Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Cartilage bone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cartilage forms the major part of bone in the very young; this accounts for the great flexibility and resiliency of the infant skeleton. Gradually, calcium phosphate collects in the cartilage, and it becomes harder and more brittle. Some of the cartilage cells break loose, so that channels develop in the bone shaft.

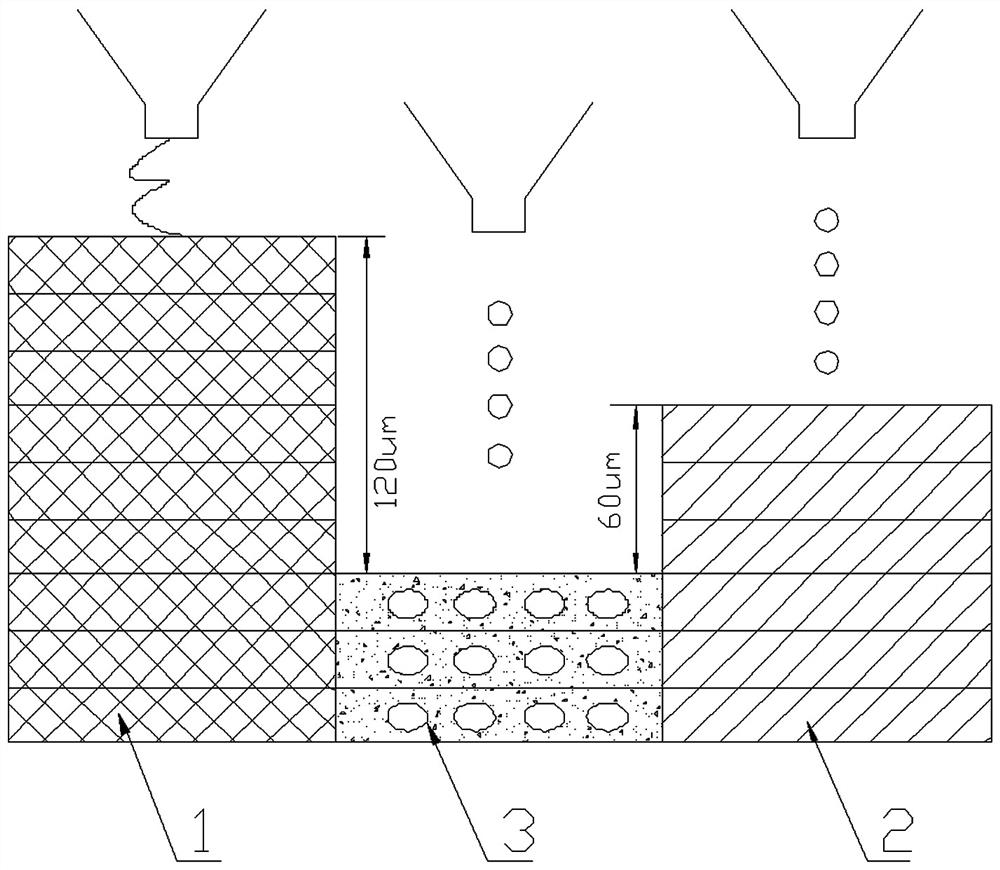

A gradient laminated composite supporting frame material based on bionic structures and its preparation method

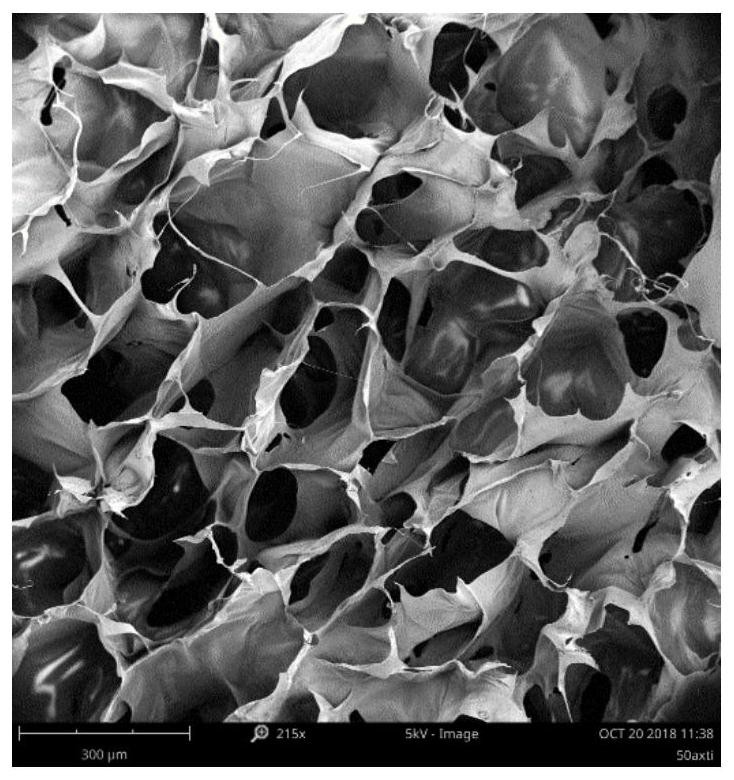

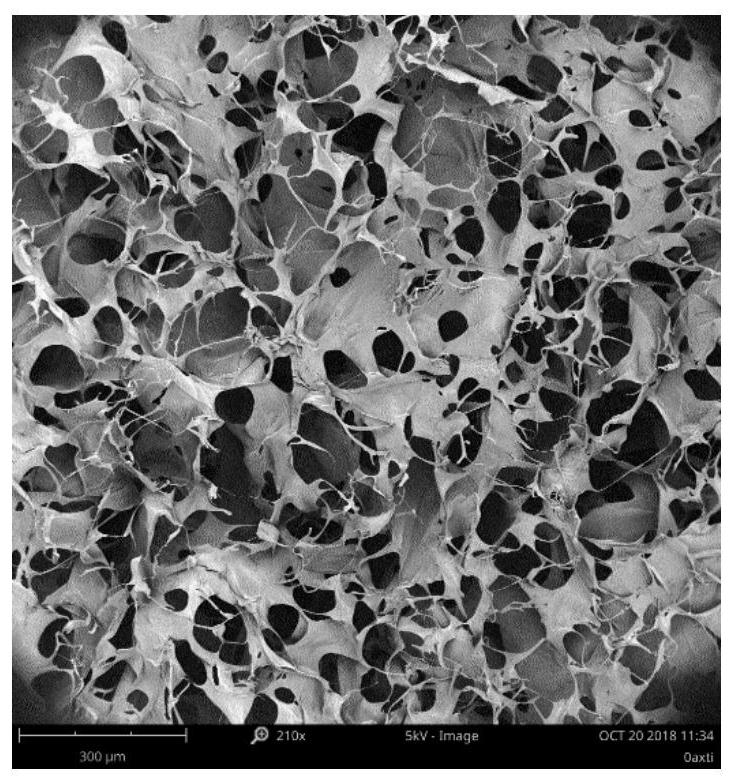

The invention relates to a kind of laminated gradient composite scaffold material based on the bionic structure and its preparation method. The said material has three or more layers of porous structure, comprising of hyaluronic acid, PLGA, PLA, collagen II and nano-hydroxyapatite (nano-HA) , beta- tricalcium phosphate ( beta-TCP). The upper layer is made by collagen II / hyaluronic acid or PLGA and PLA imitating the cartilage layer. With the counterfeit the calcified cartilage layer in the middle, it is one layer or multi- sublayer, made by nano-HA or beta-TCP with collagen II / hyaluronic acid or PLGA and PLA; the bottom is made of nano-HA or beta-TCP with collagen II or PLGA and PLA. From top to bottom, the content of inorganic material increases in its layers, about 0 to 60 mass percent of layers. The aperture of the scaffold material is 50 to 450 micron, with 70 to 93 percent porosity. The scaffold material made by this invention has an adjustable degradation rate, good mechanical and biocompatible properties, can adapt to culture with cartilage bone cells and compound with growth factor and small molecular or peptides, it can be used to repair cartilage simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

Composition for Increasing Body Height

ActiveUS20080312142A1Increased blood levelsExtend height of bodyCompound screeningApoptosis detectionCyclaseCartilage bone

This invention provides a composition for increasing a body height of a patient with short stature or an individual other than patients with short stature. More specifically, the invention provides: a composition for increasing the body height of an individual comprising a guanyl cyclase B (GC-B) activator as an active ingredient, the composition being to be administered to an individual free from FGFR3 abnormality; a method for increasing the body height of an individual free from FGFR3 abnormality which comprises activating GC-B; a method for screening an agent for increasing the body height of an individual which comprises selecting an agent for increasing the body height using GC-B activity as an indication; and a method for extending a cartilage bone free from FGFR3 abnormality which comprises activating GC-B in an individual.

Owner:KAZUWA NAKAO

Improved in vitro method of culturing mammalian cells for autologous cell implantation/transplantation methods

A production method for producing cell colony forming units in vitro from a mammalian tissue explant, the method comprises the steps of a) growing a piece of the mammalian tissue explant in a growth medium to obtain cell colony forming units from immature cells from the piece of explant, and b) harvesting cells from one or more of the cell colony forming units for use in Autologous Cell Implantation / transplantation methods. The mammalian tissue explant is selected from the group consisting of cartilage; bone such as, e.g., bone marrow; connective tissue; muscle tissue such as, e.g., smooth muscle tissue, heart tissue, liver tissue and skeletal muscle tissue; skin tissue such as, e.g., periosteum; mucosal tissue; brain tissue, pancreas tissue and blood vessels. In particularly, the mammalian tissue explant is cartilage, such as elastic, fibro, hyalin or articular hyalin cartilage. The cells obtained are suitable for use in autologous implantation / transplantation methods. In a specific embodiment, the cell obtained are chondroytes, especially for use in autologous chondrocyte implantation (ACI) methods.

Owner:INTERFACE BIOTECH

Cartilage deficiency prosthesis, preparation method thereof and integrated cartilage-bone repair material

InactiveCN101954121AGood biocompatibilityStable mechanical strengthProsthesisMass ratioArticular cartilage injuries

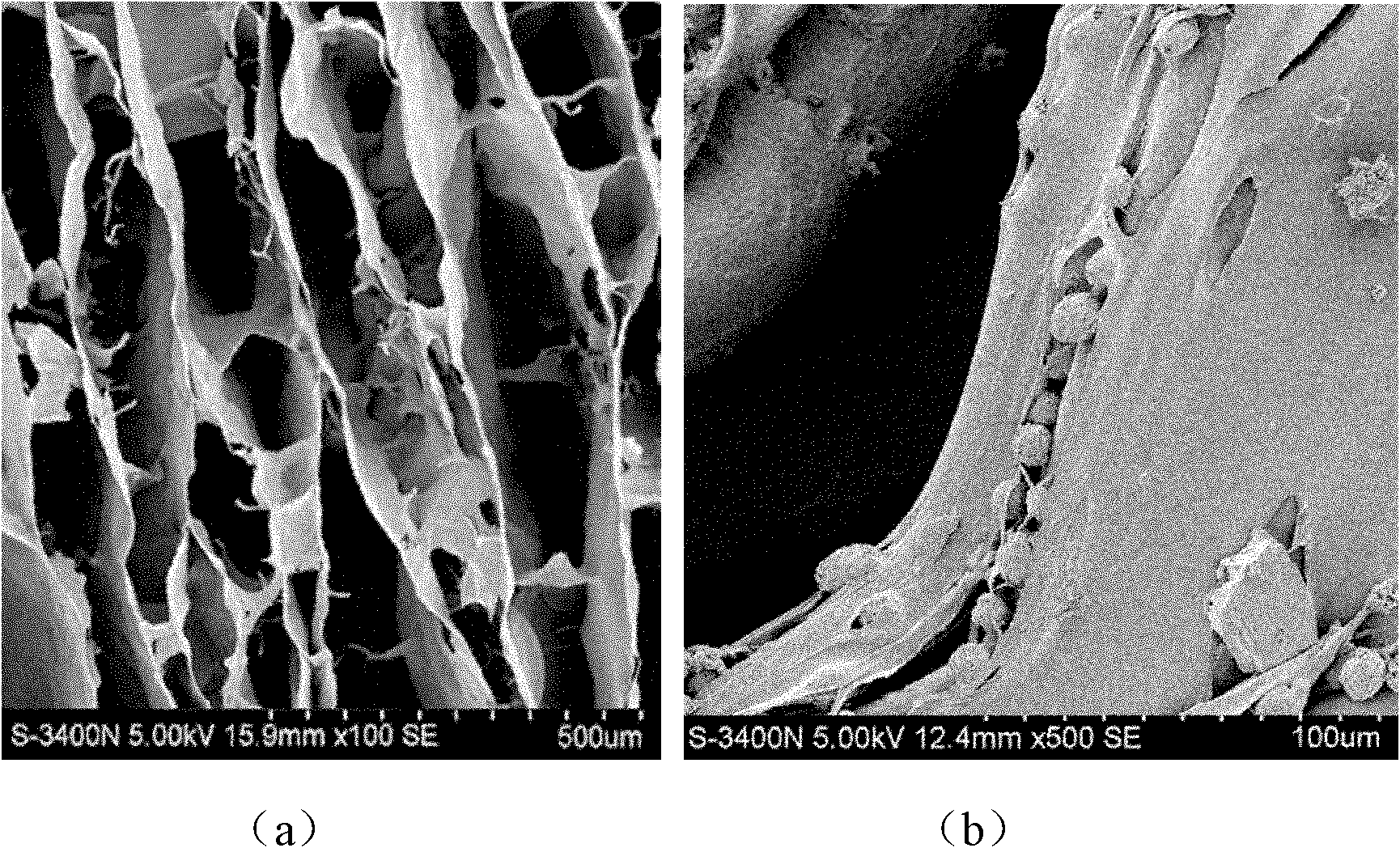

The invention discloses cartilage deficiency prosthesis, a preparation method thereof and an integrated cartilage-bone repair material. The prosthesis is composed of collagen and proteoglycan based on the mass ratio of 1 / 3-3, wherein, the collagen is I-type collagen or II-type collagen, and the proteoglycan comprises glycosaminoglycan, chitosan or chondroitin sulfate; and natural cartilage matrixes are longitudinally arranged in the prosthesis. The integrated cartilage-bone repair material is made by compounding the prosthesis with a bone matrix material together. The cartilage defect prosthesis of an articular cartilage matrix structure of the invention can meet the repair need of articular cartilage deficiency, effectively improve repair rate of articular cartilage injury and lower disability incidence of a patient.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

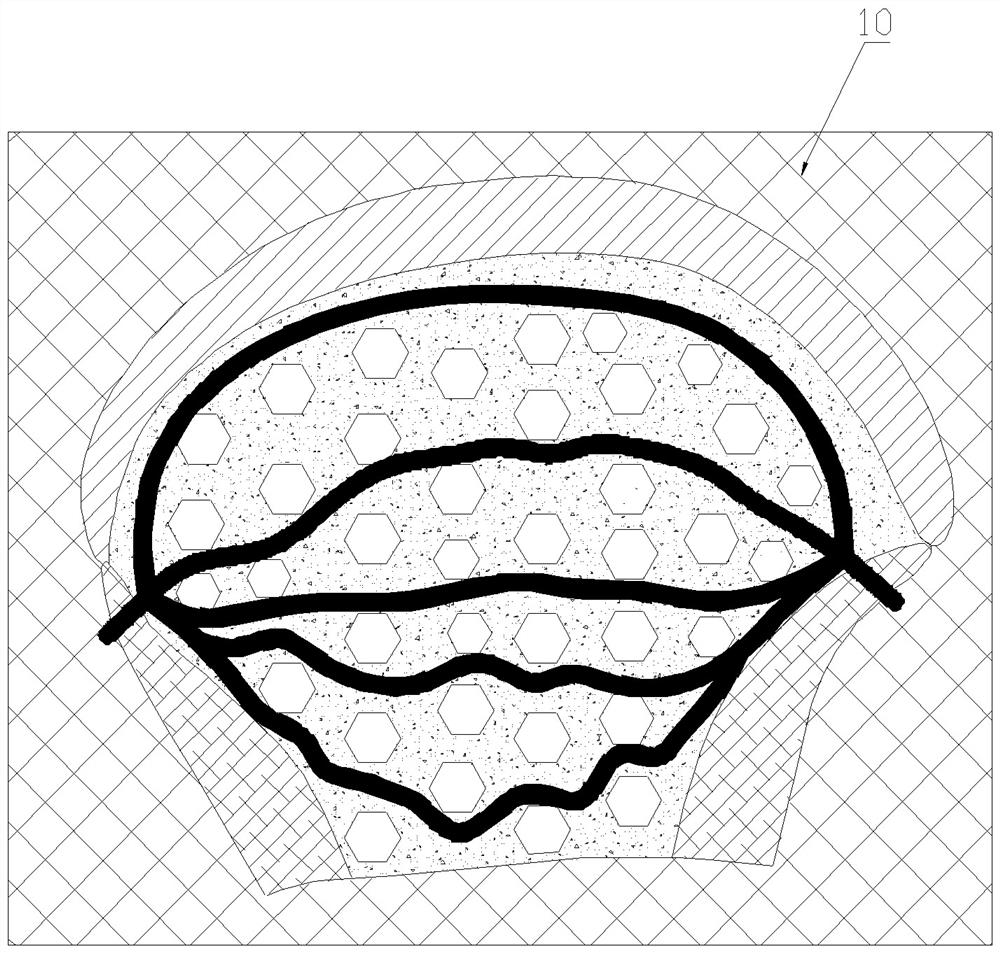

Cartilage-bone integrated porous bionic scaffold and preparation method thereof

ActiveCN110180025ASolve the problem of not being able to accurately control the shape of 3D printingAdd control functionTissue regenerationProsthesisComputer Aided DesignAcellular matrix

The invention relates to a cartilage-bone integrated porous bionic scaffold and a preparation method thereof. The preparation method comprises the following steps: preparing cartilage acellular matrixpowder, and preparing bone tissue demineralized bone matrix powder; preparing gelatin or a collagen solution; preparing gelatin or collagen suspension containing a cartilage acellular matrix, and preparing gelatin or collagen suspension containing a demineralized bone matrix; preparing gelatin or collagen suspension containing the cartilage acellular matrix and the demineralized bone matrix; constructing a cartilage-bone integrated three-dimensional digital model through computer aided design, and forming a cartilage-bone integrated kernel grid framework through three-dimensional printing; fixing the cartilage-bone integrated grid framework in a cylindrical mould, pouring the gelatin or collagen suspension containing the demineralized bone matrix, preparing a bone phase scaffold, pouringthe gelatin or collagen suspension containing the cartilage acellular matrix and the demineralized bone matrix, preparing a junctional phase scaffold, pouring the gelatin or collagen suspension containing the cartilage acellular matrix again, preparing a cartilage phase scaffold, and preparing into the cartilage-bone integrated three-dimensional frozen scaffold.

Owner:SHANGHAI TISSUE ENG LIFE SCI

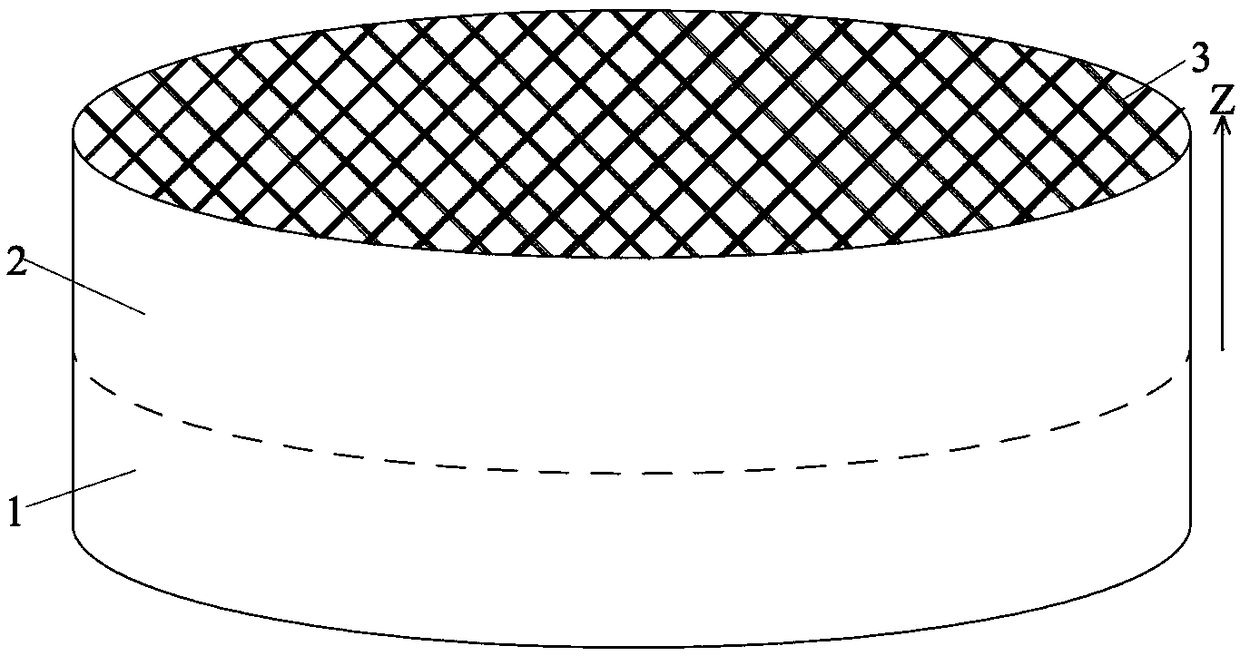

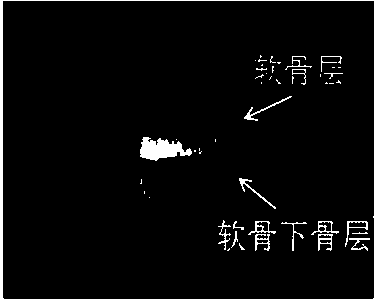

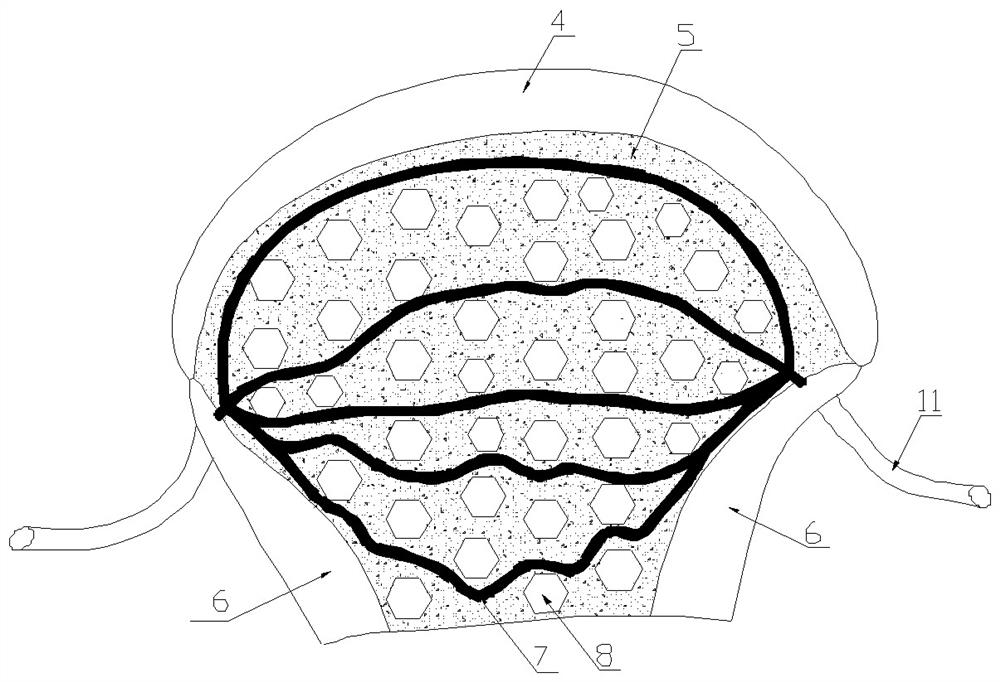

Preparation for repairing cartilage defects or cartilage/bone defects in human or animal joints

InactiveUSRE43714E1Reduce absorptionResistant to resorptionBone implantJoint implantsMetatarsal bone partRepair tissue

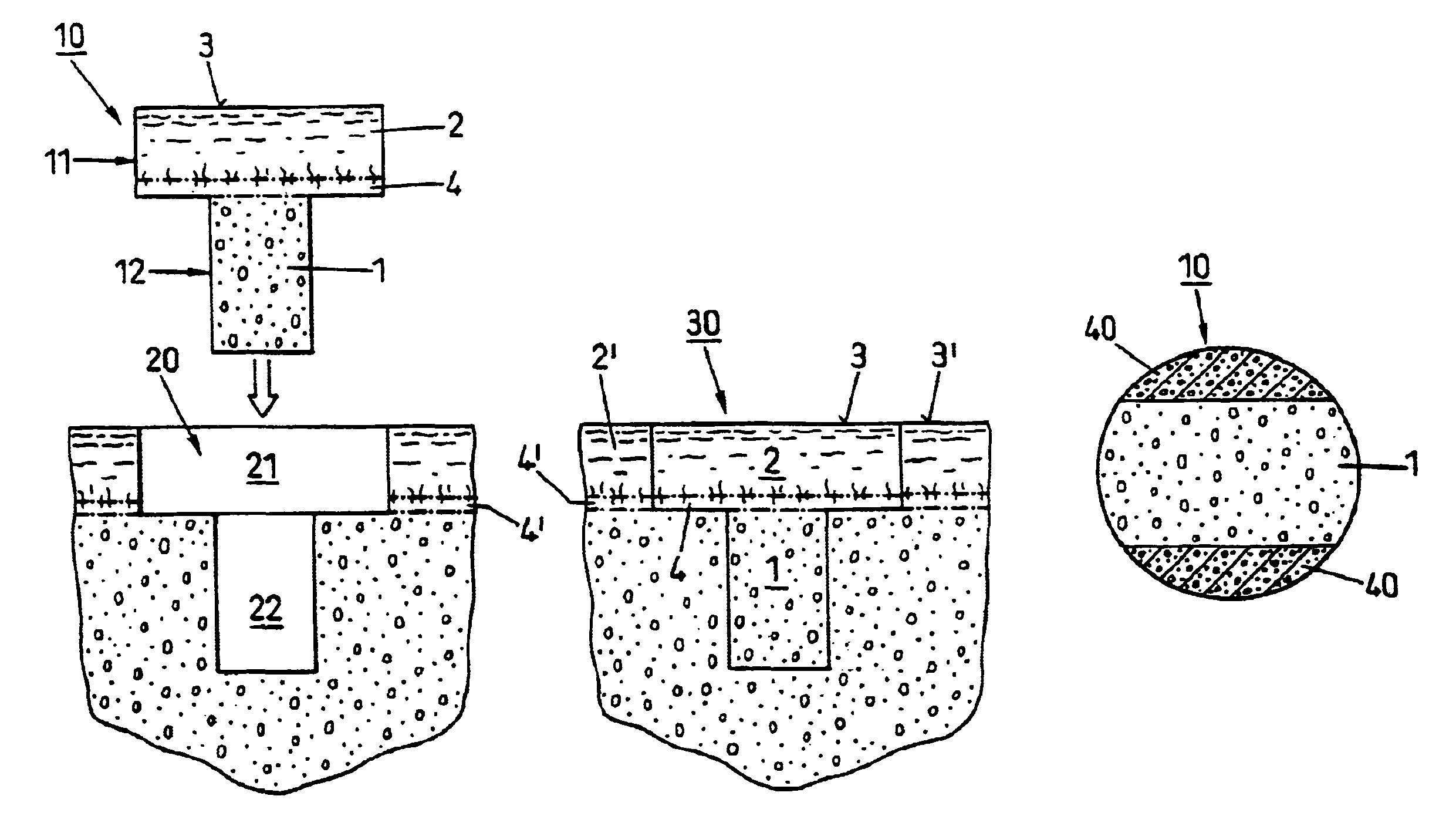

Repairs of cartilage defects or of cartilage / bone defects in human or animal joints with the help of devices including a bone part (1), a cartilage layer (2) and a subchondral bone plate (4) or an imitation of such a plate in the transition region between the cartilage layer (2) and the bone part (1). After implantation, the bone part (4) is resorbed and is replaced by reparative tissue only after being essentially totally resorbed. In a critical phase of the healing process, a mechanically inferior cyst is located in the place of the implanted bone part (1). In order to prevent the cartilage layer (2) from sinking into the cyst space during this critical phase of the healing process the device has a top part (11). and a bottom part (12), wherein the top part (11) consists essentially of the cartilage layer (2) and the subchondral bone plate (4) and the bottom part (12) corresponds essentially to the bone part (1) and wherein the top part (11) parallel to the subchondral bone plate (4) has a larger diameter than the bottom part (12). After implantation in a suitable opening or bore (20), the cartilage layer (2) and the subchondral bone plate (4) are supported not only on the bone part (1) but also on native bone tissue having a loading capacity not changing during the healing process. Therefore, the implanted cartilage layer cannot sink during the healing process.

Owner:ZIMMER ORTHOBIOLOGICS

Method of increasing differentiation of chondrogenic progenitor cells

The present inventors disclose a method of promoting cartilage, bone or ligament repair or inducing cartilage tissue repair or regeneration, said method comprising increasing ZNF145 or a fragment, homologue, variant or derivative thereof in chondrogenic progenitor cells— For example, expression or activity in mesenchymal stem cells. The inventors also provide a chondrogenic progenitor cell, such as a mesenchymal stem cell (MSC), engineered to increase the expression or activity of ZNF145, or a fragment, homologue, variant or derivative thereof.

Owner:AGENCY FOR SCI TECH & RES

Hollow stent for inducing regeneration and moulding of cartilage/bone tissues

The invention relates to a hollow stent for inducing the regeneration and moulding of cartilage / bone tissues. The structure of the stent comprises an overall three dimensional hollow structure; and a plurality of holes in the surface. The hardness should meet the requirements of cartilage / bone tissues in the repaired parts. The stent should have a good biocompatibility and is made of a biologically degradable material. The biologically degradable material can be made into filling and repairing materials such as artificial auricular cartilage stents, artificial nose bridges, and the like, and can also be made into artificial bone stents with various sizes. The prepared stents with special structures can be combined with cultured cartilage / bone cells in vitro and then implanted into human body. Or, small cartilage blocks and cartilage sheets are filled into the hollow stents. The stents can be implanted into human body at first, and then cartilage / bone cells are injected into the stents. The inoculated cartilage / bone cells proliferate and pass down in the hollow three-dimensional stents, bones or cartilage tissues with the shape of the stents gradually form during the period, and tissues with similar functions and shapes can be obtained.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

Non-fibrogenesis collagen material and a manufacturing method thereof

InactiveUS20130337227A1High strengthHigh transparencyConnective tissue peptidesPeptide/protein ingredientsWound dressingCell culture media

The object of the present invention is to provide a non-fibrogenesis collagen material which has a sufficient strength and can be used as a cell culture substrate, a scaffold material for regenerative medicine (for example, material for tissue engineering of cartilage, bone, ligament, corneal stroma, skin, or liver), an implantation material (for example, wound dressing material, bone grafting material, hemostatic material, anti-adhesive material) or a carrier for drug delivery. The object of the present invention can be solved by a non-fibrogenesis collagen material characterized by comprising a fish-derived collagen.

Owner:TOKYO INST OF TECH

Gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof

InactiveCN103656745AGood biocompatibilityPromote degradationBone implantGlycidyl methacrylateLactide

The invention discloses a gel-poly(lactide-co-glycolide) (PLGA) two-phase gradient transition cartilage-bone repair material and preparation thereof. The material is cylindrical and consists of an upper material and a lower material, wherein the upper material is glycidyl methacrylate-modified carboxymethyl chitosan and gelatin; the lower material is porous PLGA. The preparation process comprises the following steps: preparing a gelatin microsphere serving as a pore-forming agent into a PLGA porous scaffold of which one end face is a conical concave surface; preparing a gel solution by using the modified chitosan and modified gelatin; dripping the gel solution on the PLGA porous scaffold of the conical concave surface, inverting, performing ultraviolet light cross-linking to obtain the gel-PLGA two-phase gradient transition cartilage-bone repair material. The material has high biocompatibility and biodegradability, is in a two-phase gradient transition structure, is tightly combined without drop and is simple in preparation process.

Owner:TIANJIN UNIV

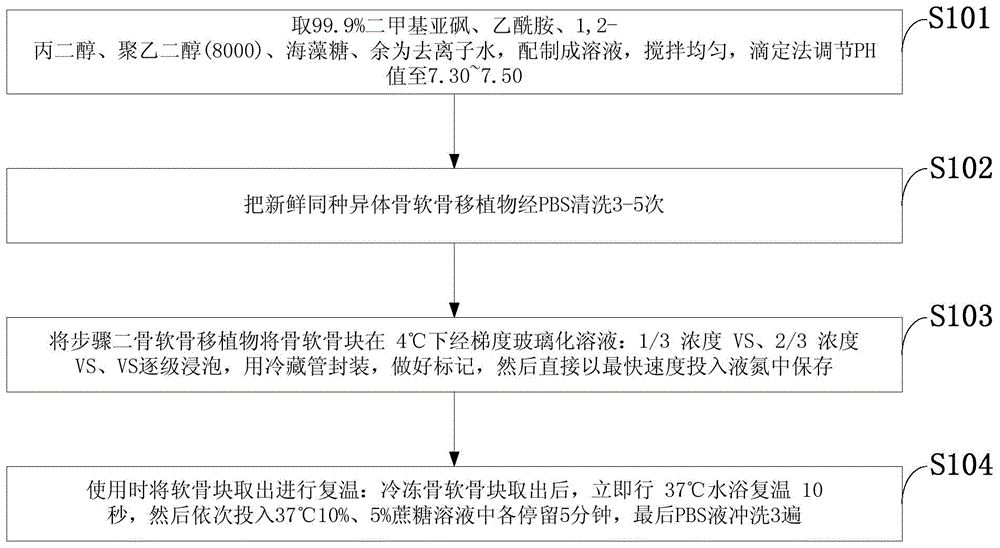

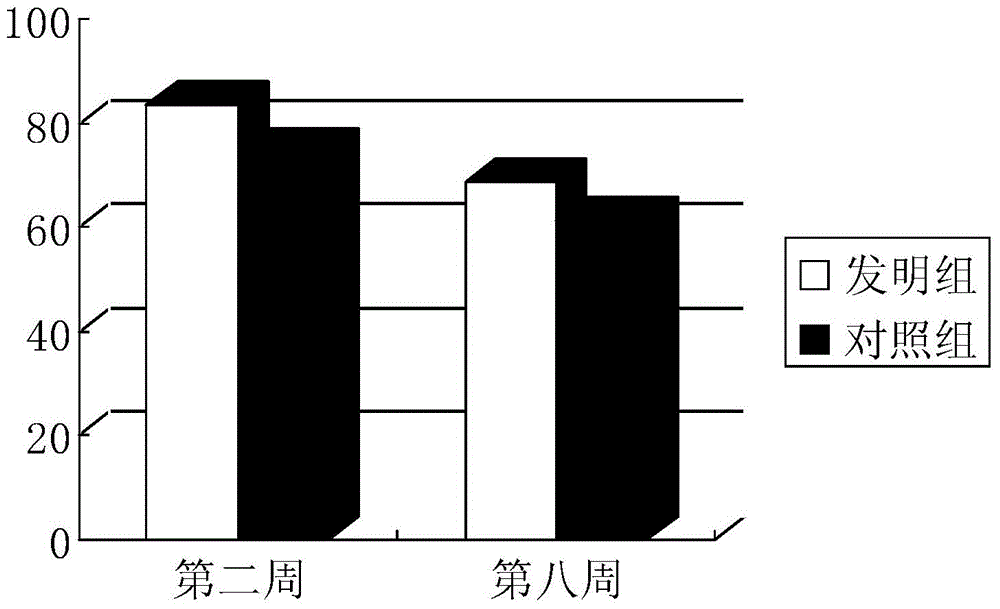

Cartilago articularis vitrification cryoprotectant and cartilage preservation method

ActiveCN104938478AImprove the preservation effectLong storage timeDead animal preservationWater bathsHigh cell

The invention discloses a cartilago articularis vitrification cryoprotectant and a cartilage preservation method. Each 1000ml of a vitrification cryoprotectant comprises 150-250ml of 99.9% dimethyl sulfoxide, 110-200g of acetamide, 70-120ml of 1,2-propylene glycol, 10-80g of polyethylene glycol, 20-100g of trehalose and the balance of deionized water. The cartilage preservation method comprises the following steps: soaking cartilage bone blocks at 4 DEG C by a gradient vitrification cryoprotectant sequentially for 10 minutes, packaging by a refrigerating pipe, putting into liquid nitrogen and storing; taking out before transplanting, rewarming, and carrying out water bath rewarming at 37 DEG C for 10 seconds; then putting cartilage bone blocks in a 10% saccharose solution and a 5% saccharose solution at 37 DEG C respectively, and remaining for 5 minutes; and finally washing by a phosphate buffer for 3 times so as to transplant and apply. According to the invention, the cartilago articularis tissues can be stored for a long time, the relatively high cell survival rate of cartilage is maintained, and the osteochondral graft preservation effect is enhanced; the cartilago articularis vitrification cryoprotectant and the cartilage preservation method are applied to the cartilage tissue library and the clinical cartilage transplantation.

Owner:TAISHAN MEDICAL UNIV

Bone and cartilage integrated repair support and preparation method thereof

ActiveCN108992212AAvoid deformationHigh Compression ModulusBone implantJoint implantsCartilage cellsCartilage bone

The invention provides a bone and cartilage integrated repair support and a preparation method thereof. The bone and cartilage integrated repair support comprises a bone repair layer and a cartilage repair layer connected with the bone repair layer; the bone repair layer comprises a biodegradable synthetic polymeric compound and a powder component with osteogenic activity; and the cartilage repairlayer comprises a biodegradable synthetic polymeric compound and a powder component with a cartilage formation activity. The bone and cartilage integrated repair support can stimulate a defect part of cartilages and sub-cartilage bones in a targeted way and facilitates tissue regeneration. Further, the cartilage recovered layer of the support includes cartilage cells, so that cartilage repair canbe accelerated, and the cartilage repair quality is improved.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

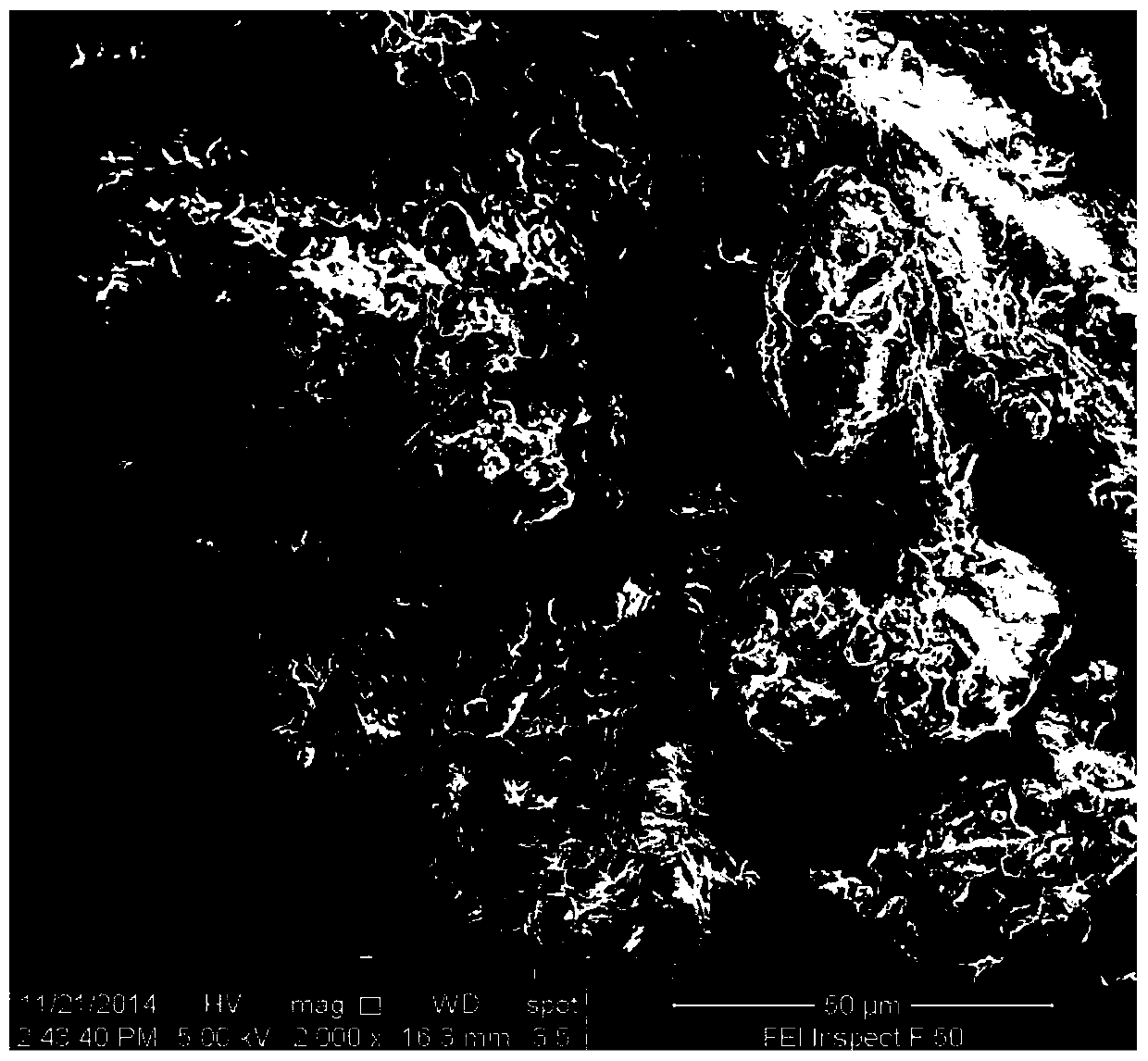

Preparation method of nano-fiber scaffold for promoting cartilage regeneration

InactiveCN107802888AImprove biological activityExtended release timeFilament/thread formingTissue regenerationFiberRelease time

The invention belongs to the field of tissue engineering, and discloses a preparation method of a nano-fiber scaffold for promoting cartilage regeneration to solve the problem that Nell-1 serving as anovel cartilage-derived growth factor can promote cartilage bone cell functions, but is easily inactivated in the process of being integrated into a tissue engineering cartilage scaffold. The preparation method includes the steps: firstly, preparing Nell-1 supported chitosan nano-particle solution and collagen / poly (L-lactic acid)-copolymer (epsilon-caprolactone) mixed solution; secondly, preparing a PLLA-CL / collagen nano-fiber mesh by coaxial electro-spinning and dynamic liquid collection technology; finally, preparing the collagen / HA mixed nano-fiber scaffold by collagen and hyaluronic acid(HA). The operation method is simple, the prepared nano-fiber scaffold is good in biological compatibility, biological activity of the growth factor can be protected, the release time of the growth factor is prolonged, and cartilage repair and regeneration can be promoted.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

High-strength collagen fiber membrane and a manufacturing method thereof

InactiveUS20140044948A1Slow changeHigh tensile strengthPeptide/protein ingredientsSurgeryWound dressingCell culture media

The object of the present invention is to provide a collagen fiber membrane, which has sufficient strength and can be used as a cell culture substrate, a scaffold material for regenerative medicine (for example, material for tissue engineering of cartilage, bone, ligament, corneal stroma, skin, or liver), an implantation material (for example, wound dressing material, bone grafting material, hemostatic material, anti-adhesive material) or a carrier for drug delivery. The object of the present invention can be solved by a fish-derived collagen fiber membrane, characterized in that (1) a tensile strength is 30 MPa or more, (2) a density determined by the gravimetric method, is 0.4 g / cm3 or more, and (3) an average membrane thickness is 1 μm to 2 mm, and a variation in membrane thickness is plus or minus 30%, relative to the average membrane thickness.

Owner:TOKYO INST OF TECH

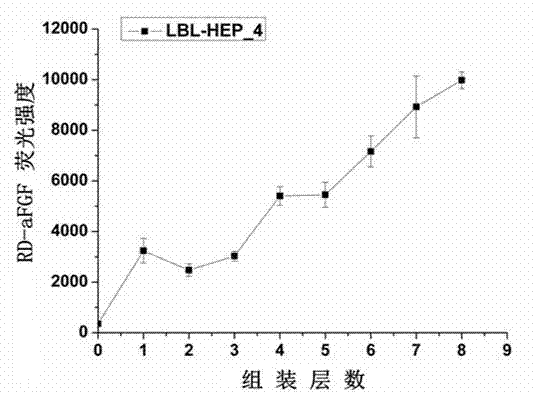

Growth factor controllable slow-releasing system composite multilayer membrane promoting ossification and preparation method thereof

InactiveCN104758981AImprove biological activityRegulatory loadProsthesisMultilayer membraneTissue repair

The invention discloses a surface modification method of a bio-material promoting ossification and a growth factor controllable slow-releasing system composite multilayer membrane promoting the ossification. In particular, the invention relates to a biological multilayer membrane which is constructed on the surface of the bio-material in a layer-by-layer electrostatic self-assembly manner through a layer-by-layer self-assembly technology and a growth factor slow-controllable-releasing technology with casein and heparin as a negative electric macro-molecular layer and collagen and a growth factor as a positive electric macro-molecular layer, wherein the obtain the multilayer membrane is in a structure of a circulation of a casein layer / heparin layer and a collagen / growth factor layer. In the invention, the four biological macro-molecules having excellent physico-chemical properties are deposited onto a same substrate material alternatingly, so that not only is the biological activity of the growth factor protected, but also the load amount and slow releasing of the growth factor can be controlled and adjusted. In addition, the multilayer membrane is excellent in biological mineralization promoting and ossification promoting capabilities and meanwhile can improve adhesion, growth and proliferation of mesenchymal stem cells. The multilayer membrane can be widely used in tissue repair engineering of cartilage, bone, blood vessel, nerve, cardiac valve and the like.

Owner:SUN YAT SEN UNIV

A gradient laminated composite supporting frame material based on bionic structures and its preparation method

The invention relates to a kind of laminated gradient composite scaffold material based on the bionic structure and its preparation method. The said material has three or more layers of porous structure, comprising of hyaluronic acid, PLGA, PLA, collagen II and nano-hydroxyapatite (nano-HA) , beta- tricalcium phosphate ( beta-TCP). The upper layer is made by collagen II / hyaluronic acid or PLGA and PLA imitating the cartilage layer. With the counterfeit the calcified cartilage layer in the middle, it is one layer or multi- sublayer, made by nano-HA or beta-TCP with collagen II / hyaluronic acid or PLGA and PLA; the bottom is made of nano-HA or beta-TCP with collagen II or PLGA and PLA. From top to bottom, the content of inorganic material increases in its layers, about 0 to 60 mass percent of layers. The aperture of the scaffold material is 50 to 450 micron, with 70 to 93 percent porosity. The scaffold material made by this invention has an adjustable degradation rate, good mechanical and biocompatible properties, can adapt to culture with cartilage bone cells and compound with growth factor and small molecular or peptides, it can be used to repair cartilage simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of bionic directional double-layer hydrogel for bone/cartilage repair

InactiveCN112043871ATo achieve the purpose of regenerationImprove mechanical propertiesTissue regenerationProsthesisOsseointegrationCartilage repair

The invention discloses a preparation method of bionic directional double-layer hydrogel for repairing bone / cartilage, and belongs to the field of a biomaterial. The preparation method comprises the following steps of respectively preparing a growth factor modified cellulose nanocrystalline PDA-CNC for inducing cartilage regeneration and a hydroxyapatite in-situ mineralization modified cellulose nanocrystalline CaP-CNC by utilizing an adhesion effect based on mussel-imitating polydopamine; and enabling the PDA-CNC and natural macromolecules having good biocompatibility to be made into an upper-layer hydrogel prepolymer solution. Based on the directional arrangement characteristic of the upper-layer hydrogel prepolymer solution under the action of shearing force, a force field is adjusted by means of injection extrusion and the like, so that cellulose nanocrystals are arrayed in a hydrogel matrix in an oriented manner. The CaP-CNC is added into the lower-layer hydrogel, so that the mechanical strength of the lower-layer hydrogel is improved, and the hydrogel has osseointegration. By adjusting technological parameters, the upper layer and the lower layer of a hydrogel matrix have different active ingredients, structures and mechanical properties, natural cartilage / bone tissue can be simulated, and integrated repair and regeneration of cartilage and bone tissue are facilitated.

Owner:SOUTHWEST JIAOTONG UNIV

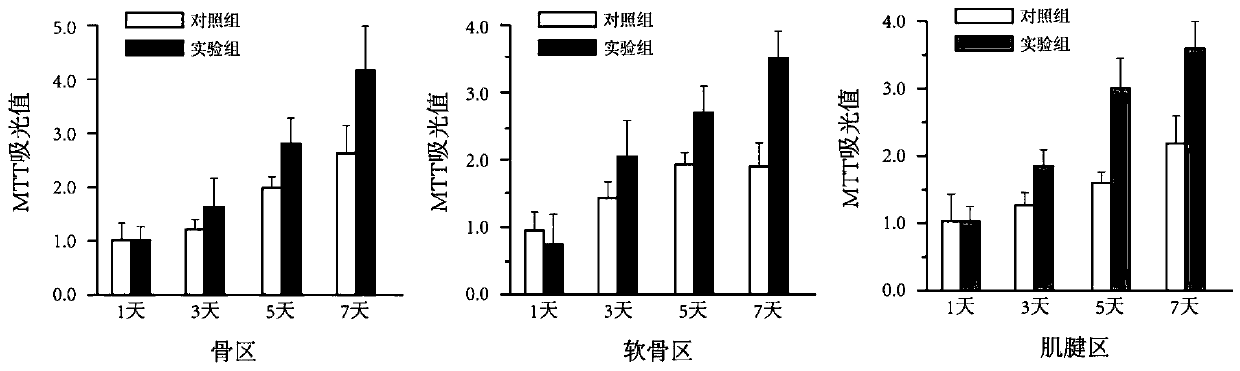

Tendon-bone combined three-phase scaffold prepared by fusion electrospinning three-dimensional printing

InactiveCN109837215APromote proliferation and repairConducive to joint repairAdditive manufacturing apparatusTissue/virus culture apparatusMicrosphereCartilage bone

The invention belongs to the technical field of medical treatment, and particularly relates to a tendon-bone combined three-phase scaffold prepared by fusion electrospinning three-dimensional printing. A method comprises the following steps: S1, cell cultivation; S2, bracket preparation; and S3, cell planting. The method can accurately control the fiber diameter and the printing path by using a fusion electrostatic spinning three-dimensional printing technology, thereby greatly improving the printing precision; by using a spinning solution containing cytokine microspheres for electrospinning printing, the electrospinning fibers containing a large amount of cytokines can be obtained; and through different three-dimensional printing path parameters, the tendon-cartilage-bone three-phase scaffold can be obtained by printing. The scaffold obtained by the method has a bone-cartilage-tendon tissue gradient structure, has high structure precision, carries a large amount of microspheres with cytokines for slow release, promotes cell proliferation repair, and is beneficial to tendon-bone combined and normal function recovery.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

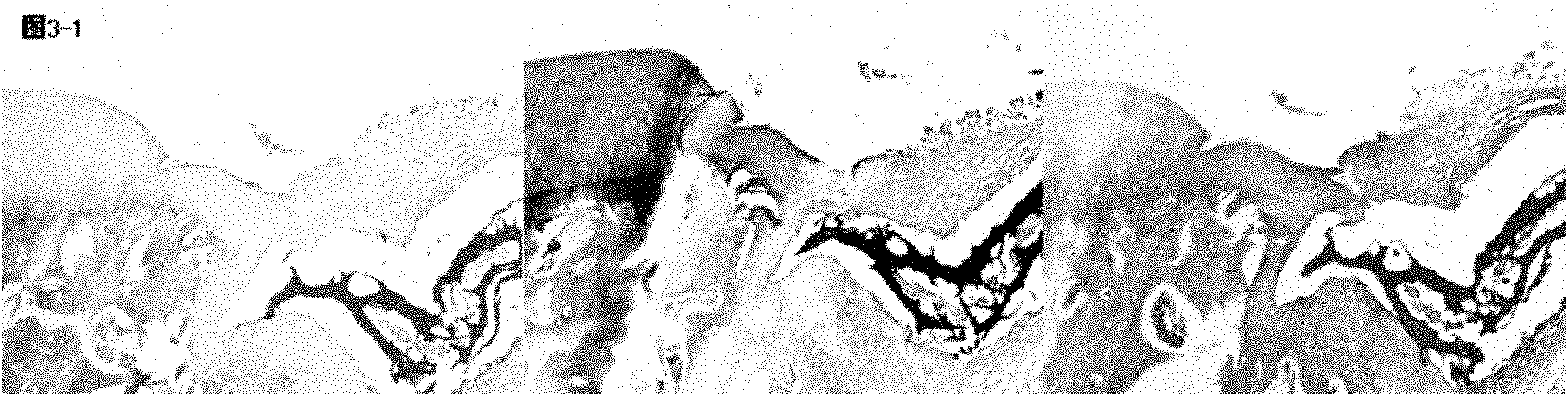

Cartilage-bone repair support with bionic gradient and preparation method thereof

ActiveCN109481736ARealize the structureRealize the biomimetic process of compositionTissue regenerationProsthesisApatiteTarsal Joint

The invention discloses a cartilage-bone repair support with bionic gradient and a preparation method thereof. For the cartilage-bone repair support, a cartilage layer of an interwoven porous structure is prepared from sodium hyaluronate and chitosan, a subchondral bone layer of a porous structure is prepared from graphene oxide, chitosan and nano-hydroxyapatite, and structure, composition and function bionics of natural articular cartilage is realized by combining a coprecipitation method and a gradient refrigeration technology by referring to an in-situ bionic thorough. The obtained supporthas an upper layer of structure and a lower layer of structure, nano-hydroxyapatite presents change of bionic gradient distribution which is gradually increased from the cartilage layer to the subchondral bone layer; meanwhile, the cartilage layer in the upper layer is of a mutually penetrating interwoven hierarchical pore structure, the subchondral bone layer is of an array microtube structure which is axially arranged and is vertically through, the support material is excellent in mechanical performance, strong in interface bonding property and good in biological performance, and is expectedto become a novel composite material for treating cartilage-bone defect.

Owner:FUZHOU UNIV

Self-assembly collagen template tissue engineering material as well as preparation method and application thereof

ActiveCN105802251AImprove mechanical propertiesGel time controllableProsthesisBiocompatibilityDrug biological activity

The invention discloses a self-assembly collagen template tissue engineering material as well as a preparation method and application thereof, and belongs to the field of biomedical materials. The self-assembly collagen template tissue engineering material is prepared from collagen and polyhydroxy alcohol by cross-linking and solidification through glutamine transaminase. The preparation method is simple, and is convenient to operate, controllable in process parameter and low in cost. The cross-linking by adopting a microbial enzyme is superior to that by adopting other cross-linking agents; the toxic and side effects of, for example, methacrylic anhydride (MA), a photoinitiator and the like to a cell are avoided; the obtained material has better biological activity, biocompatibility and mechanical properties, can be used for constructing a better three-dimensional scaffold system for the growth of the cell, and can be also used for loading a medicine. The material can be used for the generation of new tissue and the repair of injured tissue, and is clinically used for the fields of tissue engineering of cartilage, bones, skin, blood vessels and the like.

Owner:CHENGDU UNIV

Artificial rotator cuff patch capable of inducing tendon-bone gradient structure formation and preparation method thereof

InactiveCN111359012ALong-term regenerationPromote formationElectro-spinningTissue regenerationYarnCTGF

The invention belongs to the technical field of surgical patches, and provides an artificial rotator cuff patch capable of inducing tendon-bone gradient structure formation and a preparation method thereof. The method comprises the following steps: selecting PET yarns as an inner layer and a gelatin solution in which CTGF, KGN and induction factors of nano-hydroxyapatite are respectively dispersedas an outer layer; spraying the gelatin solution onto the PET yarns by using an electrostatic spinning technology so as to obtian CTGF yarns, KGN yarns and nano hydroxyapatite yarns, wherein the three kinds of yarns are all nanofiber yarns with a double-layer structure; and then performing weaving according to the direction of CTGF-KGN-nano hydroxyapatite to obtain a nanofiber yarn stent with a knitted double-layer structure, namely the artificial rotator cuff patch capable of inducing the formation of a tendon-bone gradient structure. The preparation method of the artificial rotator cuff patch capable of inducing formation of the tendon-bone gradient structure is simple, and the obtained three-section artificial rotator cuff patch can promote formation of the tendon-fibrous cartilage-bone gradient structure, and has good mechanical properties, biocompatibility and clinical application prospects.

Owner:李军

3D printed porous polyether-ether-ketone stent and preparation method and application of stent

InactiveCN112316215ASolve the problem of elastic modulus mismatchAdditive manufacturing apparatusTissue regeneration3d printBiomechanics

The invention relates to a 3D printed porous polyether-ether-ketone stent and a preparation method and application of the stent. The method comprises the following steps: scanning a damaged area at abone joint to obtain corresponding three-dimensional data; conducting modeling according to the obtained three-dimensional data to obtain a filler model capable of filling the damaged area; and performing 3D printing according to the filler model to prepare and obtain the stent. The stent with a porous structure is manufactured by a 3D printing technology, so that the elasticity modulus and hardness of the stent can be reduced, the stent can be matched with biomechanical properties of soft tissues such as cartilage, bone-cartilage, meniscus and tendon bone at bone joints, and the difficulty ofapplying a polyether-ether-ketone material to soft tissue injury repair is solved.

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Material combining porous ultrahigh molecular weight polyethylene and bionic cartilage and manufacturing technology

InactiveCN103418032BImprove bindingNo deformation and shrinkageProsthesisManufacturing technologyPolyvinyl alcohol

Owner:CHINA UNIV OF MINING & TECH

Injectable poly(4-hydroxybutyrate) (P4HB) porous microsphere preparation without stem cell or growth factor loading

InactiveCN112807485AImprove adhesionPromote value-addedPharmaceutical delivery mechanismTissue regenerationCell-Extracellular MatrixCartilage bone

The invention discloses an injectable poly(4-hydroxybutyrate) (P4HB) porous microsphere preparation without stem cell or growth factor loading. The injectable poly(4-hydroxybutyrate) (P4HB) porous microsphere preparation is a porous microsphere constructed by poly(4-hydroxybutyrate) and a copolymer thereof through a pore-foaming agent. The invention further provides a preparation method of the microsphere and application of the microsphere in bone defect repairing. The prepared porous microsphere has the mechanical property similar to that of an extracellular matrix, can be used for enhancing progenitor cell aggregation through the porous structure of the microsphere on the premise of without stem cell or growth factor loading, so that the internal repairing capacity of bones can be supported, and intracartilage ossification bone repairing can be completed through a single material.

Owner:QINGDAO UNIV OF SCI & TECH

Bracket for joint repair

ActiveCN108201633BImprove mechanical propertiesImprove seepage characteristicsTissue regenerationProsthesisSubchondral boneCartilage bone

The invention discloses a scaffold for repairing joints. The scaffold is composed of a porous polymer material layer and a porous metal material layer from top to bottom. The porous metal material layer is a gradient porous metal material layer. The scaffold effectively realizes artificial joint simulation and good force transmission, has excellent mechanical properties and good percolation characteristics, is conducive to colonization, differentiation and proliferation of cartilage and bone cells and is an integrated articular cartilage and subchondral bone repair scaffold.

Owner:CHONGQING RUNZE PHARM CO LTD

Cartilage-bone integrated porous bionic scaffold and preparation method thereof

ActiveCN110180025BLow immunogenicityPromote formationTissue regenerationProsthesis3d printComputer Aided Design

The invention relates to a cartilage-bone integrated porous bionic scaffold and a preparation method thereof. The preparation method comprises: preparing cartilage decellularized matrix powder, preparing bone tissue decalcified bone matrix powder; preparing gelatin or collagen solution; preparing cartilage-containing decellularized matrix Prepare gelatin or collagen suspension containing decalcified bone matrix; prepare gelatin or collagen suspension containing cartilage decellularized matrix and decalcified bone matrix; construct cartilage-bone by computer-aided design An integrated three-dimensional digital model, which is 3D printed into a cartilage-bone integrated core grid frame; the cartilage-bone integrated grid frame is fixed in a cylindrical mold and perfused with gelatin or collagen suspension containing decalcified bone matrix , prepare the bone phase scaffold, perfuse the gelatin or collagen suspension containing cartilage decellularized matrix and decalcified bone matrix, prepare the junctional phase scaffold, and then perfuse the gelatin or collagen suspension containing cartilage decellularized matrix, prepare the cartilage phase scaffold, make Chondrogenic-osseointegrated three-dimensional cryo-stent.

Owner:SHANGHAI TISSUE ENG LIFE SCI

A kind of allogeneic bone powder and its preparation method and application

Disclosed are an allogeneic bone and / or cartilage bone meal and a preparation method and use thereof, comprising the following steps: (1) pulverizing an allogeneic bone and / or cartilage; (2) blending the pulverized allogeneic bone and / or cartilage and a nuclease to conduct an enzymatic reaction; (3) incubating and washing the pulverized allogeneic bone and / or cartilage with a detergent and an optional first chelating agent; (4) optionally conducting a decalcification treatment with a second chelating agent on the pulverized allogeneic bone and / or cartilage; and (5) grinding the allogeneic bone and / or cartilage after same is treated in step (2), step (3) and optional step (4). Also disclosed are a gel composition, biological scaffolds and a biological gel material containing the bone meal prepared from the above-mentioned method, and a preparation method and use thereof.

Owner:蒋青 +2

Cartilage-bone-bone marrow composite tissue structure and method based on living cell 3D printing

ActiveCN110302428BAchieve internal nutrient supplyPrevent collapseAdditive manufacturing apparatusTissue regeneration3d printPerfusion Culture

The invention discloses a cartilage-bone-bone marrow composite tissue structure and method based on 3D printing of living cells. The biological information of bone tissue is collected, input into a computer for bionic modeling, and the preparation is suitable for cartilage, osteogenesis, mesenchymal stem, and blood vessels. Bio-ink for cells such as endothelium; prepare hard materials for printing dense bone areas; prepare various casting agents; inoculate living cells in corresponding bio-inks at a certain density; load various types of printing inks separately 3D printing is carried out after setting the printing parameters in the printer silo, and the printed bone tissue is cultured in a tissue engineering bionic incubator. After a certain period of time, the cast is removed at different times by temperature control, enzyme control or light control. The artificial blood vessels are grafted outside the cartilage-bone-bone marrow composite tissue, and cultured in a tissue engineering bionic incubator with continuous cycle perfusion to realize the pre-maturation of the printed tissue. It realizes the long-term survival and biological function of 3D printed bone tissue.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

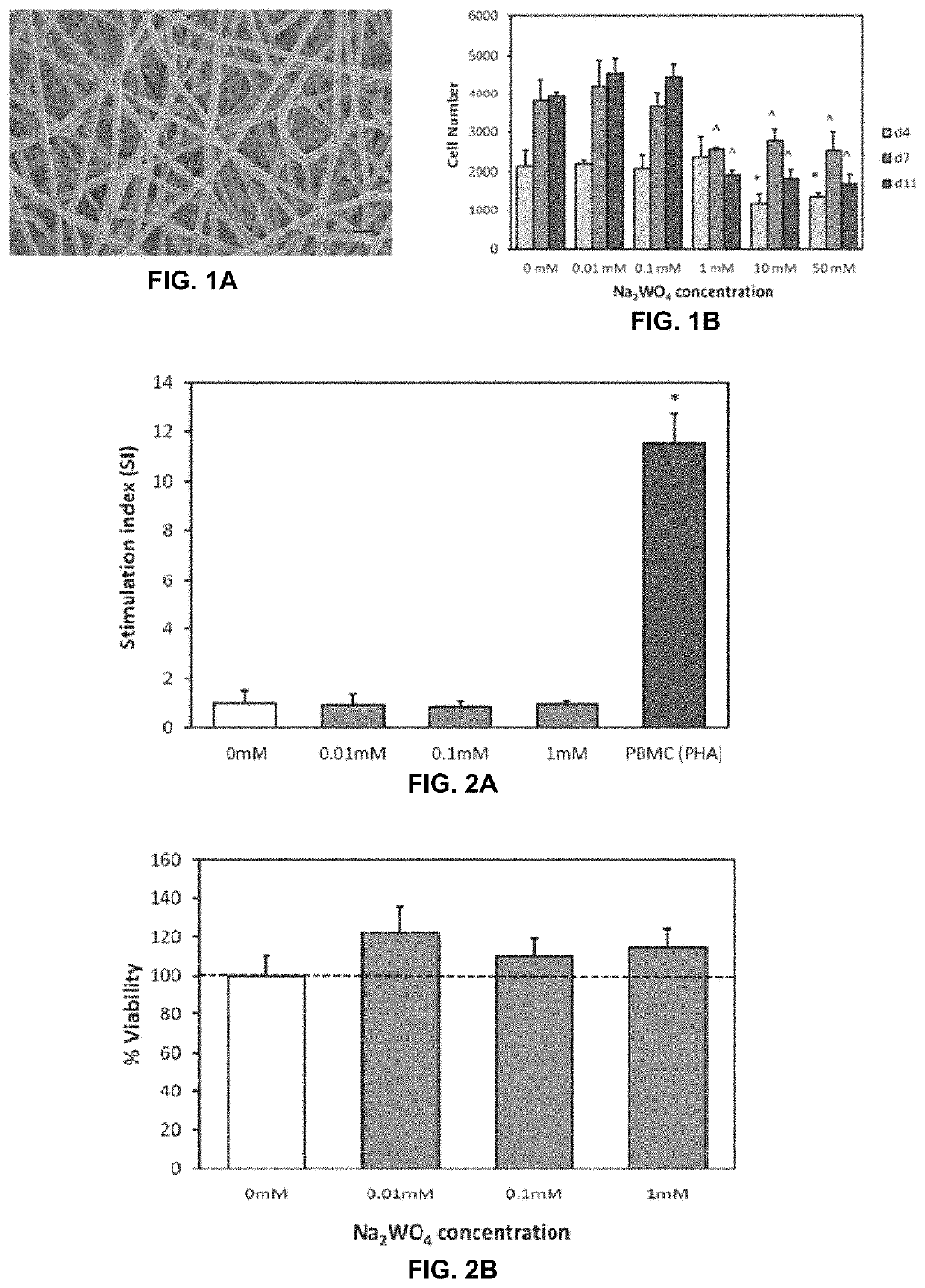

System and method for insulin-mimetic of cartilage, bone, or osteochondral repair and piezoelectric composite scaffold

ActiveUS10772909B2Promote growthPromoting differentiationHeavy metal active ingredientsInorganic non-active ingredientsCartilage bonePancreatic hormone

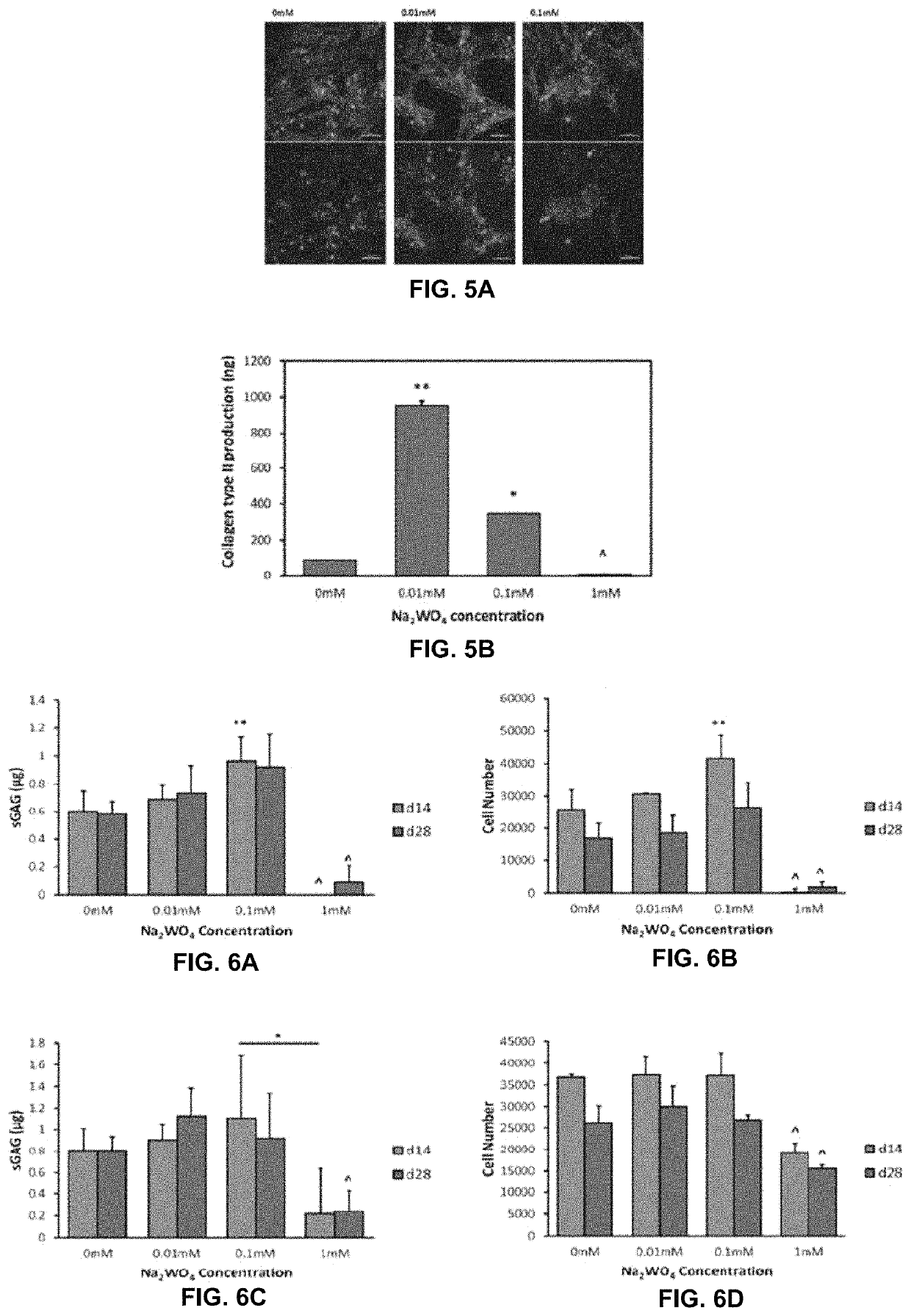

Shown and described is an insulin-mimetic as an inductive agent for cartilage and / or bone repair is disclosed. Sodium tungstate (Na2WO4) was utilized as an inductive factor to enhance human mesenchymal stem cell (MSC) chondrogenesis. The chondrogenic differentiation of MSCs was enhanced in the presence of low concentrations of Na2WO4 as compared to control, without Na2WO4. Also disclosed is a composite scaffold capable of supporting cell and tissue growth. The composite scaffold could include zinc oxide and polycaprolactone.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Osteochondral microfluidic chip culture equipment, osteochondral microfluidic chip analysis equipment including the same

ActiveCN109082378BReduce volumeRealize real-time observation and analysisBioreactor/fermenter combinationsBiological substance pretreatmentsCartilage boneMicrochip Analysis

The present invention provides an osteochondral microfluidic chip culture device and an osteochondral microfluidic chip analysis device containing the same; the osteochondral microfluidic chip culture device includes an osteochondral culture layer and communicates with the osteochondral culture layer The nutrient solution channel and the cell metabolic fluid channel connected with the osteochondral culture layer. The osteochondral microfluidic chip culture equipment provided by the present invention realizes the construction of the three-layer structure of cartilage, bone and calcified layer and the subsequent culture process, fully embodies the characteristics of bionics, can simulate the real osteochondral growth environment, and can simultaneously realize bone and cartilage regeneration and subsequent analysis.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com