Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Solve low adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

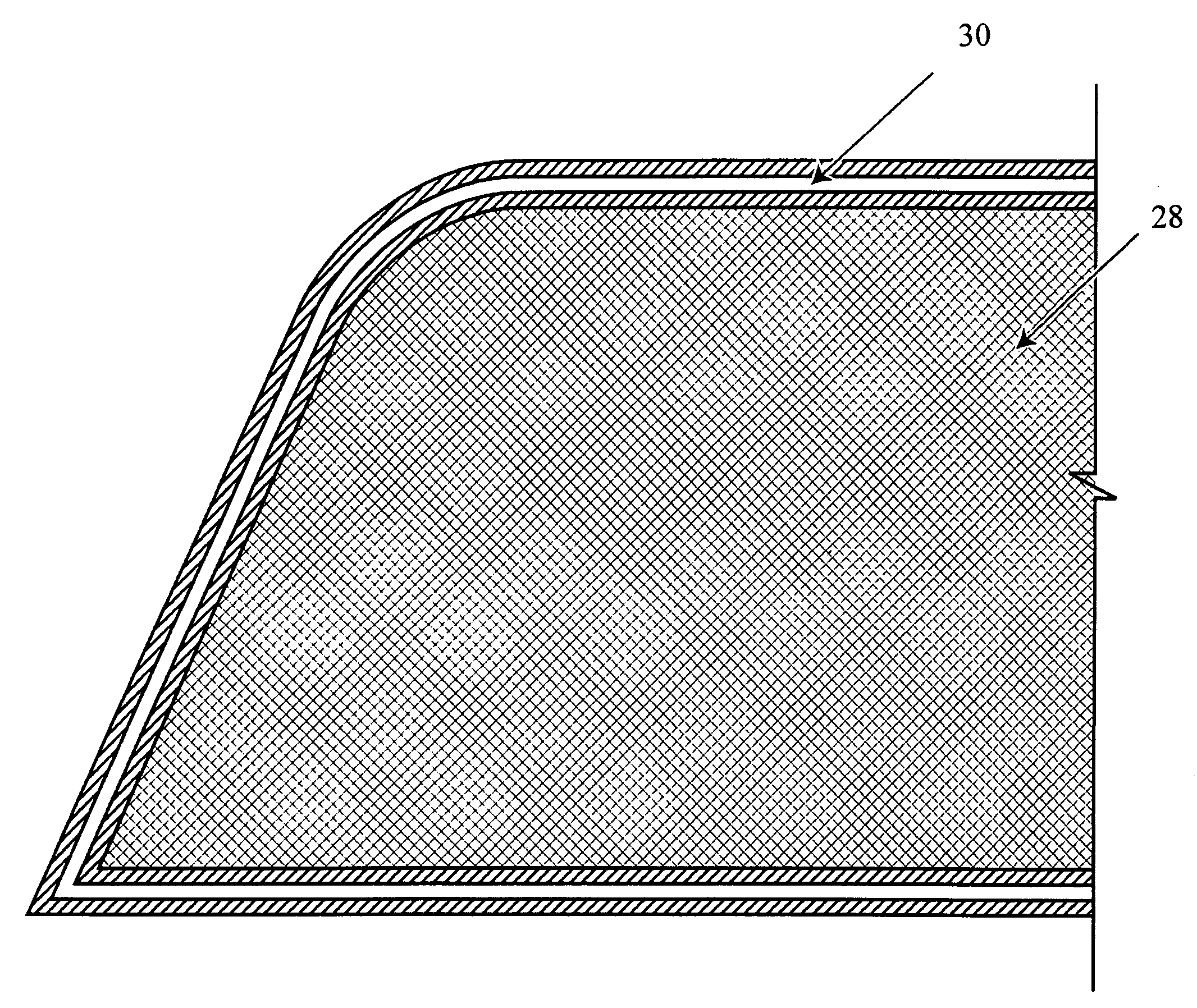

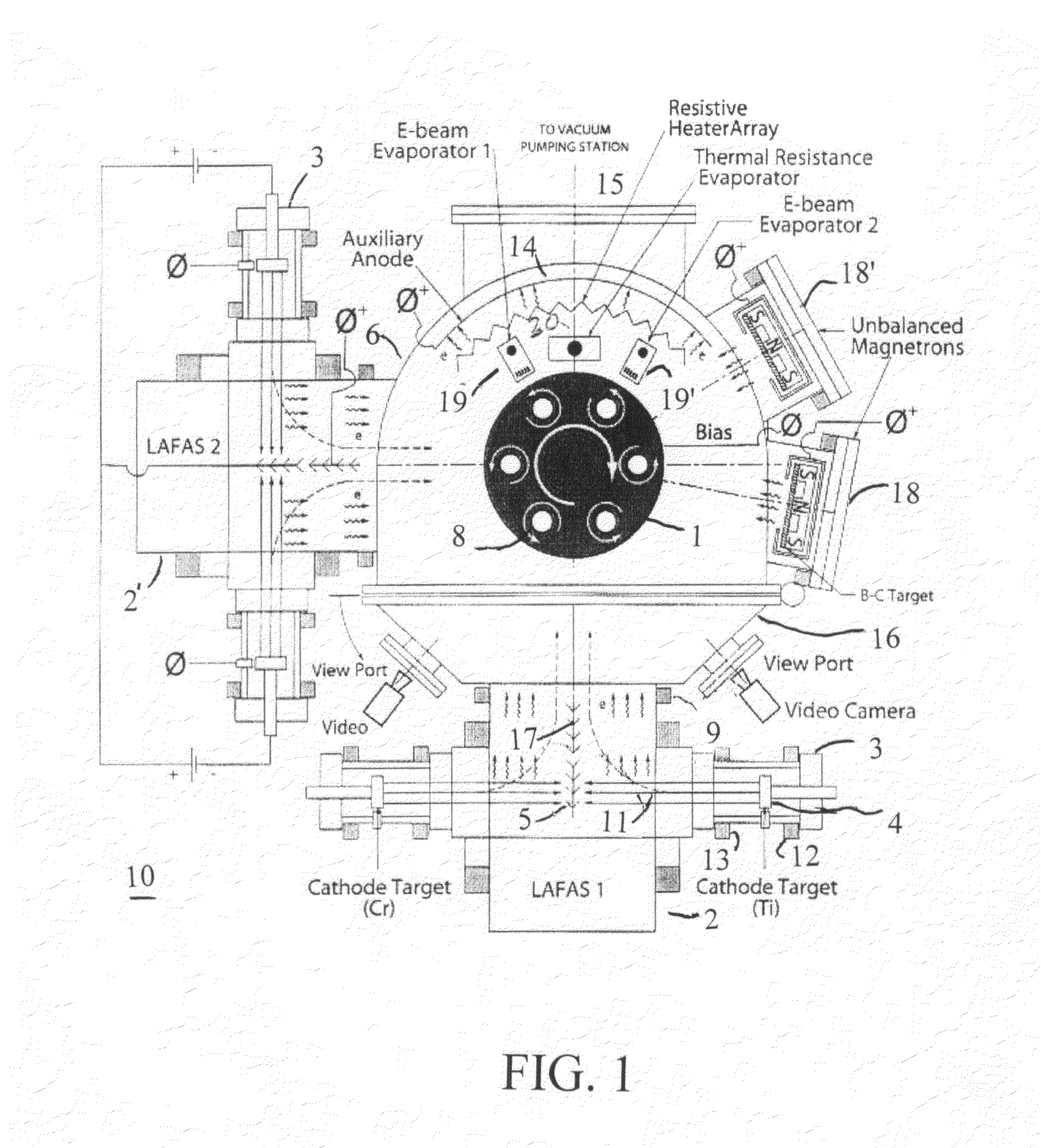

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Transparent conductive film for flat panel displays

ActiveUS20040086717A1High transmittanceLow electric resistanceSolid-state devicesVacuum evaporation coatingTransmittanceIndium

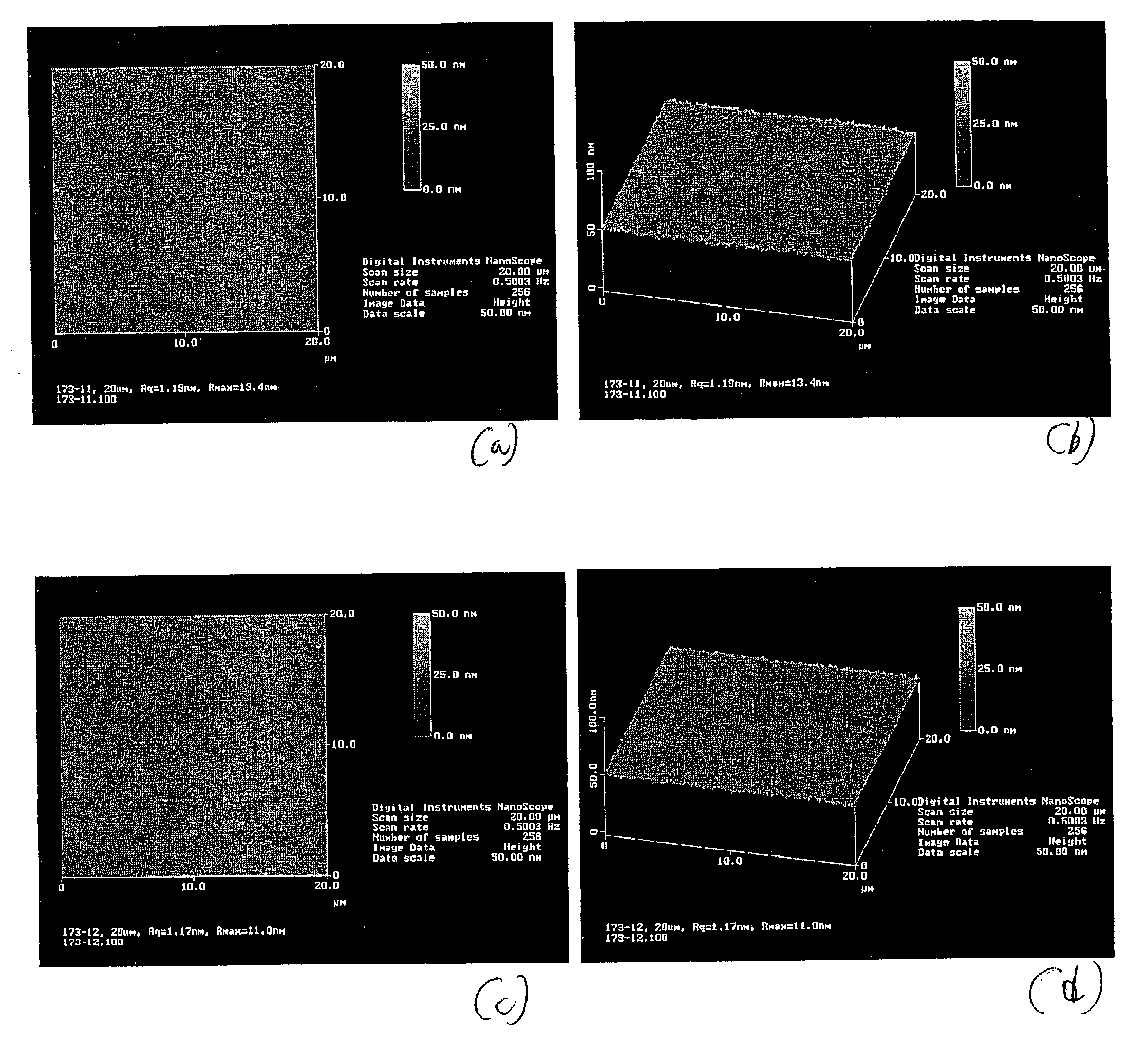

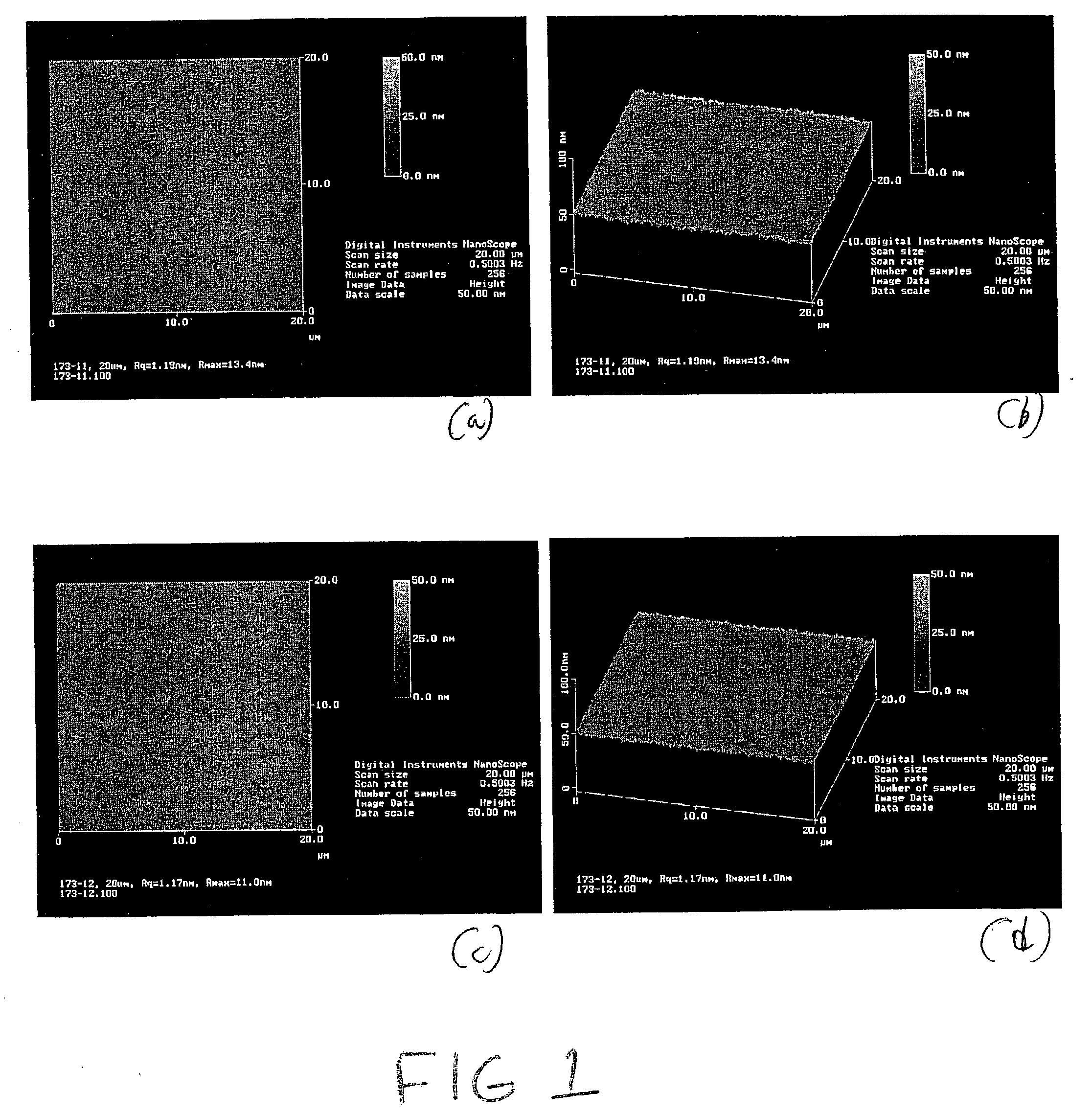

Transparent conductive films for flat panel displays and methods for producing them are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film, the multi-layered conductive metallic film comprising two layers of an alloy selected from the group consisting of indium cerium oxide (InCeO) and indium tin oxide (ITO) surrounding a layer of an alloy of silver, palladium, and copper (Ag / Pd / Cu); and (3) collecting the composite film in continuous rolls. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising a multilayered film as described above formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 80% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the multi-layered metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:XYLON LLC

Process for uniformly coating hollow bodies

InactiveUS20020155218A1Low costShorten the timeLiquid surface applicatorsLinings/internal coatingsMaterials scienceCoating

The present invention relates to a process for uniformly coating hollow bodies, in which one open end of the hollow body is closed off in a gas-tight manner by a cover, the hollow body is introduced into a plasma-induced CVD reactor, vacuum is applied to the hollow body, a coating temperature is established and the plasma-induced coating takes place. The present invention also relates to the use of the process for uniformly coating hollow bodies according to the invention for coating tubes, vessels, syringe bodies, reflectors, domes and funnels.

Owner:SCHOTT AG

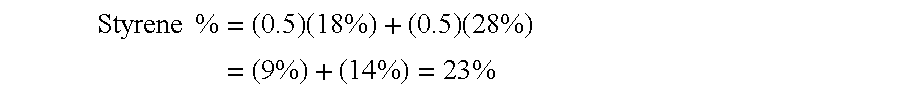

High shear pressure sensitive adhesive composition

InactiveUS20080070053A1Well-balanced propertyImprove adhesionFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePlasticizer

A hot melt pressure sensitive adhesive composition includes ABA block copolymer(s), a midblock resin, a plasticizer, and optionally, an endblock resin. The A block is derived from styrene and B block is derived from butadiene or its hydrogenated version. The block copolymer(s) has an average styrene content of from about 15% to about 35%, an average diblock content of no less than about 20%, and an average solution viscosity of less than about 1,000 cps.

Owner:HB FULLER CO

Silicone coating compositions and coated articles

InactiveUS20050244659A1Eliminate coat crackingImprove balanceLayered productsCoatingsCrack resistanceArame

A silicone coating composition comprising (A) a silicone resin resulting from (co)hydrolytic condensation of an alkoxysilane or a partial hydrolytic condensate thereof, (B) an aromatic-free compound for curing the silicone resin, and (C) a solvent remains stable during shelf storage. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness, mar resistance, adhesion, toughness and crack resistance.

Owner:SHIN ETSU CHEM IND CO LTD

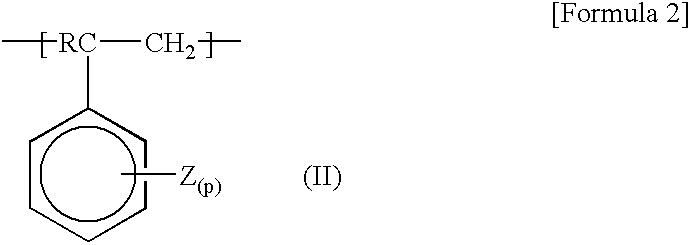

Aromatic vinyl/isoprene block copolymer, process for the production thereof, and hardenable pressure-sensitive adhesive composition containing the same

An aromatic vinyl compound-isoprene block copolymer composition comprising (i) 5-50 wt. % a branched copolymer of the formula: (A-B)nX wherein A is a polymer block of an aromatic vinyl monomer, B is a polymer block of isoprene, and X is a residue of a polyfunctional coupling agent, and (ii) 50-95 wt. % of a diblock copolymer of the formula: A-B wherein A and B are as defined above. This copolymer composition is produced by allowing an aromatic vinyl monomer to contact with an organic lithium initiator to prepare a polymer block A; incorporating isoprene thereto to prepare a diblock copolymer A-B; and then, adding a polyfunctional coupling agent to convert a part of the diblock copolymer A-B to the branched copolymer (A-B)nX. This block copolymer composition is useful for an adhesive or pressure sensitive adhesive composition.

Owner:ZEON CORP

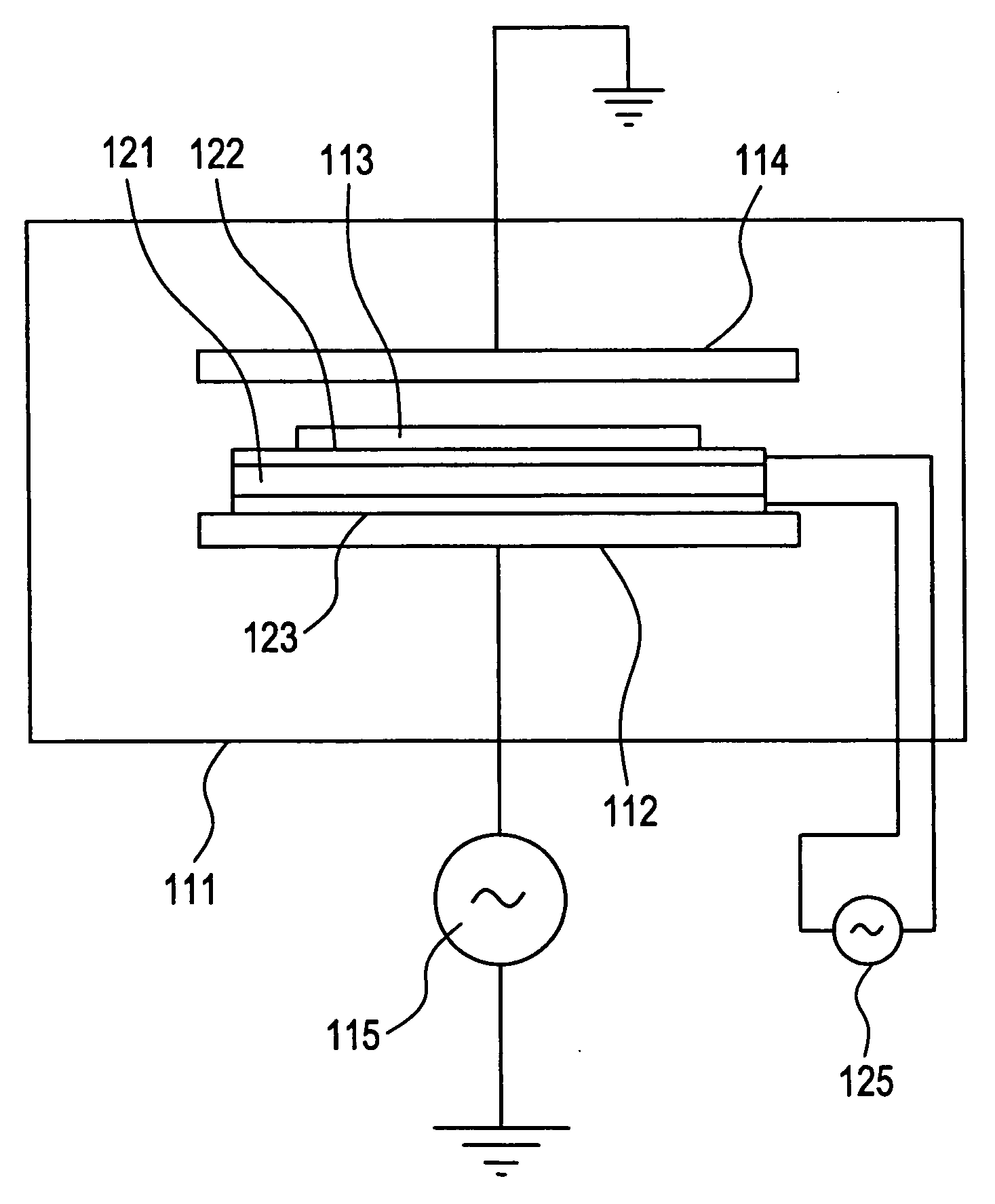

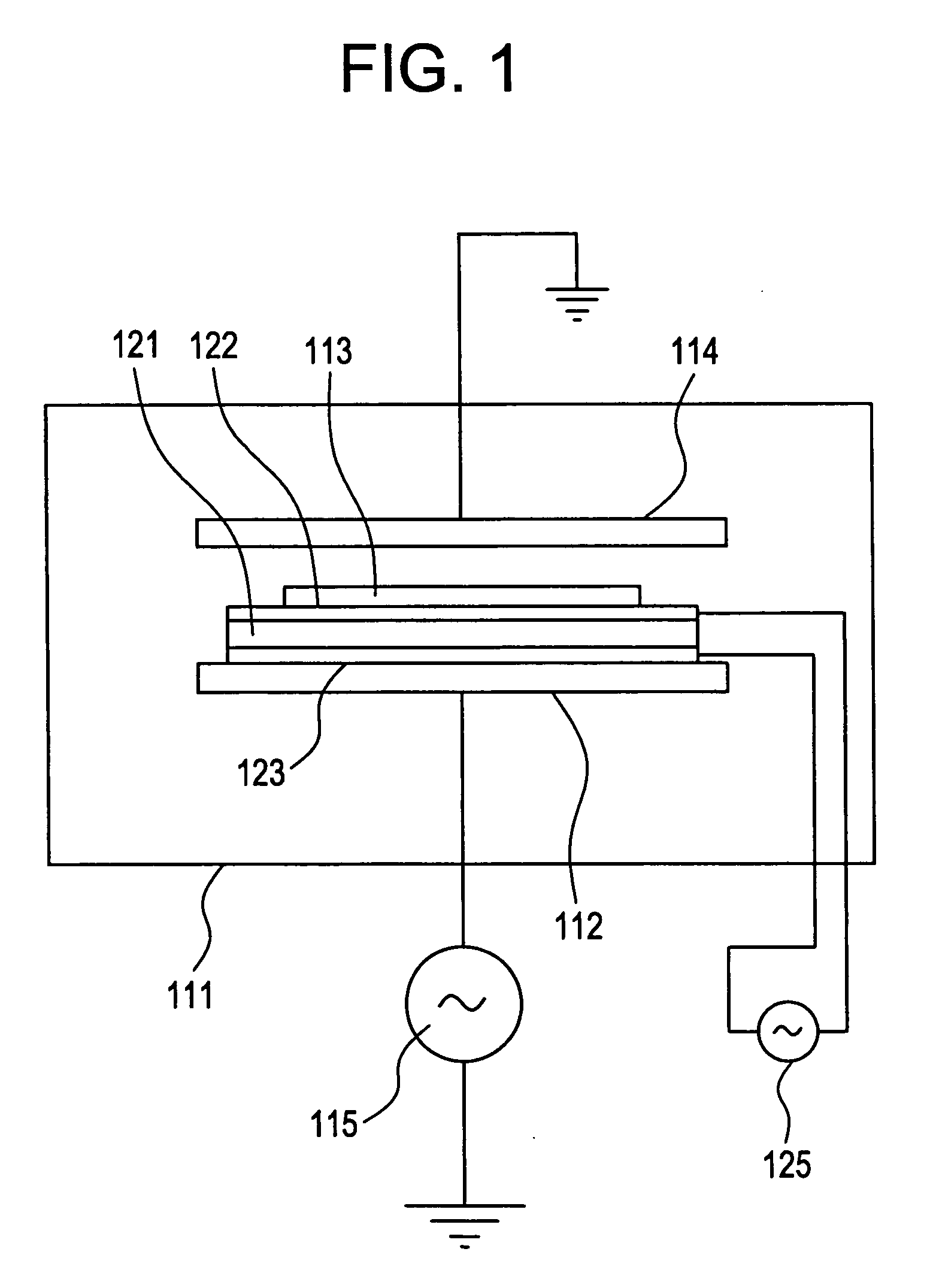

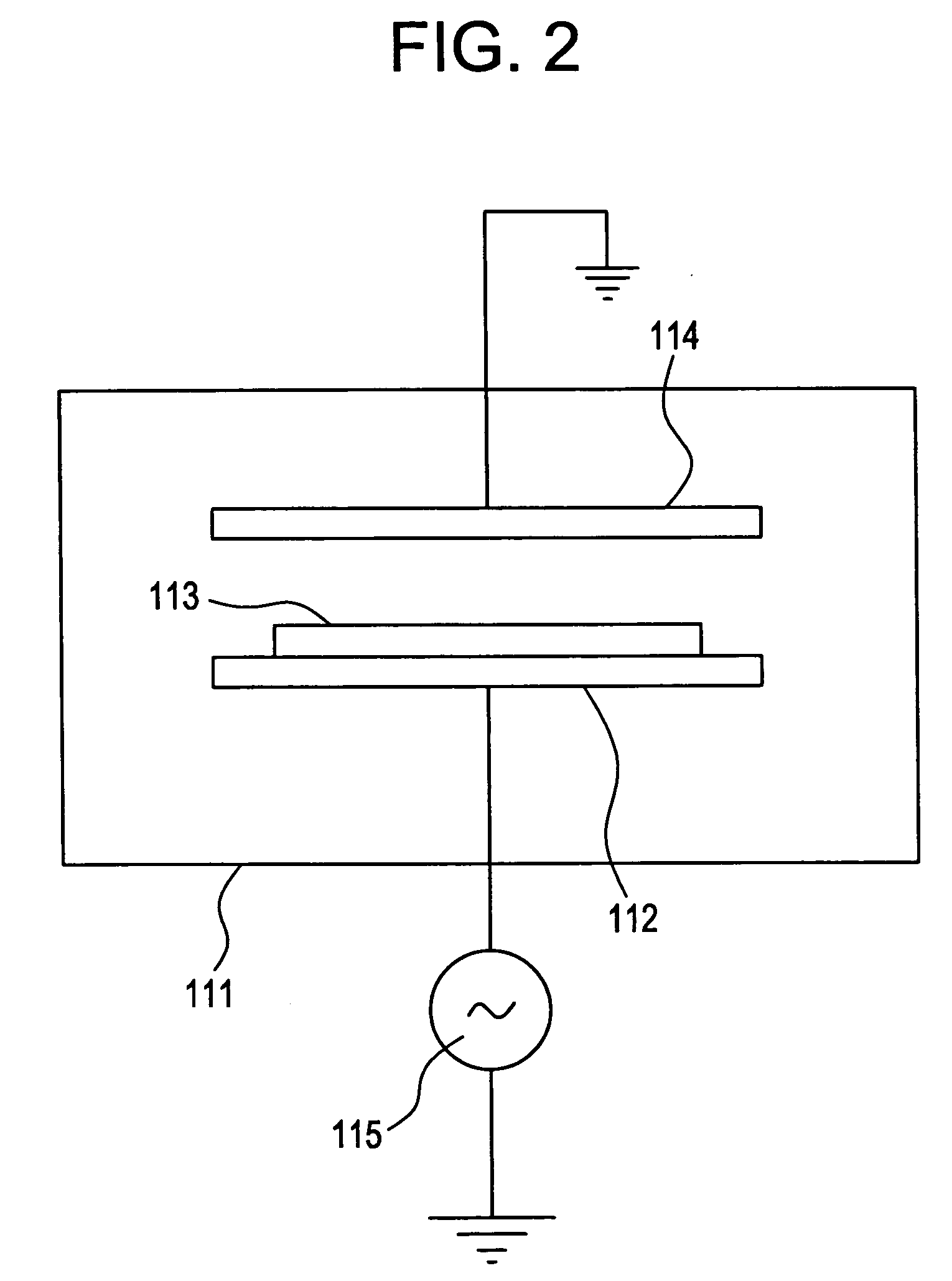

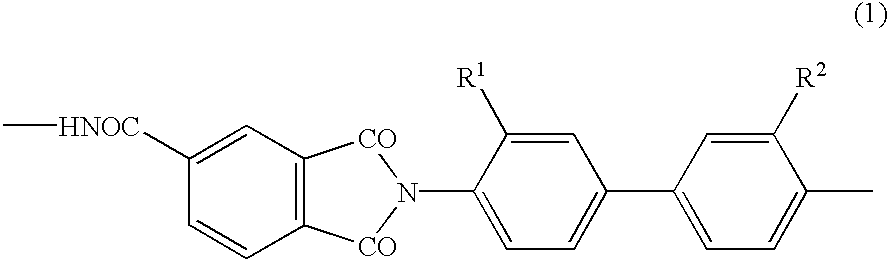

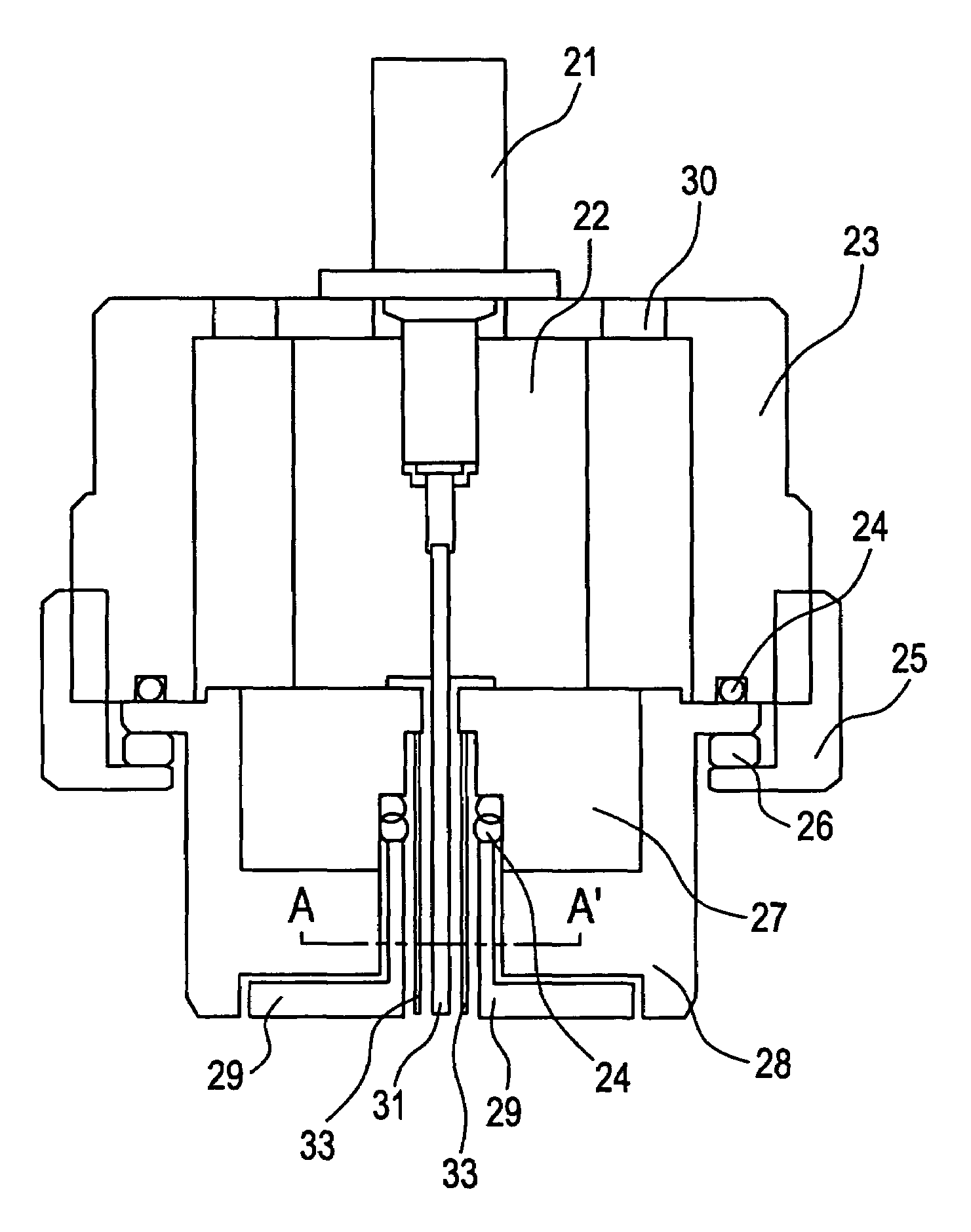

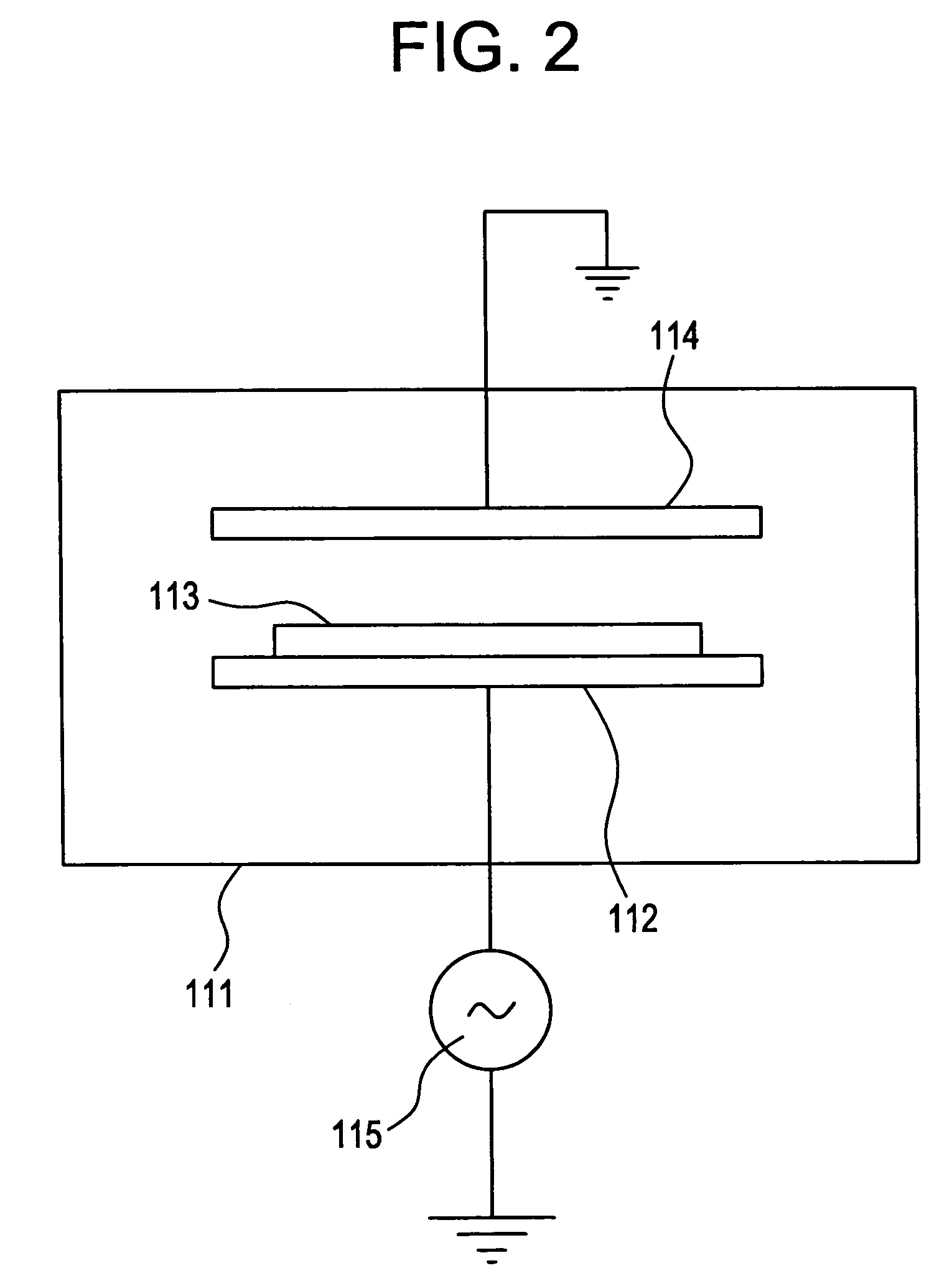

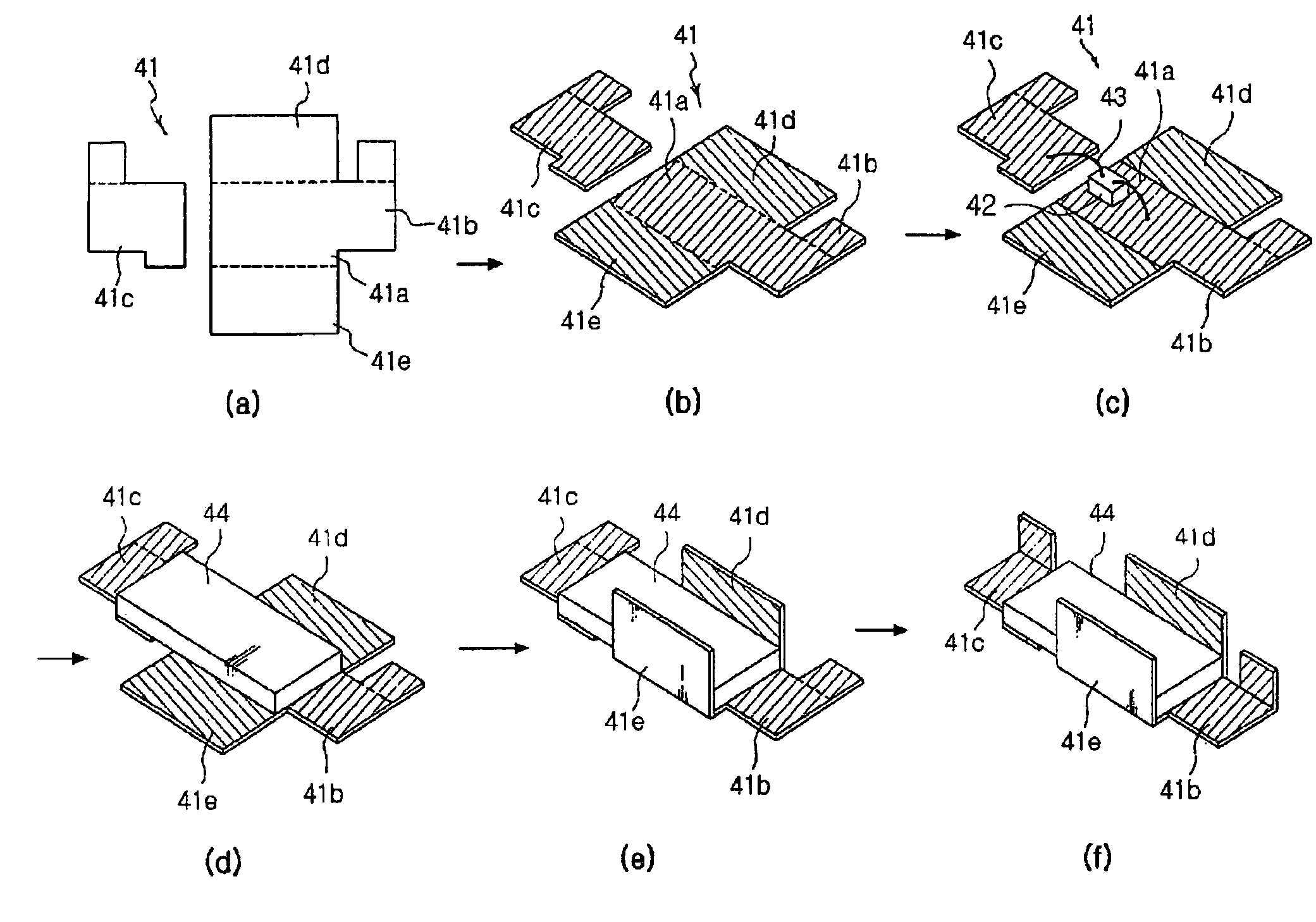

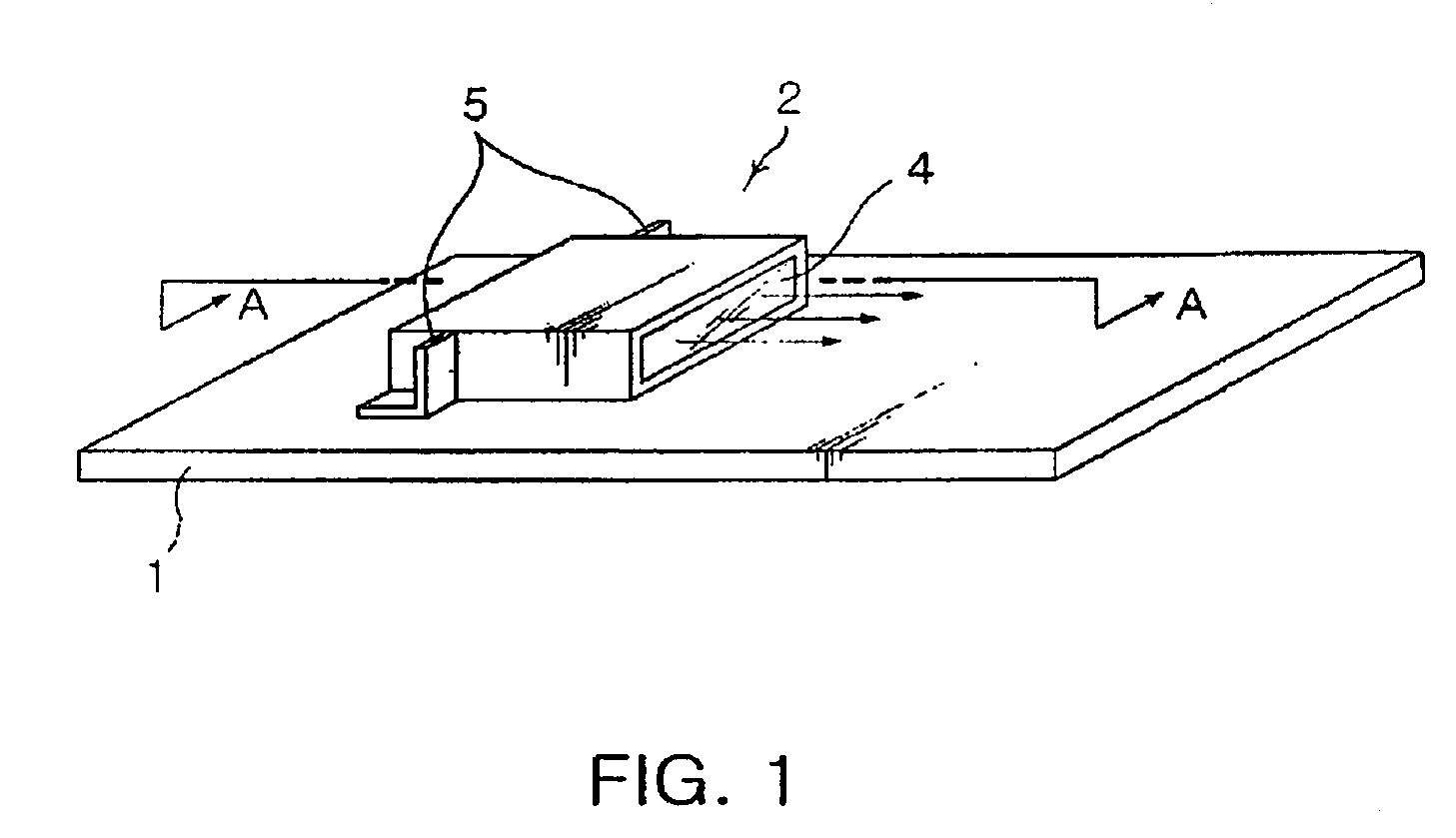

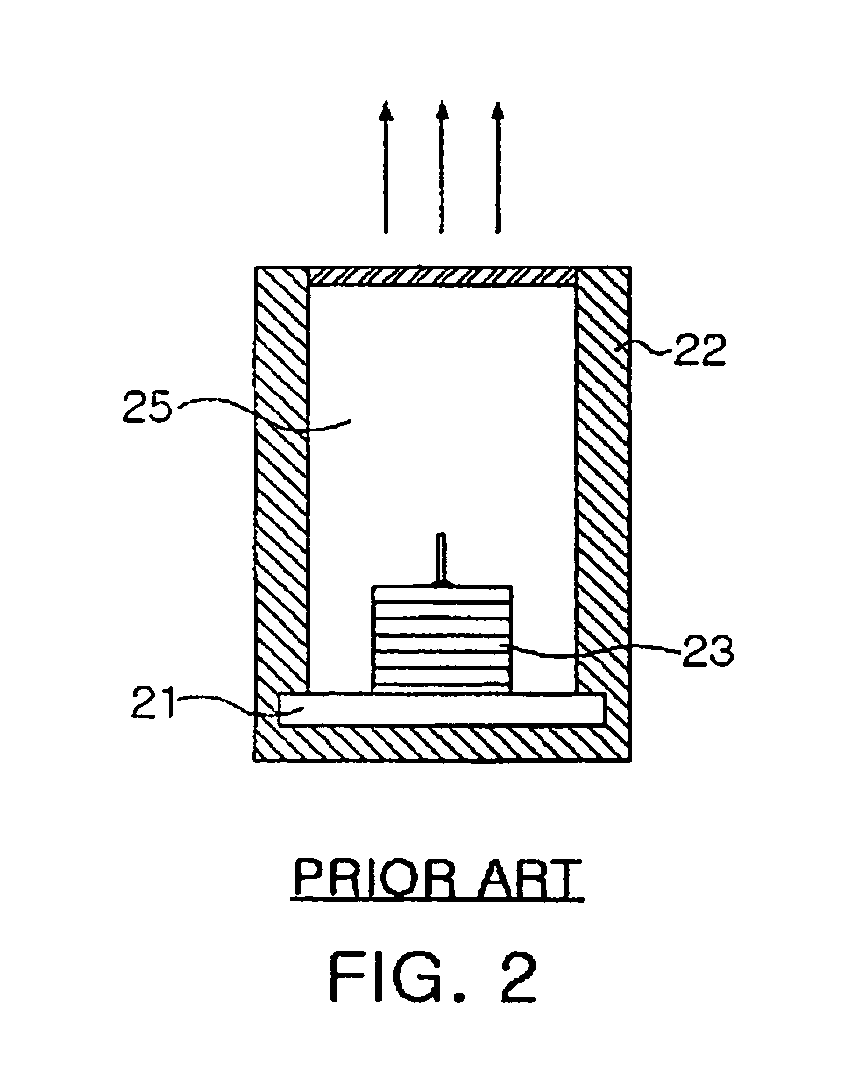

Apparatus for fabricating coating and method of fabricating the coating

InactiveUS20050089648A1Improve throughputLow costLiquid surface applicatorsMolten spray coatingHigh frequency powerHigh density

In an apparatus for fabricating a carbon coating, an object such as a magnetic recording medium is disposed on a side of an electrode connected to a high-frequency power supply. Ultrasonic vibrations are supplied to the object. Discharge is generated between the electrode connected to the high-frequency power supply and a grounded electrode to fabricate a carbon coating on the surface of the object. Also, an electrode interval is set to 6 mm or less, pressure between the electrodes is set to 15 Torr to 100 Torr, whereby high-density plasma is generated to form an ion sheath on an anode side. Therefore, a coating is fabricated on the surface of the object by bombardment of ions.

Owner:SEMICON ENERGY LAB CO LTD

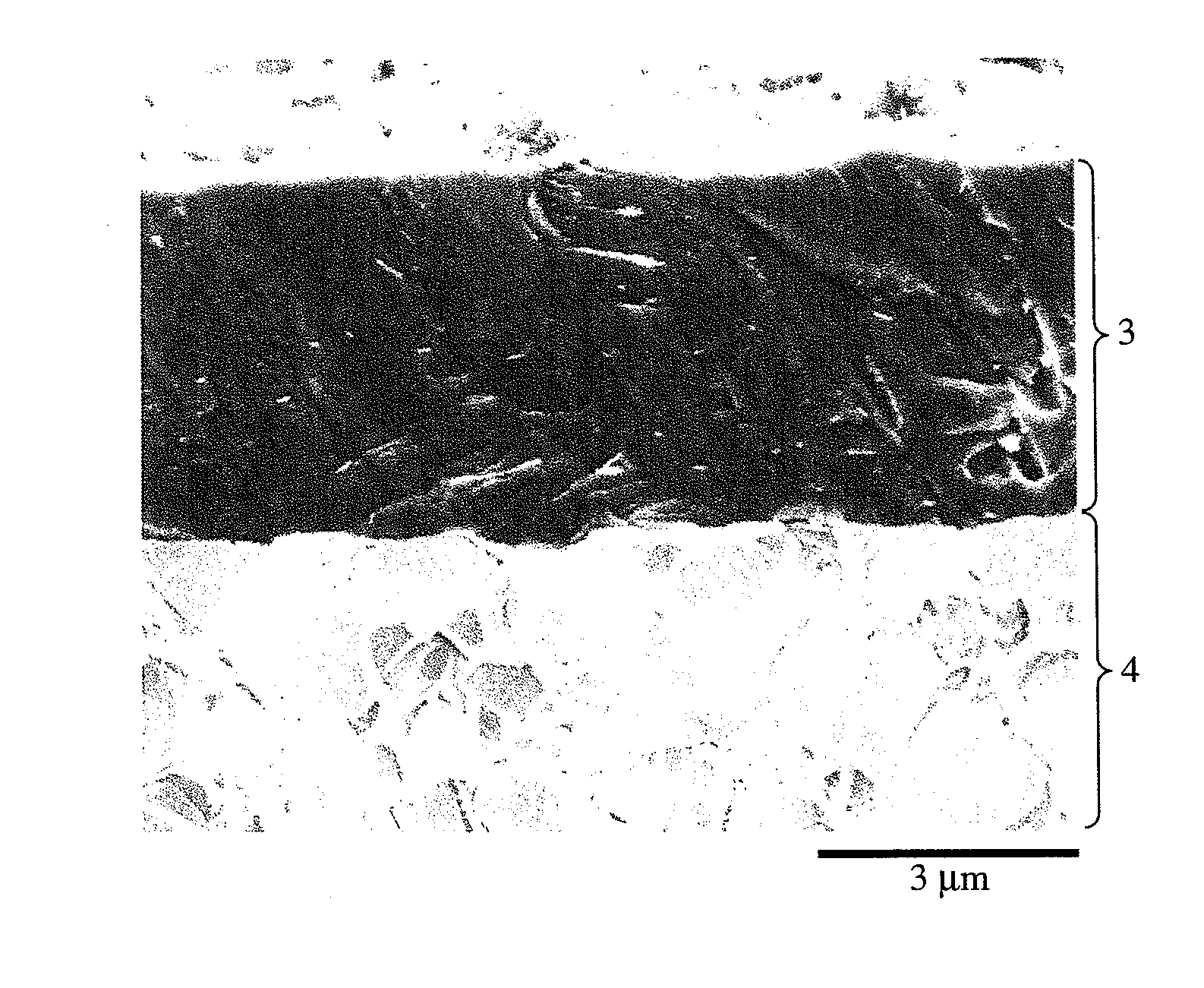

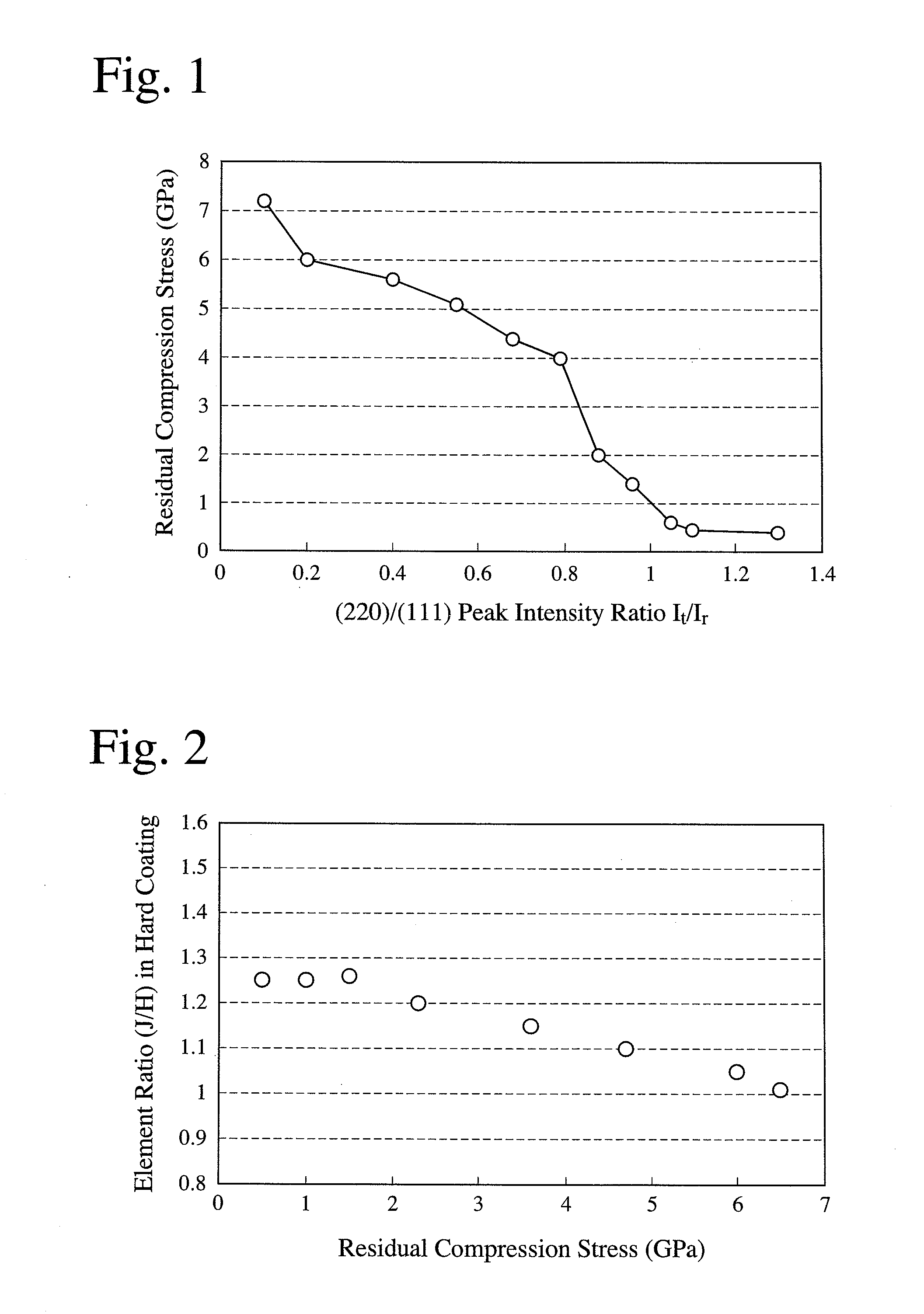

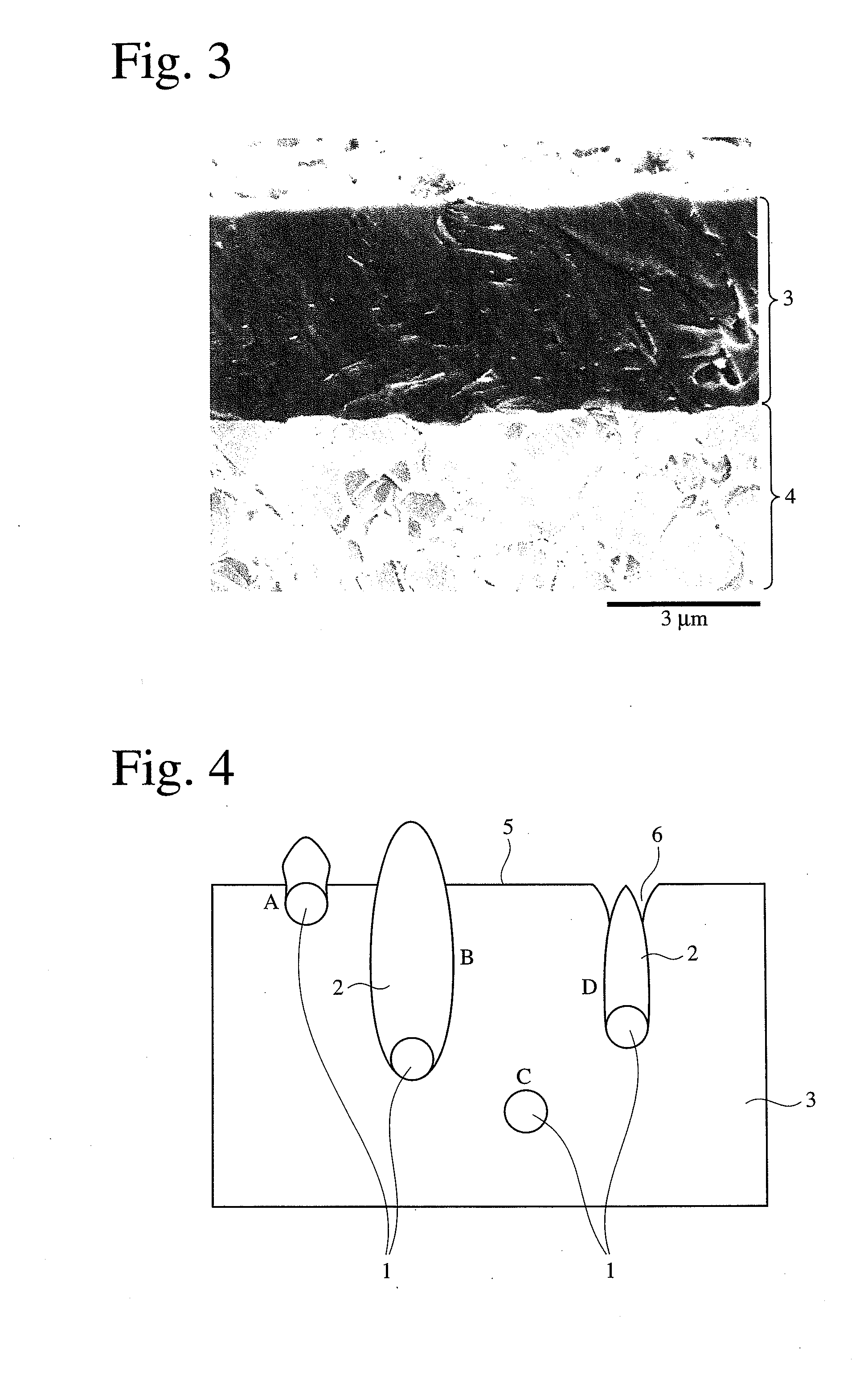

Hard-coated member, and its production method

ActiveUS20100215912A1Improve adhesionReduce coatingVacuum evaporation coatingSputtering coatingX-rayMaterials science

The hard-coated member of the present invention having a compression-stress-loaded hard coating having a thickness of 5 μm or more, the hard coating having a face-centered cubic structure having a composition represented by (Me1-aXa)α(N1-x-yCxOy), wherein Me is at least one element selected from Groups 4a, 5a and 6a, X is at least one element selected from the group consisting of Al, Si, B and S, a, x and y are respectively the contents (atomic ratios) of X, C and O, and α is a ratio of (Me1-aXa) to (N1-x-yCxOy), meeting 0.1≦a≦0.65, 0≦x≦0.1, 0≦y≦0.1, and 0.85≦α≦1.25; and the X-ray diffraction of the hard coating having a peak intensity Ir of a (111) plane, a peak intensity Is of a (200) plane, and a peak intensity It of a (220) plane, meeting 2≦Is / Ir, and 0.2≦It / Ir≦1, and the (200) plane having a half-value W(°)≦0.7.

Owner:HITACHI TOOL ENG LTD

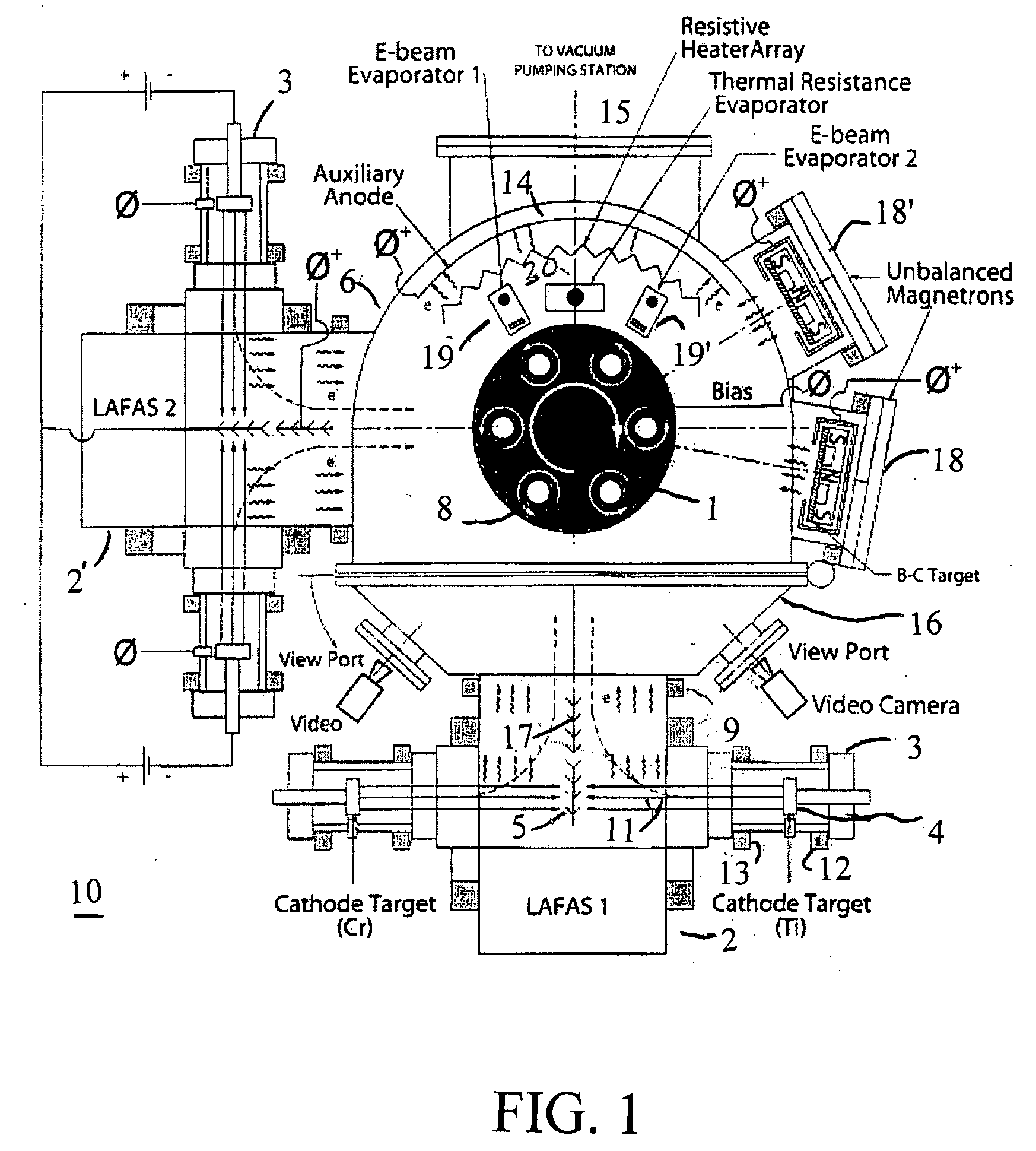

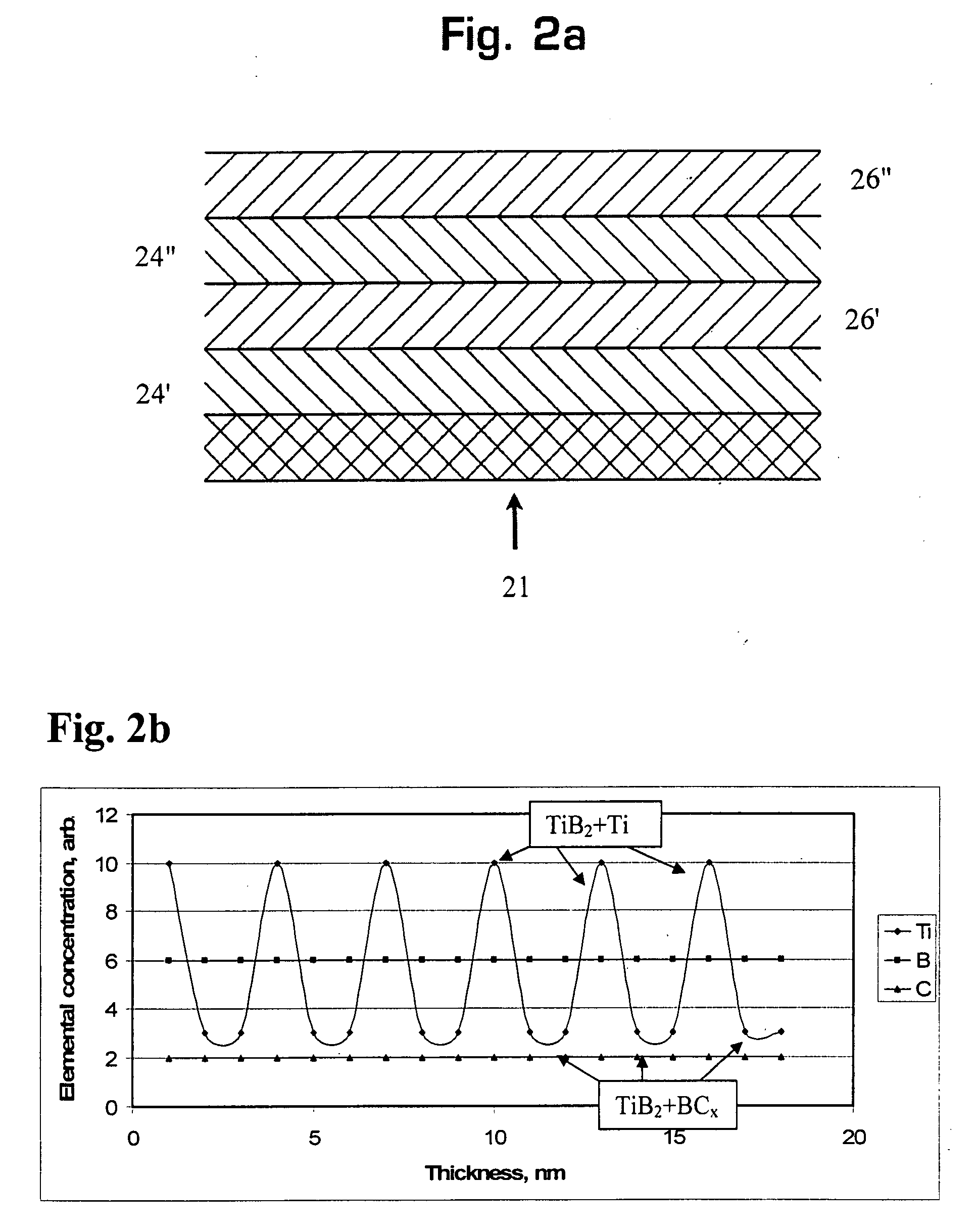

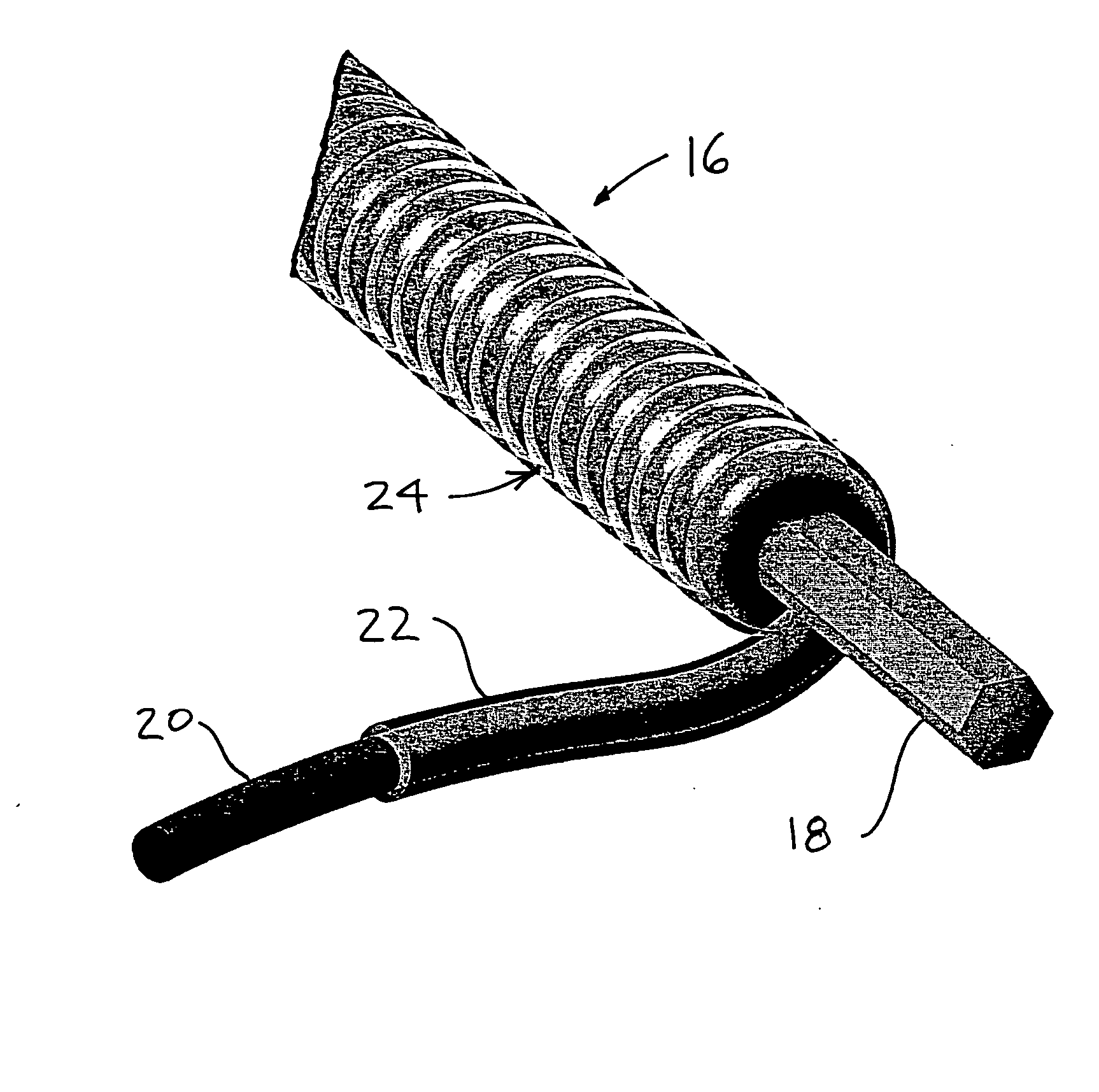

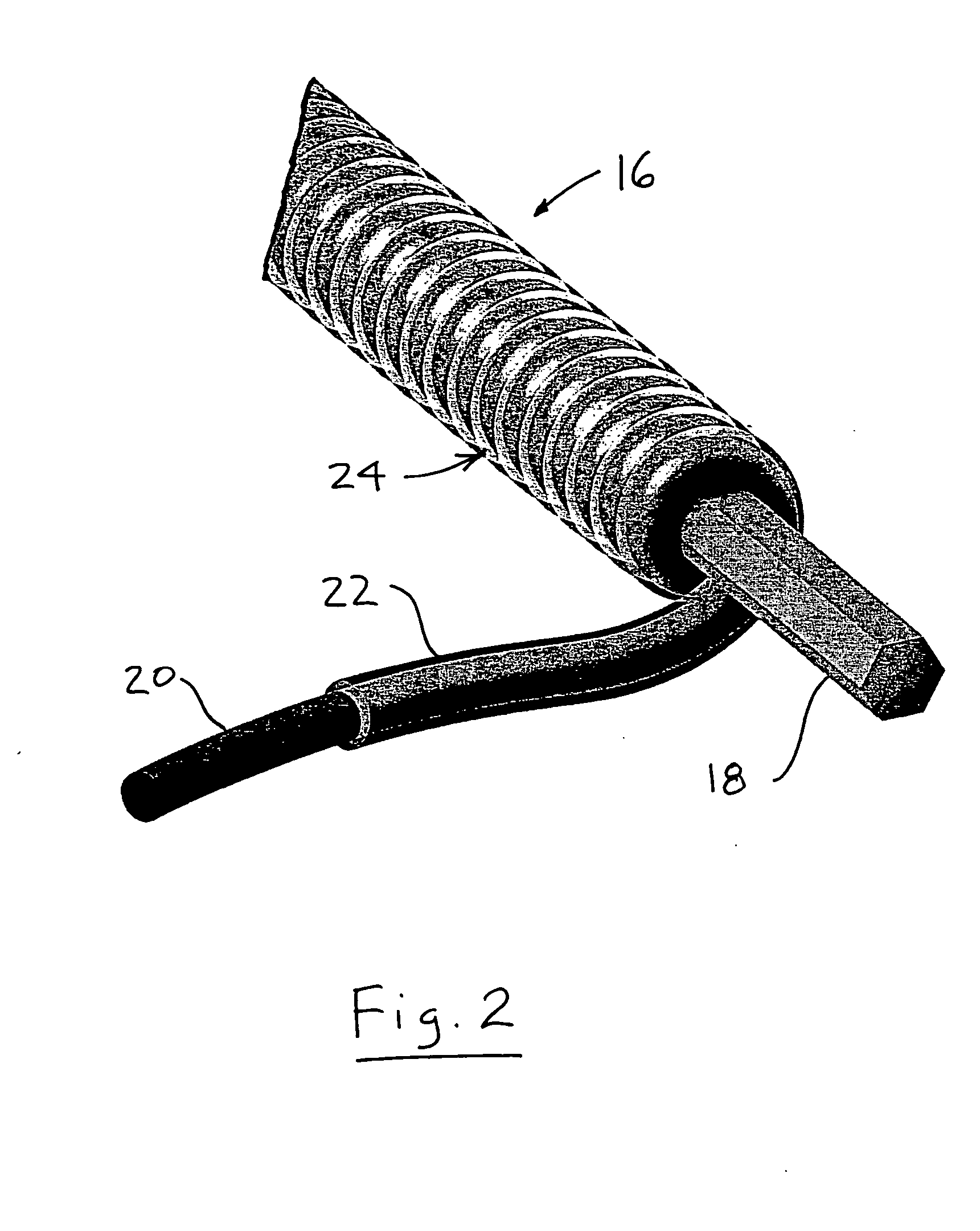

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS7939172B2Stable cutting edgeReduce frictionPigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Method for coating wire for a musical instrument string, and coated string

InactiveUS20060174745A1Increase line speedMore reliabilityStringed musical instrumentsUltravioletElectron

A musical instrument string having a tarnish resistant exterior surface, comprising a metal wire at least a portion of which has an ultra-violet (U-V) or electron beam (EB) radiation cured polymeric coating defining the exterior surface and having a coating thickness preferably less than 0.0004 inch (0.4 mil). A method of coating a musical instrument string, and a guitar having such coated strings, are also disclosed.

Owner:D'ADDARIO

Transparent laminate, plastic lens for eyeglass and primer composition

InactiveUS20020159160A1Good weather resistanceImprove impact resistancePolyurea/polyurethane coatingsMountingsAnti-reflective coatingPolymer science

A novel primer composition which does not need to be thermally cured at a high temperature after it is applied to a plastic substrate and a transparent laminate, for example, a plastic lens for spectacles, which comprises the above primer composition and has high impact resistance and high heat resistance even when a transparent anti-reflection coat is formed. This transparent laminate comprises a transparent plastic substrate and a coating film formed on at least one side of the plastic substrate by applying and curing a liquid primer composition which comprises (A) a self-emulsifiable emulsion of a linear polyurethane having a pendant carboxylic acid group and no crosslinked structure between polymer chains, (B) a sol of an inorganic oxide having a hydrophobic group on the surface, and (C) a compound having 5 to 9 carbon atoms and at least one hydroxyl group and at least one oxygen atom other than an oxygen atom constituting a hydroxyl group in the molecule.

Owner:SDC TECHNOLOGIES INC

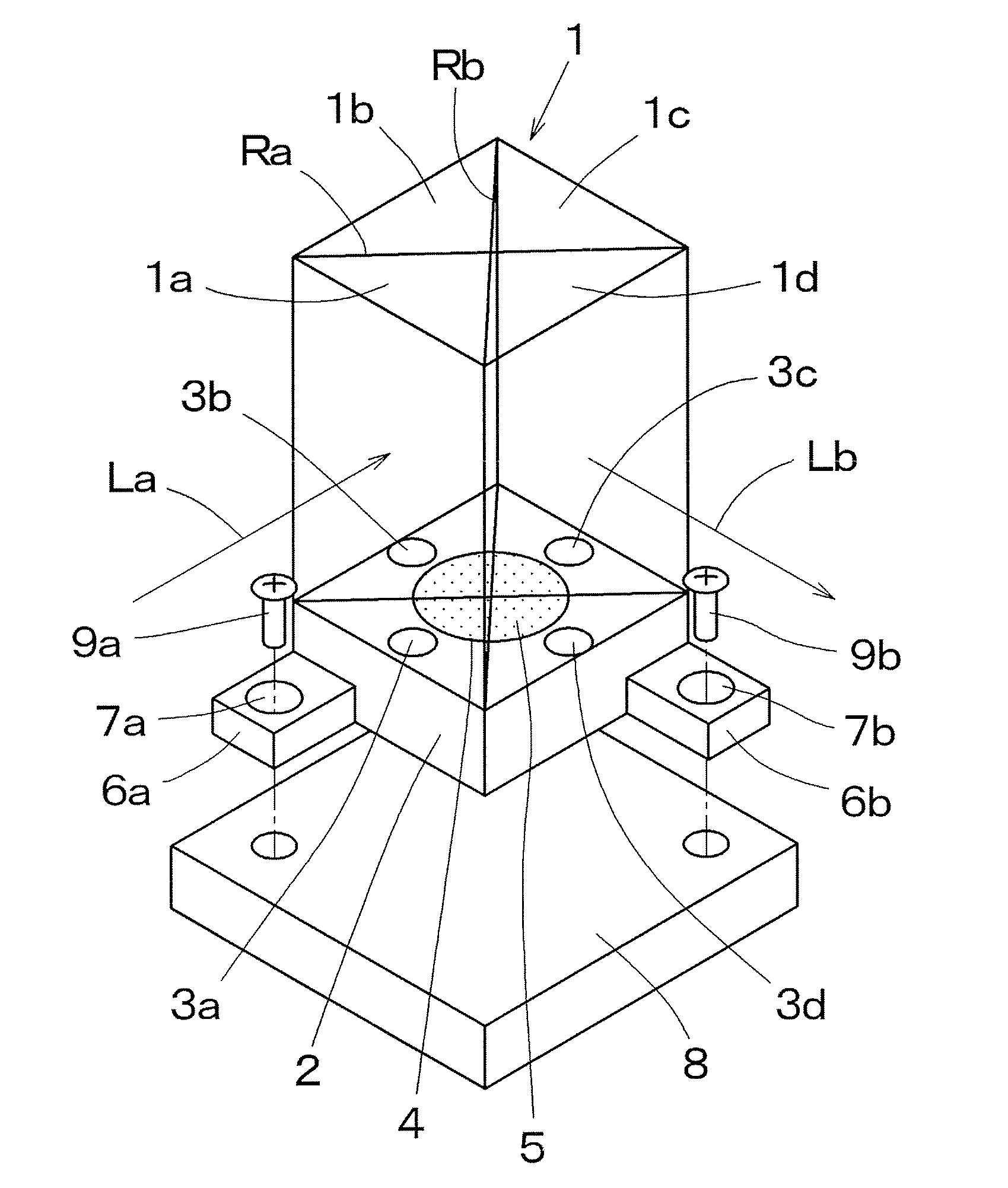

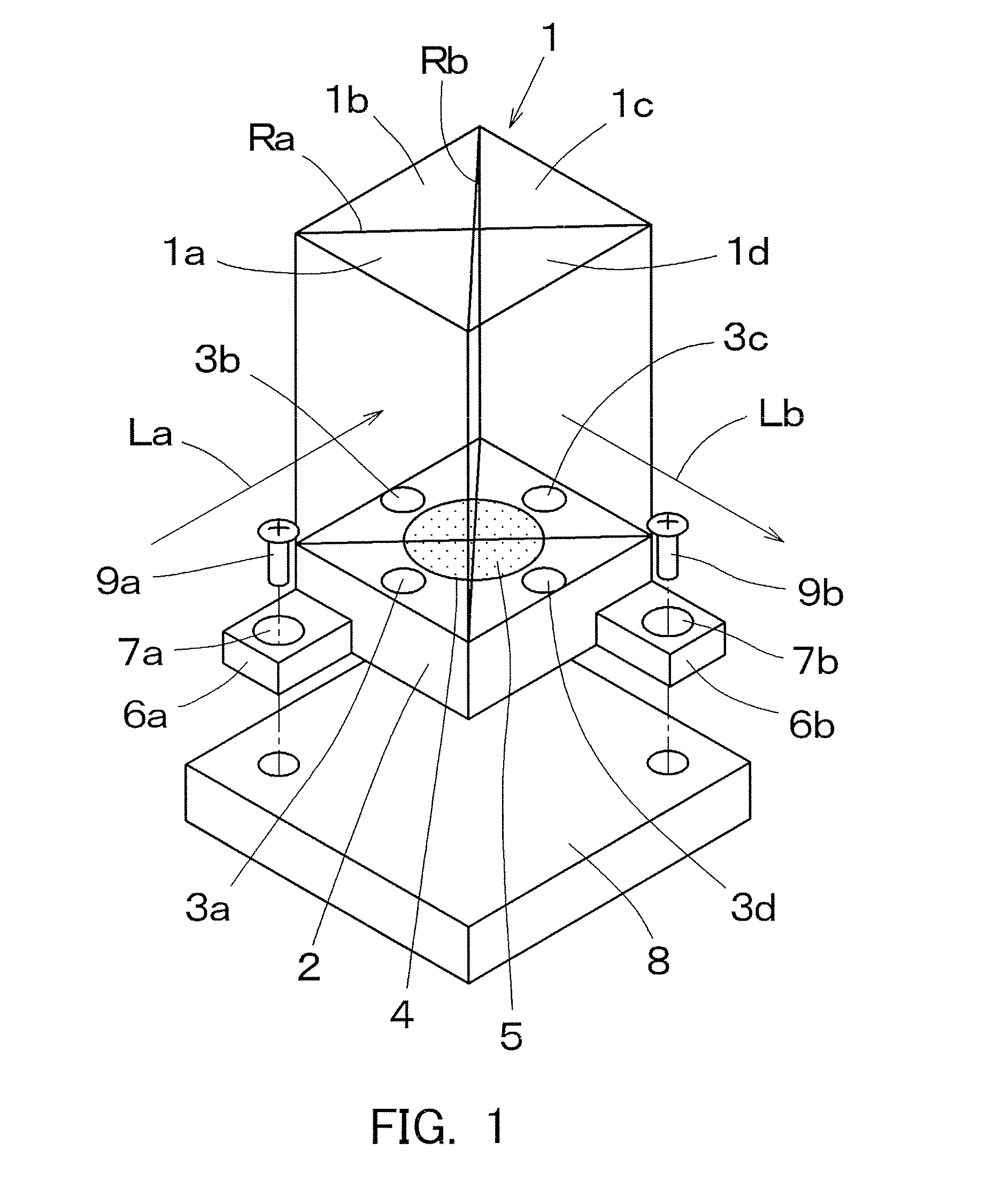

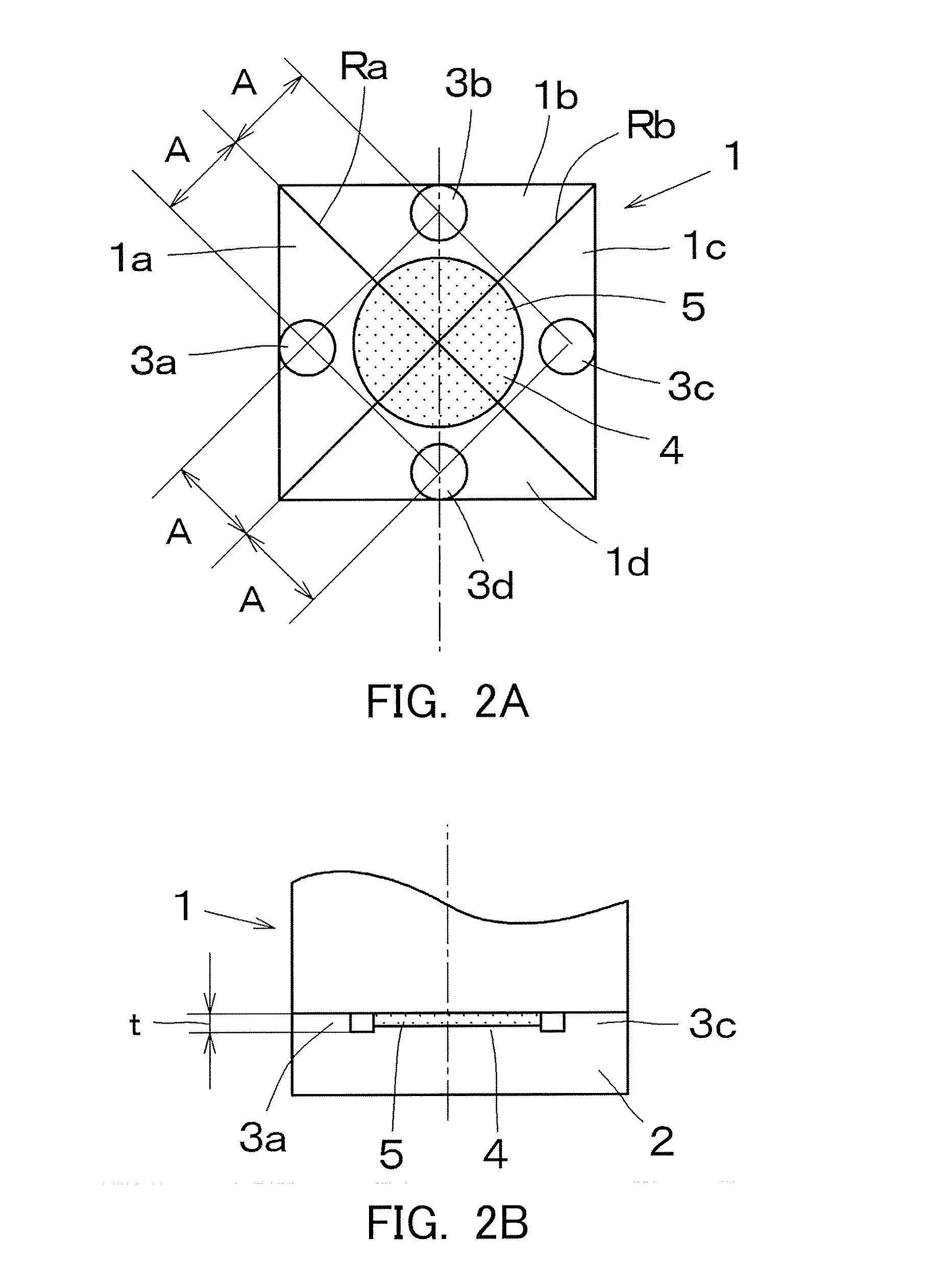

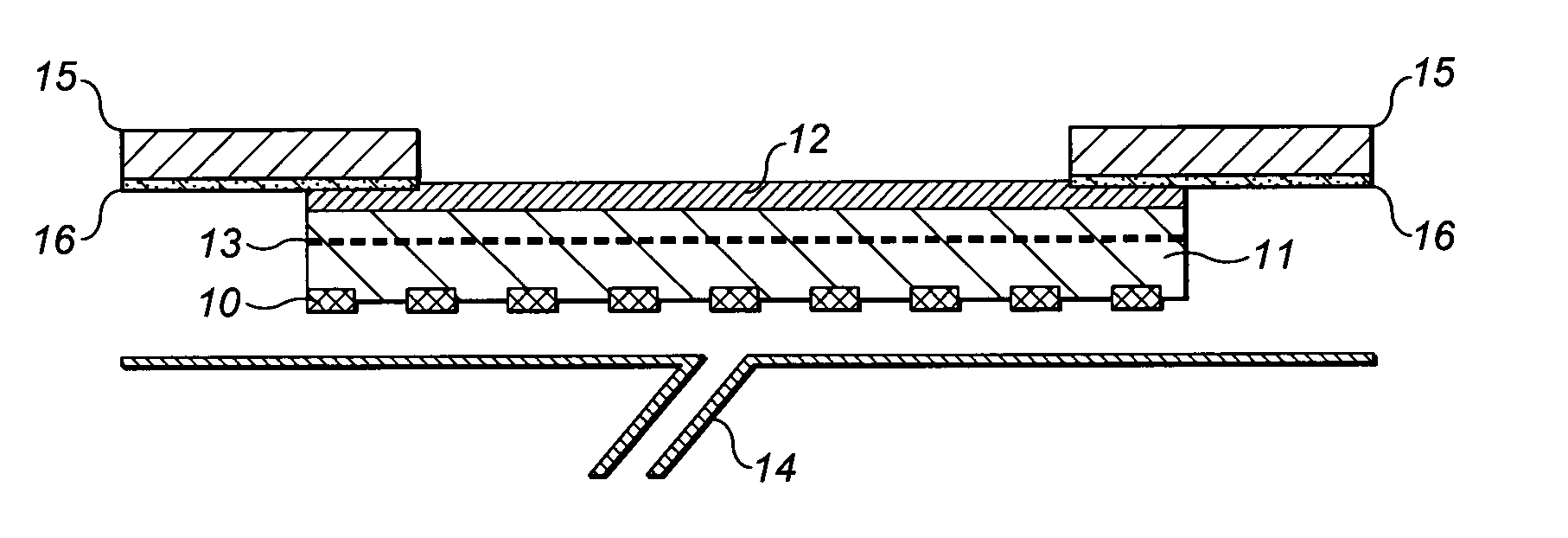

Prism unit and a projection image display apparatus

ActiveUS20090141360A1Prevents deterioration of optical performanceImprove environmental reliabilityPrismsMountingsProjection imagePrism

A prism unit includes a prism having at least one optical surface in its inside, and a prism base disposing the prism, the prism base including at least three seating surfaces that are attached to a surface orthogonal to the optical surface of the prism, a seating surface bonded part that is bonded to the prism by an adhesive. At least the three seating surfaces and the seating surface bonded part are symmetrically arranged on the optical surface of the prism.

Owner:CANON KK

Corrosion-resistant pipe and method for the preparation thereof

InactiveUS6706350B2Improve heat resistanceMaintain good propertiesSynthetic resin layered productsAnti-corrosive paintsPolymer sciencePolyolefin

A corrosion-resistant pipe is formed by covering a surface of a pipe with a resin composition that contains (A) 1 to 98 parts by weight of a polyphenylene ether resin; (B) 1 to 98 parts by weight of a polystyrene resin; (C) 1 to 98 parts by weight of a polyolefin resin; wherein the total of (A), (B), and (C) is 100 parts by weight; and (D) 0.1 to 100 parts by weight of a compatibility reagent per 100 parts by weight total of (A), (B), and (C).

Owner:SHPP GLOBAL TECH BV

Flexible metal-clad laminate and process for preparing the same

InactiveUS20020160211A1Improve featuresSolve low adhesionInsulating substrate metal adhesion improvementPretreated surfacesPolymer scienceMetal foil

Disclosed are a flexible metal-clad laminate comprising a metal foil and a heat-resistant resin film layer formed on one side of the metal foil, the heat-resistant resin film layer comprising a crosslinked condensation polymer and having an N-methyl-2-pyrrolidone-insolule content of at least 1%, and a method for producing the flexible metal-clad laminate comprising the steps of applying a heat-resistant resin solution to a metal foil; predrying the metal foil until the heat-resistant resin layer has an residual solvent content of 10 to 40% by weight; and carrying out solvent removal and heat-treatment while controlling the crosslinking reaction of the resin.

Owner:TOYOBO CO LTD

Apparatus for fabricating coating and method of fabricating the coating

InactiveUS7700164B2Reduce in quantitySolve low adhesionLiquid surface applicatorsMolten spray coatingHigh frequency powerHigh density

In an apparatus for fabricating a carbon coating, an object such as a magnetic recording medium is disposed on a side of an electrode connected to a high-frequency power supply. Ultrasonic vibrations are supplied to the object. Discharge is generated between the electrode connected to the high-frequency power supply and a grounded electrode to fabricate a carbon coating on the surface of the object. Also, an electrode interval is set to 6 mm or less, pressure between the electrodes is set to 15 Torr to 100 Torr, whereby high-density plasma is generated to form an ion sheath on an anode side. Therefore, a coating is fabricated on the surface of the object by bombardment of ions.

Owner:SEMICON ENERGY LAB CO LTD

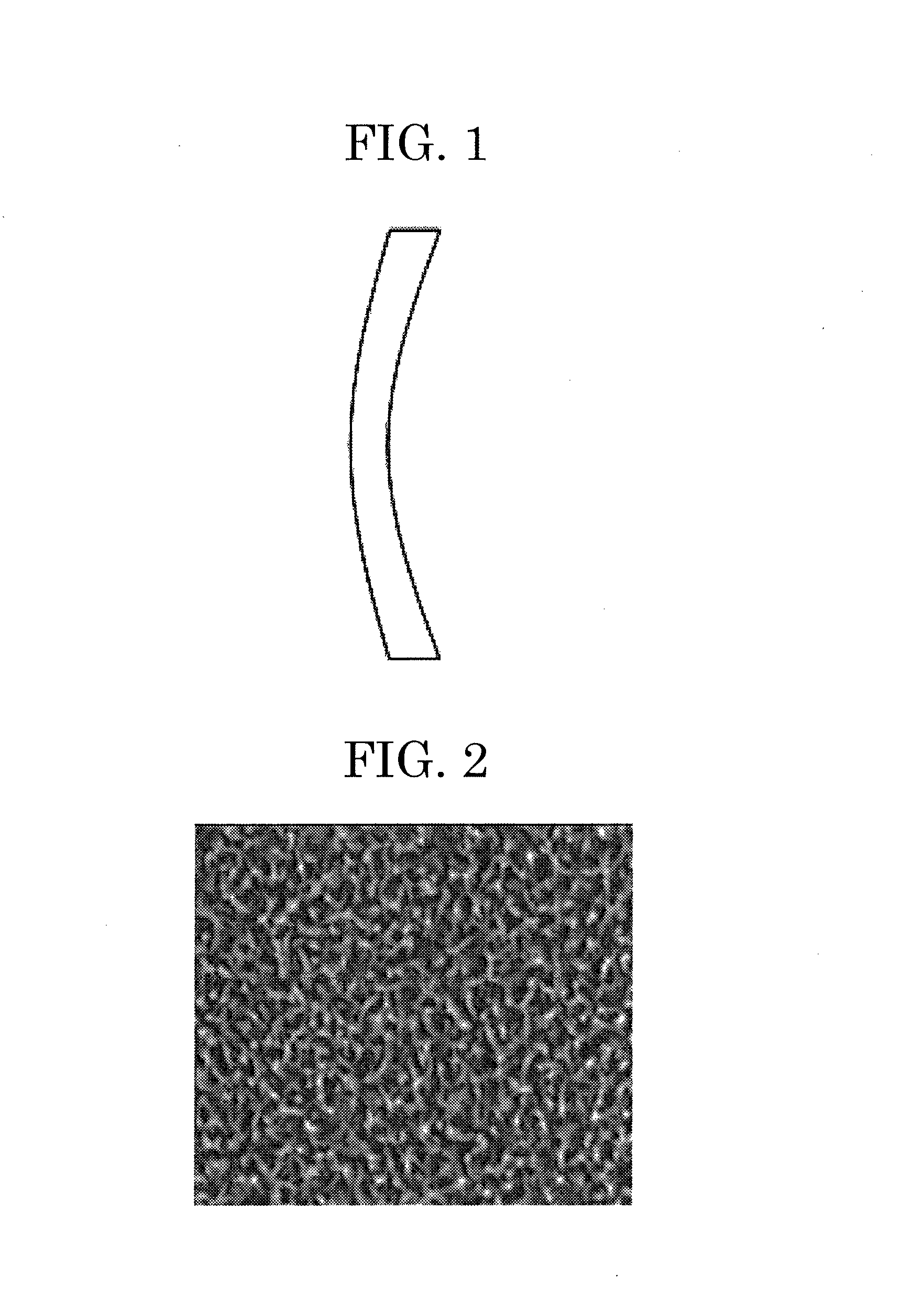

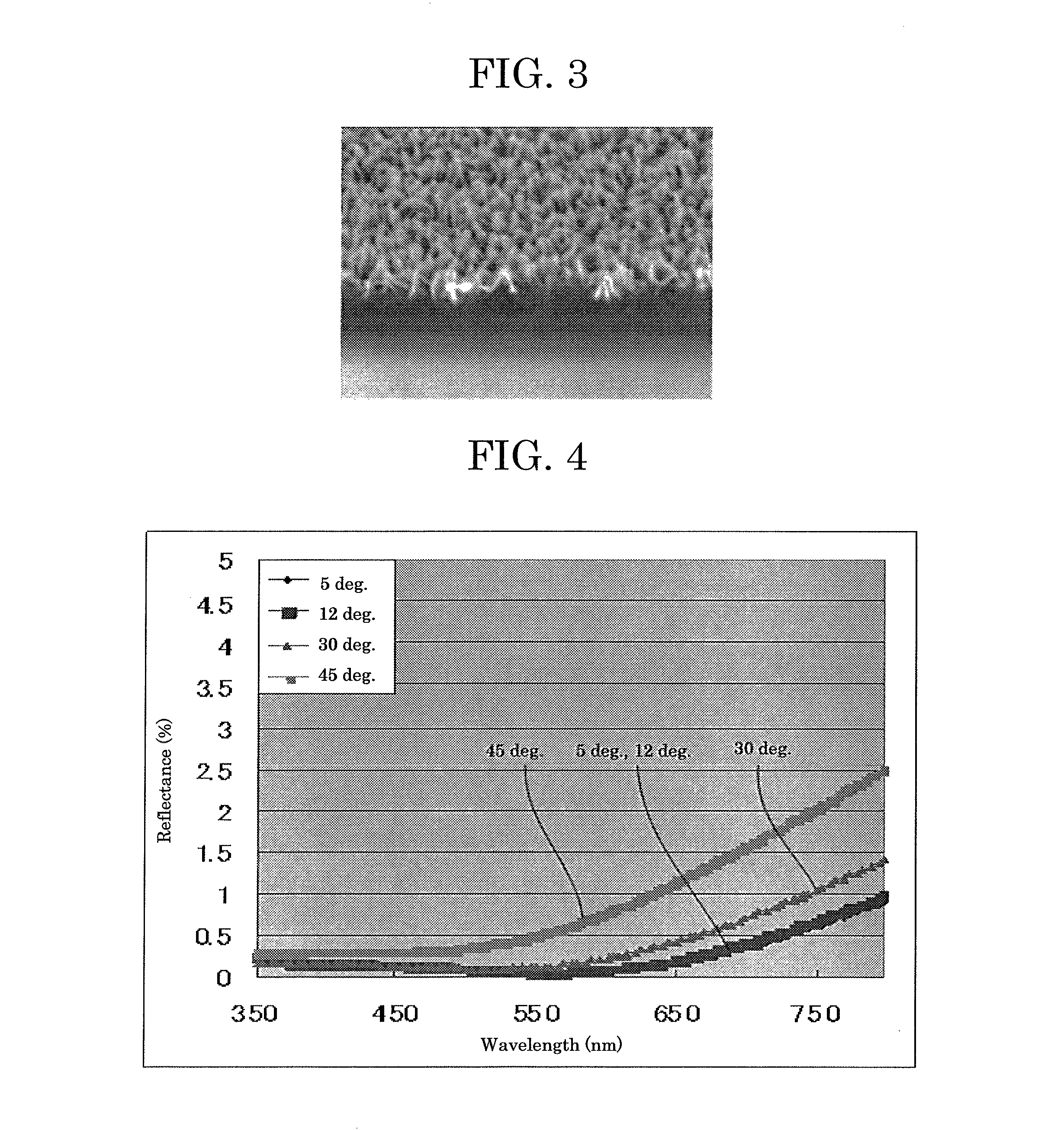

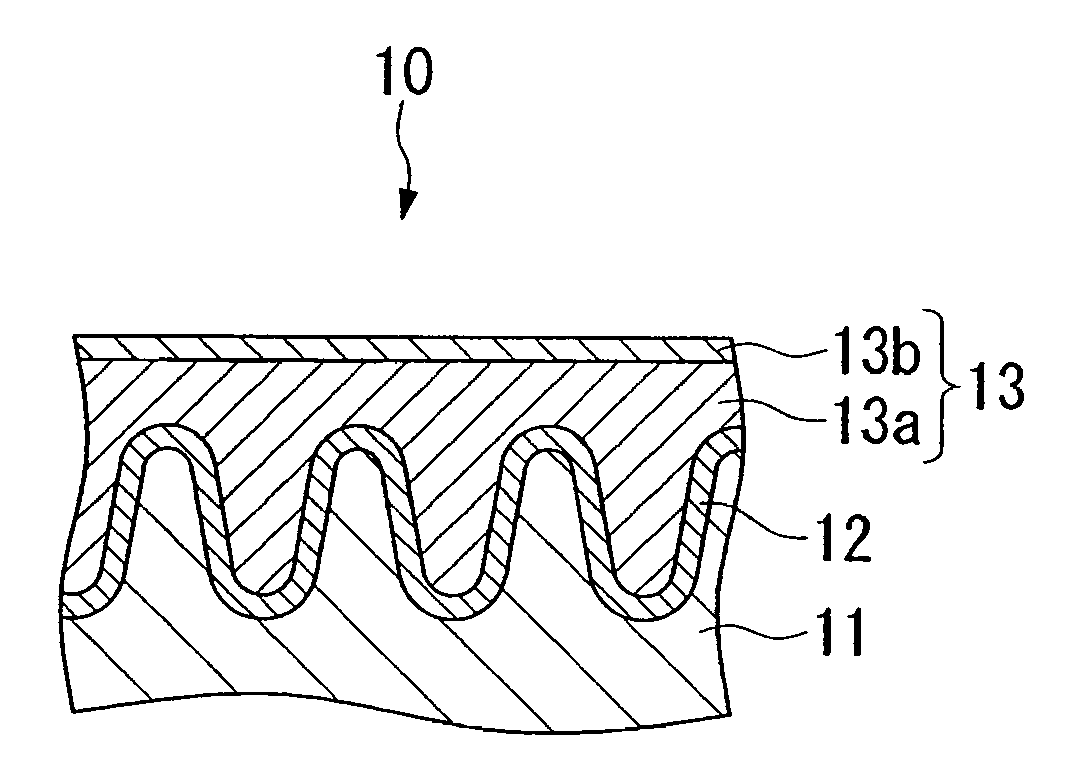

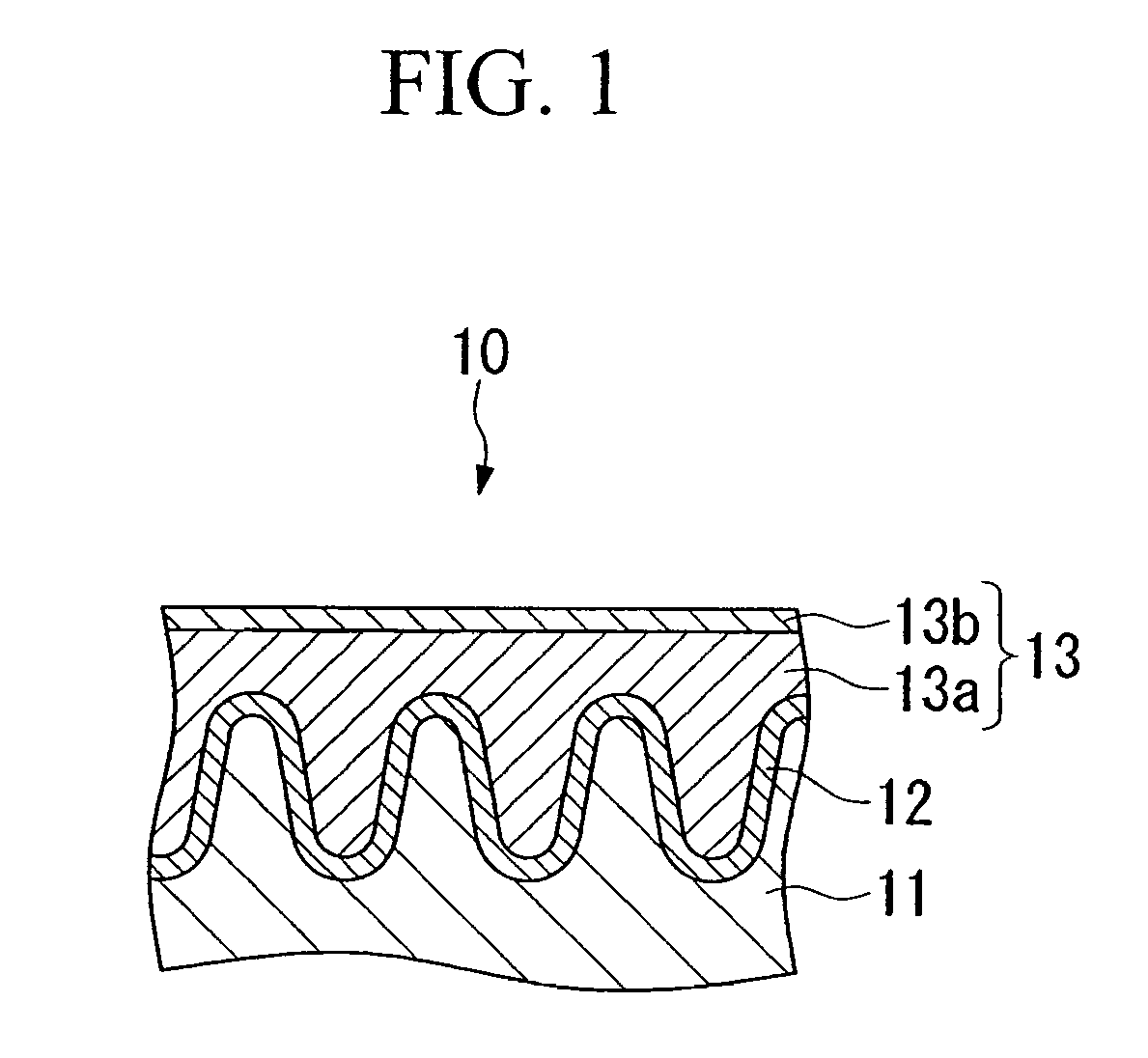

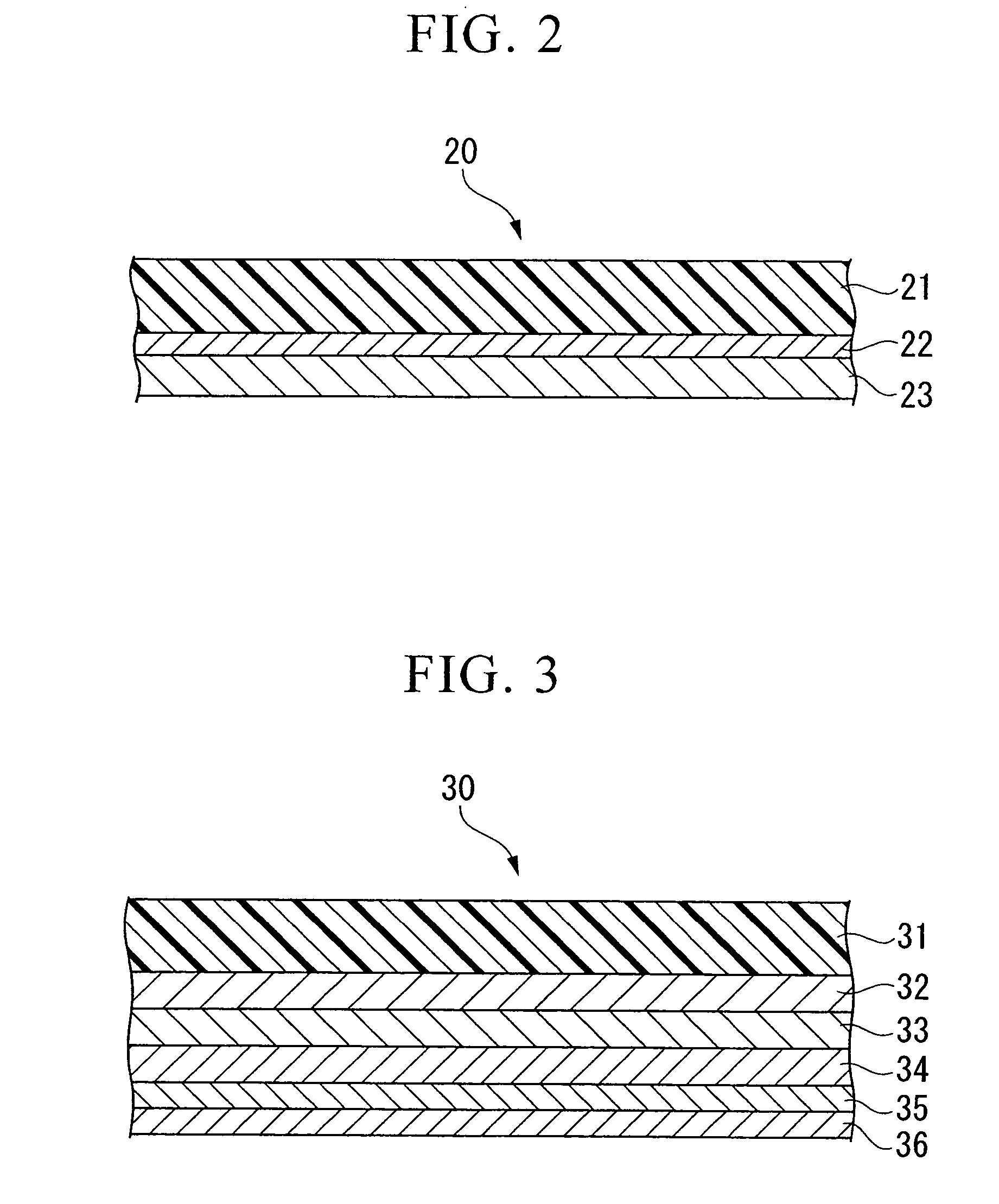

Optical member and method for producing same

ActiveUS20140016204A1High film adhesionLimited film thicknessOptical articlesCoatingsConvex structureGas phase

Provided is an optical member, including: a substrate having an at least partially curved surface; a concave-convex structure at an outermost surface, the concave-convex structure being prepared by hydrothermal treatment of a layer formed by gas-phase deposition of at least one of simple aluminum and a compound containing aluminum on the substrate; and a dielectric layer formed by gas-phase deposition between the substrate and the concave-convex structure.

Owner:FUJIFILM CORP

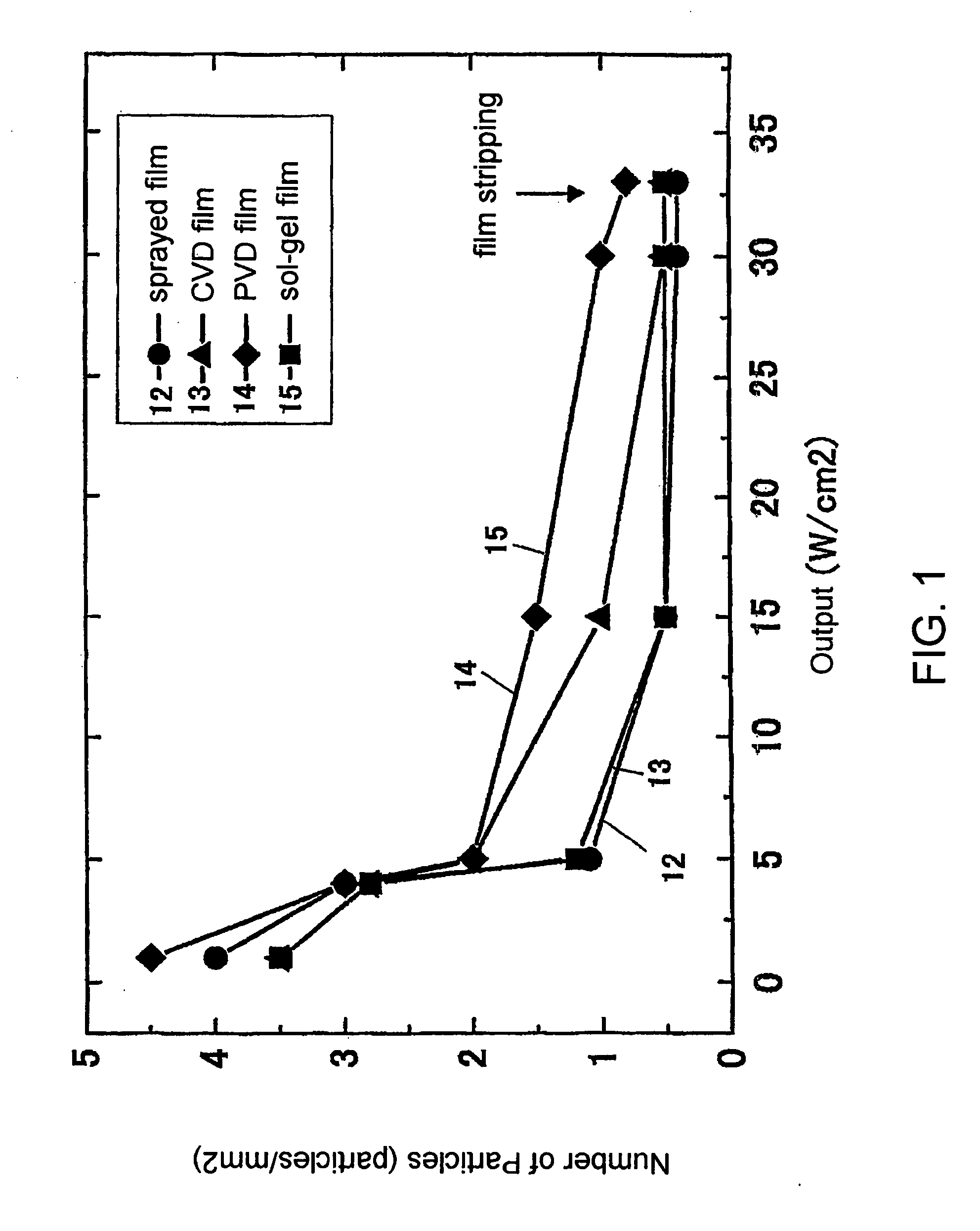

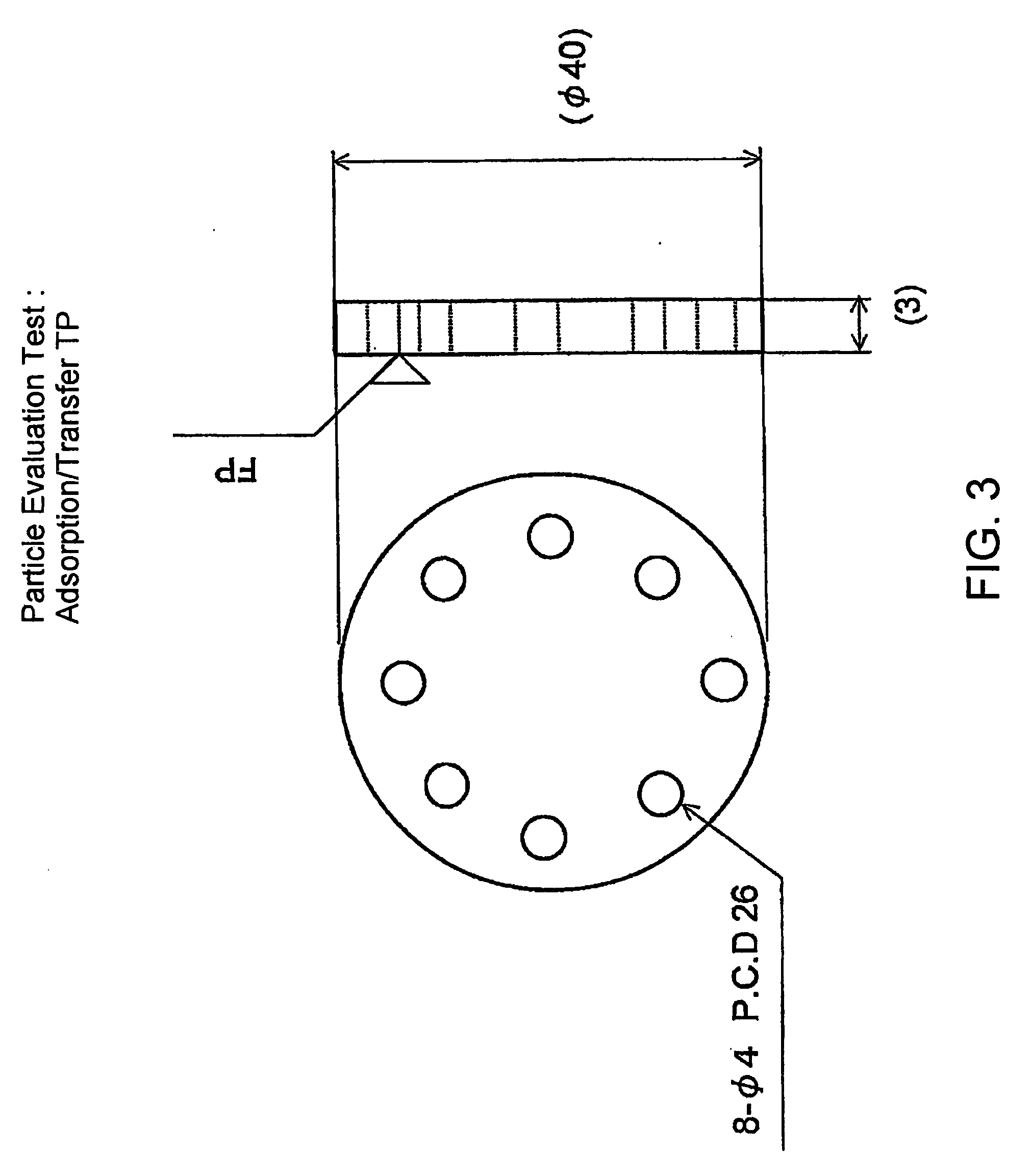

Multilayer structural body and method for cleaning the same

InactiveUS20090133713A1Quickly and economically copeLarge structure sizeMolten spray coatingElectrostatic cleaningMetallurgyCleaning methods

It has been difficult to provide a large-sized ceramic member quickly and economically. A multilayer structure is produced by forming a ceramic film on a base which is made of a material that can be shaped comparatively easily. The ceramic film is formed by a plasma spraying method, CVD method, PVD method, sol-gel method or the like. Alternatively, the ceramic film may be formed by a method combined with a spray deposit film.

Owner:TOHOKU UNIV +1

Emulsion type acrylic pressure sensitive adhesives

InactiveUS20050250887A1High peel adhesionSolve low adhesionEster polymer adhesivesEmulsion paintsEmulsionAging resistance

The invention relates to a composition of an emulsion type, acrylic, pressure sensitive adhesive, which includes (a) 15 to 35 parts per hundred of dialkyl dicarboxylate, (b) 15 to 35 parts per hundred of vinyl esters, (c) 35 to 65 parts per hundred of alkyl acrylates or alkyl mathacrylates; (d) 0.1 to 2.0 parts per hundred of cross-linker based on the total weight of (a)+(b)+(c), (e) 0.2˜2.0 parts per hundred of hydroxy alkyl acrylates or hydroxy alkyl mathacrylates, (f) 0.1 to 1.0 parts per hundred nonionic surfactant, (g) 0.4 to 3.0 parts per hundred of anionic surfactant, (h) 0.1˜0.5 parts per hundred of reactive surfactant; which react with de-ionized water, an initiator and a buffer. The adhesives composition has excellent water-whitening resistance and aging resistance properties.

Owner:CHIEF INVESTMENT

Solventless addition-curable pressure sensitive silicone adhesive composition and adhesive article

ActiveUS20120045635A1High flexibilitySolve low adhesionSynthetic resin layered productsRecord information storageSolventPressure sensitive

A solventless addition-curable pressure sensitive silicone adhesive composition is provided. The composition comprises (A) an alkenyl group-containing polydiorganosiloxane; (B) a condensation product of (a) a polydiorganosiloxane having hydroxyl group or an alkoxy group on opposite ends of the molecular chain and (b) a polyorganosiloxane containing R13SiO1 / 2 unit and SiO2 unit as critical components and also a HOSiO3 / 2 unit in the molecule; (C1) a polyorganohydrosiloxane having at least three SiH groups per molecule; (C2) a polydiorganohydrosiloxane having SiH group on opposite ends; and (D) a platinum group metal catalyst. Use of the present composition enables production of a pressure sensitive adhesive agent having flexibility, pressure sensitive adhesiveness, and heat resistance, and the present composition is particularly effective for use as a buffer member having pressure sensitive adhesiveness.

Owner:SHIN ETSU CHEM IND CO LTD

Low-voc-emission waterborne coating having high hardness and good adhesion and process for producing the same

A low-VOC-emission waterborne coating is prepared from a waterborne acrylic emulsion, a hydrophilic cross-linking agent, a coalescing agent, additives and a pigment, and the waterborne acrylic emulsion is formed from performing emulsion polymerization on those reactive monomers including an alkyl-group-containing methyl acrylate, a hydroxyl-group-containing methyl acrylate, a carboxyl-group-containing methacrylic acid, a hydroxyl-group-containing acrylic polyester (polyether) polyol, and a methyl acrylate containing alkene-based unsaturated functional groups, which features high hardness, good adhesion, high luster, high acid resistance, high alkali resistance, good weatherability, high solvent resistance, high scrap resistance and high thermal shock resistance.

Owner:NANYA PLASTICS CORP

Plaster having laminated support

InactiveUS20050042269A1Good adhesionGood flexibilitySynthetic resin layered productsPlastersPolyesterEngineering

A patch comprising a laminated backing layer and a drug-containing pressure-sensitive adhesive layer, wherein the laminated backing layer consists of a knitted fabric laminated on one side of a polyester film, and the drug-containing pressure-sensitive adhesive layer is laminated on the other side of the polyester film, wherein the knitted fabric has a 30% longitudinal modulus of 0.1 kg / 5 cm to 20 kg / 5 cm and a 30% lateral modulus of not more than 10 kg / 5 cm, and a 30% longitudinal modulus / 30% lateral modulus ratio of not less than 2.

Owner:HISAMITSU PHARM CO INC

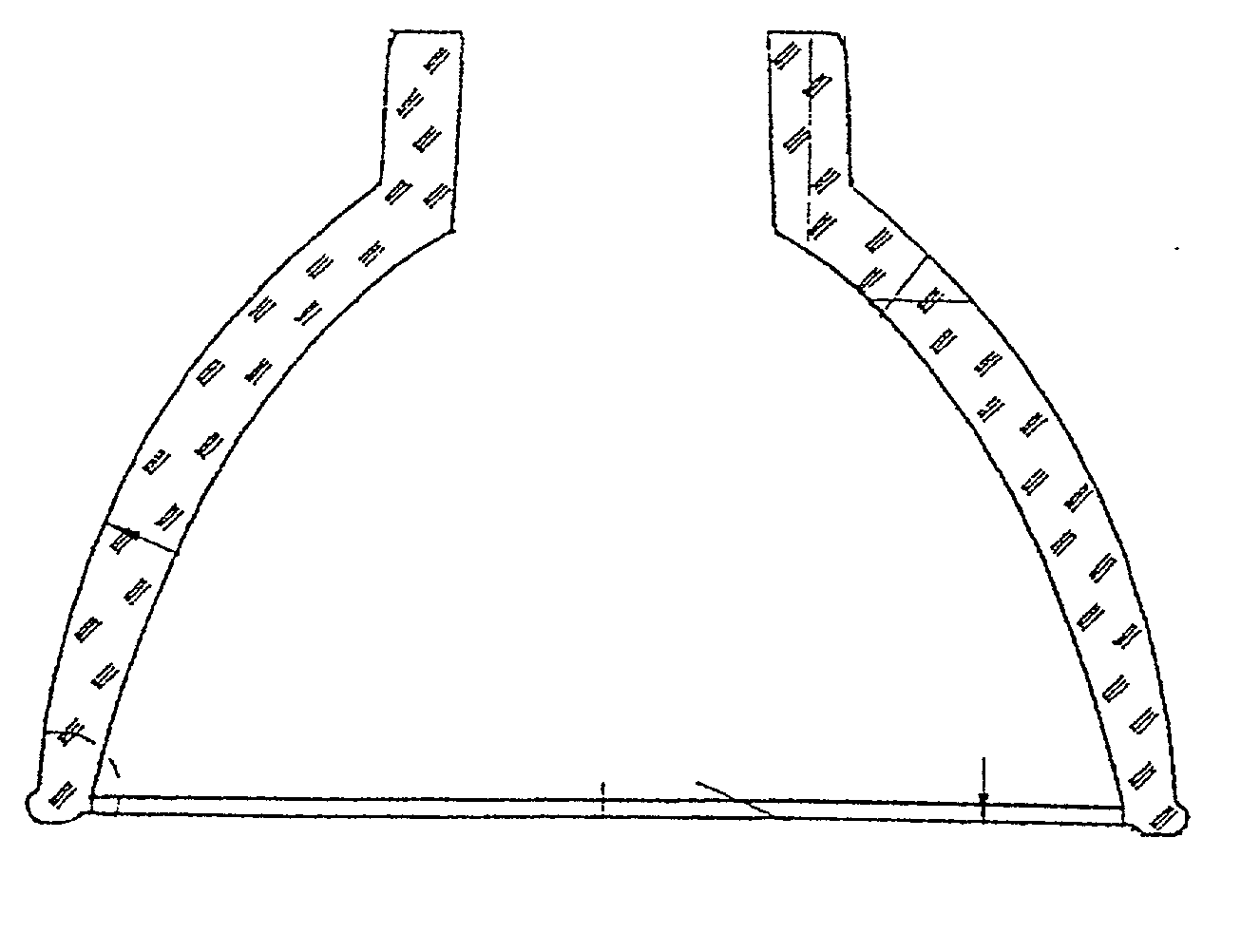

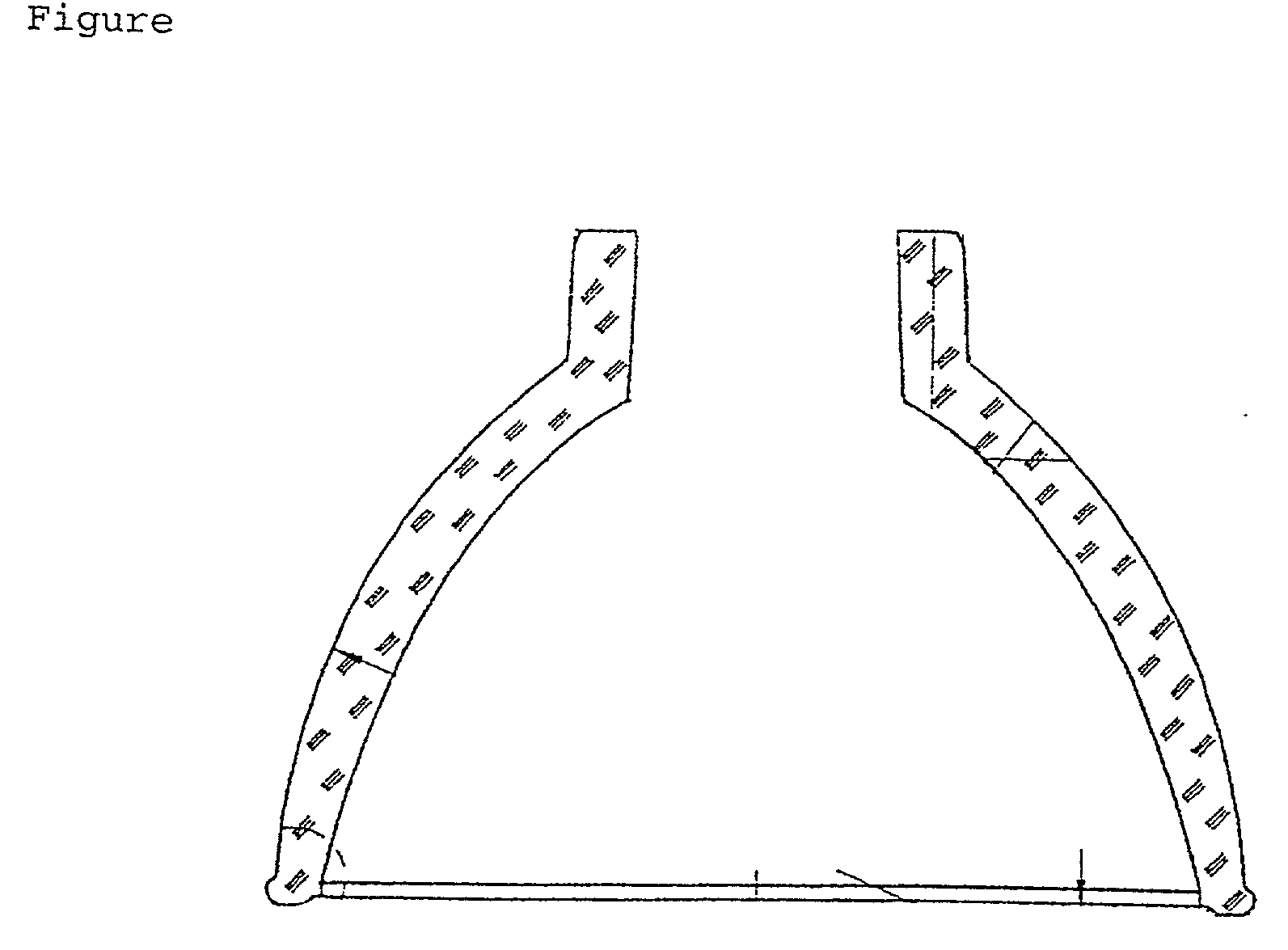

Method of manufacturing light-emitting diode device

InactiveUS6984539B2Excellent luminous propertiesSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLead frame

A method of manufacturing a light-emitting diode (LED) device includes forming a lead frame having a first pattern part mounted with an LED chip, a second pattern part electrically connected to the first pattern part to be used as an electrode, a third pattern part spaced from the first pattern part to be electrically insulated from the first pattern part and used as another electrode, and a fourth pattern part and a fifth pattern part integrated with both sides of the first pattern part, forming a layer plated with a metal having high reflectivity on the fourth and fifth pattern parts, and upwardly folding the fourth and fifth pattern parts to be perpendicular to the first pattern part to form reflective surfaces.

Owner:SAMSUNG ELECTRONICS CO LTD

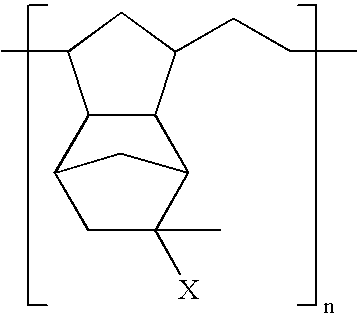

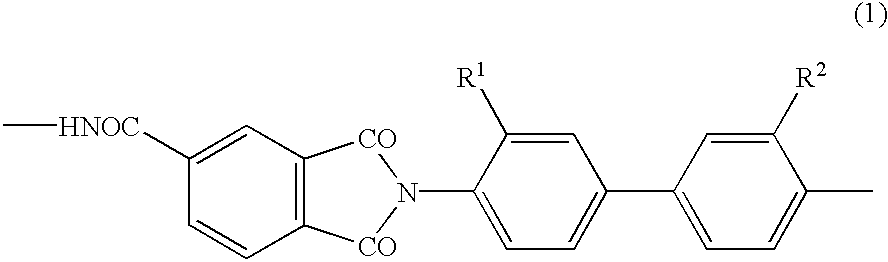

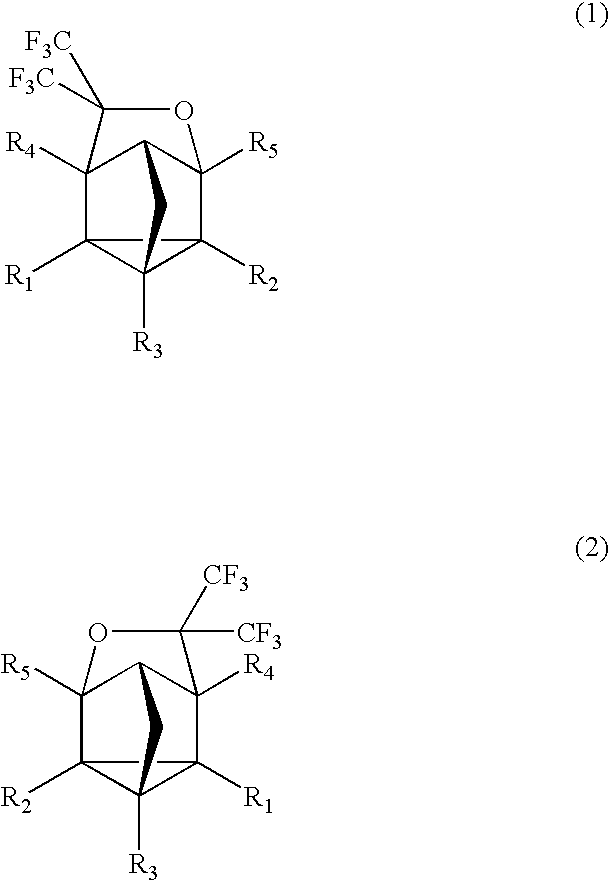

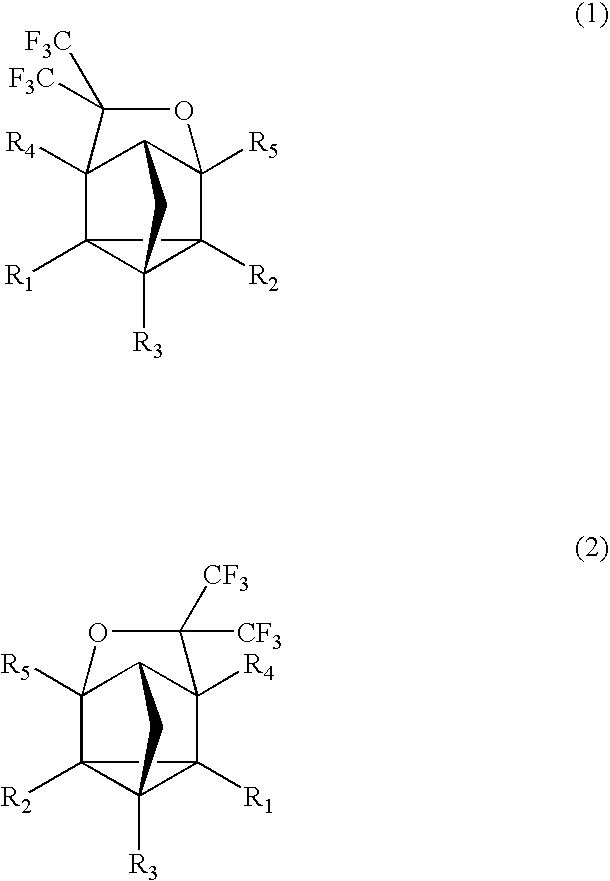

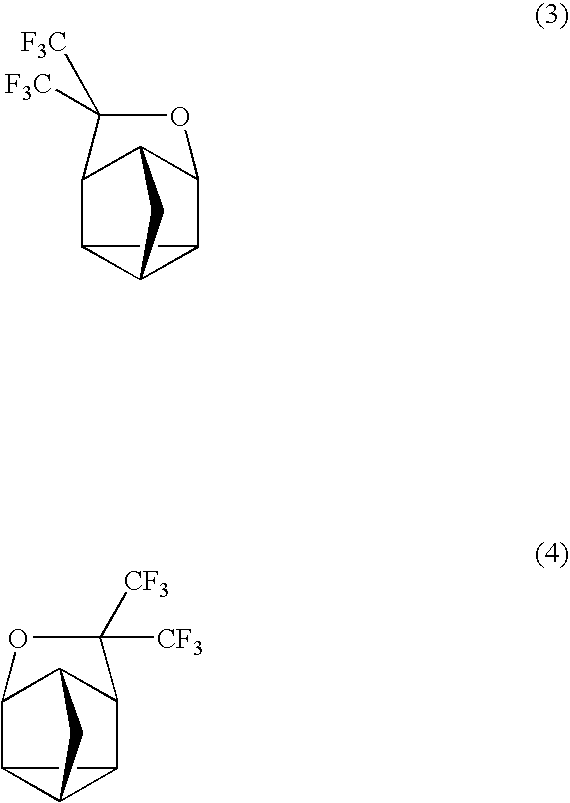

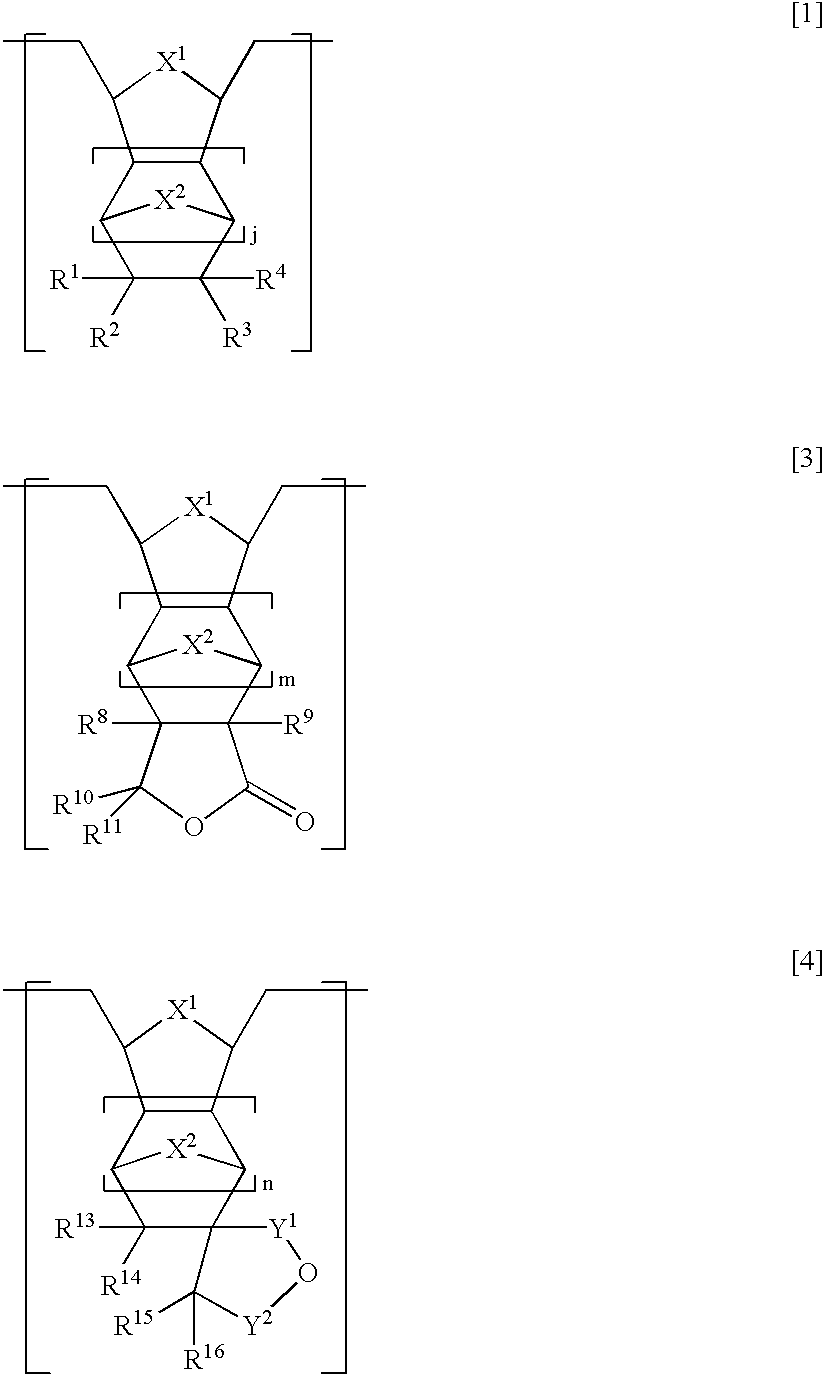

Fluorinated cyclic compound, polymerizable fluoromonomer, fluoropolymer, resist material comprising the same, and method of forming pattern with the same

InactiveUS20060135744A1High transparencyIncrease resistanceOrganic chemistryPhotosensitive materialsPolymer scienceFluoropolymer

The present invention relates to a novel fluorine-containing cyclic compound that is derived from a norbornadiene and hexafluoroacetone and has an oxacyclopentane or oxacyclobutane structure. This compound may be represented by the following formula (1) or (2). Furthermore, the present invention relates to a fluorine-containing high-molecular compound prepared by a polymerization or copolymerization using this fluorine-containing cyclic compound or its derivative. By using such fluorine-containing high-molecular compound, it is possible to provide a superior resist material and a fine pattern forming process using the same.

Owner:CENT GLASS CO LTD

Chemical conversion solution for metal structure and surface treating method

InactiveUS20110094630A1Improve coating adhesionControl and reduceElectrophoretic coatingsSolid state diffusion coatingZinc compoundsSludge

The present invention provides a chemical conversion solution and the surface treating method for realizing high corrosion resistance and high coating adhesion of the metal surface, as well as high throwing power during electrodeposition, and generating no sludge.A chemical conversion solution comprising (A) at least one compound selected from water-soluble germanium compound, water-soluble tin compound, and water-soluble copper compound, (B) at least one compound selected from water-soluble titanium compound and water-soluble zirconium compound, (C) at least one water-soluble nitrate compound, (D) at least one compound selected from water-soluble aluminum compound and water-soluble magnesium compound, (E) at least one water-soluble zinc compound, and (F) at least one fluorine compound, and, the coating process for the metal structure.

Owner:HENKEL KGAA

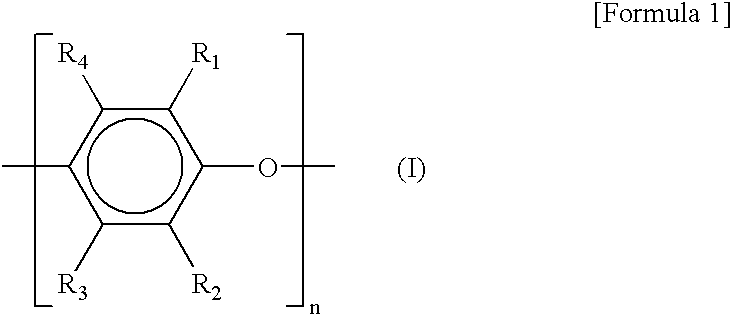

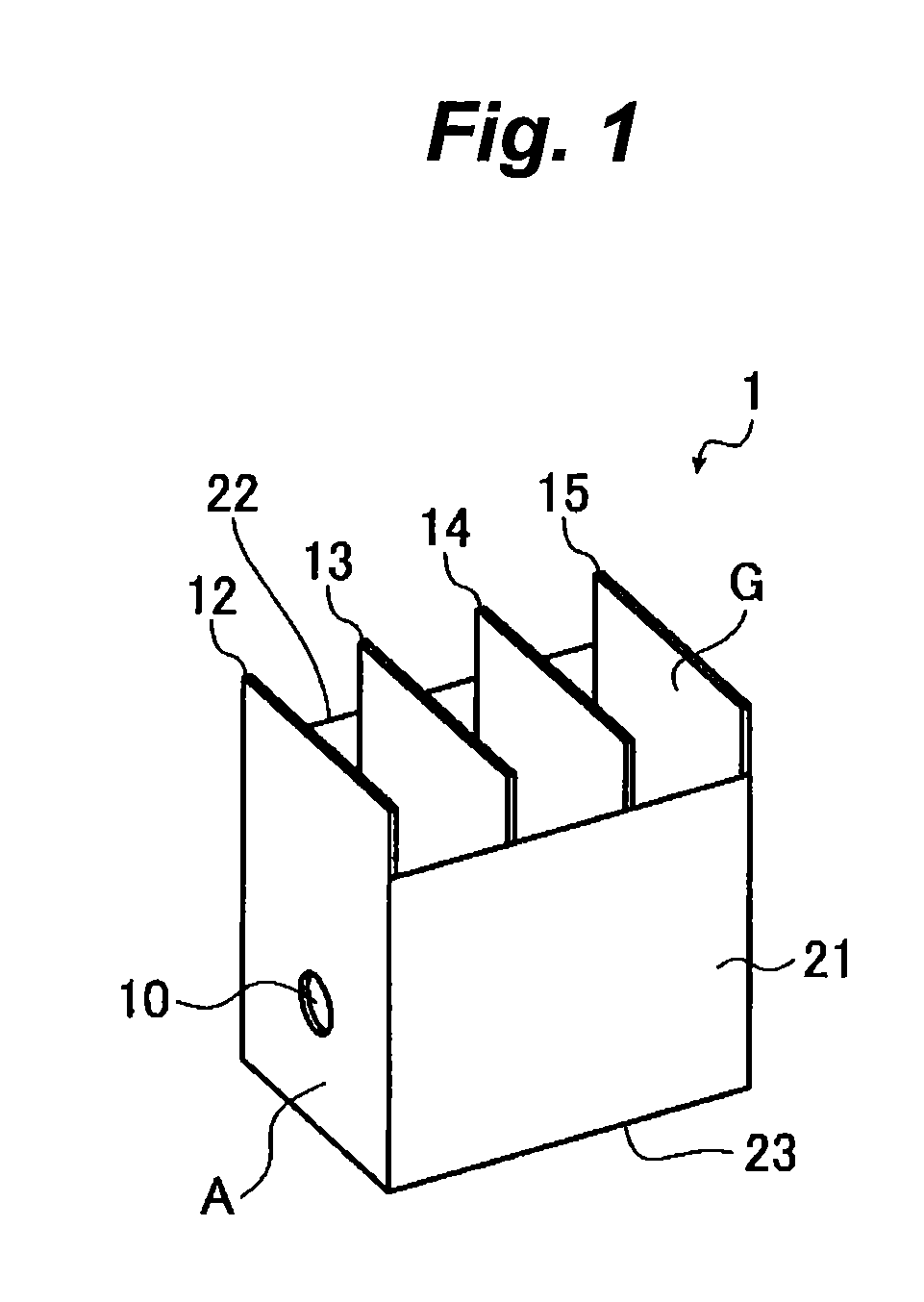

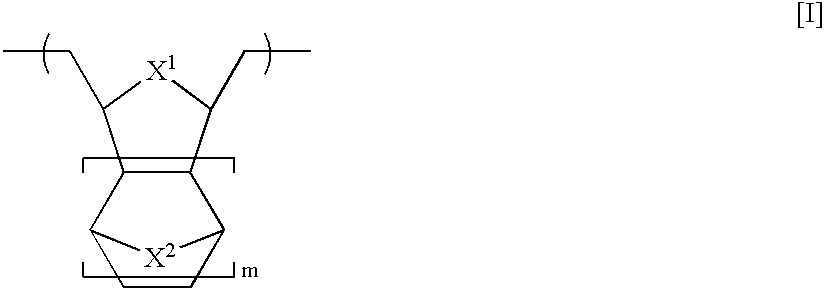

Resist patterning process

InactiveUS6878508B2High light transmittanceHighly integratedElectric discharge tubesPhotosensitive materialsChemistryResist

A resist patterning process is provided comprising the steps of (a) applying a resist composition onto a substrate to form a resist film, (b) prebaking the resist film, (c) exposing the prebaked resist film to a pattern of radiation, (d) post-exposure baking the exposed resist film, (e) developing the resist film to form a resist pattern, and (f) post baking the resist pattern for causing thermal flow. The resist composition contains a polymer comprising structural units of formula [I] in a backbone and having acid labile groups on side chains as a base resin and a photoacid generator. X1 and X2 are —O—, —S—, —NR—, —PR— or —CR2—, R is H or C1-20 alkyl, and m is 0 or an integer of 1 to 3. The invention is effective for improving the degree of integration of semiconductor LSI.

Owner:SHIN ETSU CHEM IND CO LTD

Powder Coating Composition with New Pigment

InactiveUS20100331456A1Good lookingReduced orange peelPigmenting treatmentPretreated surfacesPolyresinPolymer chemistry

Owner:EI DU PONT DE NEMOURS & CO

Conductive composition and conductive cross-linked product, capacitor and production method thereof, and antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium

ActiveUS7666326B2Improve conductivityLower impedanceHybrid capacitor electrolytesHybrid capacitor electrodesCross-linkElectron donor

A conductive composition comprises a π conjugated conductive polymer, a dopant, and a nitrogen-containing aromatic cyclic compound. A capacitor comprises an anode composed of a porous material of valve metal, a dielectric layer formed by oxidizing the surface of the anode, and a cathode provided on the dielectric layer and having a solid electrolyte layer containing a π conjugated conductive polymer, which comprises an electron donor compound containing an electron donor element provided between the dielectric layer and the cathode. Another capacitor is based on the above-described capacitor, wherein the solid electrolyte layer further comprises a dopant and a nitrogen-containing aromatic cyclic compound. An antistatic coating material comprises a π conjugated conductive polymer, a solubilising polymer containing an anion group and / or an electron attractive group, a nitrogen-containing aromatic cyclic compound, and a solvent. An antistatic coating is formed by applying the antistatic coating material.

Owner:SHIN-ETSU POLYMER CO LTD

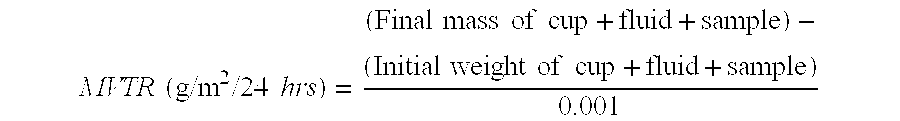

Hydrogel composites and wound dressings

InactiveUS20110135726A1Low levelImprove adhesionPowder deliveryAbsorbent padsWound dressingReticular formation

The present invention provides an absorbent hydrogel composite for use in the manufacture of an article for application to a fluid-emitting surface, e.g. a wound, the composite having a laminar structure comprising first and second layers, the first layer being a surface contacting layer comprising a porous net structure having a surface contacting face and an outwardly directed face, the second layer comprising a low-crosslinked absorbent hydrogel disposed over the outwardly directed face of the first layer and arranged so that in use it is in fluid flow communication with the surface through apertures of the net structure.

Owner:FIRST WATER

Adhesive composition and bonding method

ActiveUS20100236716A1Improve retentionImprove productivityAdhesive processesLaminationLiquid compositionAldehyde

To provide an adhesive composition having high adhesion and quick curing properties on the second time scale, and having a high retention in a durability test such as a high temperature and high humidity test.A two-part type adhesive composition which comprises a first agent comprising (A) a nitrile butadiene rubber having an acrylonitrile content of from 10 to 30%, (B) a polymerizable (meth)acrylic liquid composition, (C) an organic peroxide and (D) a basic compound having an amine structure, and a second agent comprising (E) a reaction condensate of an amine and an aldehyde and (F) a reducing agent containing copper, preferably, an adhesive composition wherein the first agent contains a photopolymerization initiator, and a bonding method using it.

Owner:DENKA CO LTD

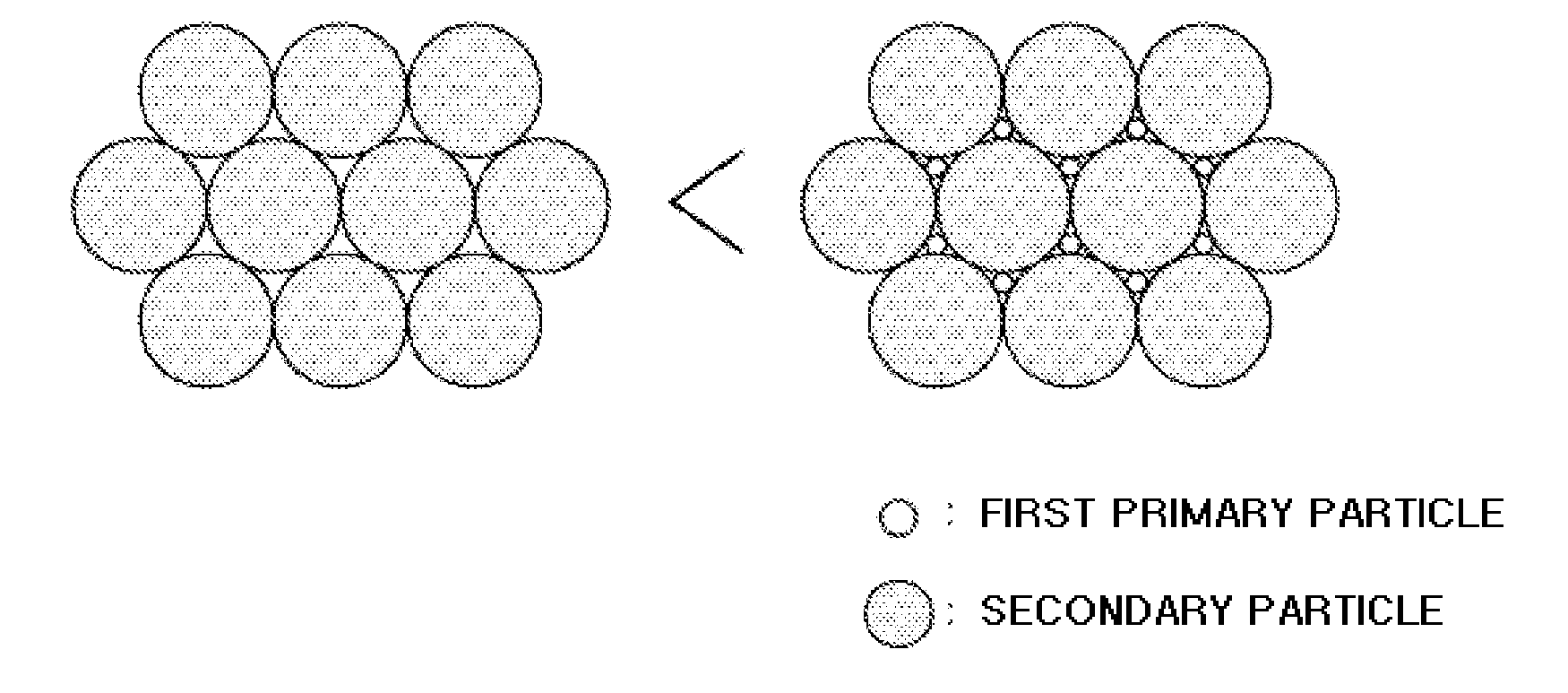

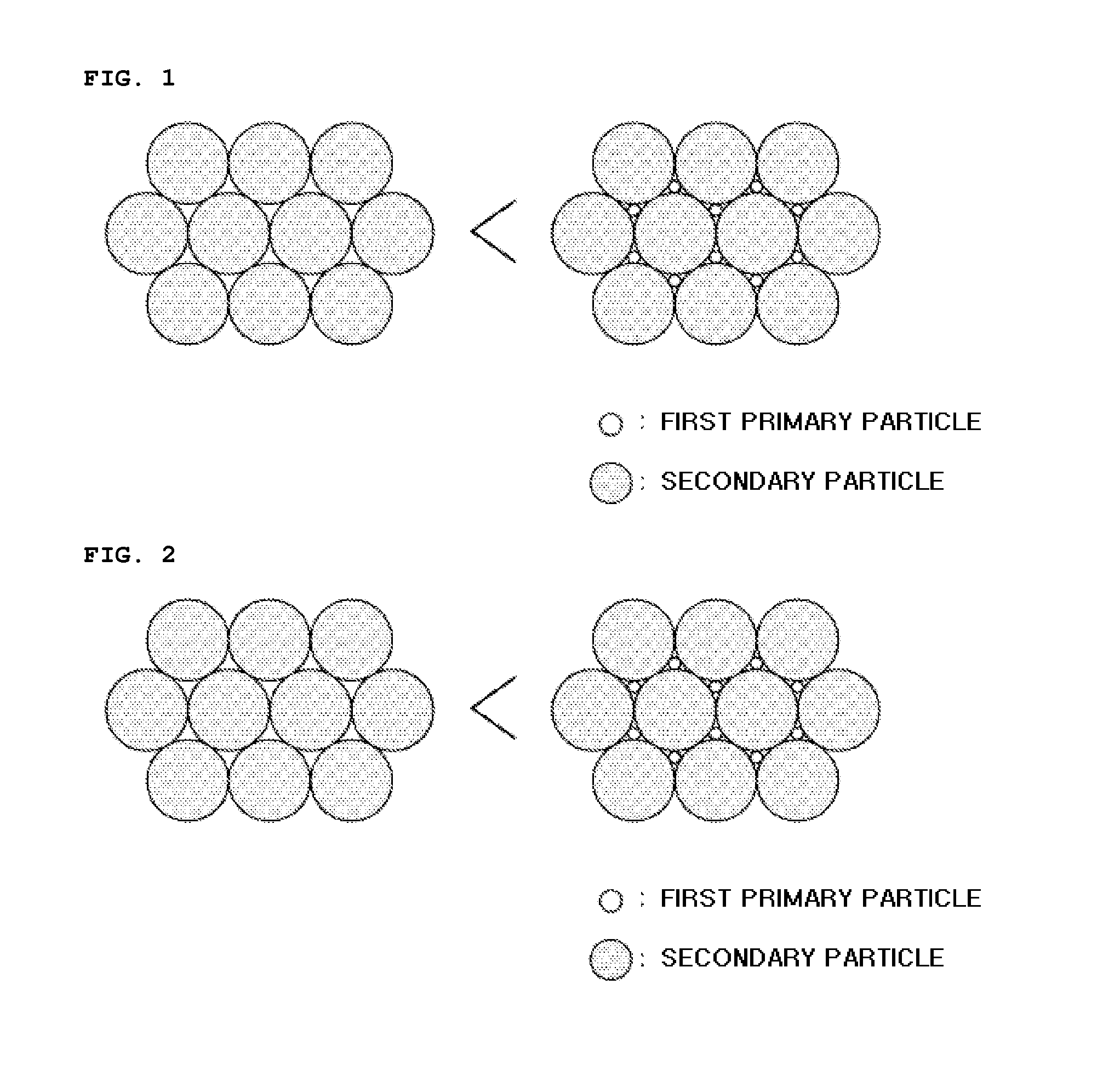

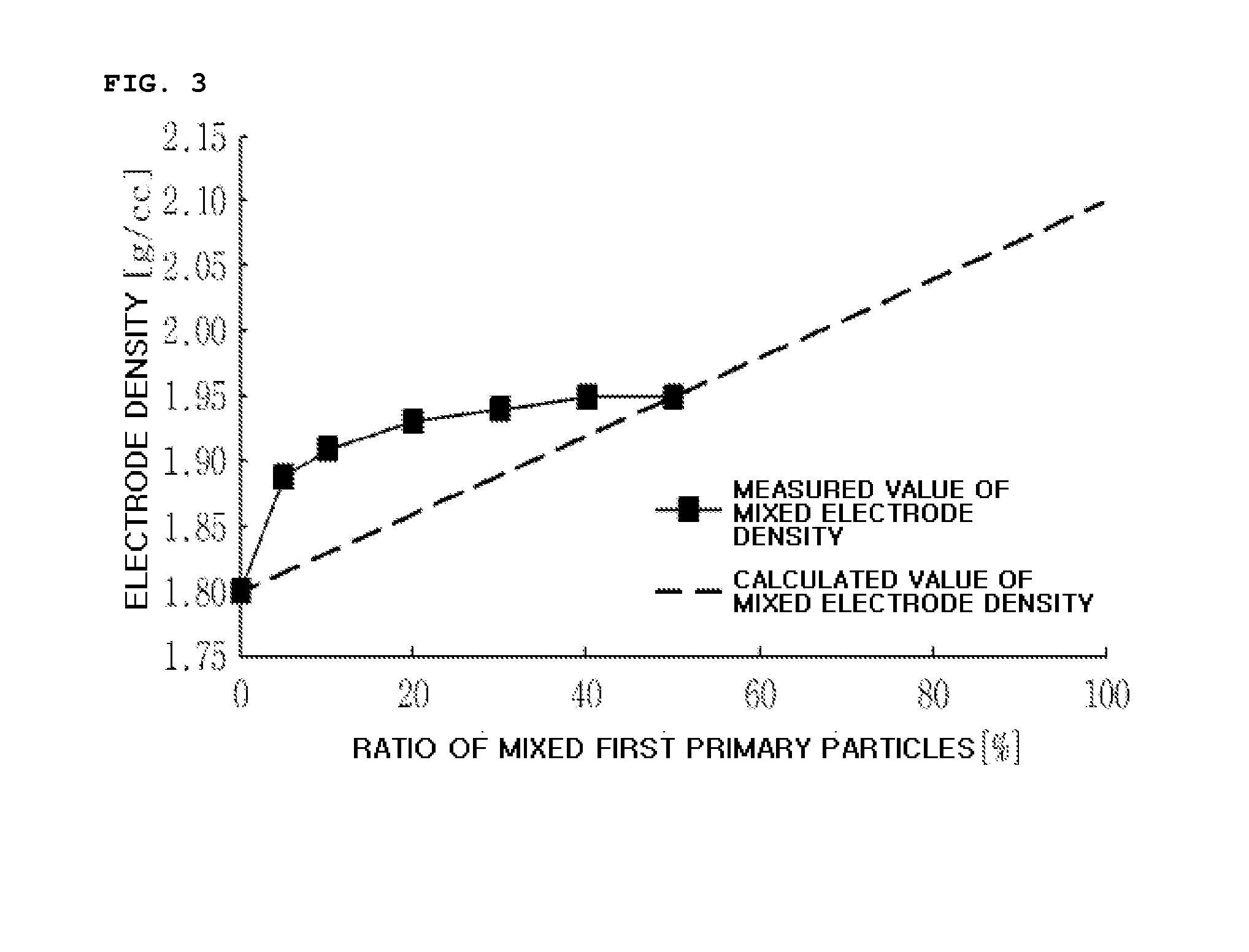

Bimodal type anode active material and lithium secondary battery including the same

ActiveUS20140027679A1High-density electrodeImprove rate performanceNon-metal conductorsElectric discharge heatingHigh rateIndium

Provided is an anode active material including a compound of Chemical Formula 1 below that may realize a high-density electrode and may simultaneously improve adhesion to the electrode and high rate capability, wherein the compound of Chemical Formula 1 includes first primary particles and secondary particles, and a ratio of the first primary particles to the secondary particles is in a range of 5:95 to 50:50:LixMyOz [Chemical Formula 1]where M is any one independently selected from the group consisting of titanium (Ti), tin (Sn), copper (Cu), lead (Pb), antimony (Sb), zinc (Zn), iron (Fe), indium (In), aluminum (Al), and zirconium (Zr) or a mixture of two or more thereof; and x, y, and z are determined according to an oxidation number of M.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com