmospheric corrosion resistance structure in this embodiment is carried out by using the steel plate production line or the medium and heavy plate production line, including the converter or electric furnace smelting process, the refining process outside the furnace, the vacuum treatment process, the continuous casting process, and the slab Reheating process, controlled rolling process and controlled cooling process, heat treatment process.

[0017] Among them, the heat treatment method for improving the corrosion resistance of steel plates used in structures resistant to marine atmospheric corrosion is as follows: for steel plates with a thickness of 6mm, the cooling rate after rolling is 15°C / s, the sub-temperature normalizing temperature is 760°C, and the heating time is 10min (that is, 1.6 min / mm), the holding time is 12min (ie 2.0min / mm), and then air-cooled to room temperature. The yield strength of the steel p...

Embodiment 2

[0019] The production process of the steel plate for marine atmospheric corrosion resistance structure in this embodiment is carried out by using the steel plate production line or the medium and heavy plate production line, including the converter or electric furnace smelting process, the refining process outside the furnace, the vacuum treatment process, the continuous casting process, and the slab Reheating process, controlled rolling process and controlled cooling process, heat treatment process.

[0020] Among them, the heat treatment method for improving the corrosion resistance of steel plates used in structures resistant to marine atmospheric corrosion is: for steel plates with a thickness of 16mm, the cooling rate after rolling is 40°C / s, the sub-temperature normalizing temperature is 800°C, and the heating time is 34min (that is, 2.1 min / mm), the holding time is 23min (ie 1.4min / mm), and then air-cooled to room temperature. The yield strength of the steel plate is 50...

Embodiment 3

[0022] The production process of the steel plate for marine atmospheric corrosion resistance structure in this embodiment is carried out by using the steel plate production line or the medium and heavy plate production line, including the converter or electric furnace smelting process, the refining process outside the furnace, the vacuum treatment process, the continuous casting process, and the slab Reheating process, controlled rolling process and controlled cooling process, heat treatment process.

[0023] Among them, the heat treatment method for improving the corrosion resistance of steel plates used in structures resistant to marine atmospheric corrosion is: for steel plates with a thickness of 50mm, the cooling rate after rolling is 35°C / s, the sub-temperature normalizing temperature is 820°C, and the heating time is 55min (that is, 1.1 min / mm), the holding time is 35min (ie 0.7min / mm), and then air-cooled to room temperature. The yield strength of the steel plate is 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com