Injectable poly(4-hydroxybutyrate) (P4HB) porous microsphere preparation without stem cell or growth factor loading

A technology of hydroxybutyrate and porous microspheres, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

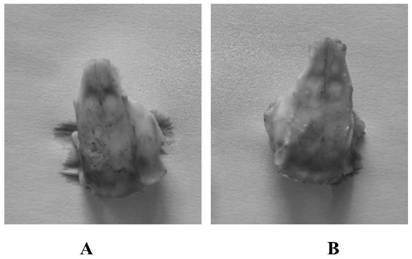

Image

Examples

Embodiment 1

[0030] Embodiment 1 prepares small-aperture poly(4-hydroxybutyrate) microspheres

[0031] Weigh 100 mg of poly(4-hydroxybutyrate), with a weight average molecular weight of 80,000 g / mol, and add 2 mL of chloroform to dissolve it to obtain solution A.

[0032] Weigh 10 mg of polyethylene glycol with a molecular weight of 1000 g / mol, add 1 mL of ultrapure water to dissolve it to obtain solution B.

[0033] The solutions A and B were mixed and homogenized for 5 min to obtain the primary emulsion.

[0034] Pour the primary emulsion into an aqueous solution of polyvinyl alcohol (1%) and stir to evaporate the solvent, freeze-dry after centrifugation, and sterilize and encapsulate to finally obtain a small-pore poly(4-hydroxybutyrate) microsphere preparation with a particle size of 100- 200μm, the average pore size is 2-10μm.

Embodiment 2

[0035] Embodiment 2 prepares macroporous poly(4-hydroxybutyrate) microspheres

[0036] Weigh 200 mg of poly(4-hydroxybutyrate), with a weight average molecular weight of 100,000 g / mol, add 4 mL of chloroform to dissolve it to obtain solution A.

[0037] Weigh 20 mg of ammonium bicarbonate and add 2 mL of ultrapure water to dissolve it to obtain solution B.

[0038] The solutions A and B were mixed and homogenized for 5 min to obtain the primary emulsion.

[0039] Pour the primary emulsion into polyvinyl alcohol (1%) aqueous solution, stir to evaporate the solvent, freeze-dry after centrifugation.

[0040] The porous poly(4-hydroxybutyrate) microspheres were hydrolyzed with sodium hydroxide (0.1M) solution, washed with ultrapure water, centrifuged, freeze-dried, sterilized and encapsulated to obtain macroporous poly(4- Hydroxybutyrate) microsphere preparation, the particle size is 300-500 μm, and the average pore size is 20-50 μm.

Embodiment 3

[0041] Example 3 Preparation of porous polyethylene glycol-poly(4-hydroxybutyrate) diblock copolymer microspheres

[0042] Weigh 200 mg of polyethylene glycol-poly(4-hydroxybutyrate) diblock copolymer with a number average molecular weight of 9300 g / mol, add 2 mL of chloroform to dissolve it to obtain solution A.

[0043] Weigh 10 mg of ammonium bicarbonate and add 1 mL of ultrapure water to dissolve it to obtain solution B.

[0044] The solutions A and B were mixed and homogenized for 10 min to obtain the primary emulsion.

[0045] Pour the primary emulsion into an aqueous solution of polyvinyl alcohol (2%), stir to evaporate the solvent, freeze-dry after centrifugation, and sterilize and package to obtain polyethylene glycol-poly(4-hydroxybutyrate) diblock copolymer porous microspheres The preparation has a particle size of 50-100 μm and an average pore size of 2-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com