A kind of allogeneic bone powder and its preparation method and application

A technology of allograft and bone powder, which is applied in prosthetics, medical science, etc., can solve the problems of autologous bone autograft transplantation limitations, etc., and achieve enhanced osteogenesis and cartilage repair ability, low calcium, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

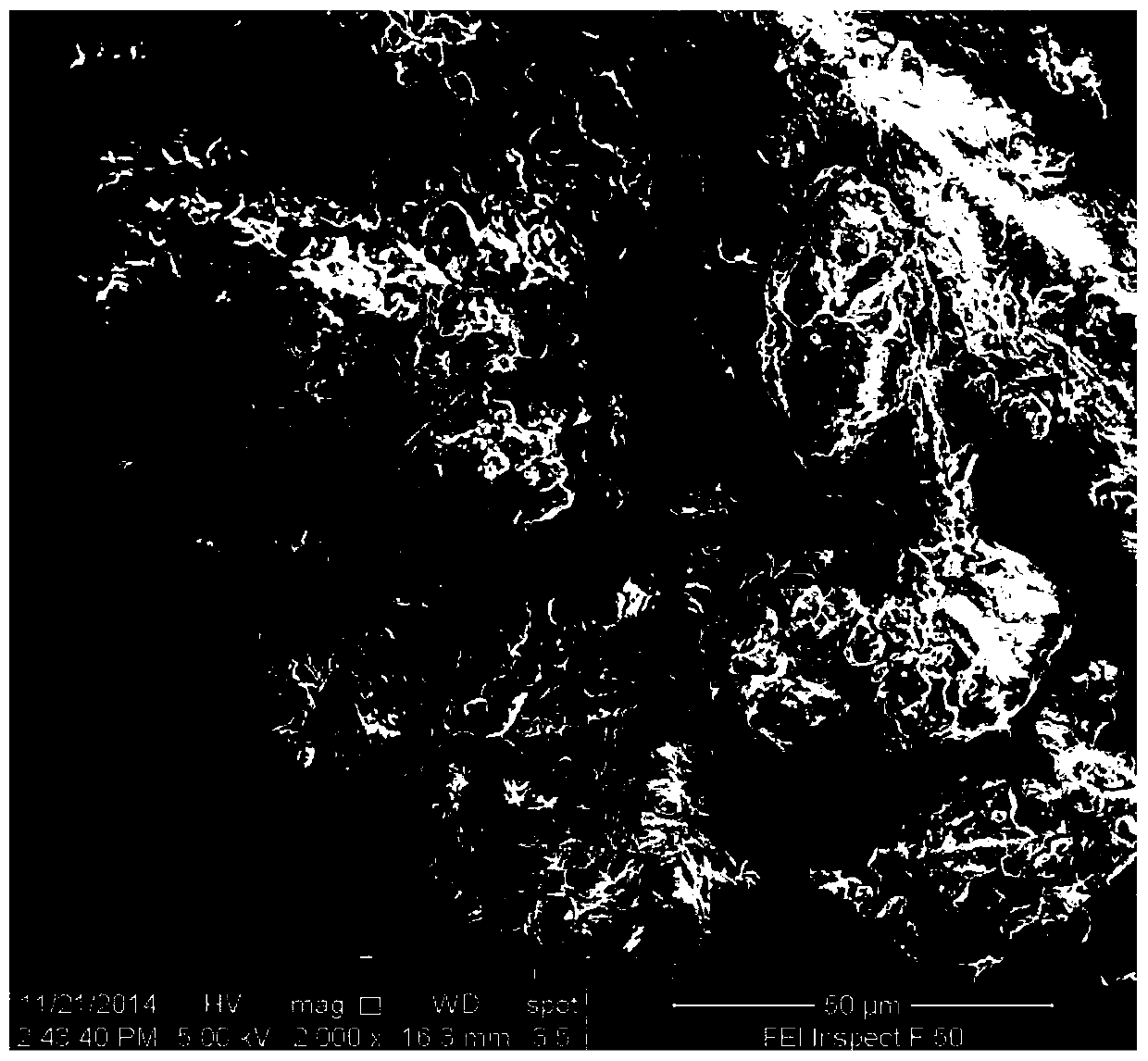

Image

Examples

Embodiment 1

[0069] 1. Take 36 long bones from the limbs of New Zealand white rabbits, cut the long bones into bone pieces, wash them, put them into a screw grinder together with liquid nitrogen, and grind them.

[0070] 2. Wash the crushed rabbit bone fragments with distilled water, centrifuge at 3000rpm / min for 5 minutes, and discard the upper liquid.

[0071] 3. Dissolve DNA hydrolase (D4527, Sigma Aldrich, USA) and RNA hydrolase (R5503, Sigma Aldrich, USA) at 0.006wt% and 0.02wt% respectively in sterile phosphate buffered saline (sterile PBS) to prepare solution, and the rabbit bone fragments obtained in step 2 were subjected to an enzymatic reaction at 37°C and incubated for 2-3 hours.

[0072] 4. After the enzymatic reaction is finished, rinse with distilled water and centrifuge at a speed of 500-2000rpm / min for 5 minutes, discard the supernatant, and repeat this step 2-3 times.

[0073] 5. Contain 1% Triton x-100 (polyethylene glycol octyl phenyl ether, X100, Sigma Aldrich, USA) wa...

Embodiment 2

[0080] 1. Take 36 limb long bones of New Zealand white rabbits, cut the long bones into bone pieces and wash them with distilled water.

[0081] 2. Contain 1% Triton x-100 (polyethylene glycol octyl phenyl ether, X100, Sigma Aldrich, USA) washing solution and 1% EDTA chelating agent containing 1% pH by volume configuration Mix the solution and incubate with the rabbit bone fragments obtained in step 1 at 4°C for 72 hours.

[0082] 3. Rinse the bone chips obtained in step 2 thoroughly with distilled water for 2-3 times.

[0083] 4. A solution containing 15% EDTA chelating agent with a pH of 7.2 is configured by volume, and the rabbit bone fragments obtained in step 3 are decalcified with the EDTA chelating agent solution for 120 hours.

[0084] 5. Rinse the bone chips obtained in step 4 thoroughly with distilled water for 2-3 times.

[0085] 6. Dissolve DNA hydrolase (D4527, Sigma Aldrich, USA) and RNA hydrolase (R5503, Sigma Aldrich, USA) at 0.006wt% and 0.02wt% respectively...

Embodiment 3

[0089] 1. Take 8 long bones from the limbs of miniature pigs, cut the long bones into bone pieces, wash them and put them into a screw grinder together with liquid nitrogen to grind them.

[0090] 2. Wash the crushed pork bone fragments with distilled water, centrifuge at 3000rpm / min for 5 minutes, and discard the upper liquid.

[0091] 3. Dissolve DNA hydrolase (D4527, Sigma Aldrich, USA) and RNA hydrolase (R5503, Sigma Aldrich, USA) at 0.006wt% and 0.02wt% respectively in sterile phosphate buffered saline (sterile PBS) to prepare solution, and the porcine bone fragments in step 2 were subjected to an enzymatic reaction at 37°C and incubated for 2-3 hours.

[0092] 4. After the enzymatic reaction, rinse with distilled water and centrifuge at 500-2000rpm / min for 5 minutes, discard the supernatant, and repeat this step 2-3 times.

[0093] 5. Contain 1% Triton x-100 (polyethylene glycol octyl phenyl ether, X100, Sigma Aldrich, USA) washing solution and 1% EDTA chelating agent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com